Summary of Contents for Lyrec TR532 Series

-

Page 1: Table Of Contents

CONTENTS SPECIFICATIONS Technical Specifications Dimensions Accessories GENERAL DESCRIPTION Service Manual Tape Deck Record/playback Amplifiers AM77 VU-meter Panel Console Remote Control Unit INSTALLATION Unpacking Interconnection Connector Table Connector Drawings Transportation OPERATION Switching On Loading Play Mode Record Mode Fast Wind Mode Edit Mode Stop Mode Tape Deck Logic... - Page 2 OPTIONS Remote Timer Display XLR-panel VU-meter Panel Mounting Facilities for External Equipment External Motor Control Free Space on 8 and 16 Track Model Transport Frame Tape Position Controller Tape Speed 7 1/2 - 15 ips 6.10 NAB - CCIR Switchable ADJUSTMENTS Reel Platform Height Supply Tension Arm Pressure...

- Page 3 SERVICE Capstan Motor System Capstan Speed Preamplifier Frequency Detector Motor Control Commutator Reel Motor Servo System Wind Speed Limit Circuit Dynamic Brake System Capstan and Guide Roller Solenoids Remote Control Unit Muting System 8.10 Demagnetization 8.11 Ventilation 8.12 Lubrication 8.13 Removing Head Block 8.14 Tension Arm Potentiometer Replacement 8.15 Performance Check SPARE PARTS...

-

Page 4: Specifications

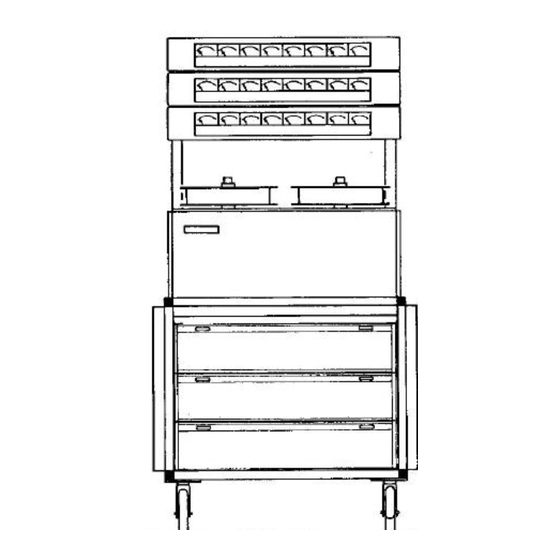

MULTITRACK RECORDER 16 AND 24 TRACKS - TR532-16 AND TR532-24 2.1 SPECIFICATION Tape speed: 15 and 30 ips. Varispeed 7½ to 60 ips. (Optional: 7½ and 15 ips. Varispeed 3 3/4 to 30 ips.) Reel type: Up to 10.5" NAB hub Long term speed stability: Better than 0.1%... - Page 5 73 cm wide x 56 cm deep x 91 cm high Inc. Vu-meter console: 16 track - 127 cm high 24 track - 137 cm high Lyrec Manufacturing A/S reserves the right to introduce modifications and improvements from time to time without prior notice. Small differences in component values or circuitry may be found between diagrams and actual electronics.

-

Page 6: 2.2 Dimensions

2.2 DIMENSIONS Remote control type RCU Remote control type TPC 1977-05-01 TR532 1977-05-02... - Page 7 Remote Control type ATC 1984-05-17 TR532...

- Page 8 LIST OF ACCESSORIES 1 Tool case, plastic 1 Set of Allen keys 1.5, 2, 2.5, 3 mm 1 Allen key 3 mm x 90 mm 1 Allen key 2 mm x 90 mm 1 Screwdriver 80 mm x 2 mm, Belzer 1 Oilcan, mini Belzer, with Esso NUTO HP 32 1 Bottle of cleaning fluid 1 Bag of Q-tips...

-

Page 9: Accessories

LIST OF ACCESSORIES 969002 Tool case, plastic 969011 Set of Allen keys 1.5, 2, 2.5, 3 mm 969016 Allen key 3 mm x 90 mm 969017 Allen key 2 mm x 90 mm 969020 Screwdriver 80 mm x 2 mm, Belzer 969036 Oilcan with Esso NUTO HP 32 501009... -

Page 10: General Description

GENERAL DESCRIPTION SERVICE MANUAL This manual covers the description, installation, operation and service instructions for the Lyrec TR532-series of 2" and 1" professional tape recorders. The available configurations are the following - TR532-8. 1" 8 track recorder - TR532-16, 2" 16 track recorder - TR532-24, 2"... -

Page 11: Record/Playback Amplifiers Am77

Close to the MAINS button are the two speed selection buttons, 15 and 30 ips. When power has been switched off the tape recorder will always come back to the previously selected speed. The power supplies for the machine are housed below the tape deck, together with the servo electronics. -

Page 12: Remote Control Unit

All heat producing elements are located at the rear of the machine so that the sides may be placed in direct contact with other equipment, thereby taking up a minimum of control room space. Low-noise fans further enhance the temperature safety margin. REMOTE CONTROL UNIT A normal feature of the machine is a very complete REMOTE CONTROL UNIT;... -

Page 13: Installation

INSTALLATION UNPACKING The machine has been packed in a container specially designed for air freight. Inspect it visually and if any damage is observed notify your carrying agent immediately. If all is normal unpack the machine carefully and retain the packing material for possible future use. Remove the front and side covers of TAPE DECK and inspect the SERVO CONTROL print boards;... -

Page 14: Connector Table

CONNECTOR TABLE NO Designation Connector Mating connector Mating type from/to connector wired by 1 LINE IN 1-4 From external User (5-8)(9-12)(13- signal source 16) (17-20)(21- 2 LINE OUT 1-4 To external USER (5-8)(9-12)(13- equipment 16) (17-20)(21- 3 Record To noise USER Indication reduction... - Page 15 CONNECTOR TYPES Type Chassis Connector Mating Connector Siemens C42334-A41-A4 with Siemens C42334-A41-A3 tray C42334-A228-C92 with shell C42334-A228-A842 Cannon DE-9S Cannon DE-9P with Shell Cannon DE51218-1 Cannon DB-25P Cannon DB25S with shell DB115339-2 Cannon DB25S Cannon DB25P with shell DBI15339-2 Siemens A42334-A44-A4 Siemens A42334-A44-A3 with tray A42334-A228-C95 with shell A42334-A228-A845...

- Page 16 Rear view, connector numbers shown without cables 1977-05-01 TR532...

-

Page 17: Connector Drawings

CONNECTOR DRAWINGS No. I LINE IN 1-4 (5-8, 9-12, 13-16, 17-20, 21-24) (all grounds internally connected) No. 2 LINE OUT 1-4 (5-8, 9-12, 13-16, 17-20, 21-24) (pins 2a, 2b, 5a, 5b not connected) No. 3 RECORD INDICATION 1-8 (9-16)(17-24) When a channel is in RECORD, output will be +24 V, other wise a high impedance to ground. -

Page 18: Transportation

TRANSPORTATION The Lyrec TR532 can be transported in a car or van. During transport it can either stand up or be laid down on it's front. For this purpose the factory has developed a special transport frame that fits the front of the recorder (see section 6.7). -

Page 19: Operation

OPERATION SWITCHING ON Connect both line cords to the appropriate voltage and press the MAINS button on the tape deck. Select the desired tape speed. The MAINS, the STOP and one of the speed buttons on the TAPE DECK and the STOP button on the REMOTE CONTROL UNIT should light up. - Page 20 Drawing No. 5.02, Tape path 1977-05-01 TR532...

-

Page 21: Fast Wind Mode

FAST WIND MODE A. From the TAPE DECK Press the WIND button and select the direction and speed of wind by setting the WIND SPEED CONTROL. B. From REMOTE CONTROL UNIT Press the appropriate button to select wind direction and alternate with the other to control speed. -

Page 22: Drop In/Out

the red LED flashes continuously; when the machine is placed in the RECORD MODE the flashing stops and the LED glows steadily. If a READY button is pressed when the machine is already in the RECORD MODE this channel will not drop into RECORD MODE although the LED will start flashing. -

Page 23: Line/Sync/Repro

5.12 LINE/SYNC/REPRO The LINE OUT signal from each PLAYBACK AMPLIFIER may be selected by one of the three following controls: LINE, SYNC and REPRO. This does not affect the recording on this track. Pressing the LINE button selects the LINE INPUT signal of that channel and routes it to the output. - Page 24 5.16 NOMINAL/VARISPEED When the NOMINAL button is pressed the LED lights up and the machine will transport the tape at fixed nominal speed of 15 or 30 ips, whichever has been selected. When the VARISPEED button is pressed the LED flashes continuously to warn of a non-normal condition; the speed of the tape now depends on the setting of the two potentiometers below the VARISPEED button.

- Page 25 TABLE 1; nominal speed 15 ips. Applicable for standard REMOTE CONTROL UNIT, RCU Display Speed (ips) Deviation % 0000 7.50 - 50.00 0100 7.89 - 47.37 0200 8.33 - 44.44 0300 8.82 - 41.18 0400 9.38 - 37.50 0500 10.00 - 33.33 0550 10.34...

- Page 26 TABLE 2; nominal speed 30 ips. Applicable for standard REMOTE REMOTE CONTROL UNIT, RCU Display Speed (ips) Deviation % 1000 15.00 - 50.00 1050 15.79 - 47.37 1100 16.67 - 44.44 1150 17.65 - 41.18 1200 18.75 - 37.50 1250 20.00 - 33.33 1275...

- Page 27 RECORD/PLAYBACK AMPLIFIERS 5.17 SYNC OUTPUT Apart from the normal sync signal which is routed to the LINE OUTPUT each AM 77 RECORD/PLAYBACK AMPLIFIER incorporates a separate sync amplifier. The signal from this extra sync output is available independently for each channel at a separate plug. This output is unbalanced and should not be terminated with less than 10 kOhms.

-

Page 28: Search Function

5.18 SPECIAL FEATURES The machine has been designed for maximum ease of operation. In this context several facilities have been included which are not normally found as standard items. HEADBLOCK To ease maintenance and format changes the HEADBLOCK uses a plug and socket interconnection with a precision mechanical seating arrangement that allows fast changeover operations. -

Page 29: Varispeed

SOLO buttons This facility (5.13) is most useful when mixing but it does not affect any other function of the machine and can be used at any time to check the contents of any individual track. SPEED CHECK Using an internal crystal reference the machine provides an easy check on its performance and the calibration of the VARISPEED settings without recourse to outside instrumentation. - Page 30 5.19 TAPE POSITION CONTROLLER, TPC (OPTIONAL) The unit is built up around a four-digit display, TAPE POSITION, which works as an ordinary tape timer. It counts in minutes and seconds at the tape speed 15 ips (7 1/2 ips available as option). Besides the TAPE POSITION-display, there are an A-display, a B-display and a KEYBOARD-display.

- Page 31 IF TAPE POSITION = B THEN STOP/SEARCH A works in a similar manner. If a LOAD FROM TAPE POSITION-key is activated, the corresponding IF TAPE POSITION = ..will be cancelled (like pressing CONTINUE). When turning on power, all displays will show 00:00, unless the option MEMORY AT POWER ON is included.

- Page 32 STORE: Pressing this key will store the number in the A-display in one of sixteen cells of an internal storage. It will be stored in the cell-number designated by the number in the second- digits of the KEYBOARD-display. If this number is zero or greater than 16, no storing will take place.

- Page 33 TABLE 3. Applicable for optional TAPE POSITION CONTROLLER, TPC. Display Selected NOMINAL speed Deviation % 15 ips 30 ips 0000 7.50 15.00 - 50.00 0100 7.89 15.79 - 47.37 0200 8.33 16.67 - 44.44 0300 8.82 17.65 - 41.18 0400 9.38 18.75 - 37.50...

-

Page 34: Tape Position Controller Tpc

TAPE POSITION CONTROLLER, TPC 6A.1 The Tape Position Controller, TPC, is a microcomputer controlled unit consisting of 7 printed circuit boards; - Central Processor Display LED-module Keyboard Interface Speed Counter Motherboard It is build into the remote control and connected to this via 3 dual- in-line plugs;... - Page 35 6A.2 DISPLAY AND LED-MODULE Consists of 16 circuits for storing and displaying Binary Coded Decimal (BCD) digits and address decoding circuits. In steady state, the BCD-digit in the latch is decoded and displayed. A pulse on the READ-line will bring the content of the latch out on the bidirectional data bus, where it will be read by the central processor.

- Page 36 The two most significant bits, C3 and C2, address one of the four display groups; Display addressed TAPE POSITION KEYBOARD while the two least significant, C1 and C0, address a digit in the group; Digit addressed Sec x 1 Sec x 10 Min x 1 Min x 10 6A.3...

- Page 37 The remaining contacts are connected in groups of 3 or 4 to a switch, that is connected to the data bus. When the switch is enabled by a READ-command, the content of the data bus will indicate which contact is pressed. The light-emitting diodes in the contacts are turned on and off by transmitting the proper bit combination on the data bus and pulsing the proper latch with a write-command.

- Page 38 6A.4 SPEED COUNTER MODULE Consists of a crystal oscillator, a counter chain, latches and preset and load oneshots. The crystal oscillator runs at 2048 kHz and is prescaled down to 2 kHz, which is fed to the 4 decade down-counter. When a speed pulse arrives (from INTERFACE) the number in the counter is stored in the latch.

- Page 39 1) Pulsing the COMMAND-line will store the content of the data bus in the command-latch. The output of the latch is then levelconverted from +15 V (CMOS) to +24 V, the tape deck control voltage. The four outputs correspond to following commands; Databus = 1 =>...

- Page 40 The relay is activated while searching, thereby letting the TPC control the wind-direction. In normal mode, wind-direction is controlled by the push-buttons. Tape deck status information is received by pulsing the STOP SENSE. The information consists of one bit indicating whether the tape speed is higher or lower than a fixed threshold.

- Page 41 The INTERRUPT signal will occur two times per second at nominal speed, 15 ips as well as 30 ips, since the tachometer roller rotates 4/15 revolution per inch of tape, and the roller has 4 windows. Therefore, the INTERRUPT signal is also used as SPEED-PULSE for the SPEED- COUNTER.

- Page 42 The offset adjustment of the distance voltage is adjusted so that at zero tape speed and zero distance, the distance voltage is equal to the speed voltage, indicated by that the comparator cannot find a stable state but picks up hum and switches continuously on the output. The weight between speed and distance is also adjustable (at both 15 and 30 ips).

- Page 43 1978-07-01 TR532 6A.6cont.

- Page 44 6A.7 MOTHERBOARD The motherboard contains edge-connectors for the other pcb's, and provides the necessary interconnections. Also it contains the chip containing the memory, and also it contains two 16 poled dual inline plugs. One plug supplies power to the complete TPC, the other contains the necessary signals for writing the tape position number in a slave display.

- Page 45 2) Press Load Keyboard from Tape Position 3) Press momentarily SEARCH KEYBOARD. This will load the distance latch with zero distance. Since the two numbers are equal, and the tape is not moving, the search will be terminated immediately. 4) P3 should now be adjusted so that the picture on the oscilloscope tends to oscillate between ground and a positive voltage.

-

Page 46: Options

OPTIONS REMOTE TIMER DISPLAY A REMOTE TIMER DISPLAY can be located, for example, in a mixing console. For this purpose the REMOTE CONTROL UNIT has a connector labeled TO SLAVE DISPLAY on the back. This connector supplies the timer signal in multiplexed BCD-code and +5 V (max 1 A) for powering of the remote display;... -

Page 47: Free Space On 8 And 16 Track Model

TPC is found in section 5.19. TAPE SPEED 7 1/2 - 15 IPS To special order the TR532 series tape recorders can be delivered with the tape speeds 7 1/2 and 15 ips. The VARISPEED range will then be 3 3/4 to 30 ips. -

Page 48: Adjustments

ADJUSTMENTS TAPE DECK MECHANICAL ADJUSTMENTS REEL PLATFORM HEIGHT, drawing No. 7.01 Insert a long 3 mm Allen key in the hole at the top of the hub and turn clockwise to lower the platform, and anti-clockwise to raise it. For lubrication, see section 8.12. SUPPLY TENSION ARM PRESSURE, drawing No. - Page 49 REEL PLATFORM HEIGHT ADJUSTMENT DRAWING 7.01 1977-05-01 TR532...

-

Page 50: Guide Roller Pressure

GUIDE ROLLER PRESSURE Use the same procedure to adjust the guide roller pressure to 1.2 kp +/- 20 %. Drawings 7.03B and 7.03C. ROLLER PERPENDICULARITY, drawing No. 7.04 The two large rollers related to each tension arm, the GUIDE ROLLER and the CAPSTAN PINCH ROLLER, are adjusted to be perpendicular to the TAPE DECK by means of three set screws in their bases. - Page 51 ADJUSTMENT TAPE TENSION AND PINCH ROLLER SERVOARM LEFT: Servo spring tension measured as shown on drawing (damping system disconnected). 275 - 325 p Tape tension (measured in front of playback head) 225 ± 10 %. SERVOARM RIGHT: 275 - 325 p Tape tension (measured after capstan pressure roller) 225 ±...

- Page 52 1977-05-01 TR532...

- Page 53 BRAKE BAND 1978-08-01 TR532...

- Page 54 7.8.1 TAPE PATH ALIGNMENT Tools needed: 2” Alignment template Allen keys 3, 2 and 4 mm The following adjustments are critical and require some experience. It is important that the adjustments are done in the order described. ALL MODE ADJUSTMENT Before any adjustments are made, it is VERY IMPORTANT that the reel platform height is correct at both supply and take-up side.

- Page 55 1980-01-10 TR 532 7. 8. 1 cont.

- Page 56 GUIDE ROLLER HEIGHT and perpendicularity All guide rollers must have correct perpendicularity, see section 7.6 The height of the rollers shall be adjusted so the alignment template is as close as possible to the lower edge of the roller, se fig. 3 and 1980-01-10 TR 532 7.8.1 cont.

- Page 57 C. GUIDE ROLLER INFLUENCE The perpendicularity and height of the guide rollers have different influence on the tape travel in different modes. The table below shows the significance of different rollers in different modes. The roller numbers refer to fig l. Mode Most significant Less significant Not significant Rewind...

- Page 58 E. TEST OF ADJUSTMENT With tape running at 15 ips, simulate minimum supply tape tension. This is obtained by manually forcing the left servoarm (fig. 1, item 2) to its utmost left position, see fig. 4. Fig. 4 In this condition, with minimum back tension, observe the tape travel and make sure the tape is within the three guides in the headblock.

- Page 59 1980-01-10 TR 532 7.8.1 cont.

-

Page 60: Tape End Microswitch

TAPE END MICROSWITCH, drawing No. 7.06 This microswitch is mounted on the left TENSION ARM ASSEMBLY. Drawing No. 7.06. Locate arm B on the shaft I of the tension arm so that the microswitch H is just activated when the tension arm reaches its rest position. - Page 61 LEFT TENSION ARM ASSEMBLY 1977-05-01 TR532...

- Page 62 1978-08-01 TR532...

-

Page 63: Tension Arm, Guide Roller And Pinch Roller Air Cylinder

7.13 TENSION ARM, GUIDE ROLLER AND PINCH ROLLER AIR CYLINDER ADJUSTMENT The damping cylinders in these mechanism all have an adjustment screw with a lock-nut at the rear end to adjust the air flow in and out of the cylinder. With a stop watch measure the time between pressing the START button and contact between the PINCH ROLLER and the CAPSTAN. - Page 64 1977-05-01 TR532...

-

Page 65: Maximum Capstan Speed

7.17 MAXIMUM CAPSTAN SPEED ADJUSTMENT Potentiometer Pl on code 3 card. The maximum capstan speed is factory adjusted to approx 70 ips. If capstan speed increases above 70 ips (i.e. by tacho lamp failure) the built in electronic overspeed fuse will automatically give the tape deck a STOP command (See section 8.4.). -

Page 66: Wind Speed Limit

7.21 WIND SPEED LIMIT adjustment Load a full reel and wind it approx to the middle so that the same amount of tape is on each reel. Press the WIND button and set the tape winding at full speed one way or the other. Hold down the NOM. speed button on the REMOTE CONTROL UNIT to obtain a speed reading on the TIMER display and adjust the WIND SPEED LIMIT potentiometer on CODE 7, TACHO LOGIC card so as to obtain a reading of 19.20 on the display. -

Page 67: Relay

7.25 RELAY 5 adjustment potentiometer In case of tacho lamp failure relay 5 is controlled by a time delay circuit adjusted by the potentiometer alongside the relay. Remove the small 5 pin connector at the top of the TACHO LOGIC, code 7 card, and place the machine in WIND. -

Page 69: Coarse Head

d) Connect the oscilloscope to pin 8 on IC 34. Set the preselected thumb-switch to 2 minutes more than the TAPE TIMER display. Press the START button (15 ips). Adjust HIGH SPEED potentiometer so that the duration of the pulses shown on the oscilloscope is 30 ms (a mark/space ratio approx equal to 1/1). -

Page 70: Fine Azimuth

Tighten screw 4 and loosen screw 2. Using a grease pencil smear across the front of each head, check the tape wrap, which should be centered on the tape gap of the PLAYBACK and RECORD heads. In the case of the ERASE head the tape must cover a wider area due to the staggered arrangement used. - Page 71 To adjust the RECORD head azimuth place the recorder in SYNC mode and use the TEST TAPE in the same manner as for the PLAYBACK head. After the FINE ADJUSTMENT procedure has been completed, check that the RECORD and PLAYBACK heads do not make contact with the fixed mumetal shield around them, as this would disturb the grounding arrangements.

- Page 72 HEAD BLOCK 1977-05-01 TR532...

-

Page 73: Am77 Adjustment Procedure

7.29 AM 77 ADJUSTMENT PROCEDURE The adjustment procedure to be described allows the user to adjust the AM 77 RECORD/PLAYBACK AMPLIFIERS so that the frequency versus amplitude record/playback response of the machine is within specification. Because the machine is adaptable to any reasonable standard no specific TEST TAPE LEVEL (TTL) or STUDIO LINE LEVEL (SLL) will be defined. - Page 74 PLAYBACK (REPRO) FREQUENCY RESPONSE ADJUSTMENT 4. Go to the frequency response section of the test tape. Select START. 5. Note the level of the 1 kHz tone. Normally 10 or 20 dB below TTL. 6. Adjust P2, µsec, so that the 6 kHz tone is equal in level to the 1 kHz tone.

-

Page 75: Record Level

3. Turn the proper BIAS CURRENT potentiometer fully anticlockwise. 4. Connect the voltmeter to LINE OUT and select REPRO. Feed a 10 kHz signal approx 20 dB below SLL to LINE IN, if tape speed is 15 ips. (At 30 ips: 20 kHz, and at 7 ½ ips: 5 kHz) 5. - Page 76 LYREC MANUFACTURING 1984-01-19 APPLICATION NOTE When updating the TR532 or the TR55 with phase-linear record equalization, this page should be included as section 7.32.8 in the TR532 manual or as point 8 under RECORD-PLAYBACK FRED. RESPONSE in the TR55 manual.

-

Page 77: Vu-Meter Panel

6. At the same level, vary the signal frequency between 30 and 200 Hz while monitoring LINE OUT. Adjust P3, LOW FREQ., on PLAYBACK EQ., REPRO, to obtain the most satisfying result. 7. Rewind the piece of tape recorded at point 6, select START and select SYNC and adjust P3 in the SYNC PLAYBACK EQ. -

Page 78: Bias Filter And Dc-Current

7.35 BIAS FILTER AND DC-CURRENT ADJUSTMENTS These adjustments are not accessible from front and the AM 77 therefore must be connected via the extension cable when adjustment is carried out. On the other hand, they are not part of any routine check, and readjustment is only necessary when components close related to the adjustable components have been substituted. - Page 79 AM 77 RECORD/PLAYBACK AMPLIFIER 1977-05-01 TR532...

- Page 80 7.1.1.Audio amplifier block diagram 1977-05-01 TR532...

- Page 81 CAPSTAN MOTOR 1977-05-01 TR532...

- Page 82 1977-05-01 TR532...

-

Page 83: Service

SERVICE THEORY OF OPERATION CAPSTAN MOTOR SYSTEM The capstan motor is a brushless DC-motor with 4 windings displaced 900 with respect to each other, placed in the air gap between the two pole permanent magnet rotor and the groove free stator. Two Hall generators measure the rotor position. - Page 84 8.3.1 CAPSTAN BRAKING To prevent tape loops at early play start after play stop, the capstan motor is braked by 5V from code 3 capstan motor control (drw. 8436/5). Transistors T3 and T2 control the braking power through point 23 connected from point 23 code 2 (drw.

-

Page 85: Motor Control Commutator

MOTOR CONTROL COMMUTATOR (code 3 card) diagram 8436/5 The four motor windings are current fed from the capstan motor control commutator according to the signals from the two Hall generators in the motor. The signal from the frequency detector (point 16) is connected to the control commutator (point 16) and determines, via transistors T4 and T5 the input from the Hall generators to the four driver transistors. -

Page 86: Wind Speed Limit Circuit

When the START button is pressed +24 V will appear at point 10 and will activate the STARTING POWER circuit which may be adjusted by means of the START POWER TIME potentiometer and the START POWER potentiometer. The normal factory adjustments for these points are max START POWER on the TAKE-UP motor. -

Page 87: Capstan And Guide Roller Solenoids

When the STOP button is pressed, relay 7 will send +24 V to point 14 and then through point 44-A to transistor latch 1 and 2. This will activate transistor 3 which gives collector voltage to transistors 4 and 5 and drive to transistors 6 and 7 which are outputs for the zero switch drivers on zeros witch print (placed behind the electrolytic capacitors). -

Page 88: Remote Control Unit Muting System

REMOTE CONTROL UNIT MUTING SYSTEM diagram 8905 When the STOP button is pressed 24 V goes to point 18 on the MASTER COMMAND print. Through transistors 5, 6 and 7, transistor 8 disconnects the -15 V supply from point 16 in all amplifier COMMAND PRINTS, thereby muting all tracks in SYNC or REPRO MODE. -

Page 89: Demagnetization

8.12 LUBRICATION A few parts in the Lyrec TR532 require periodic lubrication. The capstan top bearing should be lubricated with two drops of oil every month. Use Esso Nuto HP 32 oil as supplied with the recorder. -

Page 90: Removing Head Block

NAB reel hub From time to time it might be necessary to lubricate the rubber expander locking ring if the reels are difficult to put on to the hub. Use a few drops of Esso NUTO HP32 (as supplied with the machine) and spread it with your finger around the ring. - Page 91 REC-START-WIND-STOP Relay System Diagram 9119 Print 69-025 RELAY # 11 12 ¡ ¡ ¡ ¡ x ¡ ¡ u ¡ ¡ Stand by ¡ ¡ ¡ ¡ ¡ ¡ x ¡ ¡ Braking x ¡ ¡ ¡ z x x x ¡ ¡ Start ¡...

- Page 92 1979-10-01 TR532...

- Page 93 1977-05-01 TR532...

- Page 94 1977-05-01 TR532...

- Page 95 Drawing 8.01 1977-05-01 TR532...

- Page 96 Drawing 8.02 1977-05-01 TR532...

-

Page 97: Spare Parts

SPARE PARTS SPECIAL TOOLS Group Drawing No. Special Tools Tool case, plastic Set of Allen keys 1.5, 2, 2.5, 3, 4 mm Allen key 2 x 90 mm Allen key 3 x 90 mm Screwdriver 80 x 2 mm, Belzer Oilcan, mini Belzer, with Esso NUTO HP 32 Oilcan, mini Belzer, with ROCOL molybden oil Bottle of cleaning fluid... -

Page 98: Spare Parts

SPARE PARTS Group Drawing Spare parts Tape deck: 8171 Pressure roller complete 9022 Tape roller complete, Ø 30 8562 Tape roller complete, Ø 20 9021 Measuring roller complete Lamp for measuring roller, Rafi 2824 28 V 0.04A 8306 Holder complete with 2 pcs TIL 66 6967 Return pull spring for magnet Microswitch, Kissling MFX 1331-202... - Page 99 Fuse 4A slow Powertransistor MJ 2955 Powertransistor 2N 3055 Powerbridge 26B 1OA-7C Transistor BC 310 Zenerdiode ZF 15 Transistor BC 140 Transistor BC 160 Transistor MJE 2955 Transistor MJE 3055 Transistor RCA 40410 Integrated voltage regulator LM 32OK-15 Integrated voltage regulator LM 34OK-15 Integrated voltage regulator LM 723 Integrated amplifier LM 301 Integrated One-shot SM 74121...

-

Page 100: Application Notes

APPLICATION NOTES 10.1 EFFECTS As shown in the block diagram it is possible to obtain phasing or flanging effects on specific channels using the SYNC OUTPUTS and only one extra tape recorder. The record/playback time delay of this recorder should be adjusted to be as close as possible to the TR532's and a variable-speed machine is the ideal, of course, but judicious use of handbraking and splicing tape can do wonders! When the delay is exactly equal there is no difference between the signals reaching the... - Page 101 Drawing 10.01 1977-05-01 TR532...

- Page 102 10.2 APPLICATION NOTE Subject: Availability of playback signal during winding. Purpose: Possibility to read playback signal during winding. Normally all outputs are muted during winding. This muting can only be cancelled by pressing the defeat button or turning the edit handle. For customers who record time code on one track for synchronizing this may be inconvenient.

- Page 103 APPLICATION NOTE 10.3 SOLO function Normally when using the SOLO function all other channels switch to LINE IN. This can be changed so that all other channels are muted. The modification is simple and requires one 10 kOhm resistor for each channel.

- Page 104 1977-07-08 TR53/TR532 10.3 cont.

- Page 105 1977-07-08 TR53/TR532 10.3 cont.

- Page 106 10.4 APPLICATION NOTE START after SEARCH in RCU's Normally a search is terminated with a STOP command. With this modification, it is possible to select with a switch, whether the machine will go to STOP or START after SEARCH. In the remote control unit, insert a diode in the wire from STOP-LAMP (pin 5a) to pin 16 on the SEARCH LOGIC.

- Page 107 APPLICATION NOTE 10.5 Applicable for remote control units type RCU and TPC GROUP BUILDING WITH THE REMOTE CONTROL By programming the audio commanders in a special sequence, the tracks can be split up into three groups for remix. Each group can be recalled with one button.

- Page 108 APPLICATION NOTE 10.6 Applicable for remote control type ATC GROUP BUILDING WITH THE REMOTE CONTROL By programming the audio commanders in a special sequence, the tracks can be split up in 3 or 4 groups for remix. Each group can be recalled with one button.

- Page 109 RECALLING GROUPS After programming only group 1 is active. Provided no signals are routed to the recorder, group 2 will be silent as it is switched to LINE. Group 3 and 4 are electronically muted. To recall group 2, simply press the MASTER REPRO button This will switch group 2 from SOLO - LINE into SOLO - REPRO and these tracks are added to group 1.

-

Page 110: 11 Service Bulletins

11 SERVICE BULLETINS 11.1 EQUALISATION For customers having NAB test tape and aligning for CCIR or vice versa, the table below might be useful. Response from amplifier adjusted for 15 ips NAB when using a 15 ips CCIR test tape, Ereq. - Page 111 11.2 Subject: To reduce hum. Procedure: 1. Take out the tape deck control box by: Unscrewing four screws at the rear of the box. Open the tape deck to tilted position. Remove: 2 connectors on the left side. Remove: 3 connectors to the control printed circuit board.

- Page 112 11.3 Purpose: To reduce click-noise when switching amplifier state (I.e. LINE SYNC REPRO). Remedy: Install a 2.2 µF capacitor across each base emitter of the LINE, SYNC- and REPRO line drivers in the amplifier commander print located in the Remote Control Unit. Procedure: 1.

- Page 113 11.4 SERVICE BULLETIN 1978-05-01 Purpose: Improvement of START POWER Circuit. This improvement is factory installed as from November lst, 1977. Start power (on take up reel) is adjusted to be injected during the period from START until correct tape speed is obtained. If the start power drops before correct tape speed is obtained, tape loop will appear at the right hand servo arm.

- Page 114 2. Install a wire from Code 4 (power stabilizer) pin 6 to Code 1 pin 6 (-12 V). (If a wire is already soldered to Code 1 pin 6, remove this and re-solder to a not used neighbor pin.) 3. Install a wire from Code 1 pin 37 to Zeroswitch pin A3. After this modification it is possible to adjust the start power to be injected through the whole acceleration period.

- Page 115 WIND POWER ADJUSTMENT With equal amount of tape on both reels, select WIND on the tape deck. Set the WIND control to its exact middle position. Hold the left reel with your hand and adjust P7, wind power, so both servo arms rest in their middle positions.

- Page 116 11.5 SERVICE BULLETIN Modification of: Code 1 servo system print Purpose: Improvement of start up characteristic Parts needed: 1 Transistor BC214 1 Resistor 10 kOhm Modification: 1. The input pin 14 should be connected directly to resistor R34. Move the existing wire from one leg of P8 to resistor R34.

- Page 117 1978-05-01 TR532 11.5...

- Page 118 1978-05-01 TR532 11.5...

- Page 119 1978-05-01 TR532 11.5...

- Page 120 1978-05-01 TR532 11.5...

- Page 121 11.6 SERVICE BULLETIN Slow response in changing speed, varispeed - nomspeed, comes from filter capacitor C2 22 µF in code 2 capstan motor control. Switching from varispeed to nomspeed a discharging of C2 will start but through point 9 and master commander point 22 and P1 "fine", P2 "coarse", R38 750e to point 19 and back to code 2 point 11, TS2 will be kept in varispeed condition for some time.

- Page 122 11.7 SERVICE BULLETIN Subject: Reliability of crimp-connectors The rectifiers mounted on the backplate of the recorder are all connected with AMP crimp-connectors. We have recently experienced some cases of intermittent bad connections between the wire and the AMP connector. As it concerns the main power supply a number of symptoms can occur and usually when the recorder has been switched off for a longer time.

- Page 123 11.8 SERVICE BULLETIN Lifetime of tape timer lamp - This improvement is factory installed as from December 1977. - To increase the lifetime of the lamp driving the tape timer logic, the circuit controlling the lamp needs the following change on code 7 tachometer logic print;...

- Page 124 11.9 SERVICE BULLETIN Reducing SYNC to REPRO crosstalk The crosstalk is induced to the repro preamp from the SYNC OUT output wire on the amplifier PCB. To reduce it, cut the PCB-wire connected to pin B13 as close to the connector finger as possible and in the other end as close to the 33e resistor as possible, and substitute the PCB-wire with a short piece of shielded cable.

- Page 125 11.10 SERVICE BULLETIN Subject: Elimination of unwanted mode switching, caused by mains transients. Mains transient can under some conditions cause the remote control commander prints to switch from RECORD or READY to SAFE or VARISPEED switch to NOM speed. Remedy: To further improve transient suppression, install two filter capacitors (1 µF 35V and 10 µF 16V tantal capacitor) on the integrated +5V regulator (LM309/LM340-5).

- Page 126 11.11 SERVICE BULLETIN NEW IMPROVED BRAKE BAND, FELT-COATED, has been introduced. The new type gives a smoother operation and increased lifetime. When switching to the new type both brake bands must be changed as well as the servo spring. - Before mounting the new brake band, carefully clean the brakedrum from any grease.

- Page 127 - Note that changing servo springs demands a careful check or adjustment of the damping system connected to each servo arm. - Watch left hand servo arm when left hand reel is full of tape and right hand servo arm when right hand reel is full of tape. - If any tape loop appears during the servo arm traveling in acceleration period, damping is too high.

- Page 128 1979-05-31 HB TIMING CONSIDERATIONS IN THE LYREC AM77 RECORD/PLAYBACK AMPLIFIER All components referring to drawing 9171 Record Timing (see fig. 1) 1a. Drop in When recording starts, pin B11 on the amplifier immediately rises to +24V, "a" on fig. 1.

- Page 129 1b. Drop out When recording stops, pin B11 immediately turns to high impedance ("a"). Again the collector of TS26 ("b") is delayed 40-50 msec and then goes low. However, due to C49 and D25 the relay is held active until the bias is completely turned off. If this was not the case, the record head would be disconnected from the bias signal abruptly, resulting in a crack-noise on the tape.

- Page 130 RECORD DELAY Since the bias and erase current rise simultaneously when dropping into record, the piece of tape between the erase head and the record head will not be erased but recorded. If the drop in is done on a silent piece of tape, nothing will happen, otherwise there will be an overlap with a level rise as result.

- Page 131 The delay circuit is designed for 15 and 30 ips tape speeds. Other tape speeds made to order. The delay circuit can be applied to all Lyrec recorders of series TR532. It must however be emphasized that this timing circuit do not compensate for the noise reduction switching.

- Page 134 1980-12-17 HB SERVICE BULLETIN AM77-amplifier improvements 1. Erase current symmetry It has proved necessary to block the possibility of dc-current flow in the erase-head. Especially on recorders with a no longer quite new record-head, this will eliminate excessive low-frequency noise being recorded on tape (sometimes referred to as "Rocks").

- Page 136 1981-03-13 Drop in/Drop out timing considerations -------------------------------------- Due to tolerances in component values, the noise at drop in/drop out can in some cases be an inconvenience. This can be improved by changing some components. The table below shows present values as well as values for improved performance. The zener diodes D44 and D52 are listed as they in some series have a different value.

- Page 137 1984-08-20 Subject: RECORD RELAY, AM77 RECORD – PLAYBACK AMPLIFIER The record relay, ITT PZ4 A2625/PZ4 A2629, 36 V used on the record- playback amplifier AM77 is no longer available. It may be substituted by type PZ4 A2615 or A2626, which is a 24 V version of the same relay, if a 6.2 V zener diode is installed in series with the relay coil.

- Page 138 BULLETIN 01/87 MODEL TR532 TYPICAL BASIC SETTINGS FOR TAPE TRANSPORT CODE 1, SERVO SYSTEM DIAGRAM 9870 -------------------------------------------------------------------- Pl, START POWER Adjust to MAX power. P2, WIND POWER Adjust to middle position. P3, START POWER TIME Adjust to 3/4 of maximum. CODE 2, CAPSTAN MOTOR CONTROL DIAGRAM 8605/3 --------------------------------------------------------------------...

- Page 139 CODE 3, COMMUTATOR DIAGRAM 8436/5 ------------------------------------------------------------------- Pl, OVER SPEED FUSE Adjust to command STOP for capstan speeds higher than 60 ips. P2, BALANCE Adjust for minimum peaks as seen at CODE 3 test point, or to minimum linear wow & flutter.

- Page 140 Bulletin 01/88 (Page 1/3) Valid for models TR532 and TR533 REMOVING AND REFITTING OF CAPSTAN SHAFT Removal of capstan shaft. 1. Disconnect mains power 2. Remove the machine front cover. 3. Remove the headblock top cover. 4. Slacken the screw for the capstan top bearing (located under the headblock top plate).

- Page 141 INSTALLATION OF NEW CAPSTAN SHAFT Re-assemble in reverse order but note the following points; NOTE: Model TR532 only. Capstan shafts supplied as from 85-01-01 has a new type of bearings and a diameter 10 mm. The new type has part no 440027 and is supplied together with a new capstan top bearing (part no 501008).

- Page 142 13. LAMP AND PHOTOTRANSISTOR POSITIONING The lamp should be placed 5-8 mm above the tacho disc and the phototransistor tube as close as possible without touching the glass disc. Connect an oscilloscope across the output of the preamplifier and check the shape of the resulting square wave. The phototransistor tube should be turned to obtain at least 4 V peak-to-peak, with best possible wave shape.

- Page 143 Drw. 2738, page 1/2 Rev. 0, Nov. 1991 SERVICE BULLETIN 827380 VALID FOR: LYREC model TR533 and TR532 multitrack recorders. SUBJECT: The original capstan motor type AD5000 is no longer manufactured. When necessary this motor can be replaced with a modern disk type motor.

- Page 144 Doc. 2738 Drw. 2738, page 2/2 Rev. 0, Nov. 1991 LAMP AND PHOTO TRANSISTOR POSITIONING 12. The lamp should be placed 5-8 mm above the glass disk. The photo transistor tube should be placed as close as possible to the glass disk WITHOUT touching it.

- Page 145 It is being substituted by MJE 2955T, which has the same specifications except for power dissipation. In all Lyrec applications, the MJE 2955T may be used directly without exceeding the maximum ratings, but it should be noted that: - pins are reversed.

- Page 146 12. DIAGRAMS TR532 HEAD CONNECTIONS TR532 1072 TAPE DECK TR532 9119 A1 NA RELAY BOARD FOR TR532 TAPE DECK 9872 AMPLIFIER POWER SUPPLY FOR TR532 9874 AMPLIFIER POWER SUPPLY - POWER BLOCK 9876 CAPSTAN SPEED PRE-AMP 9873 SERVO DRIVER BOARD FOR TR532 9875 CODE 1, TRANSFORMER SERVO SYSTEM 8643/3...

- Page 147 9235.jpg...

- Page 148 1037.jpg...

- Page 149 1038.jpg...

- Page 150 1040.jpg...

- Page 151 1070V0.jpg...

- Page 152 1072.jpg...

- Page 153 1202.jpg...

- Page 154 1996.jpg...

- Page 155 1997.jpg...

- Page 156 2739.jpg...

- Page 157 8520_4.jpg...

- Page 158 8605_3.jpg...

- Page 159 8646_3.jpg...

- Page 160 9120.jpg...

- Page 161 9147.jpg...

- Page 162 9876.jpg...

- Page 163 9455.jpg...

- Page 164 9456.jpg...

- Page 165 9457.jpg...

- Page 166 9458.jpg...

- Page 167 9459.jpg...

- Page 168 9460.jpg...

- Page 169 9461.jpg...

- Page 170 9475.jpg...

- Page 171 9476.jpg...

- Page 172 9524.jpg...

- Page 173 9525.jpg...

- Page 174 9582.jpg...

- Page 175 9870.jpg...

- Page 176 9871.jpg...

- Page 177 9872.jpg...

- Page 178 9873.jpg...

- Page 179 9874.jpg...

- Page 180 9875.jpg...

- Page 186 470e RECORD PHASE LEVEL SHIFT MED-HIGH FREQ R12* IC 1 IC 1 PIN 4 PIN 11 R10* SEE NOTE 100n BIAS 100n HIGH FREQ -15V +15V PCB 84-03x IC1: TL 074 OR EQUIVALENT *: 1% TOL. NOTE: WITH HX PRO: CONNECTED TO 0V, P1 = 50K WITHOUT HX PRO: CONNECTED TO +15V, P1 = 1K R10-12 R14 C2...

- Page 195 This Manual or Schematic is a FREE DOWNLOAD For everyone… From the archives of Analogrules.com AudioSchematics.com If you have paid anything for this Manual or Schematic You have been RIPPED OFF Demand your money back And let us know who is stealing our files and charging for downloads free...

Need help?

Do you have a question about the TR532 Series and is the answer not in the manual?

Questions and answers