Summary of Contents for Flam SC 1.2 GZ

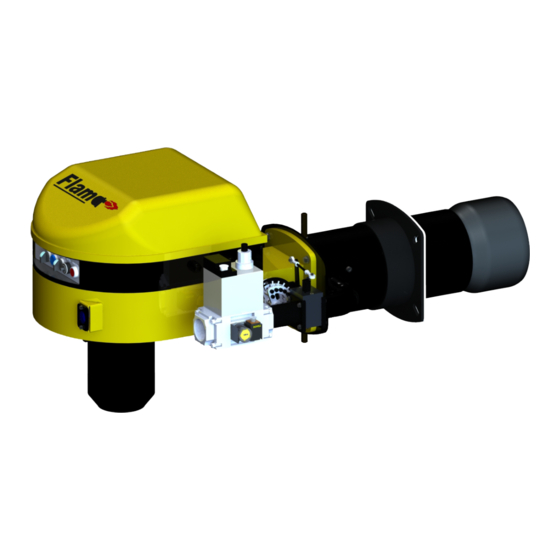

- Page 1 Two Stage Gas Burner Model: Gama Body Type: SC 1.2 GZ SC 5.1 GZ SC 2.1 GZ SC 5.2 GZ SC 2.2 GZ SC 8.1 GZ SC 3.1 GZ SC 8.2 GZ SC 3.2 GZ SC 8.3 GZ English Language:...

-

Page 2: Table Of Contents

INDEX BURNER SPECIFICATIONS ................3 CERTIFICATES ....................4 BODY TYPES ....................5 PRODUCT ENCODE ..................6 DECLARATION OF CONFORMITY ...............7 WARNING NOTES ..................8 ELECTRICAL WARNING SIGNS ..............11 PRESSURE DROPS ..................12 FLAME LENGHT AND DIAMETERS (GAS) ..........14 CAPACITY CURVES ..................15 BURNER DATA TABLE ................17 BURNER DIMENSION TABLE .............. -

Page 3: Burner Specifications

BURNER SPECIFICATIONS EASY SETUP Flamtec burners are easy to set up with the prototype structure. Flam It can be used with different options in ovens, dryers, generators, water and steam boilers. Horizontal and upwards can be set up. FUELS It can be used with artificial fuels like gas (G), motor (L), fuel oil (H) and other biogas, LPG. -

Page 4: Certificates

CERTIFICATES Gas Burner CE Design Module Production Module CE, ISO 9001: 2008 Quality Management Certificate and continue with the sales market. CE Design Module, CE Production Module, ISO 9001: 2008 Quality Management Certificates and CE Certificates can be accepted for the Motor-Gas Double Fuel Burners. GZ GAMA Gas Two Stage... -

Page 5: Body Types

BODY TYPES We use up to 17,800 kW of our Alfa type body for gas,oil and gas /oil fuels. We use Beta body up to 7.800 kW in heavy oil and gas / heavy oil fuels. We use up to 11,000 kW of our Gama burners in our gas-fired burners. -

Page 6: Product Encode

PRODUCT ENCODE SC. 12-2-G-M-(P)-Beta Body Type Body Size Body Capacity Work Options Fuel Type Operation Mode BODY SIZE: 0-1-2-3-5-8-10-12-14-16-18-20-22 BODY CAPACITY: 1-2-3 FUEL TYPE: G-GAS L-LIGHT OIL H-HEAVY OIL GL-GAS/LIGHT OIL GH-GAS/HEAVY OIL OPERATION MODE: S-SINGLE STAGE Z-TWO STAGE M-MODULATING WORKING OPTIONS: (P)-PNEUMATIC MODULATION (M)- MECHANIC MODULATION... -

Page 7: Declaration Of Conformity

DECLARATION OF CONFORMITY Before using the burner for the first time, please ensure that the product is an integral part of this manual, which is supplied with the burner. Read USER’S WARNING FOR USING BURNER” section carefully. Burner and system operations must only perform by authorized personnel. -

Page 8: Warning Notes

WARNING NOTES USE THE BURNER SAFELY USER important information on safe use, maintenance, WARNING NOTES and installation. Keep the guide where you can find it when you need it. Materials must be installed by qualified technicians 1. General Information according to current standards and manufacturer’s This product must only be used in accordance instructions. -

Page 9: Electrical Connection

WARNING NOTES 4.Burners regulations. c) Check that NOx and unburned gases causing air This device should only be used in boilers for pollution do not exceed the permissible limit values applications that are connected to hot water boilers, according to the current legislation. ovens or other similar equipment and are not d) To check that the safety devices and control exposed to atmospheric agents (rain, dust, etc.). - Page 10 WARNING NOTES for the RC circuit. --Do not leave your device in operation when you Use of any electric parts; It is subject to compliance are not using it and always keep the gas valve closed. with the basic principles of electric safety rules - When the user goes away for a while, turn off the reported below;...

-

Page 11: Electrical Warning Signs

ELECTRICAL WARNING SIGNS ENERGY CLOSE WITHOUT CAUTION VOLTAGE OPENING THE SHUTTER DAMPER ADJUSTMENT ENGINE ROTATION (OXYGEN ADJUSTMENT) GZ GAMA Gas Two Stage... -

Page 12: Pressure Drops

PRESSURE DROPS Gas Pressure Drop n barrel and gas tra n Gas Pressure Drop n barrel and gas tra n Gas Pressure Drop n barrel Gas Pressure Drop n barrel mbar mbar 17,5 17,5 12,5 12,5 SC 2.1 SC 1.2 Gas Pressure Drop n barrel and gas tra n Gas Pressure Drop n barrel Gas Pressure Drop n barrel and gas tra n... - Page 13 PRESSURE DROPS Gas Pressure Drop n barrel and gas tra n Gas Pressure Drop n barrel and gas tra n Gas Pressure Drop n barrel Gas Pressure Drop n barrel mbar mbar SC 8.2 SC 8.3 1150 1380 1610 1200 1500 1800 2100...

-

Page 14: Flame Lenght And Diameters (Gas)

FLAME LENGHT AND DIAMETERS (GAS) GZ GAMA Gas Two Stage... -

Page 15: Capacity Curves

CAPACITY CURVES mbar SC 1.2 SC 2.1 SC 2.2 mbar SC 3.1 SC 3.2 SC 5.2 SC 5.1 1000 1250 GZ GAMA Gas Two Stage... - Page 16 CAPACITY CURVES mbar SC 8.1 SC 8.2 SC 8.3 1000 1500 1750 2000 1250 2250 2500 2750 GZ GAMA Gas Two Stage...

-

Page 17: Burner Data Table

GAS INPUT Power Motor Type PRESSURE kcal/h m3/h Supply mbar min-max min-max min-max SC 1.2 GZ 43.000 154.000 0,15 21-300 1N - 50 Hz 230V SC 2.1 GZ 68.800 240.000 0,25 21-300 1N - 50 Hz 230V SC 2.2 GZ 86.000... -

Page 18: Burner Dimension Table

BURNER DIMENSION TABLE ØC C2 ØC3 ØE ØF SC 1.2 GZ SC 2.1 GZ SC 2.2 GZ SC 3.1 GZ SC 3.2 GZ 1070 SC 5.1 GZ 1160 SC 5.2 GZ 1180 SC 8.1 GZ 1230 SC 8.2 GZ 1250 SC 8.3 GZ... -

Page 19: Mounting

MOUNTING GZ GAMA Gas Two Stage... -

Page 20: Operational Explanation

OPERATIONAL EXPLANATION Phases PAUSE: Burner air shutter is open is fixed in position by hand. There is no gas in gas train. PRE-SWEEPING: The burner fan motor starts to operate following the command from the boiler oven thermostat or pressure switch. There is no gas passage in this phase. -

Page 21: Exploded Picture

EXPLODED PICTURE GZ GAMA Gas Two Stage... -

Page 22: Numbered Exploded Picture

NUMBERED EXPLODED PICTURE GZ GAMA Gas Two Stage... -

Page 23: Ignition Electrode Turbulator And Its Position

IGNITION ELECTRODE TURBULATOR AND ITS POSITION The position of the ignition electrode and the turbulators is important to ensure proper combustion. The distance of the ignition electrode to the pilot gas bubble and the distance between the turbulator and the bushes must be specified. 45,0 2-3 mm 45,00°... -

Page 24: Gas And Air Pressure Swich

GAS AND AIR PRESSURE SWICH operating in the first stage, increase the adjustment pressure by turning the respective knob clockwise until the burner stops. Then turn the knob from the set point to about 20% counter-clockwise and run the burner again to check the accuracy. If the burner stalls again, turn the knob a little further, as opposed to clockwise.Caution: As a rule, the air pressure limits the CO in the flue gas to be... -

Page 25: Gas Valve Connection

GAS VALVE CONNECTION 1) Measuring and dropping unit MULTI-BURNER, PRESSURE 2) Cutting valve GAS PIPELINE CONNECTION 3) Filter DIAGRAM IN THE IN 4) Reducing INTERMEDIATE LEVEL 5) Counter 6) Emergency shut-off valve (installed outside the building) 7) Ball valve 8) Filter 9) Final reducer or stabilizer 10) Vibration receiver 11) Double flange... -

Page 26: Maintenance

MAINTENANCE • The electrical connection should be cut off first and the gas completely closed. • The burner does not require special maintenance. However, it is a good practice to periodically check that the gas filter is clean and the ignition electrode is intact. •... -

Page 27: Commissioning Procedure

COMMISSIONING PROCEDURE The burners purchased from our company are important for the first time that the technical manager of the company who engages in the commissioning, purchasing or mechanical and electrical installation work is present during the commissioning of the burner. The controls and works on the table below must be completed so that your burner, who has been purchased, can be activated without any problems at a time. -

Page 28: Packing

PACKING Lenght(a) cm Width(b) cm Height(c) cm SC 1.2 GZ SC 2.1 GZ SC 2.2 GZ SC 3.1 GZ 1080 SC 3.2 GZ 1080 SC 5.1 GZ 1170 SC 5.2 GZ 1190 SC 8.1 GZ 1240 SC 8.2 GZ 1260 SC 8.3 GZ... -

Page 29: Equipments

EQUIPMENTS Inlet Pressureı 0,5 - 6 Bar mbar Burner Operating gas pinlet pressure 150 - 300 mbar 1- Ball Valve 2- Compensator 8- MİN. Gas pressure switch 8A - MAX. Gas pressure switch 3- Testing Nipple 9- Multiblock Valve 4- Gas filter 1 0- Burner 5- Manometer (with tap ) 11- Firing Valve... - Page 30 Selkoc Isıtma ve Soğutma Otomasyon San. Tic. Ltd. Şti. İsmetpaşa Mah. Hisar Sok. Üstün İş Merkezi. No: 20/53 Tel: +90 212 501 48 54 Fax: +90 212 501 48 57 info@selkoc.com.tr www.selkoc.com.tr...

Need help?

Do you have a question about the SC 1.2 GZ and is the answer not in the manual?

Questions and answers