Table of Contents

Advertisement

Quick Links

WELDING SYSTEM

MODELS:

PK-500-LG-*

PK-500-LH-*

PK-500-LW-*

(*INDICATES VOLTAGE REFERENCE)

Distributed by:

Revised: July 30, 2012

OPERATING

INSTRUCTIONS

GULLCO INTERNATIONAL LIMITED – CANADA

Phone: 905-953-4140

GULLCO INTERNATIONAL INC. – U.S.A.

Phone: 440-439-8333

GULLCO INTERNATIONAL [U.K.] LIMITED - EUROPE

Phone: +44 1257-253579

GULLCO INTERNATIONAL PTY LIMITED - AUSTRALIA

Phone: 61 (0) 7 3348-5515

GULLCO INTERNATIONAL LIMITED – INDIA

Phone: 91-20-65260382

GULLCO INTERNATIONAL SHANGHAI – LIMITED

Phone: +8621-50460341

Fax: 905-953-4138

Fax: 440-439-3634

Fax: +44 1257-254629

Fax: 61 (0) 7 3348-5510

Fax: 91-20-26836656

Fax: +8621-50463554

Website: www.gullco.com

e-mail: sales@gullco.com

e-mail: ussales@gullco.com

e-mail:uksales@gullco.com

e-mail: ausales@gullco.com

e-mail: India.lo@gullco.com

e-mail: c.zhang@gullco.com

GD-070

Advertisement

Table of Contents

Summary of Contents for GULLCO Pipe Kat PK-500-LG Series

- Page 1 Fax: 905-953-4138 e-mail: sales@gullco.com GULLCO INTERNATIONAL INC. – U.S.A. Phone: 440-439-8333 Fax: 440-439-3634 e-mail: ussales@gullco.com GULLCO INTERNATIONAL [U.K.] LIMITED - EUROPE Phone: +44 1257-253579 Fax: +44 1257-254629 e-mail:uksales@gullco.com GULLCO INTERNATIONAL PTY LIMITED - AUSTRALIA Phone: 61 (0) 7 3348-5515 Fax: 61 (0) 7 3348-5510 e-mail: ausales@gullco.com...

-

Page 5: Table Of Contents

TABLE OF CONTENTS SAFETY INSTRUCTIONS ..........................2 SAFETY PRECAUTIONS ..........................3 PIPE KAT SYSTEM COMPONENTS ......................4 ® GENERAL DESCRIPTION ........................... 5 PIPE BAND ..............................6 PIPE BAND SIZING ..........................6 MOUNTING PIPE BAND (TRACK) ON THE PIPE ................... 7 MOUNTING THE CARRIAGE ON THE PIPE BAND (TRACK) ............... -

Page 6: Safety Instructions

SAFETY INSTRUCTIONS Although the PIPE KAT is manufactured for safe and dependable operation, it is impossible to ® anticipate those combinations of circumstances which could result in an accident. An operator of the PIPE KAT is cautioned to always practice "Safety First" during each phase of operation, ®... -

Page 7: Safety Precautions

SAFETY PRECAUTIONS The following cautionary/warning label is attached to each “PIPE KAT” main control box ® The above label pictorially represents the following: “Warning:- Read the manual before turning the unit on and before performing service. Also, positively disconnect the unit from all power supplies before servicing!”... -

Page 8: Pipe Kat ® System Components

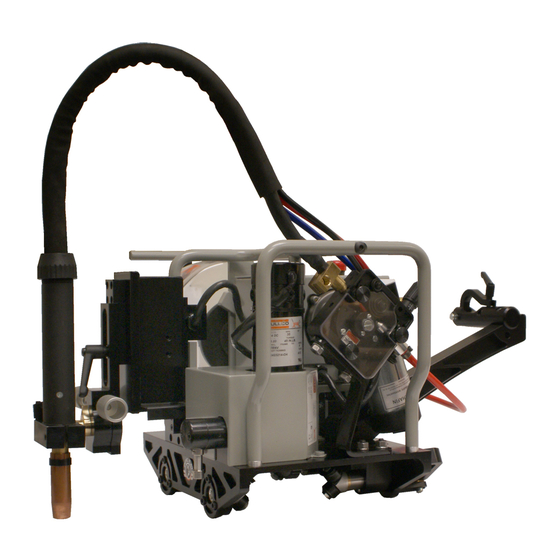

THE PIPE KAT WELDING SYSTEM COMPONENTS ® This manual covers the operation instructions of the following PIPE KAT systems ® PK-500-LG-*, PK-500-LH-*, PK-500-LW-* (* indicates input voltage: “A”=42 VAC; “B” =115 VAC; “C”= 230 VAC). PIPE KAT CARRIAGE PIPE KAT PIPE KAT ®... -

Page 9: General Description

The wire spool holder accepts standard 8” / 10 lbs [20.3cm/4.54kgs] spools. The Gullco Linear Oscillator is a compact, light weight, yet durable, reciprocating device with a high torque, high resolution and low vibration stepper motor. It imparts a linear motion to the weld gun. -

Page 10: Pipe Band

PIPE BAND The Pipe Band is constructed from extruded aluminum and uses adjustable stand-offs that serve as spacers to maintain the correct distance from the band to the pipe. The Pipe Band utilizes a quick adjustment latches that allows the operator to mount and remove the band easily. -

Page 11: Mounting Pipe Band (Track) On The Pipe

MOUNTING PIPE BAND (TRACK) ON THE PIPE 1. Loosen latch screws on both top swing latches and bottom fixed latches. Do not remove these screws. 2. Swing open the top pair of latches. 3. Separate or split the two bottom halves (fixed latches) of track away from each other. Important ! The bottom halves must be a minimum of 3/16”... -

Page 12: Mounting The Carriage On The Pipe Band (Track)

MOUNTING THE CARRIAGE ON THE PIPE BAND (TRACK) The drive engagement lever (shown below) extends out the side of the carriage drive assembly and allows the operator to engage or disengage the drive gear the rack on pipe band. The drive gear can either be engaged or disengaged when mounting the carriage on the track. -

Page 13: Carriage Umbilical

CARRIAGE UMBILICAL The umbilical assembly provides communication between the Main Control Box and the PIPE KAT carriage, in addition to supplying cooling water, shielding gas and electrical welding ® power to the torch. The umbilical comprises of one control cable that provides power and communication to the carriage, two water hoses (supply and return), shielding gas hose and welding electrode cable. - Page 14 Connection to the PIPE KAT Main Control includes: ® 1) Additional 15 ft welding power supply electrode cable 2) One (1) large electrical connector for communication supply to the carriage 3) One (1) male plug for the shielding gas supply to the torch 4) Additional 15 ft of water cooling hoses (supply &...

-

Page 15: Remote Pendant

REMOTE PENDANT The Remote pendant is used in conjunction with the main control to provide adjustment during setup, initiate the weld cycle, provide fine adjustment during welding, and to stop the weld cycle. During setup the pendant is used to provide the following: Position the carriage to the welding start position Adjust oscillator center position Adjust torch height in relation to the pipe... - Page 16 RED POWER LED: The red LED is illuminated to indicate there is power to the pendant. It also flashes whenever there is an error code displayed on the controls. WIRE FEED SPEED TRIM OVERRIDE: This speed adjustment knob allows for fine adjustment in wire feed when the PIPE KAT is in auto cycle mode (welding), this serves as a fine ®...

-

Page 17: Pipe Kat ® Carriage

to control and maintain the quality of the welding process. Width is increased or decreased in 0.01 Inch/CM increments. OSCILLATION CENTER POSITION ADJUSTMENT: This adjustment knob allows the operator to adjust the center position of the torch oscillation while in the auto cycle mode (welding) or to jog the torch to the desired position prior to welding. - Page 18 WIRE FEED PINCH ROLLER PRESSURE ADJUSTMENT: Allows the operator to adjust and maintain roller pressure on the wire feeder. WIRE SPOOL TENSION ADJUSTMENT: Allows the operator to adjust and maintain spool tension EMERGENCY STOP: The emergancy stop button serves as a safety feature that will terminate all operations and shut down the PIPE KAT unit when pressed.

- Page 19 TORCH SLIDE: The Torch Slide provides 2” or [50.8 mm] of motorized torch tip-to-work vertical adjustment. Adjustment is achieved by using the Torch Slide Jog switch located on the Remote Pendant. TORCH PIVOT: Use the locking handle to adjust the angle of the welding torch to the pipe. TORCH MOUNTING BRACKET: This adjustment bracket mounts the torch to the motorized Torch Slide;...

-

Page 20: Main Control Box Operation

MAIN CONTROL BOX OPERATION NOTE: Make sure all electrical connections are connected before powering up the PIPE KAT ® Do Not disconnect any electrical connections while the power is ON, always power down the PIPE KAT before ® doing so. FRONT PANEL The main control unit houses all standard controls for the carriage. -

Page 21: Left Side Panel

LEFT SIDE PANEL The left side panel of the main control contains AC POWER the following features: CORD MAIN POWER ON/OFF SWITCH: This power switch provides power to AC POWER FUSE the main control, carriage and the remote pendant. MAIN POWER ON/ OFF SWITCH AC POWER CORD: The main control is available with three... -

Page 22: Right Side Panel

FLOW SWITCH (OPTIONAL): This connector is part of the optional Coolant Flow Switch Kit and is used to transfer a signal from the flow switch (not shown) to the control, indicating whether suitable coolant flow is present or not. The flow switch is mounted in-line with the coolant supply line. When there is sufficient coolant flow through the flow switch (setting adjustable by the operator) a relay closes. -

Page 23: Carriage Oscillator Control

CARRIAGE OSCILLATOR CONTROL This control operates the motorized linear oscillator slide that is mounted on the PIPE KAT ® carriage, which moves the welding gun laterally across the weld joint, for positioning and for oscillation of the weld. See below. It is a highly sophisticated, yet easy to use, multi- processor based control drives a high torque, high resolution, low vibration stepper motor located in the... -

Page 24: Oscillator Control Programming

The S rotary switch increases (clockwise adjustment) or decreases (counter- clockwise adjustment) the oscillation stroke speed. The increments of adjustment and the minimum and maximum allowable stroke speeds are dependent on the preferred units of measurement (see the Oscillator Motor Setup Screen later in this manual for details).The current value is displayed on the LCD screen. - Page 25 When in the programming mode, only the “A”, ”C” and the rotary switches and the Programming Button will be used. The “A” rotary switch is used to navigate forward and backward between screens (pages). rotary switch is used to navigate forward and backward between adjustable fields of the current screen (page).

-

Page 26: General Programming Mode

GENERAL PROGRAMMING MODE The sequence of level 1 (General Programming Mode) program screen displays is as follows: Rotate the A rotary switch clockwise to move forward through the screens. Rotate the A rotary switch counter-clockwise to move backwards through the screens. - Page 27 The Oscillator Control Features & Setup Screen Field Field The Features & Setup Screen has the following features: Field = The Auto Cycle storage number to be recalled. The number shown in this field will be the program that will be copied from storage and applied to the running (operational) mode values when exited from programming mode.

- Page 28 Oscillator Control Auto Cycle Storage Screens There are a total of ten (10) Auto Cycle Storage Screens, and each screen is identified by the “Auto Cycle Storage Number” (numbered 1 to 10) as shown in the following image. The units of measure for the oscillation width (W) and the oscillation speed (S) are programmable (level 2 - Advanced Programming Mode).

-

Page 29: Advanced Programming Mode

“DEGREES” is for use with radial oscillator heads only and not applicable for this model of PIPE KAT ). See the “Table of Oscillator Head Values” to find the Units ® of Travel per Step for common Gullco Oscillator Heads. - Page 30 The Oscillator Control Motor Board is located inside the control box that is mounted on the PIPE KAT carriage. ® Dip Switch S42: Switch # 1 Switch # 2 Setting Future use When used on a Gullco Pipe KAT ® Future use Future use...

-

Page 31: Pipe Kat Oscillator Control Error Codes

PIPE KAT OSCILLATOR CONTROL ERROR CODES ® Error codes are displayed on the LCD screen accompanied with the warning buzzer and flashing red L.E.D. on the Remote Pendant. ER.41 (Running condition problem) During normal operation of the linear oscillator if the control encounters an issue with controlling the linear slide the control will display ER.41. - Page 32 ER.44: (PWS main control communication) During normal operation of the PIPE KAT the main control communicates with the oscillator ® control, if for any reason this communication becomes corrupt ER.44 will be displayed on the control. ER.45: (Oscillator control keypad) The Oscillator control uses and keypad and a display located in the main control box.

-

Page 33: Oscillator Control Factory Defaults

OSCILLATOR CONTROL FACTORY DEFAULTS The default factory programming when shipped General programming screen Advanced programming screen (INCHES) Advanced programming screen (CM) C B A C B A... -

Page 34: Carriage Control

CARRIAGE CONTROL A highly sophisticated, yet easy to use, multi-processor based control that commands the carriage drive motor, the wire feeder, the vertical torch slide, the power source contactor signal, the shielding gas solenoid, the water cooler (optional) and interfaces with the Oscillator Control, and the coolant flow switch to provide a fully automated and programmable welding system. - Page 35 operator to navigate through the different fields (indicated by the selected field flashing) by rotating the knob either clockwise or counter-clockwise. PROGRAMMING BUTTON: The Program push button changes the control state from running (operational) mode to programming mode, and back to running mode. While-ever the control is in programming mode, the program icon on the lower right corner of the LCD screen will appear as follows.

- Page 36 A & C torch oscillation dwell orientation: This momentary push button allows the operator to set the orientation of the A & C dwell positions for the linear torch oscillator. This orientation is indicated on the display by an image of the welding torch shown next to an image that symbolizes the welding carriage.

- Page 37 CARRIAGE WELDING DIRECTION AND TORCH OSCILLATION DWELL POSITION The four (4) screens shown below depict the display on the Pipe KAT main control and the ® relationship between the carriage welding direction push button and the oscillation dwell position push button. Pushing the carriage direction push button toggles the welding direction of the Pipe KAT...

-

Page 38: Carriage Control Programming

CARRIAGE CONTROL PROGRAMMING There are two levels of programming General Programming Mode: this first level of programmable features is meant to be easily accessible to the operator and requires that the Program push button be pressed for a minimum of one (1) seconds, but no more than seven (7) seconds. The screens that are accessible under this mode are: o Screen 1:- Shielding gas preflow/Wire feed soft start speed. -

Page 39: General Programming Mode

GENERAL PROGRAMMING MODE While the carriage is stopped, i.e. not in a weld cycle, press the program push button for a minimum of one (1) second but no more than seven (7) seconds to go from the main screen to the General Programming Screen 1. -

Page 40: Advanced Programming Mode

ADVANCED PROGRAMMING MODE While the carriage is stopped, i.e. not in a weld cycle, press the program push button for a minimum of eight (8) seconds to go from the main screen to the Advanced Programming Screen1. To navigate between the advanced programming screens press the Auto Cycle Stop push button. - Page 41 Carriage Maximum Speed Adjustment: This sets the maximum speed at which the motor control will allow (the speed is capped at this set percentage). The variable value range is from 1 to 100 percent of full speed, in increments of 1%. Factory set at 100. Screen 3: Wire Feed Over-Current: This sets the maximum current draw that the wire feed motor control will allow before activating an error code and...

- Page 42 Example: For the screen shown to the right it was determined the welding power source being used had a welding voltage range of 1- 40 volts, it was also verified that the remote analog control signal for welding voltage was 0-10 VDC. Information for the wire feed speed showed that the standard wire feeder that is normally used with this power source had a speed range 0 to 1000 IPM (inch per minute), it was also verified that the remote...

-

Page 43: Pipe Kat ® Carriage Control Error Codes

PIPE KAT CARRIAGE CONTROL ERROR CODES ® These codes are displayed on the Carriage Control accompanied with the warning buzzer and flashing red L.E.D. on the Remote Pendant. In addition the codes will be stored on the advanced programming screen (5) for diagnostic purposes. The codes are cleared by correcting the problem and pressing the Auto Cycle Stop push button after correcting the problem. - Page 44 Er.95: Vertical torch slide motor limit switch – no limit switch signal. Er.97: Vertical torch slide motor control board high temp – temperature of torch slide motor control board has exceeded 96°C [205°F]. Er.51: Main control box I/O board: the I/O board (PK-200-307) located in the main control box has malfunctioned.

-

Page 45: Carriage Control Factory Defaults

CARRIAGE CONTROL FACTORY DEFAULTS The default factory programming when shipped General programming (INCHES) General programming (CM) Screen (1) Screen (1) Screen (2) Screen (2) Advanced programming (INCHES) Advanced programming (CM) Screen (1) Screen (1) - Page 46 Screen (2) Screen (2) 44.2 Screen (3) Screen (3) 1608 Screen (4) Screen (4) Screen (5) Screen (5)

-

Page 47: Automatic Cycle Operation

AUTOMATIC CYCLE OPERATION Preparation for an Automatic Weld Cycle: 1. Mount the Pipe Band (track) on the pipe as described on page 7. 2. Mount the carriage to the Pipe Band (track) as described on page 8. 3. Connect the umbilical cable/hose assembly between the PIPE KAT carriage and the ®... -

Page 48: Automatic Cycle Sequence Of Events

19. If a test cycle is to be performed (simulated auto cycle, without activation of the: wire feed motor; weld contactor signal; or gas solenoid valve), place the Weld Enabled/Disabled switch in the Disabled ( ) position. 20. When ready, press the Auto Cycle Start push button ( ), located on the Remote pendant, for two (2) seconds or more. - Page 49 10. Upon Completion of the Crater-Fill Duration the wire feed will stop and the Burn-Back Duration timing cycle is initiated (see page 35). 11. Upon completion of the Burn-Back Duration the Remote Arc Start Relay is de-energized (opening the welding power source’s remote contactor circuit) and the Shielding Gas Post-Flow Duration timing cycle is initiated (see page 35).

-

Page 50: Optional Equipment

OPTIONAL EQUIPMENT COOLANT FLOW SWITCH KIT: With the integration of this coolant flow switch, the PIPE KAT ® system will only permit welding when the flow switch detects suitable coolant flow through the torch, preventing welding problems and torch damage due to overheating, P/N PK-200-174. WATER COOLER POWER INTERFACE KIT: This interface allows the PIPE KAT control to ®... - Page 51 CARRIAGE UMBILICAL EXTENSION ASSEMBLY: Extension Assembly provides an additional 25ft of length to the carriage umbilical assembly P/N PK-500-163-G/N/W. The maximum combined total length of Carriage Umbilical assembly and Extension assembly must not exceed 50ft. Distances over 50ft will result in communication signal loss between the Main Control and Carriage causing erratic operation of the PIPE KAT system.

- Page 52 REVISION LIST July 2012 Manual release...

- Page 54 www.GULLCO.com...

Need help?

Do you have a question about the Pipe Kat PK-500-LG Series and is the answer not in the manual?

Questions and answers