Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Edur LBU Series

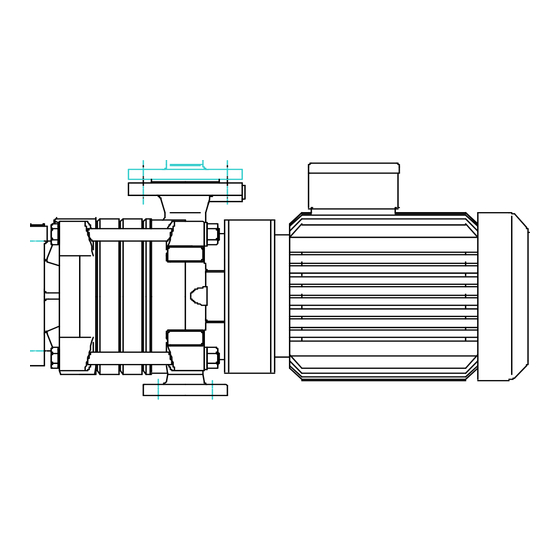

- Page 1 Operating Instruction Segmental Type Pumps Please keep your Operating Instruction in a safe place! Type Serial No. EDUR-Pumpenfabrik Postfach 1949 · D-24018 Kiel Eduard Redlien GmbH & Co. KG Tel. (+431) 689868 · Fax (+431) 6898800 E-mail: info@edur.de · http://www.edur.de...

-

Page 2: Table Of Contents

Contents Security Identification of Safety Instructions in the Operating Manual Qualification and Training of Operating Personnel Hazards in the Event of Non-Compliance with the Safety Instructions Compliance with Regulations Pertaining to Safety at Work Safety Instructions relevant for Operation Safety Instructions relevant for Maintenance, Inspection and Assembly Work Unauthorized Alterations and Production of Spare Parts... -

Page 3: Security

General Instructions non-compliance with which would give rise to malfunctioning of the machinery are most important operational data identify by the word mentioned type label. sound pressure L following VDI-guidelines 3743 sheet 1 CAUTION depending on the nominal pump power input P will be seen from the diagram underneath. -

Page 4: Safety At Work

Compliance with Regulations Unauthorized Alterations and Production of Spare Parts Pertaining to Safety at Work Any modifications may be made to the machine When operating the pump, the safety instructions only after consultation with the manufacturer. Using spare parts and accessories authorised by contained in this manual, the relevant national the manufacturer is in the interest of safety. -

Page 5: Intermediate Storage

For transport only the screws CAUTION between foot of suction casing and base plate are tightened at our works. Please take care that before setting into operation the screws have to be released by all means resp. in case of a transport again have to be tightened. In this regard also see section 4.1 Intermediate Storage Fig. -

Page 6: Place Of Operation

Place of Operation The pump unit must be freely accessible for the purpose of supervision, servicing, maintenance, mounting and dismounting. Avoid using it in corrosive and very dusty surroundings. The limiting values of the electric drive unit with regard to the insulation material class and the types of protection must be observed. -

Page 7: Coupling Protection

Coupling Protection 4.5.4 Additional Connections For the position and dimension of required The pump must not be operated if additional connections as e.g. for rinse, stop and coupling protection is not fitted. If this quench liquid, refer to the labels supplied with the coupling protection is not supplied by pump or to the drawings in the operating the manufacturer, the operator of the pump must... -

Page 8: Restarting

In case of corrosive / abrasive CAUTION Until the liquid starts moving against atmospheric media to be pumped pressurized pressure, the hydrostatic pressure for self-priming components have to be checked regularly in order pumps must not exceed 1 bar with reference to to detect wear in time - before a damage occurs. -

Page 9: Preparation

It must be possible to rotate the slide slightly after For unit-construction pumps, the pump and motor having tightened the lid or insert. If tightening of must not be separated for the axial fixing of the the gland lid or insert results in the pump being pump shaft. -

Page 10: Mounting Of The Motor

by means of the shaft nut and/or the hexagon nut. 6.2.3.4 Mounting of Mechanical Seal If this is not observed, the bearings will be When mounting the mechanical damaged. CAUTION seals, you must proceed very The starting torques for the tie bolts and locking carefully and with precision. - Page 11 Observe enclosed, separate mounting Stressed mechanical seal dependent on instructions for those types of mechanical seals direction of rotation with conical springs which are not listed. (fig. 6.2.3.4b) Stressed mechanical seal independent of direction of rotation with elastomer bellows (fig. 6.2.3.4a) Fig.

-

Page 12: Disturbance

7 Disturbance To eliminate disturbance, the pump must have CAUTION reached the environmental temperature and must be drained of air and pressure. The chart shows a list of potential errors and their possible causes. For errors which are not listed here or which have other reasons, please consult us. - Page 15 Declaration of Conformity As defined by machinery directive 98/37/EC Annex II A Herewith we declare that the pump unit supplied with mounted electric drive complies with the following provisions applying to it EC-machinery directive (98/37/EC, Annex I No. 1) EC-low voltage directive (73/23/EEC) Applied harmonized standards EN 809 EN 953...

- Page 16 17102,8 / 071001...

Need help?

Do you have a question about the LBU Series and is the answer not in the manual?

Questions and answers