Table of Contents

Advertisement

OPERATOR'S MANUAL

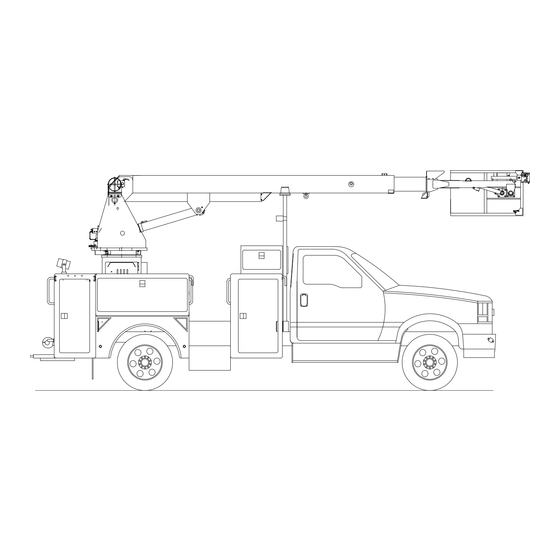

TELESCOPIC AERIAL DEVICE

Line Runner 700-40

Posi-Plus Technologies Inc. Copyright © 2018

COPYRIGHT-WARNING

ANY REPRODUCTION OR DISTRIBUTION OF THIS WORK, IN WHOLE OR IN PART, BY ANY MEANS

WHATSOEVER, IS STRICTLY PROHIBITED WITHOUT THE EXPRESS WRITTEN CONSENT OF POSI-

PLUS TECHNOLOGIES INC.

700-OPEA-004

Advertisement

Table of Contents

Summary of Contents for Posi-Plus Line Runner 700-40

- Page 1 OPERATOR'S MANUAL TELESCOPIC AERIAL DEVICE Line Runner 700-40 Posi-Plus Technologies Inc. Copyright © 2018 COPYRIGHT-WARNING ANY REPRODUCTION OR DISTRIBUTION OF THIS WORK, IN WHOLE OR IN PART, BY ANY MEANS WHATSOEVER, IS STRICTLY PROHIBITED WITHOUT THE EXPRESS WRITTEN CONSENT OF POSI- PLUS TECHNOLOGIES INC.

-

Page 2: Table Of Contents

TABLE OF CONTENTS Section 1 - Unit specifications About this manual ........................... 4 General specifications ........................4 Standard optional features ......................4 Components identification ......................5 Reach diagrams ..........................6 Section 2 - Safety Accident prevention signs ....................... 7 Safety instructions ........................... 7 Safety information ........................... - Page 3 Preface The Posi-Plus Line Runner 700 aerial device is the result of Posi-Plus advanced technology and quality awareness in design, engineering and manufacturing. At the time of delivery from the factory, this unit met or exceeded all applicable standards published by both the Canadian Standards Association CSA-C225 and the American National Standards Institute ANSI A92.2.

-

Page 4: Section 1 - Unit Specifications

General specifications The Posi-Plus model 700 uses a telescopic boom design that is capable of movement through 100°, from -20° below horizontal to 80° above horizontal. The turntable has a 370°... -

Page 5: Components Identification

Components identification INTERCOM TURRET PEDESTAL TELESCOPIC PLATFORM LOWER BOOM BOOM LOWER CONTROLS STABILIZER BAR STABILIZER BAR (IF APPLICABLE) (IF APPLICABLE) Oct-18-700 Operation Page 5 of 34... -

Page 6: Reach Diagrams

Oct-18-700 Operation Page 6 of 34... -

Page 7: Section 2 - Safety

These accident prevention signs are prepared by an industry council. If for any reason any of the accident prevention signs are lost or become illegible, replacements may be obtained from Posi-Plus. Safety instructions This "safety alert symbol" is used throughout this manual to indicate danger, warning, caution, and attention instructions. -

Page 8: Safety Information

This aerial device should never be altered or modified in any way which might affect the structural integrity or operational characteristics without the specific written approval of Posi-Plus Technologies Inc. Unauthorized alterations or modifications will void the warranty. Of greater concern is the possibility that unauthorized modification could adversely affect the safe operation of the unit, resulting in personal injury and/or property damage. - Page 9 All platform occupant(s) must always wear a certified CSA or OSHA approved full body harness attached and secured to the anchor provided at the upper controls’ station before entering the platform. All platform occupants must always wear appropriate personal protective devices at all times (i.e.

- Page 10 Danger This aerial device is not insulating and carries no dielectric rating. Death or serious injury can result from the use of such equipment in contact with or with inadequate clearance from an energized conductor. Maintain safe clearance from electrical power lines and apparatus. The operator must allow for platform sway, rock or sag.

-

Page 11: Section 3 - Safety Decals

A copy of each decal follows the listing. If for any reason any of the accident prevention signs are lost or become illegible, replacements can be obtained from your Posi-Plus dealer. This section will help you to find the decal to be replaced. - Page 12 Oct-18-700 Operation Page 12 of 34...

-

Page 13: Section 4 - Before You Operate

Section 4 – Before you operate Capacity and stability The maximum platform capacity for this aerial device is stated on the aerial device identification placard mounted on the side of the pedestal. A sample of the aerial device identification placard may be found at Section 3 of this Operator's Manual. The Posi+ Line Runner 700 aerial device has been designed to be operated as a mobile aerial device. -

Page 14: Operation Near Energized Conductors

Caution Operators are instructed to operate the aerial device controls smoothly, avoiding sudden reversals in direction or abrupt stops. This aerial device will meet or exceed the extreme requirements for stability as set forth in the CAN/CSA-C225 and ANSI A92.2 Standards, as delivered. Even so, in extreme conditions of rough control, dynamic or shock loading may have a detrimental effect on stability. -

Page 15: Daily Preoperational Checks

Daily preoperational checks The aerial device should be inspected at the beginning of each work day, before going out on the job. By spending a few moments every day inspecting the unit, potential service and safety problems may be detected. The following inspections and tests shall be performed by the operator immediately prior to first use at the beginning of each shift. - Page 16 9. Test the override systems of this unit. The lower controls must override the upper controls. If the overrides (station selector) are not operating correctly, the machine should not be used until the problem is corrected. 10. With no one in the platform, cycle the aerial device functions through the complete range of motion from the lower control station.

- Page 17 Figure 4.1 Oct-18-700 Operation Page 17 of 34...

-

Page 18: Preparing For Operation

Preparing for operation 1. Positioning of the vehicle will be governed by the reach of the booms and the work to be done. 2. The driver and the operator are both responsible for placing the vehicle in the proper position for safe operation of the lift at all times and in every condition. The operator must make sure that any signals that might be used are understood by all personnel concerned, including bystanders. -

Page 19: Section 5 - Controls

Section 5 - Controls In cab controls The in cab controls are: Switches controlling the PTO and the strobe lights Intercom. Intercom system The intercom system consists of a master unit mounted in the cab and a slave unit mounted at the platform. - Page 20 Upgraded intercom system (optional) The upgraded intercom system consists of a master unit mounted in the cab and a slave unit mounted at the platform. The master unit is wired into the cab control station and supplies DC power to the slave unit.

-

Page 21: Lower Controls

Lower controls 1. A red master switch push/pull button at the electrical junction box that will either turn "ON" the electricity to both, the lower controls and to the upper controls and it will act as an emergency stop at the lower controls. So, if this switch is in the "OFF" position, both the lower and upper controls become inactive. -

Page 22: Upper Controls

Upper controls The one-hand joystick control mounted on the side of the platform operates the aerial device movement. The functions operated are: Upper boom “EXTEND/RETRACT” Rotation “CLOCKWISE/COUNTERCLOCKWISE” Lower boom “UP/DOWN” In addition to providing for directional control of the aerial device, the single handle controller has an interlock button (trigger) fitted into the handle. - Page 23 Boom upper controls The one-hand joystick control mounted on the side of the platform operates the aerial device movement. Emergency stop Whenever required the emergency stop can be used to stop all boom functions. To activate, push down the red push button that is installed on top of the upper controls’...

-

Page 24: Section 6 - Operation

Section 6 - Operation Booms This unit is a non-overcenter type design that uses a hydraulic cylinder to raise and lower the boom. The boom may be actuated from the upper controls' joystick. The lower hydraulic controls may also be used to operate the boom when the toggle switch at pedestal is maintained in the "Override”... -

Page 25: Personnel Platform

Personnel Platform This aerial device is equipped with an aluminum platform. Danger The aluminum platform at the boom tip area does not provide any protection against electrical continuity. It cannot protect against any contact with energized lines Caution Use care when getting on and off the unit and/or when entering and exiting the platform to avoid slipping or falling. -

Page 26: Platform Leveling System

Danger During operation of this aerial device, all platform occupant(s) of this aerial device must always wear a certified CSA or OSHA approved full body harness attached to a lanyard while operating the unit from the platform. The lanyard must be secured to the lanyard anchor (D-ring) at the boom tip. -

Page 27: Lower Boom Lifting Eye

Lower boom lifting eye This attachment adapts the lower boom for light-duty material handling. The lifting eye provides a secure mounting for a shackle at the end of the lower boom. The lifting eye is rated for 1000 pounds at any boom angle. Warning The lower boom lifting eye should only be used when the platform is not occupied. -

Page 28: Section 7 - Protection Systems

Section 7 - Protection systems Limitations of protection systems The Line Runner 700 aerial device is equipped with protection systems that are intended to protect the machine from being overloaded due to operator errors. However, even with these protection systems, the unit can be damaged if the operator disregards the recommended methods and procedures described in this manual. -

Page 29: Section 8 - Emergency Operation

Section 8 - Emergency operation Operating safely Should the occupant of the platform suffer injury while aloft, disabling that person from operating the platform controls, the platform may be lowered by means of the overriding lower controls. Danger Before attempting to lower the platform with the lower control, for the protection of the ground personnel, it must first be determined that the vehicle is not energized. - Page 30 From the upper controls, to start the emergency DC pump, press and hold the "Emergency pump" switch while operating with the control joystick. From the lower controls, to start the emergency DC pump, hold the switch in the "emergency pump" position while operating the toggle switches. The pump will continue to operate as long as the switch is held in this position.

-

Page 31: Section 9 - Troubleshooting

Section 9 - Troubleshooting Normal operation of the aerial device may be interrupted by a failure or malfunction in the engine or hydraulic system. The chart below summarizes trouble situations, with typical symptoms and troubleshooting procedures. Troubleshooting chart Symptom Possible Cause Corrective Action All functions Pump, PTO or clutch failure. -

Page 32: Section 10 - Care Of The Unit

Maintenance Manual. At no time should an aerial device be altered or modified without the specific written approval from Posi-Plus Technologies Inc. Hydraulic system The condition of the hydraulic oil is the major factor in obtaining long life and trouble free service from the pump, motor, valves, cylinders, seals, etc. - Page 33 improper oil, or excessive engine/pump speed. In any case, the cause of the overheating should be identified and corrected immediately. The oil level in the hydraulic reservoir should be checked daily as described in the daily preoperational checks section. With the unit on level ground, booms in the boom rest, the oil level should be between the Add and the Full marks on the filler cap dipstick or applicable sight gauge.

-

Page 34: Structures And Mechanical Systems

When cleaning with high pressure washers or steam cleaning, care should be taken not to apply pressure directly to electrical connections, control panels or electrical components. At no time should this Posi-Plus aerial device the altered or modified without the specific written approval from Posi-Plus Technologies Inc. Oct-18-700...

Need help?

Do you have a question about the Line Runner 700-40 and is the answer not in the manual?

Questions and answers