Subscribe to Our Youtube Channel

Summary of Contents for Evenheat Rampmaster RM3

- Page 1 Rampmaster Operating Manual Heat Treat ver. RM3 – Feb 2017 Rampmaster ® Control Operating Manual Page 1 of 25 Use your Smart-phone to scan this QR code to watch Rampmaster how-to Programming Videos!

-

Page 2: Table Of Contents

Heat Treat ver. RM3 – Feb 2017 Thank you for purchasing a Rampmaster equipped heat treating oven from Evenheat. The Rampmaster is preferred by many for heat treating as it allows up to 12 custom user programs, numerical keypad and alarm features not found on our Set-Pro control. To dive right into programming see our Quick Start Programming on page 2. -

Page 3: Quick Custom Mode Programming

Rampmaster Operating Manual Heat Treat ver. RM3 – Feb 2017 Use this Quick Guide to Immediately Begin Programming Your Heat Treating Program This Quick Start Guide to programming is a fairly straight forward, key-by-key approach to programming your heat treat program. It doesn’t go into much detail beyond what keys to press for most heat treating programs. -

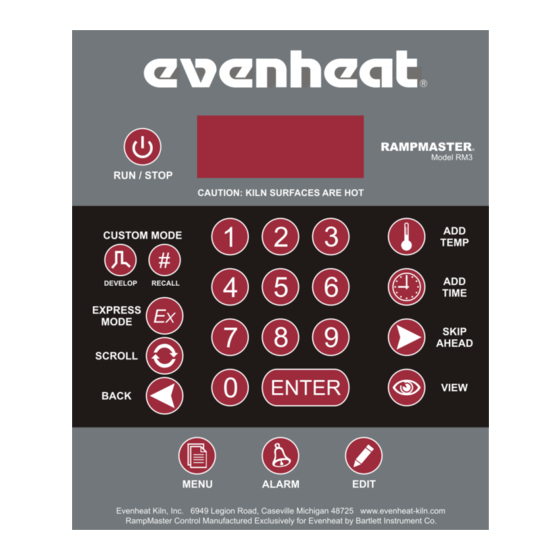

Page 4: Rampmaster Key Layout

Rampmaster Operating Manual Heat Treat ver. RM3 – Feb 2017 Rampmaster Key Layout The Rampmaster key layout and key functions are designed to provide easy and uncomplicated use. All programming functions are located to the left side while all “On-the-Fly” features are located to the right. It’s a very intuitive design that works well in the heat of battle. We’ve also minimized keystrokes by using dedicated, single function keys where we can. -

Page 5: Rampmaster Key Descriptions

Rampmaster Operating Manual Heat Treat ver. RM3 – Feb 2017 Rampmaster Key Descriptions RUN/STOP The Run/Stop key starts and stops the heat treating process. If a running program is stopped and then restarted, the Rampmaster picks up at the first segment containing the current chamber temperature. -

Page 6: Detailed Custom Mode Programming

Rampmaster Operating Manual Heat Treat ver. RM3 – Feb 2017 Custom Mode Programming The Custom Mode is a method of programming that allows you to precisely define every aspect of the heat treating process. You’re creating a custom program designed for the work at hand. During programming you will be asked to enter in data for rate of temperature increase (or decrease), the set point temperature you would like to reach and hold time at the set point temperature. - Page 7 Rampmaster Operating Manual Heat Treat ver. RM3 – Feb 2017 Custom Mode Programming Continued from Previous Page To run the program, press the Run/Stop key one time. Four horizontal dashes will appear. Press the Enter key. - ON- will appear briefly and then chamber temperature. The Rampmaster is now running your Custom Mode program. When the heat treat process is complete the display alternates between CPLT, current chamber temperature and total process time.

-

Page 8: Programming & Use Features

To Quiet the Beginning of Process Hold Alarm - Simply press the number 1 key to silence the alarm. Evenheat offers an optional loud alarm devise that simply attaches to your oven control panel to provide a loud, 80+ decibel alarm. This optional alarm is great for cutting through shop noise so you’ll never miss the opportunity to quench at the right time. -

Page 9: Recalling A Custom Mode Program

Rampmaster Operating Manual Heat Treat ver. RM3 – Feb 2017 Programming & Use Features Continued from Previous Page Recalling a Custom Mode Program You may choose to run a previously stored Custom Mode program. With the display reading STbY simply press the RECALL key one time. The display will read PROG and some number. -

Page 10: Delay Start Feature

The maximum temperature that can be programmed in the Rampmaster is 2200°F ( 1204°C). This maximum is factory set to limit oven operation. This maximum can be set higher for other applications. Please consult Evenheat if you wish to adjust this setting. -

Page 11: On-The-Fly Features

Rampmaster Operating Manual Heat Treat ver. RM3 – Feb 2017 On-The-Fly Features The Rampmaster contains a set of features that allow you to adjust the process while it’s actually running! We’ve dubbed these as “On-the-Fly”. With these features it’s possible to add a little bit of time to a hold if needed, add a little bit of temp to a hold or just leave the segment entirely and move to the next segment in the program. -

Page 12: Suspend

Rampmaster Operating Manual Heat Treat ver. RM3 – Feb 2017 On-the-Fly Features Continued from Previous Page Suspend The Suspend feature works much like the Add Time feature, but with a twist: you may suspend the program (cause the temperature to hold) during a ramping portion of the process. -

Page 13: Rampmaster Display Conditions

Rampmaster Operating Manual Heat Treat ver. RM3 – Feb 2017 Rampmaster Display Conditions The LED display of the Rampmaster displays different data depending upon what’s happening. Listed below are the possible display conditions. Display Alternating Between STbY (Standby) and Temperature — Program is not running: oven chamber temperature is displayed. Display Reading Temperature - Program is running and is ramping to temperature: oven chamber temperature is displayed. -

Page 14: Rampmaster Key Function Tables

Rampmaster Operating Manual Heat Treat ver. RM3 – Feb 2017 Key Function Tables RUN/STOP While at the Standby Position (STbY) While Running a Program At Any Other Position Pressing once begins to run Pressing once completely stops currently running Returns the Rampmaster to Standby the currently loaded program program and returns the Rampmaster to Standby DEVELOP... -

Page 15: Use Your Smart-Phone To Scan This Qr Code To Watch Rampmaster How-To Programming Videos

Rampmaster Operating Manual Heat Treat ver. RM3 – Feb 2017 BACK While at the Standby Position (STbY) While Running a Program At Any Other Position When programming using Custom Mode and No Function No Function when viewing Menu options, pressing BACK will display the previous selection. -

Page 16: Use Your Smart-Phone To Scan This Qr Code To Watch Rampmaster How-To Programming Videos

Menu’s includes Options, System, Pressing once allows for adjustment of a feature No Function Diagnostic and Factory. not available on Evenheat heat treat ovens Numerical Keys While at the Standby Position (STbY) While Running a Program At Any Other Position... -

Page 17: Menu-Configuration Tools

Start — The Rampmaster allows you to start the heat treating process at a later time. You may delay the start for up 99 hours and 99 minutes. For no Delay Start use 0.00. Please note that Evenheat recommends that the oven be monitored during the entire heat treating process, this includes the delay start time as well. -

Page 18: System Menu

Rampmaster Operating Manual Heat Treat ver. RM3 – Feb 2017 SYST—System System tools involve preferences. Listed below are your options for the System Menu. Use the SCROLL key to display the System menu choices. Once you get to the menu item you would like to modify press the ENTER key, key in the change and press the ENTER key. -

Page 19: Diagnostic Menu

The Diagnostic tools contain a group of power service and oven performance information. This information can be helpful in determining possible causes of performance problems. While this information gives the informed user plenty of data to work from you’ll want to contact Evenheat technicians for evaluation and technical advice. -

Page 20: Factory Menu

Therefore, these settings are not available without consultation with Evenheat technicians. TCOS — Thermocouple Offset — In the unlikely event that a thermocouple is reading temperature incorrectly it’s possible to offset the displayed temperature to match the actual chamber temperature. -

Page 21: Error Display Messages

During an ascending ramp, chamber temperature is falling. Condition must persist for 22-1/2 minutes before the error is triggered. Probable causes are Control Relay Failure, Element Failure or Sudden Drop in Supply Voltage. E– 9 Improper thermocouple installed or improper thermocouple software setting. Standard thermocouples for all Evenheat models is TYPE K. E– A Invalid program variable. -

Page 22: Trouble Shooting

Oven Trouble Shooting Listed below are some of the more probable oven problems you’ll encounter along with their most common cause and repair advice. Please feel free to contact Evenheat for assistance when dealing with these and other potential problems. No Display Check to see that the oven is actually plugged in. -

Page 23: Heat Treat Data

Heat Treat Data The following heat treat data has been provided to Evenheat by various sources. We suggest you view this data as a starting and reference point on which to build your heat treating experience. What works for these guys may or may not necessarily work for you. -

Page 24: Use Your Smart-Phone To Scan This Qr Code To Watch Rampmaster How-To Programming Videos

154CM, CPM154, ATS34 All three of these, heat treat the same. After a full speed ramp up to temperature, they soak 45 minutes to an hour in the Evenheat Oven at 1950F degrees. Then they get placed – still in the foil – spine down – then flat - on a 1” aluminum plate. The second aluminum plate is placed on top and pressure is applied. -

Page 25: Use Your Smart-Phone To Scan This Qr Code To Watch Rampmaster How-To Programming Videos

Rampmaster Operating Manual Heat Treat ver. RM3 – Feb 2017 Questions and Answers provided by Rob Ridley of Ranger Original - continued Q5: I heard ATS34 etc can be tempered at a high or low range. Is this true? A5: Sort of – but the high range gives you reduced toughness and corrosion resistance. It should be avoided. Q6: Are there other ways to heat treat these steels? A6: Heck yes! Air quenching, Oil quenching, Salt baths, Vacuum furnaces….

Need help?

Do you have a question about the Rampmaster RM3 and is the answer not in the manual?

Questions and answers