Table of Contents

Advertisement

Quick Links

This appliance is for use with natural or propane gas. Read these

instructions thoroughly before commencing installation.

1.0 Introduction

1.1 Basic Information

1.2 Warranty

4.1 Uncrating and Preparation

4.4 Gas Connection

WARNING: Improper installation, adjust-

ment, alteration, service or maintenance can

cause injury or property damage. All work

must be carried out by competent persons, i.e.

a registered CORGI installer.

PLEASE READ THESE INSTRUCTIONS

THOROUGHLY BEFORE COMMENCING

WORK.

HAZARD INTENSITY LEVELS

1. DANGER: Failure to comply will result in severe

personal injury or death and/or property damage.

2. WARNING: Failure to comply could result in

severe personal injury or death and/or property

damage.

3. CAUTION: Failure to comply could result in

minor personal injury and/or property damage.

WARNING: The electrical isolator should

only be used in an emergency and should not

be used for closing down the main burner, as

it switches off the fan prematurely and may

damage the heat exchanger, invalidating the

warranty.

0063

Table of Contents

4.6 Room Thermostat Siting

5.2 Fitting Outlet Duct

6.6 Adjustments - Main Burner and Pilot

7.1 Requirements and Procedure

Gas-Fired Duct Furnace

Installation Form GB/WA/030/1099

Installation, Commissioning, and Service

APPLIES TO:

8.4 Pilot Ignition System (Optional)

9.3 Model T with Spark Pilot

1.0 INTRODUCTION

1.1 Basic Information

The instructions in this manual apply to Model T Series warm air

heaters. Model T Series heaters are designed for use with the installer's

air supply system. Units are suitable for inserting into ductwork or

may be directly coupled to an air supply fan. UNITS SHOULD BE

USED FOR INDOOR INSTALLATIONS ONLY.

Models T Series heaters are 80% thermal efficient. A permanent

electricity supply of 230 volts, 50 Hz, single phase is required.

Model T heaters are approved for:

Type B

- Gravity Vent, Open Flue

11

Category II

- use with G20 natural gas or G31 propane gas

2H3P

Each unit is fitted with a permanent pilot. A thermoelectric flame

supervision device monitors the pilot flame to prevent an explosive

condition occurring.

1.2 Warranty

Warranty is void if ...

a. Heater is installed in atmospheres containing flammable

vapours or atmospheres containing chlorinated or haloge-

nated hydrocarbons or atmospheres containing any silicone,

aluminum oxide, etc. that adheres to spark ignition flame

sensing probes.

b. The installation is not in accordance with these instructions.

Form GB/WA/030, Mfg No. 177853, Page 1

AMBI-RAD

Model T

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Ambi-Rad T Series

-

Page 1: Table Of Contents

1.1 Basic Information cause injury or property damage. All work The instructions in this manual apply to Model T Series warm air must be carried out by competent persons, i.e. heaters. Model T Series heaters are designed for use with the installer's air supply system. -

Page 2: Technical Data

2.0 TECHNICAL DATA 2.1 Specifications 2.1.1 TABLE 1 - Model T SPECIFICATIONS Maximum Gas Rate Maximum Gas ! for G20 Rate # for G31 Heat Input Heat Output Size Natural Gas Propane Gas BT UH BT UH 22.0 75,000 17.3 60,000 2.05 0.83... -

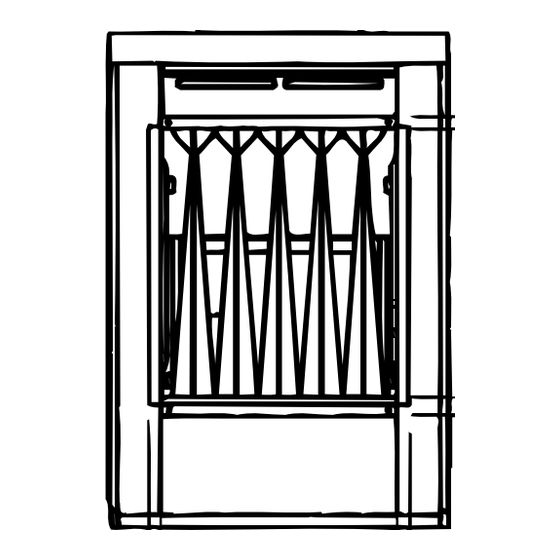

Page 3: Dimensions

2.3 DIMENSIONS Figure 2 TABLE 4 M odel 1048 1048 1187 1016 1054 1048 1327 1156 1194 1187 1327 1156 1194 1187 Form GB/WA/030, Mfg No. 177853, Page 3... -

Page 4: General Requirements

3.0 GENERAL REQUIREMENTS 3.1 Related Documents The unit heater is fitted with an integral draught diverter. It is important that all gas appliances are installed by competent persons, i.e. a Do not use an external draught diverter, barometric registered CORGI installer, in accordance with the relevant requirements of the damper and/or restrictive damper. -

Page 5: Electrical Supply

Do not suspend from the the heater has incurred any damage in shipment, file a claim with heater side or top panel. AMBI-RAD within 48 hours. Check the data plate for the gas specifications and electrical charac- Figure 2 - Suspension... -

Page 6: Electrical Connections

4.0 INSTALLATION (cont'd) 4.3 Fitting the Flue System (cont'd) 4.5 Electrical Connections Any joints should be secured using three pop rivets or All electrical connections should be made in the heater terminal box. Screw- sheradized sheet metal screws at each joint. The joints type terminals are provided. -

Page 7: Air Distribution Systems

5.0 AIR DISTRIBUTION SYSTEM 5.1 Blower Connection Proper arrangement of blower and furnace with respect to angle of approach of the duct connection and the arrangement of the discharge opening of the blower are shown. Blowers should be bottom horizontal discharge when coupled to the furnace. When a top horizontal blower is connected to the furnace, be sure that sufficient length of duct is provided to permit even flow of air at the end of the duct. -

Page 8: Commissioning And Testing

6.0 COMMISSIONING AND TESTING The commissioning and testing should only be carried out by a competent person. This section should be read completely and fully under- stood. A commissioning service is available from AMBI-RAD. 6.1 Electrical Check $ $ $ $ $ Locate the multifunctional control valve and identify the control knob. -

Page 9: Air Distribution System

Figure 5 - Multifunctional Control Valves Control Knob - Pressure depress while Regulator (NOTE: When measuring gas pressure, do not lighting pilot Cover Screw remove screw. Loosen enough to allow gas pressure to register. ) Multifunctional Control Valve on a Heater with a Standard Permanent Pilot Inlet Pressure Pilot Regulating... -

Page 10: Handing Over

Advise the user/purchaser that for safe and efficient operation, the heater must be serviced at least annually. A complete after sales service is available from AMBI-RAD. 7.0 SERVICING INSTRUCTIONS 2. -

Page 11: Pilot Burner Injector

A complete spares service is available from AMBI-RAD. 8.2 Pilot Burner Injector 1. If connected, disconnect the pilot tubing from the pilot burner. 2. Fit a new pilot burner injector. -

Page 12: Multifunctional Control Valve

8.0 REMOVAL AND REPLACEMENT OF PARTS (cont'd) 8.6 Multifunctional Control Valve Figure 16 - Non-Control Side of the Heater with Cabinet Panel Removed showing the Limit Control 1. Ensure the electrical supply is isolated. Capillary Tubing 2. Remove the pilot supply tube and the spark tension lead. 3. -

Page 13: Circuit Diagrams

9.0 CIRCUIT DIAGRAMS 9.1 Site Wiring 9.1.1 Site Wiring for Heater SITE CONNECTION DIAGRAM with Standard CUSTOMER SUPPLIED WIRING Permanent Pilot and Single Stage Control 230 VOLT THERMOSTAT CUSTOMER BLOWER MOTOR 230 VOLT CONTACTOR 50 HERTZ SUPPLY OPTIONAL FAN SWITCH 9.1.2 Site Wiring for Heater SITE CONNECTION DIAGRAM with Optional Spark... -

Page 14: Model T With Permanent Pilot

9.0 CIRCUIT DIAGRAMS (cont'd) 9.2 Heater Circuit Diagram 9.2.1 Model T with Permanent Pilot and Single-Stage Gas Valve T 75 - 400 175346 CUSTOMER'S BLOWER MOTOR CONTACTOR 230V FROM TIME SIGNAL THERMOSTAT EARTH SUMMER FAN 230V ROOM THERMOSTAT 230V 50Hz SUPPLY Form GB/WA/030, Page 14... - Page 15 9.2.2 Model T with Optional Spark Ignition and Single-Stage Gas Valve T 75 - 400 CUSTOMER'S BLOWER MOTOR CONTACTOR 175347 230V FROM TIME SIGNAL W/PR REMOTE RESET THERMOSTAT EARTH SUMMER FAN 230V ROOM THERMOSTAT 230V 50Hz SUPPLY Form GB/WA/030, Mfg No. 177853, Page 15...

- Page 16 9.0 CIRCUIT DIAGRAMS (cont'd) 9.2 Heater Circuit Diagram 9.2.3 Model T with Optional Spark Ignition and Optional Two-Stage Gas Valve CUSTOMER'S T 75 - 400 BLOWER MOTOR CONTACTOR 175348 230V FROM TIME SIGNAL REMOTE RESET W/PR THERMOSTAT EARTH SUMMER FAN 230V ROOM THERMOSTAT 230V 50Hz...

-

Page 17: Fault Finding Charts

10.0 FAULT FINDING CHARTS 10.1 Main Fault Finding Chart WARNING: All fault finding Applies to Model T with a should only be carried out by a Standard Permanent Pilot competent service engineer. Is the temperature controller "ON" and if used, is the time clock "ON"? Set temperature controller up to operate... - Page 18 10.2 .1 Permanent Pilot Does not Remain Alight Is the gas Correct the supply pressure 20 gas supply mbar? pressure. Adjust pilot flame. Refer to Refer to Figure 8. 6.6.2 and/or check pilot Does the pilot flame injector for dirt. Clean with adequately impinge on the solvent and compressed thermocouple?

- Page 19 10.0 FAULT FINDING CHARTS (cont'd) Is polarity of mains correct? 10.2.2 Heater with Optional Spark Ignition -- Does the Ignition inlet gas pressure Correct agree with the data polarity. Controller badge? Repeatedly Locks Out Correct the gas Wait 15 seconds supply and press reset pressure.

- Page 20 10.3 Limit Control Fault Finding Chart (Limit Control Trips) NOTE: Interruption of the main electrical sup- ply to the air supply fan when the heater is in Fault finding chart assumes that the furnace operation may cause the limit control to trip. Check that the supply is not being interrupted has been in service and operating correctly.

-

Page 21: Exploded Diagrams

11.0 EXPLODED DIAGRAMS 11.1 Standard Heater Cabinet Parts Item Description Bottom Pan Aluminized 15244 15244 15248 14618 14618 14624 14624 14625 14625 15249 14632 14632 Stainless Steel 15978 26167 15979 15979 15980 15980 15981 15981 26168 15982 15982 Rear Corner Leg w/Wire Access 11004 11004... - Page 22 11.0 EXPLODED DIAGRAMS (cont'd) 11.2 Drafthood/Inner Cabinet Parts Item Description Draft Hood Left Side 1 85808 85808 85808 85808 85808 85808 85808 85808 85808 85808 85808 85808 1 85807 85807 85807 85807 85807 85807 85807 85807 85807 85807 85807 85807 Draft Hood Right Side 1 85778 85778 85782 85786 85786 85790 85790 85793 85793 85796 85799 85799 Draft Hood Rear Baffle...

-

Page 23: Short List Of Parts

Item Description Heat Aluminized 1 145496 145496 145497 145498 145498 145499 145499 145500 145500 145501 145502 145502 Exchanger 321 Stainless 1 145513 145513 145514 145515 145515 145516 145516 145517 145517 145518 145519 145519 Assembly 409 Stainless 1 145506 145506 145507 145508 145508 145509 145509 145510 145510 145511 145512 145512 Limit Control w/Capillary Tube 1 134808 134808 134808 134808 134808 134808 134808 141749 141749 141749 141749 141749 Limit Control Bracket... - Page 24 Sales & Service by: AMBI-RAD AMBI-RAD AMBI-RAD AMBI-RAD AMBI-RAD ® Energy Efficient Heating Systems Ambi-Rad Limited, Fens Pool Avenue, Wallows Industrial Estate, Brierley Hill, West Midlands DY5 1QA Telephone: 01384 489 700 Fax: 01384 489 707 Form GB/WA/030, Page 24 ©...

Need help?

Do you have a question about the T Series and is the answer not in the manual?

Questions and answers