Table of Contents

Advertisement

8SMC5-USB User Manual

1.

About

1.

General information

2.

Benefits

3.

Table of specifications

4.

Specifications

2.

Safety instructions

3.

Overview and getting started

1.

One axis configuration

2.

Example of a motor connection

3.

Manual profile setting

4.

Calculation of the nominal current

5.

Possible problems and solutions

4.

Technical specification

1.

Appearance and connectors

1.

Controller board

2.

One axis system

3.

Two axis system

2.

Kinematics and rotation modes

1.

Predefined speed rotation mode

2.

Rotation for predefined point

3.

Predefined displacement mode

4.

Acceleration mode

5.

Backlash compensation

6.

Rotation reversal

7.

Recommendations for accurate rotation

8.

PID-algorithm for DC engine control

9.

Stop motion modes

10.

PID-algorithm for BLDC engine control

3.

Main features

1.

Supported motor types

2.

Motor limiters

3.

Limit switches

4.

Automatic Home position calibration

5.

Operation with encoders

6.

Revolution sensor

7.

Steps loss detection

8.

Power control

9.

Critical parameters

10.

Saving the parameters in the controller flash memory

11.

User defined position units

4.

Safe operation

5.

Additional features

1.

Operating modes indication

2.

Operations with magnetic brake

3.

Joystick control

4.

Left-Right buttons control

5.

TTL synchronization

6.

Design of multi-axis system

7.

General purpose digital input-output

8.

General purpose analog input

9.

External driver control interface

10.

Serial port

11.

Saving the position in controller's FRAM memory

12.

The Standa stages detection

6.

Secondary features

1.

Zero position adjustment

2.

User-defined position adjustment

3.

Controller status

4.

USB connection autorecovery

5.

XILab application User's guide

1.

About XILab

2.

Main windows of the XILab application

1.

XILab Start window

2.

XILab Main window in single-axis control mode

3.

XILab Main window in multi-axis control mode

4.

Application Settings

5.

Charts

6.

Scripts

Page 1 / 345

The official technical support channel @SMC5TechSupport ( https://t.me/SMC5TechSupport).

Page 1 / 345

For quick simple questions you can contact us via Telegram.

Available online Mon-Fri 8:00-16:00 UTC.

Download user manual in pdf

Advertisement

Table of Contents

Summary of Contents for Standa 8SMC5-USB

- Page 1 Page 1 / 345 Download user manual in pdf For quick simple questions you can contact us via Telegram. The official technical support channel @SMC5TechSupport ( https://t.me/SMC5TechSupport). Available online Mon-Fri 8:00-16:00 UTC. 8SMC5-USB User Manual About General information Benefits Table of specifications...

- Page 2 Page 2 / 345 XiLab Log Controller Settings Settings of kinematics (Stepper motor) Motion range and limit switches Critical board ratings Power consumption settings Home position settings Synchronization settings Brake settings Position control Settings of external control devices UART settings General purpose input-output settings Motor type settings Settings of kinematics (DC motor)

- Page 3 Page 3 / 345 8MR174 - Motorized Rotation Stage 8MR190 - Motorized Rotation Stage 8MR191 - Motorized Rotation Stage 8MRB250 - Large Motorized Rotation Stage 8MRU - Universal Motorized Rotation Stages 8MPR16-1 - Motorized Polarizer Rotator 8MRH240 - Large High Capacity Rotary Stage Vertical Translation Stages 8MVT100 - Vertical Translation Stage 8MVT120 - Vertical Translation Stage...

- Page 4 Page 4 / 345 1. About General information Benefits Table of specifications Specifications Page 4 / 345...

- Page 5 The motor connector on the controller board is the same as one used by Standa company and it fits to all the Standa stages. USB connector provides easy communication and work with computer.

- Page 6 Motion is smoother and faster than ever with innovation encoder based close-loop on all 8SMC5-USB motor controllers. It combines advantages of BLDC motor control with cheapness of conventional stepper motors. No hidden catch, no stall or hitch, just free move!

- Page 7 Page 7 / 345 1.3. Table of specifications Power supply external 12V - 48V DC Current up to 5A (depending on the voltage) from external power supply consumption Current up to 3A motor winding Protection types current overload protection, voltage overload protection, short circuit protection, motor hotplug/unplug protection move left/right, move to point, shift on delta, continuous speed, acceleration and deceleration ramps, backlash Motion modes compensation mode, automatic home position calibration mode...

-

Page 8: Specifications

Additional features available via motor connector Processing the signals from one or two limit switches; software configurable. The Standa stages recognition and automatic downloading of the configuration file right from the stage if the last one supports this feature. The "step loss" detection and position recovery using either a revolution sensor or a quadrature encoder (if the stage supports this feature). -

Page 9: Programming The Controller

Page 9 / 345 Limit switches indication pins designed for LED direct connection. Specifications: TTL 3.3V, 2mA. Digital "Power" and "Status" pins duplicate the status LED and designed for direct connection of LEDs. Specifications: TTL 3.3V, 2mA. External driver control interface allowing to control any type of external driver using three signals: enable, direction, clock. Multiaxis systems development. -

Page 10: Safety Instructions

Top view of the controller board. A grounding terminal marked with the red square Typical connection diagram for a controller (board, systems in box): Motor Power Controller 220 V supply 8SMC5-USB Controller grounded via minus electrode of power cable connection diagram Motor Power Controller 220 V supply... -

Page 11: Controller Board

Page 11 / 345 Warning. Power supply unit should be able to supply sufficient current to rotate the motor. As an absolute minimum it should be able to supply where is the minimum working current of power supply unit, is the operating current in the winding, is power supply unit stabilized voltage, and is rated operating voltage of the motor. - Page 12 XILab software for Windows 7. One axis configuration - a brief description of the beginning of work with the controller + 8SMC5-USB for one axis +. It is also considered quick XiLab setup and lists all necessary equipment. Example of a motor connection - connection of stepper motor Nanotec ST5918L3008-B with encoder CUI INC AMT112S-V to 8SMC5-USB controller.

-

Page 13: System Requirements

All necessary software to work with the controller can be downloaded from software page. USB A - mini-B cable USB-A to mini-USB-B cable. For detailed information about the USB cable please read the data connector chapter. 8SMC5-USB controller Page 13 / 345... - Page 14 Page 14 / 345 The motor controller board. The controller appearance may differ from the one shown on the above figure depending on its configuration and version. For detailed information about versions please read the Appearance and connectors 8SMC5 chapter. Positioner or motor The stepper motor-based positioner.

- Page 15 Page 15 / 345 XILab main installation window. Press “Next>” button and follow the instructions on screen. All the necessary software including all drivers, packages and programs will be installed automatically. After installation is finished, the XiLab software starts by default and the following window will open: XILab "No devices found"...

- Page 16 Page 16 / 345 XILab main window. Open “Settings...”, then press “Restore from file...” and select the configuration file for your positioner from the opened C:\Program Files\XILab\profiles\ folder. The values applicable for your positioner will automatically fill all the fields of “Settings...” menu. If the necessary file isn't found, please refer to the Configuration files chapter.

-

Page 17: Functional Test

Page 17 / 345 XILab, the Settings menu window. Warning. For the controller to work with stepper motors it is required to properly set up: working current, displacement limits and limit switches critical parameters, limiters, power supply mode. If you decide to configure your controller by yourself, please check these parameters carefully! Congratulations, your controller is ready for operation! Functional test Check if the controller is configured properly by pressing left or right button in the central row of XILab main window control buttons. - Page 18 Page 18 / 345 Control from user applications Xilab software is a convenient way to control stages connected to 8SMC5-USB controller. However, if you need to control the 8SMC5- USB from your own application, you may do so by using libximc library.

- Page 19 Preparation To get started, we need: Motor; Encoder; Pinout of D-SUB connector for 8SMC5-USB; Motor datasheet Encoder datasheet Soldering equipment: soldering-iron, wires, flux, solder, nippers, heat shrink tubes of different sizes; Screws M2.5x6 for fixing the encoder; D-SUB cover + connector (male) and wires for cable manufacturing;...

- Page 20 Page 20 / 345 Connecting the motor and encoder to the controller Before you begin, assemble the encoder in accordance with the appropriate instructions. The motor without encoder. Note 2 holes M2.5 to which is usually attached an encoder Motor with attached encoder Let us look in the specification of the engine and find the wiring diagram (for Nanotec ST5918L3008-B it is at the bottom right in the specification): Motor contacts...

- Page 21 Page 21 / 345 To connect encoder, open its datasheet and find 5 contacts on encoder connector: A+ (channel A), B+ (channel B, shifted relative to A by 90 degrees), Z+ (rev counter), 5V, GND. They should be taken from the encoder as 5 separate wires and put together with the wires from the motor as they then go to a connector.

- Page 22 Page 22 / 345 Now you can connect it to 8SMC5-USB. Description and profile settings are given in the next chapter Manual profile setting Page 22 / 345...

- Page 23 Page 23 / 345 3.3. Manual profile setting Introduction 3.3. Manual profile setting All necessary parameters are set after motor connection (see Example of a Introduction motor connection where the Nanotec ST5918L3008-B motor connection is Getting started described). There we will consider the setting of the profile for Nanotec Nominal current setting ST5918L3008-B stepper motor.

- Page 24 Page 24 / 345 calculate the number of steps per revolution, knowing that one revolution consists of 360 degrees. Make sure that movement to the right from the main window of XiLab corresponds to the movement to the right of the stage. If not, then check the box Reverse field Stepper motor ->...

- Page 25 Page 25 / 345 If it is possible to get limit switches activate them and note the correspondence between indicators in XiLab and each particular switch. Then start the system at the low speed (<100 ш/с) when it is far away from limit switches and make sure that the system moves to the right switch.

- Page 26 Page 26 / 345 It is possible to activate the position control by encoder. To do this, in the tab Position control mark Position control and specify allowable error in terms of encoder counts in the Threshold field. Then, when a mismatch between position and encoder counts occurs, indicator SLIP will light in the bottom of XiLab main window.

- Page 27 Page 27 / 345 3.4. Calculation of the nominal current In order to stepper engine gave maximum torque, but it does not overheat, it is important to specify such technical characteristic as the rated current. The greater a current in the motor winding, the greater the torque at the axis. It is important to remember that with an increase a current flowing through the winding, thermal power released by the motor increases.

- Page 28 Motor controllers in this case will provide the maximum torque without overheating the engine. For all Standa motorized positioners prepared configuration files that contain the specified nominal current as rms. The corresponding flag is set. Thus the engines operate at optimum settings.

-

Page 29: Possible Problems And Solutions

Ask a question Send an e-mail: 8smc4@standa.lt Controller is not found in XiLab Solution: Comment to the diagram: 8SMC5-USB-B9-1 - one axis system 8SMC5-USB-B9-2 - two axes system The following decision maps show the actions for different operating systems. Windows:... - Page 30 Page 30 / 345 Linux: Page 30 / 345...

- Page 31 Page 31 / 345 Comment to "Can't open device" problem solution: When working with USB-... converter in Linux it appears as /dev/ttyUSB device. XiLab shows it in a list, but when you try to open it, an error "can't open device" occurs due to the lack of permissions to the device. To solve this problem, create a file: /etc/udev/rules.d/31-ximc.rules and add the next line into it: SUBSYSTEM=="usb", ATTR{idVendor}=="067b", MODE="0666"...

- Page 32 Page 32 / 345 Unable to rotate the motor by the controller Controller has Alarm state Click Stop in the main window of XiLab. Controller must return to its normal state. If this approach was not helpful and Alarm state emerged again, do the following: Being in XiLab go to the Maximum ratings tab.

- Page 33 Page 33 / 345 proper motor current in the winding varies according to a sine or cosine. In the broken motor much stronger differences of the current from harmonic form can be noticed. Working case In the charts below you can see the problems. For example, winding B is open circuit. Probably it is broken. Also, voltage and current forms are distorted.

- Page 34 Design of multi-axis system General purpose digital input-output General purpose analog input External driver control interface Serial port Saving the position in controller's FRAM memory The Standa stages detection Secondary features Zero position adjustment User-defined position adjustment Controller status USB connection autorecovery...

-

Page 35: Appearance And Connectors

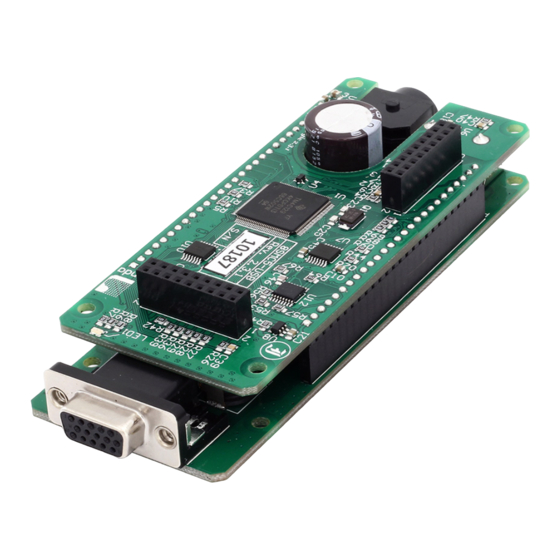

Page 35 / 345 4.1. Appearance and connectors 8SMC5-USB controllers are available in 3 different versions: Controller board One axis system Two axes system Page 35 / 345... - Page 36 Page 36 / 345 4.1.1. Controller board 8SMC5 Dimensions and arrangement Structurally the controlled is designed as two boards, 46x126,75mm each, rigidly connected to each other. A logic controller and control systems are mounted at the bottom board, a power part is at the top board. A radiator at the power part is available. Top view on the controller.

- Page 37 4 - Phase A of SM or + DC of the motor or phase A on BLDC motor 5 - 500mA - for 8SMC5, stabilized output for encoder power supply 6 - One-wire interface for positioner identification (for Standa hardware only) 7 - Logic ground for limit switches, encoder, etc.

-

Page 38: Backplane Connector

Page 38 / 345 IMPORTANT. Never supply the power to the controller and do not plug it to power connector if you are not confident that your power supply parameters conform to the requirements. Never attempt to plug the power supply to the controller if you are not sure power supply unit and controller connectors are compatible! The acceptable connection parameters are described in Safety... - Page 39 Page 39 / 345 Pin function of CN1: 1 - Power GND 12-48В. 2 - Joy, an analog 0-3 V input used for external joystick connection. 3 - Power GND 12-48В. 4 - Pot, an analog 0-3 V input used for general purpose.

- Page 40 4 - Phase A of SM or + DC of the motor or phase A on BLDC motor 5 - 500mA - for 8SMC5, stabilized output for encoder power supply 6 - One-wire interface for positioner identification (for Standa hardware only) 7 - Logic ground for limit switches, encoder, etc.

- Page 41 Page 41 / 345 One- and two-axis controller models in metal cases use Kycon 4-pin DC power connector (part number KPPX-4P, anacapa.kycon.com). Pinout: 1 - Power, "-". 2 - Power, "+". 12-48V. 3 - Power, "-". 4 - Power, "+". 12-48V. IMPORTANT.

- Page 42 Page 42 / 345 One-axis controller model contains a HDB-26 female DSub connector. Pinout of the supplementary HDB-26 connector, front view. Pinout: 1 - NC, not used. 2 - NC, not used. 3 - NC, not used. 4 - GND, ground. 5 - NC, not used.

- Page 43 4 - Phase A of SM or + DC of the motor or phase A on BLDC motor 5 - 500mA - for 8SMC5, stabilized output for encoder power supply 6 - One-wire interface for positioner identification (for Standa hardware only) 7 - Logic ground for limit switches, encoder, etc.

- Page 44 Page 44 / 345 One- and two-axis controller models in metal cases use Kycon 4-pin DC power connector (part number KPPX-4P, anacapa.kycon.com). Pinout: 1 - Power, "-". 2 - Power, "+". 12-48V. 3 - Power, "-". 4 - Power, "+". 12-48V. IMPORTANT.

- Page 45 Page 45 / 345 A single-axis or two-axis controller model may contain a 9pin DSub male joystick connector. Pinout of the joystick connector, front view. Pinout: 1 - BUT_R_1, right button input, axis 1. 2 - Joy_2, analog 0-3V joystick input, axis 2.

- Page 46 Page 46 / 345 Pinout: 1 - RX_2, serial port input, axis 2. 2 - Synchronization input, axis 2. 3 - TX_2, serial port output, axis 2. 4 - GND, ground. 5 - Synchronization output, axis 2. 6 - Synchronization input, axis 1. 7 - Synchronization output, axis 1.

- Page 47 Page 47 / 345 4.2. Kinematics and rotation modes Predefined speed rotation mode Rotation for predefined point Predefined displacement mode Acceleration mode Backlash compensation Rotation reversal Recommendations for accurate rotation PID-algorithm for DC engine control Stop motion modes PID-algorithm for BLDC engine control Page 47 / 345...

- Page 48 Page 48 / 345 4.2.1. Predefined speed rotation mode Predefined speed rotation mode is the main operating mode of the controller for all the motor types. It allows to maintain the predefined rotation speed at a distance from the destination point and is usually used simultaneously with Rotation for predefined point Predefined displacement modes.

- Page 49 Page 49 / 345 4.2.2. Rotation for predefined point The rotation to predefined point mode is the main operating mode for all the types of motors and is usually used simultaneously with predefined speed rotation mode. It provides moving the stage to the defined position with absolute value for destination point coordinates which is different from predefined displacement mode.

- Page 50 Page 50 / 345 4.2.3. Predefined displacement mode The predefined displacement mode provides displacement of the stage for predefined value relative to zero position (if this is a first command since the controller started) or relative to position reached by the motor after the previous commands are completed, i.e., the destination point coordinate is a relative value.

-

Page 51: Acceleration Mode

Page 51 / 345 4.2.4. Acceleration mode The acceleration function is active by default. The acceleration is used for smooth start or finish of the rotation without shocks that are inevitable when the predefined speed is reached instantly. Moreover, inertia of rotor and the other components of stage usually doesn't allow instant gathering of high speed which results in the loss of steps as well as failure in rotation during the operation without feedback. -

Page 52: Backlash Compensation

Page 52 / 345 4.2.5. Backlash compensation Backlash occurs in any mechanical device, e.g., in reduction gear or in worm-gear. Backlash results in differences in physical stage position when approaching the same point from different directions, whereas the motor shaft is exactly in the required position. Backlash compensation mode is used in order to eliminate such ambiquity. - Page 53 Page 53 / 345 4.2.6. Rotation reversal It is a common agreement that the coordinate increase corresponds to movement to the right, whereas its decrease corresponds to movement to the left. The rotation is to be reversed either if this rule is not satisfied due to physical stage location, or if the stage is supplied with an anchor which is pointed so that it doesn't match coordinate increase.

- Page 54 Page 54 / 345 4.2.7. Recommendations for accurate rotation The controller can automatically adjust itself for the required mode, in order to maintain either the speed or the coordinate. However, both the speed and the adjustment property depend on the controller settings. The stepper motor working in steps and microsteps positioning mode can instantly reach the required operating conditions.

- Page 55 Page 55 / 345 4.2.8. PID-algorithm for DC engine control Algorithm description DC engine is controlled by the PID regulator, with the coordinate as the controlled parameter. The controlled coordinate changes according to motion settings and incoming commands to provide motion capability. We will call controller coordinate the running position.

- Page 56 Page 56 / 345 Time until final stop in target position (lower is better). No slip on approach to the target position. No oscillations around target position before stopping. No spontaneous shifts from the target position after stopping. Low noise when moving. Noise level is increased when only one of the PID coefficients is increased. One can choose individual criterion priority depending on the task at hand when tuning PID regulator.

-

Page 57: Emergency Stop

Page 57 / 345 4.2.9. Stop motion modes There are two stop motion modes in the controller: emergency stop; stop with deceleration. Emergency stop Emergency stop is initiated by the command STOP. The controller tries to instantly stop the rotation of the motor shaft. This can lead to missed steps in a stepper motor, if no feedback is used. - Page 58 Page 58 / 345 4.2.10. PID-algorithm for BLDC engine control Algorithm description BLDC engine is controlled by the PID regulator, with the coordinate as the controlled parameter. The controlled coordinate changes according to motion settings and incoming commands to provide motion capability. We will call controller coordinate the running position.

- Page 59 Page 59 / 345 2. Set the coefficients calculated by formulas, click Apply. Click the Zero button on the main XiLab window. Set 0 to the Move to field, send the command. The engine should stop. Try to move the position manually, make sure that the response is correct - the engine tries to return to zero position (the encoder reverse is set correctly).

-

Page 60: Main Features

Page 60 / 345 4.3. Main features Supported motor types Motor limiters Limit switches Automatic Home position calibration Operation with encoders Revolution sensor Steps loss detection Power control Critical parameters Saving the parameters in the controller flash memory User defined position units 8SMC5 Page 60 / 345... -

Page 61: Supported Motor Types

Page 61 / 345 4.3.1. Supported motor types Currently the controller supports stepper and DC motor types. The parameters of supported motors are described in Specifications chapter. Stepper motors Rated current is the main parameter of the stepper motor. The rated current is adjustable at the Settings of kinematics (Stepper motor) section. - Page 62 Page 62 / 345 IMPORTANT. Wrong PID regulator settings might lead to stage failure. All supplied profiles are preset with correct PID settings. It is not recommended to alter these settings unless absolutely necessary. BLDC motors Firmwares 4.1.x and older support BLDC motors controlling. Like DC motors, controlling BLDC motors reqiures feedback. Main BLDC motor parameters are maximum current and number of poles, which can be set on Settings of kinematics (BLDC motor).

- Page 63 Page 63 / 345 Motor RT/L 0.19576 0.07253 0.07168 4118L1804R 0.02715 4118S1404R 0.02844 4247 0.0273 D42.3 0.0223 5618 0.0146 5618R 0.0146 5918 0.0116 5918B 0.012 VSS42 0.029 VSS43 0.0256 0.04248 DCERE25 0.2106 The motor's overheat is determined by this sequence: calculation.

- Page 64 Page 64 / 345 4.3.2. Motor limiters Motor winding current and voltage limiters and motor shaft revolution speed limiters are provided to ensure safe operation. These limiters, if activated, will lead to gradual power and rotation speed decrease until the parameters being limited are within acceptable range.

-

Page 65: Limit Switches

Page 65 / 345 4.3.3. Limit switches Limit switches designation Limit switches are designed in order either to prevent the stage movement out of permissible physical movement range or to limit its movement range according to user-defined requirements. Incorrect setting of the limit switches may result to stage jam if the controller goes beyond the permissible range. - Page 66 Page 66 / 345 The settings of which limit is left or right is required by the controller. Sometimes it is unknown a priori, just it is clear that both limit switches are connected and fire if the corresponding limit of the motion range is reached. The stage jam is possible if the limit switches are configured improperly.

- Page 67 Page 67 / 345 4.3.4. Automatic Home position calibration This feature is used for detection and placing the movement to the starting position. This option of the controller is designed for simple search of "Home", or "Zero" position by user himself, with no need of any programming skills. The Home position is set relative to one or two external sensors and/or to an external signal.

- Page 68 Page 68 / 345 How to use the script: place the movement to the desired position launch the script and wait until it's finished. As a result, the movement will be in the same position and all the following calls of homing function will move it there. Make sure to save the settings to controller's nonvolatile memory.

- Page 69 Page 69 / 345 4.3.5. Operation with encoders Application of encoders Encoders are designed for creation of accurate and fast feedback according to the coordinate for all the electric motor types.The feedback is performed by the motor shaft position, by stage's linear position, by the motorized table rotation angle or by any other parameter related to the shaft position and measured by using the two-channel quadrature encoder complying the requirements described in Specifications SMC5...

-

Page 70: Encoder Connection

Page 70 / 345 Encoder connection The encoder is connected to the controller via D-SUB 15 pin connector, which is in all systems ( controller board, one-axis two-axis in box The diagram of single-ended encoder connection using D-SUB 15 pin connector. The diagram of differential encoder connection using D-SUB 15 pin connector. -

Page 71: Revolution Sensor

The revolution sensor should be connected to the controller via 15pin D-SUB connector, which is in all systems ( controller board, one- axis two-axis in box). Scheme of revolution sensor connection to the 8SMC5-USB based system Page 71 / 345... - Page 72 Page 72 / 345 4.3.7. Steps loss detection This mode is generally used while operating the stepper motor at full speed or limit loads when the shaft jam resulting to the steps loss is possible. In this case an additional position sensor (revolution sensor) or encoder...

- Page 73 Page 73 / 345 Note. The position control of the revolution sensor can't detect the shaft rotation at the zero speed, i.e., if the motor is shut down and the shaft is rotated manually, it won't be detected. Page 73 / 345...

-

Page 74: Power Control

Page 74 / 345 4.3.8. Power control Current consumption reduction Controller has an option to set current when idle to reduce power consumption. This mode is active by default. It is widely used to lower stepper motor heating in hold mode while keeping position maintenance accuracy. Hold current is set as a percentage of nominal winding current. - Page 75 Page 75 / 345 4.3.9. Critical parameters Minimum and maximum values of currents, voltages and temperatures are used for safe controller operation. Any value out of acceptable range leads to the motion stop, windings power-down and Alarm state for the controller. Exiting the Alarm state is possble only after the critical parameter returns to normal and the STOP command is sent to the controller.

- Page 76 Page 76 / 345 4.3.10. Saving the parameters in the controller flash memory The controller provides an option to save all its parameters into the non-volatile memory. The configuration is restored when the controller is powered on, after that the controller itself is instantly ready for operation. The stage requires no new adjustment every time the power is on.

- Page 77 Page 77 / 345 4.3.11. User defined position units Controller position is set and read in stepper motor steps or encoder counts, if encoder is available and enabled. Is it convenient to set position in mm (in case of translation stages), in degrees (in case of rotator stages) or in any other natural units. Controller software can translate coordinates to user-defined units: user can set a ratio, where a certain amount of controller steps is equal to the certain amount of user-defined units.

-

Page 78: Safe Operation

Page 78 / 345 4.4. Safe operation Several controller settings are directly connected with safe operation. If these settings are set wrong it may lead to controller or stage damage. Positioning element can be damaged by exceeded power, rotation speed, or by moving outside the allowed movement range. Usually it is enough to load a preset profile for your stage for safe operation, where all necessary settings are already made. -

Page 79: Additional Features

Joystick control Left-Right buttons control TTL synchronization Design of multi-axis system General purpose digital input-output General purpose analog input External driver control interface Serial port Saving the position in controller's FRAM memory The Standa stages detection Page 79 / 345... - Page 80 Page 80 / 345 4.5.1. Operating modes indication Controller status Mode indication is provided in controller. For this purpose one dual-color LED is located on the board. Green Power indicator shows presence of 3.3 V power supply of controller. Red Status indicator represents controller operating mode. Simultaneous glowing of both lights looks like yellow glow.

- Page 81 Page 81 / 345 Connection of the limit indicators to the controller board One-axis and two-axis systems LEDs on the front panel of controllers in the box ( one-axis two-axis systems) are indicators for power, status and limit switches, therefore a connection diagram is not required. Page 81 / 345...

-

Page 82: Description Of Operation

In order to use magnetic brake check if your controller system is equipped with a special converter board. Models which meets this demands can be identified by letters BR in its title, for example 8SMC5-USB-B8-1BR Contact pin responsible for magnetic brake control in boxed versions of controller is located on the HDM26 26 pin connector connection diagram is shown below. - Page 83 Page 83 / 345 Connection of magnetic brake to one-axis or two-axis systems Page 83 / 345...

-

Page 84: Joystick Control

Page 84 / 345 4.5.3. Joystick control General information Controller accepts an input from an analog joystick with voltage in 0-3 V range. Voltage in the equilibrium (central) position and voltage in minimum and maximum position can be set to any value from the working range, if the following condition holds: minimum position <... - Page 85 Page 85 / 345 Connection of joystick to the controller board via BPC connector One-axis and two-axis systems Joystick connector is available only in two-axis system. A connection diagram is shown below. Connection of joystick to the two-axis system via D-SUB 9 pin connector Page 85 / 345...

- Page 86 Page 86 / 345 4.5.4. Left-Right buttons control For each system it is possible to control the movement of a motor with the buttons. Active button state is programmable and can be logical zero or one. Controller supports a 10-item speed array MaxSpeed[0-9], which is used both for joystick and button control.

- Page 87 Page 87 / 345 Scheme of buttons connection to the HDB-26 connector Page 87 / 345...

-

Page 88: Principle Of Operation

Page 88 / 345 4.5.5. TTL synchronization Principle of operation TTL-synchronization is used to synchronize controller motion with external devices and/or events. For example, the controller can output synchronization pulse each time it moves a certain distance. Vice versa, controller can shift a certain distance on incoming synchronization pulse, for example from an experimental setup which is ready to move to the next measurement position. -

Page 89: Pulse Time

Page 89 / 345 Note. Sync in settings may be saved in controller flash (non-volatile) memory. In this case everything related to synchronization may also be said about autonomous controller operation. For example, you may set up shift on offset on syncin pulse with syncout pulse on movement stop and connect the controller to a standalone measurement device, which starts measurements on its own input sync pulse and outputs a sync pulse on measurement end. - Page 90 Page 90 / 345 Clutter time Movement does not start because input pulses are shorter than debounce time Warning. If a second syncin pulse is received while controller is still moving then the end position will be offset by two times the shift distance from the start, if a third pulse is received, then by three times, etc. Clutter time Clutter time Motion stops Moving time...

- Page 91 Page 91 / 345 Motion stops Clutter time Clutter time Moving time Moving time Motion starts Two separate shifts with two start and two stop phases Default setting is active state is one, movement on raising edge. Synchronization input may be inverted to the active state is zero, movement on trailing edge.

- Page 92 Page 92 / 345 Note. If syncout pulse length is measured in distance units and, for example, is equal to 10 stepper motor steps and "syncout pulse on stop" mode is active, then the active state on synchronization output will be set on the movement end, but will be cleared only when the motor will move 10 more steps during the next movement.

- Page 93 Page 93 / 345 Note. Whenever syncout pulses overlap they are merged into one pulse. _Syncout pulse merge illustrated, pulse generation on start, stop and shift on offset (pulse length measured in microseconds) Synchronization settings setup in XiLab is described in Synchronization settings section.

-

Page 94: Multiaxis System Design

Page 94 / 345 4.5.6. Multiaxis system design Controller axes in multiaxis systems are identified by the controller serial number. Each controller has its own unique serial number, which may be seen in XiLab software on About controller page. One can read controller serial number using get_serial_number function (see Programming guide). - Page 95 Page 95 / 345 4.5.7. General purpose digital input-output Output is located on connector. It allows user to configure it as input or output. Logical level one is considered to be active. However it can be inverted so that logical level zero is considered active. Type Logic zero level 0 V Logic one level...

- Page 96 Page 96 / 345 Among two box versions, only two axis system has the digital input/output. Corresponding contacts output on the HDB-26 connector. Scheme of connection to digital input/output for two-axis system Page 96 / 345...

- Page 97 Page 97 / 345 4.5.8. General purpose analog input Analog input may be used for other purpose. For example, it can be used to measure any external signal. Value at the analog input may be read by the GETC command and is visible in the XiLab charts.

- Page 98 Page 98 / 345 4.5.9. External driver control interface Interface allows to control any external driver with a help of 3 standard signals: enable, direction, clock. This mode is convenient when controller power capability is not enough but it is desirable to use its capabilities such as limit switches, revolution sensor, position control, scripting language, multiaxis systems, joystick/button control, magnetic brake, etc.

- Page 99 Page 99 / 345 Page 99 / 345...

-

Page 100: Serial Port

Page 100 / 345 4.5.10. Serial port Controller allows control through UART serial port with TTL 3.3 V logic. UART outputs are located on connector. Because of widespread availability of UART and adapters to USB, Bluetooth, Ethernet and other standard interfaces there is an option for wireless control (Bluetooth) or control over the internet (Ethernet). - Page 101 Page 101 / 345 Recommended scheme of connection to serial port pins for two-axis system Page 101 / 345...

- Page 102 Page 102 / 345 4.5.11. Saving the position in controller's FRAM memory Controller has a function which automatically remembers its last position. This allows one to power-off the controller after it has stopped. On the next power-on the controller will appear in the same motor position, logical position and encoder value. This will work if during the time controller was off the motor shaft was not rotated by external means.

- Page 103 4.5.12. The Standa stages detection Newest Standa positioners (please check with the manufacturer for the list of exact models) have an option to store settings and informational parameters in the internal positioner memory. This chip is flashed with correct settings, which allows one to skip optimal positioner configuration and to start working with the positioner right out of the box.

-

Page 104: Secondary Features

Page 104 / 345 4.6. Secondary features Zero position adjustment User-defined position adjustment Controller status USB connection autorecovery Page 104 / 345... - Page 105 Page 105 / 345 4.6.1. Zero position adjustment Controller supports setting of zero position. This function should be used for anchor marked stages, so that anchor position matches logical zero. Also, this function is convenient to use in case there is a single chosen physical position. To set zero position a special command is used.

- Page 106 Page 106 / 345 4.6.2. User-defined position adjustment A SPOS command can be used if it is necessary to set position and/or encoder value to some user-defined position instead of zero. New step/microstep position and encoder count values are passed as parameters to this command. If only one of these counters is needed one should use ignore flags to filter required fields.

-

Page 107: Controller Status

Page 107 / 345 4.6.3. Controller status Controller tracks its own status and can transfer it in the status structure of the GETS command. Controller status contains information about performed movement, its result, state of power supply, state of encoder, state of motor windings, digital input-output states, numeric information about position and powering voltage and currents and also error flags. - Page 108 Page 108 / 345 Power voltage (in tens of mV) USB current (in mA) USB voltage (in tens of mV) Microprocessor temperature (tenths of degrees Celsius) Status flags There are several types of flags: control command error flags, critical parameter flags, general error flags and state flags. Many flags do not remove themselves and should be reset by the STOP command.

- Page 109 Page 109 / 345 4.6.4. USB connection autorecovery This unit is designed to reboot the USB in the event of loss of communication (for example, this may occur in the event of electrostatic discharge or when the USB is disconnected without powering down the controller). The on/off state of this unit is determined by the USB_BREAK_RECONNECT flag (see Critical parameters).

- Page 110 Page 110 / 345 5. XILab application User's guide About XILab Main windows of the XILab application XILab Start window XILab Main window in single-axis control mode XILab Main window in multi-axis control mode Application Settings Charts Scripts XiLab Log Controller Settings Settings of kinematics (Stepper motor) Motion range and limit switches...

- Page 111 Page 111 / 345 5.1. About XILab XILab features a user-friendly graphical interface, which is designed for stages control, diagnostic and fine tuning of the motors driven by the controllers. XILab allows quick adjustment of connected stage by loading of previously prepared configuration files. The control process can be automated with script language that can be used either directly or to speed up the process of customized control program development.

- Page 112 Page 112 / 345 5.2. Main windows of the XILab application XILab Start window XILab Main window in single-axis control mode XILab Main window in multi-axis control mode Application Settings Charts Scripts XiLab Log Page 112 / 345...

- Page 113 Page 113 / 345 5.2.1. XILab Start window When started, XILab opens a controllers detection window. By means of libximc library, XILab queries controllers connected to the system and displays a list of found and successfully identified controllers. XILab Start Window, 0 controllers found XILab Start Window, 1 controller found XILab Start Window, 2 controllers found The list of found controllers is displayed on the start screen.

- Page 114 Page 114 / 345 Note: Since the libximc library opens XIMC devices in the exclusive access mode, when you start subsequent copies of XILab application, only free controllers will be found and available for selection. Page 114 / 345...

- Page 115 Page 115 / 345 5.2.2. XILab Main window in single-axis control mode 5.2.2. XILab Main window in single-axis control mode Motion Control Unit Movement without specifying the final position Movement to the target point Target position for motion commands Attenuator Control Unit Controller and motor status Controller Power Supply Motor status...

- Page 116 Page 116 / 345 XILab Main Window in Attenuator mode In the left part of the window in Power and Motor groups of parameters status of the controller and the motor is available. In the central part of the window there is the Control group, containing the elements of motor motion control. On the right there is a group of buttons to control the application as a whole.

- Page 117 Page 117 / 345 Button Left to the border will make the motor rotate to the left border of the slider. Right to the border , respectively, will do it to the right edge of the slider. When you press and hold the keyboard buttons Right or Left and the slider block has input focus, the movement starts in the direction of increasing or decreasing coordinate.

- Page 118 Page 118 / 345 Controller Power Supply Power group of parameters contains the following indicators: Source - source of power supply for controller. The controller may be powered by USB or by External power source. Power voltage - voltage supplied to the power module. Power current - current consumption of the power module.

- Page 119 Page 119 / 345 Program status Program group of parameters contains the following indicators: Sync buf free - free slots in the syncin command buffer (see description of ASIA command). Group of application control buttons Settings... button opens controller settings, see Application Settings.

- Page 120 Page 120 / 345 5.2.3. XILab Main window in multi-axis control mode XILab Main window In the top left part of the screen in the Position parameter group there are indicators of the current position. In the bottom left part of the window there is the Joystick and Control blocks, which are a graphical control element for several axes and a button block respectively.

-

Page 121: Control Block

Page 121 / 345 Virtual joystick block In this block, the current coordinate of the controllers is visualized as a dot with two lines on the plane for X-Y axes and the line for the Z axis. There are several possible ways to control movement of the controllers: When you click anywhere on the X-Y plane or in the Z column, the corresponding controller or controllers start to move to the selected coordinate in accordance to its own movement settings. - Page 122 Page 122 / 345 Control block The Go home button searches for the home position independently for each of the controllers; see Home position settings. The Zero button resets the current position of the motor and value of the encoder for each controller. The Soft stop button executes a soft stop for each of the controllers.

- Page 123 Page 123 / 345 Block of status indicators for controllers and motors Here are the three blocks of indicators of controllers and motors for axes X, Y and Z. In the title of the block the serial number of corresponding controller is displayed. Each block contains the following indicators: Voltage - the voltage at the power section of the motor.

- Page 124 Page 124 / 345 Common settings dialog window Common settings window contains axis order settings, curve drawing options and logging settings. You can reorder axes by choosing the axis serial, then pressing "up" or "down" buttons on the right. First axis in the list, that is, an axis with serial number listed to the right of "X axis SN = " label will be referred to as "X axis", the second one as "Y axis", the third one, if it is available, as "Z axis".

-

Page 125: Application Settings

Page 125 / 345 5.2.4. Application settings Settings button from the main window opens the Settings window. XILab Settings Main Window Application settings are presented as a hierarchical tree and are divided into three groups: controller settings - "Device configuration", XILab application settings - "Program configuration", characteristics of a stage - "Stage confuguration". - Page 126 Page 126 / 345 The OK Button closes the Settings window and saves all changes to the settings to the controller. The Cancel button closes the window without saving. The Apply button saves the settings without closing the window. The Reset button resets all setting changes that were made since the Apply button was pressed, or after opening the Settings, if the Apply button was not pressed.

- Page 127 Page 127 / 345 5.2.5. Charts Button Chart of the main window opens a window for working with charts. 5.2.5. Charts Values displayed charts Button functions XILab Charts window In the left part of the window there are Charts of variables, in the right side of the window there is the Control block, which contains the charts control elements.

-

Page 128: Button Functions

Page 128 / 345 motor; PWM level the PWM duty factor (only for DC motors); Temperature is temperature of controller processor; Joystick is value of input signal from the joystick; Analog input is value of analog input; Flags shows the state of the controller flags. Button functions Clear - clears the stored data and the Charts window;... - Page 129 Page 129 / 345 5.2.6. Scripts The "Scripts" button on the main window opens a window for working with scripts. XILab scripting window On the left side of the window a text edit field is located, on the right side of the window a Control block is located, which contains control buttons.

- Page 130 Page 130 / 345 5.2.7. XILab log XILab log window XILab log at the bottom part of the main window shows libximc library messages. It also shows messages from XILab application and Scripts interpreter. Log has 4 columns: date and time of record, the source and the message text. Messages have a logging level indicating message importance: error, warning and informational message.

-

Page 131: Controller Settings

Page 131 / 345 5.3. Controller Settings Settings of kinematics (Stepper motor) Motion range and limit switches Critical board ratings Power consumption settings Home position settings Synchronization settings Brake settings Position control Settings of external control devices UART settings General purpose input-output settings Motor type settings Settings of kinematics (DC motor) Settings of PID control loops... - Page 132 Page 132 / 345 5.3.1. Settings of kinematics (stepper motor) In the Application Settings Device configuration -> Stepper motor Settings of stepper motor kinematics window Motor parameters - directly related to the electric motor settings Revers - checking this flag associate the motor rotation direction with the position counting direction. Change the flag if positive motor rotation decreases the value on the position counter.

- Page 133 Page 133 / 345 Current as RMS - if this flag is checked engine current value is interpreted as root mean square current value. If the flag is unset, then engine current value is interpreted as maximum amplitude value. Motion setup - movement kinematics settings Working speed - movement speed.

- Page 134 Page 134 / 345 5.3.2. Motion range and limit switches In the Application Settings Device configuration -> Borders Motion range and limit switches settings window Borders setup parameter group contains borders and limit switches parameters. These parameters are used to keep the stage in the permissible physical movement limits or motion range limit in accordance with the user requirements.

- Page 135 Page 135 / 345 5.3.3. Critical board ratings In the Application Settings Device configuration -> Maximum ratings Controller critical parameters settings window Critical board ratings - This group is responsible for the maximum values of input current Max current (power) and voltage Max voltage (power) on the controller, the maximum current Max current (usb) and voltage Max voltage ( usb) for USB, the minimum voltage Min voltage (usb) for USB, and the board temperature Temperature (if the temperature is measured on the given controller version).

-

Page 136: Power Consumption Settings

Page 136 / 345 5.3.4. Power consumption settings In the Application Settings Device configuration -> Power Management Power consumption settings window Current reduction enabled - activates the reduced energy consumption mode. Current in hold mode - it determines the current in the hold mode in % of the nominal value. Value range: 0 .. 100%. Current reduction delay - parameter determines the delay between switching to the STOP mode and power reduction activation. - Page 137 Page 137 / 345 5.3.5. Home position settings In the Application Settings Device configuration -> Home position Home position settings window Tab Home position sets the home position calibration parameters. Calibration comes to automatic accurate detection of the limit switch, the revolution sensor signal or moment of getting the external signal, which determines the zero position, and grading from it by a specified offset.

-

Page 138: Synchronization Settings

Page 138 / 345 5.3.6. Synchronization settings In the Application Settings Device configuration -> TTL sync Synchronization settings window Synchronization is described in details in TTL synchronization section. Sync in Clutter time - setting minimum synchronization pulse duration (in microseconds). Defines the minimum duration, which can be detected (anti-chatter). -

Page 139: Brake Settings

Page 139 / 345 5.3.7. Brake settings In the Application Settings Device configuration -> Brake control Magnetic brake settings window Check the Brake control flag to enable magnetic brake. Parameters: Time between motor power on and brake off - time between switching the motor on and switching off the brake (ms). Time between brake off and readiness to move - time between switching off the brake and motion readiness (ms). -

Page 140: Position Control

Page 140 / 345 5.3.8. Position control In the Application Settings Device configuration -> Position control Window of Position control Check the Position control checkbox to activate the position control. Base - selection of the position control device. You can select an encoder (see Operation with encoders ) or revolution sensor in the drop-down list. - Page 141 Page 141 / 345 5.3.9. Settings of external control devices In the Application Settings Device configuration -> Control Settings of external control devices window Control mode - range of external motor control devices. Control disabled - external devices are not used Joystick - joystick is used...

- Page 142 Page 142 / 345 Reverse joystick - Reverse the joystick effects. Joystick deviation to large values results in negative speed and vice versa. Button Joystick calibration opens calibration dialog box. Dialog box of Joystick Calibration Calibration is automatic border and the dead zone detection. Below is the process description: Move the joystick to extremes to determine the borders.

-

Page 143: Uart Settings

Page 143 / 345 5.3.10. UART Settings In the Application Settings Device configuration -> UART UART settings tab Speed - Select the UART speed from the preset values in the range from 9600 bit/s to 921600 bit/s. Use parity bit - use of parity bit. Parity type - Types of parity: Even - this bit type is set when total number of bits is odd Odd - this bit type is set when total number of bits is even... - Page 144 Page 144 / 345 5.3.11. General purpose input-output settings In the Application Settings Device configuration -> EXTIO settings General purpose input-output settings tab For detailed information, please see General purpose digital input-output ExtIO setup IO pin is output - if the flag is checked the needle of ExtIO works in output mode, otherwise - in the input mode. Invert - if the flag is checked the rising edge is ignored and the falling edge is active.

- Page 145 Page 145 / 345 5.3.12. Motor type settings In the Application Settings Device configuration -> Motor type Motor type settings window Stepper motor or DC-motor - motor type indication. Control power driver should be selected as well: Integrated. This type is used for this controller modification. On discrete keys.

- Page 146 Page 146 / 345 5.3.13. Settings of kinematics (DC motor) In the Application Settings Device configuration -> DC Motor Settings of kinematics (DC motor) window Motor parameters - electric motor settings Revers - checking this flag associate the motor rotation direction with the current position counting direction. Change the status of the flag if positive motor rotation decreases the value on the position counter register.

-

Page 147: Feedback Settings

Page 147 / 345 Motion setup - settings related to the movement kinematics Working speed - movement speed. Backlash compensation - backlash compensation. Since the stage mechanics are not ideal there is a difference between approaching a given point from the right and from the left. When the backlash compensation mode is on the stage always approaches the point from one side. - Page 148 Page 148 / 345 5.3.14. Settings of PID control loops In the Application settings Device configuration -> PID control Settings of PID control loops window In this section, you can change the PID coefficients. A voltage PID is used, K_p, K_i and K_d coefficients can vary in 0..65535 range for DC motors. Fractional PID coefficients (on right) are only for BLDC motor (supported in firmware 4.1.x and older).

- Page 149 Page 149 / 345 5.3.15. About controller In the Application Settings Device configuration -> About device About device tab The Board section displays information about the controller: Serial number - device serial number. Bootloader version - bootloader version. Firmware version - firmware version. Latest firmware - latest available firmware version for this device (downloaded from the internet if internet connection is available).

- Page 150 Page 150 / 345 Information block contains information about the device: the manufacturer, device ID, device type. The data are read from the internal memory of the controller. All of this data is reported to the XILab application when the device is connected. Page 150 / 345...

- Page 151 Page 151 / 345 5.3.16. Settings of kinematics (BLDC motor) In the Application Settings Device configuration -> DC Motor Settings of kinematics (DC motor) window IMPORTANT. Only firmwares 4.1.x (and older) support BLDC control Motor parameters - electric motor settings Revers - checking this flag associate the motor rotation direction with the current position counting direction.

- Page 152 Page 152 / 345 IMPORTANT. BLDC controller always use max current and don't use max voltage because main characteristic for BLDC is max current, max voltage usually more than 8SMC5 supply voltage. Motion setup - settings related to the movement kinematics Working speed - movement speed.

- Page 153 Page 153 / 345 5.4. XILab application settings XILab general settings General motor settings Attenuator settings Cyclical motion settings Log settings Charts general settings Charts customization User units settings About the application Page 153 / 345...

- Page 154 Page 154 / 345 5.4.1. XILab general settings Program configuration in the Application Settings XILab general settings tab This tab configures the Xilab interface type and XIMC devices detection options. Skin Type group includes Xilab interface type settings. There are two interface types available: "General Motor" and "Attenuator". General Motor option enables general motor interface.

- Page 155 Page 155 / 345 Warning. If both Probe devices and Enumerate non-XIMC devices options are enabled, on startup XILab will send data to all COM-ports. If the PC has multiple Bluetooth COM-ports, due to the nature of Bluetooth operation, the queries will be conducted sequentially, and connection attempts may take from a few to tens of seconds each.

- Page 156 Page 156 / 345 5.4.2. General motor settings General motor in the Application Settings General motor settings tab This tab configures the slider display settings and secondary position display settings for a general motor device. The position slider is located in the main window and visually represents the stage current position relative to the borders.

-

Page 157: Attenuator Settings

Page 157 / 345 5.4.3. Attenuator settings In the Application Settings Program configuration -> Attenuator settings Attenuator settings tab This tab is used to configure attenuator interface. An attenuator is a device used to reduce the power level of an optical signal by passing light through one or several optical filters. - Page 158 Page 158 / 345 5.4.4. Cyclical motion settings In the Application Settings Program configuration -> Cyclic motion Cyclic motion tab Use this tab to configure the cyclic motion between two preset positions. It is used mainly for demonstration purposes. This mode is activated by Cyclic button in the main window, and deactivated by Stop button in the...

-

Page 159: Log Settings

Page 159 / 345 5.4.5. Log settings XILab log settings window On this page (Program configuration -> Log settings) you can configure the logging detail level. I n Display messages by loglevel box you can choose an option to log nothing (None), log only errors (Error), errors and warning messages (Error, Warning), errors, warnings and information messages (Error, Warning, Info) for each source: XILab application, libximc library and Scripts module. - Page 160 Page 160 / 345 5.4.6. Charts general settings Program configuration -> Graph setup in the Application Settings Charts general settings tab Visible interval - the time interval displayed in charts on the horizontal axis. Update interval - chart data update interval. Break data update when motor stopped - stops drawing charts when the motor stops.

- Page 161 Page 161 / 345 5.4.7. Charts customization In the Application Settings Program configuration -> Graph setup -> ... This section equally applies to the individual appearance settings of speed, voltage, current, PWM duty factor, temperature, and other parameter charts, which can be displayed in the XILab application. Charts customization on the example of the position chart tab Charts display settings include line style and chart vertical axis scale adjustment.

- Page 162 Page 162 / 345 5.4.8. User units settings In the Application Settings Program configuration -> User units User units tab Use this tab to configure user units display. Used to replace internal controller coordinates with units familiar to the user. User units settings: Enable user units - enables user unit display instead of steps (in case of stepper motor) or encoder counts (in case of DC motor).

-

Page 163: About The Application

Page 163 / 345 5.4.9. About the application Program configuration -> About in the Application Settings About tab This section displays the XILab application version. It also contains a link to the page with the latest Software version. User configuration file cleanup dialog "Remove all custom configuration files"... - Page 164 Page 164 / 345 5.5. Positioner specifications Positioner name Positioner general characteristics Motor characteristics Encoder specifications Hall sensor characteristics Reducing gear specifications Accessories specifications Page 164 / 345...

- Page 165 Page 165 / 345 5.5.1. Positioner name Stage configuration -> Positioner name in the Application Settings Positioner name window This block contains the positioner name (defined by user). Page 165 / 345...

- Page 166 Page 166 / 345 5.5.2. Positioner general characteristics Stage configuration -> Stage in the Application Settings Positioner general characteristics window Stage parameter prouop contains information about the stage. Manufacturer - the manufacturer name. Part number - the catalog number. Lead screw pitch - lead screw pitch. Units - stage movement measurement units (mm, degrees, steps).

- Page 167 Page 167 / 345 Vertical load capacity - the maximum vertical load on the stage. Page 167 / 345...

-

Page 168: Motor Characteristics

Page 168 / 345 5.5.3. Motor characteristics Stage configuration -> Motor in the Application Settings Motor characteristics window This section contains motor information. Manufacturer - motor manufacturer. Part number - catalog number. Motor type - motor type (stepper, DC or BLDC) Page 168 / 345... - Page 169 Page 169 / 345 Poles - number of pole pairs for DС or BLDC motors, steps per revolution for stepper motors. Phases - BLDC motor phases. Nominal voltage - nominal winding voltage. Nominal current - maximum continuous winding current for DC or BLDC motors, nominal current for stepper motors. Nominal speed - nominal speed.

-

Page 170: Encoder Specifications

Page 170 / 345 5.5.4. Encoder specifications Stage configuration -> Encoder in the Application Settings Window Encoder specifications This section contains information about encoder Manufacturer - encoder manufacturer name. Part number - the catalog number. Max. operating frequency - the maximum operating frequency. Supply voltage - acceptable supply voltage range. - Page 171 Page 171 / 345 Revolution sensor - indicates if revolution sensor is present. Rev.sensor active is high - if enabled then active revolution sensor state is logical 1, else it is logical 0. Page 171 / 345...

- Page 172 Page 172 / 345 5.5.5. Hall sensor characteristics Stage configuration -> Hall sensor in the Application Settings Hall sensor properties window This section contains information about hall sensor: Manufacturer - sensor manufacturer name. Part number - the catalog number. Max. operating frequency - the maximum operating frequency. Supply voltage - acceptable supply voltage range.

- Page 173 Page 173 / 345 5.5.6. Reducing gear specifications Stage configuration -> Gear in the Application Settings Reducing gear specifications window This section contains information about the reducing gear. Manufacturer - the manufacturer name. Part number - the catalog number. Reduction - gear transmission ratio. Max.

-

Page 174: Accessories Specifications

Page 174 / 345 5.5.7. Accessories specifications Stage configuration -> Accessories in the Application Settings Accessories specifications window This panel contains information about various accessories. Magnetic brake - magnetic brake section. Information - magnetic brake manufacturer and part number. Rated voltage - nominal magnetic brake voltage. Rated current - nominal magnetic brake current. - Page 175 Page 175 / 345 Information - temperature sensor manufacturer and part number. Temp. range - measuered temperature range. Temp. gradient - temperature gradient. Type - sensor type (thermocouple or semiconductor). Available - indicates if temperature sensor is available. Limit switches - limit switches section. SW1 available - indicates if SW1 limit switch is available.

- Page 176 Page 176 / 345 5.6. Correct shutdown Correct shutdown assumes shutdown of the motor and saving the current position by the controller. The current position is automatically saved, see Saving the position in controller's FRAM memory Exit button performs correct shutdown and exit. When you click it the application sends a soft stop command to the controller, and after the stop is complete, the application sends command of power-off.

- Page 177 Page 177 / 345 5.7. Working over network XiLab is capable of interacting with remote controllers via Ethernet. However you need a special XIMC server, which can be either obtained as a standalone program and installed on any appropriate device, or as one of the services of 8SMC4-USB-Eth1 adapter.

- Page 178 Page 178 / 345 When you restart XiLab it will find all axis connected to the system. In controller detection window choose an axis you need. You can control it in single-axis mode or in multi-axis mode if more than one axis was chosen. For additional information please refer to Getting started with XiLab software XILab application User's guide...

- Page 179 Page 179 / 345 Note. Working with multiple adapters may cause a problem when the same board responds in a broadcast requests. You can find a new device by two different ways : Disconnect other axes, find the device on the network, connect all again. Press Scan for local XIMC servers button until you find sought-for device.

- Page 180 Page 180 / 345 5.8. XILab installation Installation on Windows Installation on Windows XP Installation on Windows 7 Installation on Windows 8 Installation on Linux Installation on MacOS Page 180 / 345...

-

Page 181: Installation On Windows

Page 181 / 345 5.8.1. Installation on Windows Installation on Windows XP Installation on Windows 7 Installation on Windows 8 Page 181 / 345... -

Page 182: Installation On Windows Xp

Page 182 / 345 5.8.1.1. Installation on Windows XP Copy the installer program file to your computer. The installer file name is "xilab-<version_name>.exe". It automatically detects whether it is running on 32-bit or 64-bit version of Windows and installs the appropriate version of XiLab. Note: Only Windows XP SP3 is supported. - Page 183 Page 183 / 345 All the necessary software including drivers, packages and programs will be installed automatically. After the installation is complete the XiLab application will be started by default. Page 183 / 345...

- Page 184 Page 184 / 345 Connect the stage to the controller. Connect regulated power supply to the controller. Ground the controller or the power supply unit. Connect the controller to the computer using a USB-A - mini-USB-B cable. LED indicator on the controller board will start to flash. New Hardware Wizard will start after the first controller is connected to the computer.

- Page 185 Page 185 / 345 In the next window select "Install from a list or specific location (Advanced)" and click "Next>". Select the *.inf file on the disk with the software supplied with the controller or in the program directory (by default the path is C:\Program Files\XiLab\driver\) and click "Next".

- Page 186 Page 186 / 345 Click "Next". Click "Continue anyway". Page 186 / 345...

- Page 187 Page 187 / 345 Click "Finish". Driver installation is complete. Click Retry or run the Xilab application again if it was closed. The system will detect the connected controller and open the main Xilab window. Page 187 / 345...

- Page 188 Page 188 / 345 Page 188 / 345...

- Page 189 Page 189 / 345 5.8.1.2. Installation on Windows 7 Copy the installer program file to your computer. The installer file name is "xilab-<version_name>.exe". It automatically detects whether it is running on 32-bit or 64-bit version of Windows and installs the appropriate version of XiLab. Run the installer and follow the on-screen instructions.

- Page 190 Page 190 / 345 Page 190 / 345...

- Page 191 Page 191 / 345 All the necessary software including drivers, packages and programs will be installed automatically. After the installation is complete the XiLab application will be started by default. Connect the stage to the controller. Connect regulated power supply to the controller. Ground the controller or the power supply unit. Connect the controller to the computer using a USB-A - mini-USB-B cable.

- Page 192 Page 192 / 345 Wait until Windows detects the new device and installs the drivers for it. After the driver is successfully installed click Retry or run the Xilab application again if it was closed. The system will detect the connected controller and open the main Xilab window. Page 192 / 345...

- Page 193 Page 193 / 345 Page 193 / 345...

- Page 194 Page 194 / 345 5.8.1.3. Installation on Windows 8 Copy the installer program file to your computer. The installer file name is "xilab-<version_name>.exe". It automatically detects whether it is running on 32-bit or 64-bit version of Windows and installs the appropriate version of XiLab. Run the installer and follow the on-screen instructions.

- Page 195 Page 195 / 345 After the installation is complete the XiLab application will be started by default. Connect the stage to the controller. Connect regulated power supply to the controller. Ground the controller or the power supply unit. Connect the controller to the computer using a USB-A - mini-USB-B cable. LED indicator on the controller board will start to flash.

-

Page 196: Installation On Linux

Page 196 / 345 5.8.2. Installation on Linux 5.8.2. Installation on Linux Debian / Ubuntu Installing in graphical mode The text installer RedHat / OpenSUSE The text installer XILab package installs its files in the following directories: /usr/bin/xilab - executable file /usr/share/icons/xilab.png - Icon /usr/share/xilab/scripts/ - directory scripts /usr/share/xilab/profiles/ - directory with profiles... - Page 197 Page 197 / 345 Click on the file xilab_x.y.z-1_i386.deb (for 32-bit versions of Linux) or xilab_x.y.z-1_amd64.deb (for 64-bit versions of Linux). Installation window will appear. Click the Install package. Dependencies and Xilab application will be installed. The text installer Execute the following commands as super-user (root): gdebi "<FILEPATH>/libximc6_<LIBVERSION>-1_<ARCH>.deb"...

-

Page 198: Installation On Macos

Page 198 / 345 5.8.3. Installation on MacOS Copy the file with the installer archive to your computer. The archive with the installation program is named "xilab-<version_number>- osx64.tar.gz". Unpack the archive by a mouse click. Make right button click on installer.pkg. Page 198 / 345... - Page 199 Page 199 / 345 Choose "Open". Choose "Open". Select "Continue" in the main window of the installer. Page 199 / 345...

- Page 200 Page 200 / 345 Now select "Install." Enter the password. Wait until the installation is complete. Page 200 / 345...

- Page 201 Page 201 / 345 Select the XILab application in the Programs block Start it. Page 201 / 345...

- Page 202 Page 202 / 345 6. Programming Programming guide Working with controller in Labview Working with controller in Matlab Communication protocol specification 8SMC1-USBhF software compatibility Libximc library timeouts XILab scripts Page 202 / 345...

-

Page 203: Programming Guide

Page 203 / 345 6.1. Programming guide Programming guide is included in development kit libximc 2.X.X, where 2.X.X is the version number. It is located in /ximc- 2.X.X/ximc/doc-en/libximc7-en.pdf. Also the programming guide can be downloaded from this link. Development kit can be downloaded on Software page. - Page 204 Page 204 / 345 6.1.1. Working with controller in Labview Download Labview example from the Software page. Extract the archive and run "XImc Example One axis" file using Labview. LabView environment will start. You will see graphical user interface of the front panel of the example, which looks like a simplified XILab interface.

- Page 205 Page 205 / 345 The example uses libximc library functions. Each function has a corresponding subVI module, which has inputs and outputs corresponding to input and output parameters of this function. To call any libximc function one should first enumerate devices by using "device_enumerate", then pick any device from the list and open it using "open_device"...

- Page 206 Page 206 / 345 Let's review how to create a simple Labview program with libximc library using "Ximc simple example.vi". The program starts by calling enumerate_devices function and passing it the enumerate flags parameter (for details see Programming guide). Result of the enumerate_devices function call is an opaque pointer and is passed to the get_device_name function together with device number, whose name we want to find out (one can get total number of found devices by passing the same opaque pointer to the get_device_count function).

- Page 207 Page 207 / 345 6.1.2. Working with controller in Matlab Libximc library can be used to work with controller in Matlab. Note: SDK requires Microsoft Visual C++ Redistributable Package 9.0.307291 (provided with SDK - vcredist_x86 or vcredist_x64). Extract files from libximc development kit.

- Page 208 Page 208 / 345 In the command window you will see the output of the example which reports controller status. You can call libximc functions from Matlab program this way: define the path to the libximc.dll, bindy.dll and xiwrapper.dll dynamic link libraries and its header ximc.h and additional to libximc_thunk_pcwin64.dll and ximc.m files if you are using 64-bin environment.

- Page 209 Page 209 / 345 6.2. Communication protocol specification (v17.5) 6.2. Communication protocol specification (v17.5) Protocol description Command execution Controller-side error processing Wrong command or data CRC calculation Transmission errors Timeout resynchronization Zero byte resynchronization Library-side error processing Library return codes Zero byte synchronization procedure Controller settings setup Command SFBS...

-

Page 210: Protocol Description

Page 210 / 345 Group of commands to save and load settings Command SAVE Command READ Command SARS Command RERS Command EESV Command EERD Group of commands get the status of the controller Command GETS Command STMS Command GETM Command GETC Command GETI Command GSER Group of commands to work with the controller... - Page 211 Page 211 / 345 All data transfers are initiated by the PC, meaning that the controller waits for incoming commands and replies accordingly. Each command is followed by the controller response, with rare exceptions of some service commands. One should not send another command without waiting for the previous command answer.

- Page 212 Page 212 / 345 Timeout resynchronization If during packet reception next byte wait time exceeds timeout value, then partially received command is ignored and receive buffer is cleared. Controller timeout should be less than PC timeout, taking into account time it takes to transmit the data. Zero byte resynchronization There are no command codes that start with a zero byte ('\0').

- Page 213 Page 213 / 345 and PC library. result_nodevice. Error opening device, lost connection or failed synchronization. Device reopen and/or user action is required. If a function returns an error values of all parameters it writes to are undefined. Error code may be accompanied by detailed error description output to system log (Unix-like OS) or standard error (Windows-like OS).

- Page 214 Page 214 / 345 Answer: (18 bytes) INT32U CMD Command (answer) The number of encoder counts per shaft revolution. Range: 1..655535. The field is obsolete, it is INT16U IPS recommended to write 0 to IPS and use the extended CountsPerTurn field. You may need to update the controller firmware to the latest version.

- Page 215 Page 215 / 345 INT32U CMD Command INT32U FastHome Speed used for first motion. Range: 0..100000. INT8U uFastHome Part of the speed for first motion, microsteps. INT32U SlowHome Speed used for second motion. Range: 0..100000. INT8U uSlowHome Part of the speed for second motion, microsteps. INT32S HomeDelta Distance from break point.

- Page 216 Page 216 / 345 INT32U CMD Command (answer) INT32U FastHome Speed used for first motion. Range: 0..100000. INT8U uFastHome Part of the speed for first motion, microsteps. INT32U SlowHome Speed used for second motion. Range: 0..100000. INT8U uSlowHome Part of the speed for second motion, microsteps. INT32S HomeDelta Distance from break point.

- Page 217 Page 217 / 345 Command GMOV result_t get_move_settings (device_t id, move_settings_t* move_settings) Command code (CMD): "gmov" or 0x766F6D67. Request: (4 bytes) INT32U CMD Command Answer: (30 bytes) INT32U CMD Command (answer) INT32U Speed Target speed (for stepper motor: steps/s, for DC: rpm). Range: 0..100000. INT8U uSpeed Target speed in microstep fractions/s.

- Page 218 Page 218 / 345 INT32U CMD Command Rated voltage in tens of mV. Controller will keep the voltage drop on motor below this value if INT16U NomVoltage ENGINE_LIMIT_VOLT flag is set (used with DC only). Rated current. Controller will keep current consumed by motor below this value if ENGINE_LIMIT_CURR flag INT16U NomCurrent is set.

- Page 219 Page 219 / 345 Answer: (34 bytes) INT32U CMD Command (answer) Rated voltage in tens of mV. Controller will keep the voltage drop on motor below this value if INT16U NomVoltage ENGINE_LIMIT_VOLT flag is set (used with DC only). Rated current. Controller will keep current consumed by motor below this value if ENGINE_LIMIT_CURR flag INT16U NomCurrent is set.