Summary of Contents for Smart Avionics PB-4

- Page 1 PB-4 Propeller & Rotor Balancer Hardware Manual Smart Avionics Ltd. Revision: 1.6 www.smartavionics.com 16/04/2019...

- Page 2 PB-4 Propeller & Rotor Balancer: Hardware Manual Revision: 1.6 Publication date 16/04/2019 Copyright © 2003-2019 Smart Avionics Ltd. Android is a trademark of Google Inc. iOS is a trademark of Apple Inc. Dropbox is a trademark of Dropbox inc. Gyroplane photographs courtesy of Mike Goodrich and Jerôme Prompsy.

-

Page 3: Table Of Contents

1.1. Balancing system overview ............... 1 1.1.1. Wi-Fi network components ............. 1 1.2. Accessing the PB-4 user interface ............ 3 1.2.1. Accessing the PB-4 user interface (AP mode) ...... 3 1.2.2. Accessing the PB-4 user interface (STA mode) ....3 1.3. Batteries ..................... 4 1.4. - Page 4 www.smartavionics.com...

- Page 5 List of Figures 1.1. Wi-Fi roles when PB-4 is in AP mode ............2 1.2. Wi-Fi roles when PB-4 is in STA mode ............. 2 1.3. PB-4 panel ....................5 2.1. Accelerometer axes and orientation ............10 2.2. Accelerometer mounted on a Rotax 912 gearbox ........ 11 2.3.

- Page 6 www.smartavionics.com...

-

Page 7: Introduction

When you are at the airfield doing the balancing, you would not normally have an access point available. Fortunately, the PB-4 can be the access point (as well as being a balancer). By starting the PB-4 in AP mode, it will be an access www.smartavionics.com... -

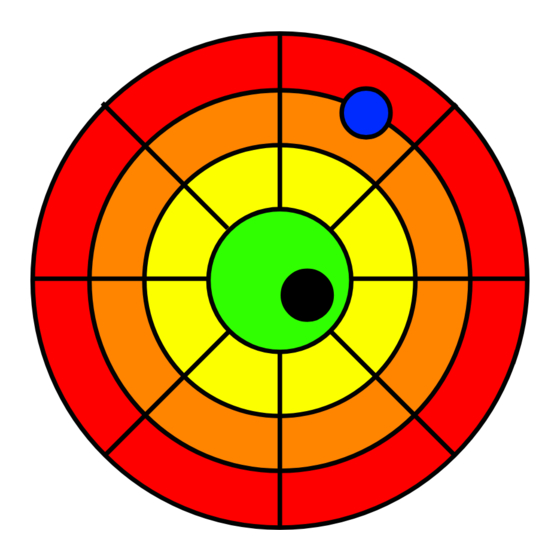

Page 8: Wi-Fi Roles When Pb-4 Is In Ap Mode

BY ACCESS POINT Fig 1.2. Wi-Fi roles when PB-4 is in STA mode For the PB-4 to be able to talk to the access point, it needs to know the access point's SSID (Wi-Fi network name) and password. The PB-4 supports Wi-Fi... -

Page 9: Accessing The Pb-4 User Interface

(click on red button) and then going to Menu / Options / PB-4 Configuration / Set Access Point Details. Once the PB-4 is able to connect to the local network, you can load the user interface page into the tablet's browser. Again, if MDNS is supported by the... -

Page 10: Batteries

2. Turn the PB-4 off (press switch until the LEDs go out). 3. Turn the PB-4 on again but this time start it in AP mode (press on/off only until LED 1 comes on). 4. Access the PB-4 user interface page with your browser as described in the previous section, connect to the PB-4 (click on red button) and then go to Menu / About. -

Page 11: Panel

Fig 1.3. PB-4 panel The panel contains: On-off The on-off switch is a push button. When turning the PB-4 on, switch how long you hold the button pressed affects the Wi-Fi mode used. Outdoors, when balancing, a short press is required to start the PB-4 in AP mode. - Page 12 This will not lose any job data stored on the PB-4. LED 1 The main purpose of LED 1 is to indicate whether the PB-4 is receiving a tacho signal. PB-4 is switched off. Green RPM is detected.

-

Page 13: Environmental Limits

5% to 95% non-condensing 1.6. Operator warning Warning The PB-4 contains a microwave transmitter (the Wi-Fi module). To be compliant with the FCC RF radiation exposure limits, the PB-4 should not be located closer than 20cm from a human body while operating. www.smartavionics.com... - Page 14 www.smartavionics.com...

-

Page 15: Preparing For Propeller Balancing

Chapter 2. Preparing for Propeller Balancing Caution Propellers can kill. Make sure that the ignition is switched off before touching the propeller. Always assume that the engine could fire when the propeller is being moved. Make sure that the aircraft is securely chocked or tied down while carrying out the balancing process. -

Page 16: Mounting The Accelerometer

Mounting the accelerometer 2.3. Mounting the accelerometer Remove sufficient cowlings to gain access to the front of the engine. Mount the accelerometer (40mm square with a 6mm hole through the middle) as near to the front of the engine as possible with the accelerometer's sensing axis pointing directly at the propeller's centre line. -

Page 17: Accelerometer Mounted On A Rotax 912 Gearbox

Mounting the accelerometer Fig 2.2. Accelerometer mounted on a Rotax 912 gearbox If the accelerometer cannot be bolted directly to the engine, some form of bracket will be required. Obviously, the details of this are engine specific but it could be as simple as a strip of metal with a hole drilled at each end. If a bracket is used, it must be sufficiently stiff to ensure that the accelerometer does not move with respect to the engine. -

Page 18: Mounting The Tacho Sensor

Mounting the tacho sensor 2.4. Mounting the tacho sensor Owing to the variation in aircraft cowling shapes and sizes, only generic instructions can be provided here. You may find that a little experimentation is required to obtain the best results. The tacho sensor is drilled for a 6mm fastener and so it may be securely bolted to the airframe using a suitable bracket. - Page 19 Mounting the tacho sensor to the cowling so that it will restrain the tacho sensor in the event of it becoming detached from the cowling. If you have any doubt as to the security of the tacho sensor, don't risk destroying it and the propeller.

-

Page 20: Attaching The Reflective Tape

Attaching the reflective tape Fig 2.4 shows the tacho sensor mounted an aircraft cowling. Important To detect the propeller RPM reliably when the propeller blades are reflective, the tacho sensor should be positioned such that the angle of the LED beam is not normal to the faces of the propeller blade. Rotate the tacho sensor so that it is approximately 30°... -

Page 21: Attaching The Cables

You may find that adding another strip of reflective tape next to the first strip will improve the situation. When the tacho sensor is connected and the PB-4 is powered up and connected to the tablet, the red LED will flash regularly. If the tacho sensor is receiving a large amount of reflected light, the LED will stop flashing. -

Page 22: Positioning The Pb-4

2.7. Positioning the PB-4 The PB-4 enclosure can be positioned in the cockpit if the cables are long enough or even just on the ground. Remember that Wi-Fi signals cannot pass through metal and so if the aircraft has a metal fuselage the person operating the tablet will have to be able to see the PB-4 enclosure. -

Page 23: Preparing For Rotor Balancing

Chapter 3. Preparing for Rotor Balancing 3.1. Mounting the sensors For gyroplane rotor balancing, the accelerometer and the tacho sensor must be mounted on the rotor head using one or more brackets. Exactly how this is achieved is dependent on the design of the rotor head. A common configuration (e.g. - Page 24 Mounting the sensors When the tacho sensor is connected and the PB-4 is powered up and connected to the tablet, the red LED will flash regularly. If the tacho sensor is receiving a large amount of reflected light, the LED will stop flashing. To check that the sensor is correctly...

-

Page 25: Sensors Mounted On An Ela Rotor Head (Top View)

1. Place the master blade at the 12 o'clock position (pointing forward when looking from above). 2. Turn on the PB-4 so that the tacho light is shining on the part to be tracked during rotation (adjust the angle of the tacho as required). -

Page 26: Sensors Mounted On An Ela Rotor Head (Side View)

Mounting the sensors Fig 3.3. Sensors mounted on an ELA rotor head (side view) Fig 3.4. Sensors mounted on an ELA rotor head (bottom view) www.smartavionics.com... -

Page 27: Positioning The Pb-4

Fig 3.5. Sensors mounted on a Magni prerotator drive 3.2. Positioning the PB-4 The PB-4 enclosure must be constrained so that it cannot become loose in flight. Preferably, it will be located inside the aircraft's cockpit where it could be held (but not by the pilot!) or tucked into a pocket, etc. If it is to be mounted outside of the cockpit, it must be securely attached to a properly designed and constructed mount. -

Page 28: Offline Capture Button

Offline capture button 3.3. Offline capture button The PB-4 kit includes a push button with cable that can be plugged in the PB-4's jack socket. Pressing the push button will capture a polar point and/or a spectrum even if the tablet is not connected to the PB-4. This means that you can capture data simply with the push button without even taking the tablet flying. -

Page 29: The Pb-4 User Interface

4.1. Getting started with the browser based user interface Just a few words here to get you started. When you load the PB-4 user interface into your browser, it will display a splash screen for a few seconds and then show an initial screen similar to 4.1. - Page 30 If you are just looking at the data for the current job, you do not need to be connected. For the full description of how to use the PB-4 browser based user interface, please go to Menu / Help.

-

Page 31: Upgrading The Pb-4'S Firmware

Menu / Options / Upload UI Files where you can select the zip file to upload. The contents of the zip file will be uploaded to the PB-4 and the next time you load the UI into your browser, you will be using the new files. -

Page 32: Upgrading The Wi-Fi Firmware

.dfu file will be uploaded to the PB-4 and the Wi-Fi module will be programmed with the new firmware. Do not turn the PB-4 off while this is being done! When the programming has finished, LED 1 should flash green quickly. Press the on/off switch and the PB-4 will continue. -

Page 33: Battery Charging & Replacement

Appendix A. Battery Charging & Replacement The PB-4 is powered by 4 x 1.2V AA size batteries. It is supplied with high quality NiMH batteries that can be recharged over 2000 times. Furthermore, these batteries self discharge very slowly and so the batteries will remain charged for a long time when the PB-4 is not in use. - Page 34 10. Reassemble the case halves and replace the 4 screws. 11. Replace the AA batteries. 12. Safely dispose of the old CR2032 battery in accordance with your local regulations. Fig A.1. Locating the PB-4 board securing screws Fig A.2. Correct orientation of RTC battery www.smartavionics.com...

-

Page 35: Specifications

Appendix B. Specifications B.1. Main unit Wi-Fi standard 2.4GHz IEEE 802.11 b/g/n Required user interface Web standards compliant browser supporting HTML5, CSS, Javascript and WebSockets. Balancing RPM range 100-13,000 RPM Tachometer channels Accelerometer channels 2 x dual-axis Spectrum display RPM 100-25,500 RPM (100 RPM per spectral line) range Spectrum (FFT) Windows... - Page 36 www.smartavionics.com...

-

Page 37: Emc Compliance & Safety Information

To ensure EMC compliance, please observe the following conditions when using the PB-4: • Do not use the PB-4 in close proximity to other electrical equipment capable of generating large amounts of electrical interference. • All electrical equipment in the aircraft that is not required for either safety reasons or to facilitate the running of the engine should be switched off while the PB-4 is being used. - Page 38 www.smartavionics.com...

-

Page 39: Ce Declaration Of Conformity

IEC 61010-1:2010 (3rd edition) and EN 61010-1:2010 “Safety requirements for electrical equipment for measurement, control and laboratory use”. Equipment type: Battery powered portable test/measurement. Environment: External/Workshop. I, the undersigned, hereby declare that the PB-4 conforms to the above Directive. Mark Burton Director Smart Avionics Ltd. - Page 40 www.smartavionics.com...

-

Page 41: Index

4, 27 cables, 15 capture offline button, 22 connect button, 24 factory reset, 5 firmware upgrading, 25 gyroplane rotor, 17 on-off switch, 5 PB-4 positioning, 16, 21 reflective tape, 14, 17 tacho sensor angle, 14, 17 mounting, 12, 17 www.smartavionics.com... - Page 42 www.smartavionics.com...

Need help?

Do you have a question about the PB-4 and is the answer not in the manual?

Questions and answers