Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Otis Elevator HydroFit

- Page 1 Owner’s Information Manual HydroFit Elevators Otis Elevator Company...

- Page 2 This publication is intended for those individuals or organizations in ownership of HydroFit elevator system and equipment manufactured and sold by Otis Elevator Company. It is expressly designed to be informative and to offer a limited understanding of the operation of these systems.

- Page 3 Table of Contents Preface........................... i Chapter 1: About Otis Elevator ..................1 Chapter 2: Performance and Safety................11 Chapter 3: Your HydroFit Elevator ................14 Chapter 4: Maintaining Your HydroFit Elevator............43 Chapter 5: Otis Maintenance and Service ..............53...

- Page 4 HYDROFIT™ Owner’s Information Manual Preface Thank you for your recent purchase of the Otis Elevator HydroFit™ system. Your new HydroFit system meets the highest safety and performance standards available in the market today. Otis has built a reputation based on quality, reliability and an OSHA-proven record of safety that’s the best in the business.

- Page 5 HYDROFIT™ Owner’s Information Manual Use of Warnings It is essential that you realize your Otis elevator is a complex piece of machinery and ssential that you realize your Otis elevator is a complex piece of machinery and ssential that you realize your Otis elevator is a complex piece of machinery and should be serviced only by a trained, authorized elevator mechanic.

- Page 6 HYDROFIT™ Owner’s Information Manual Chapter 1: About Otis Elevator Otis Elevator Company has a long and interesting history that began in the mid- nineteenth century with its founder, Elisha Graves Otis. In 1852, while employed by the Yonkers Bedstead Manufacturing Company in Yonkers, New York, Otis built a hoisting machine with a safety mechanism that prevented the platform from falling if the hoisting rope broke.

- Page 7 HYDROFIT™ Owner’s Information Manual The next problem to overcome was development of a power source to run passenger elevators. Factories warehouses with freight elevators were near water, but passenger elevators would be installed in stores, office buildings, and hotels, away from any central power source (this was 22 years before the opening of the first U.S.

- Page 8 But no French company could overcome the structural demands of putting elevators inside the tower’s curved legs. Otis Elevator successfully installed elevators, giving the company a chance to display its product at the fair’s centerpiece attraction.

- Page 9 1900s, a time when “big business” flourished. Otis Brothers & Co. merged in 1898 with several U.S. elevator companies in Boston, Chicago, and Philadelphia to become the Otis Elevator Company. Forty more, small, independent elevator companies were acquired during the period prior to World War I.

- Page 10 1969: Electric Cart United Technologies purchased the Otis Elevator Company in 1975. Otis became a wholly owned subsidiary in 1976. One of the most significant developments in elevator technology was the use of computer chips to make elevator control decisions.

- Page 11 Remote Elevator Monitoring (REM ) system, which was introduced in 1985 and installed at an Otis elevator site in the United Kingdom. REM systems monitor elevators 24 hours a day and provide diagnostic information via a telephone line to our technical center. This information assists our technicians in preventing elevator disruptions.

- Page 12 HYDROFIT™ Owner’s Information Manual ® Another important technological advance—the Elevonic 411 software based control system—was released by Otis in 1990. These sophisticated Elevonic systems made “real-time” dispatching rules based on changing traffic conditions in a building. They also managed elevator ride quality, energy consumption, motor performance, and all the in-car information displays.

- Page 13 HYDROFIT™ Owner’s Information Manual Some other Otis products include: ™ Gen2 Elevator System: The first major breakthrough in elevator lifting technology in nearly 150 years. Gen2, an elevator system for low- and mid- rise buildings, is the first to use flat coated steel belts to lift the elevator cars.

- Page 14 HYDROFIT™ Owner’s Information Manual Elevator monitoring systems provide comprehensive information about elevator condition, status, and performance. Today, Otis is recognized as the elevator industry leader, maintaining more than 1.7 million elevators and escalators worldwide. It is an $11.6 billion (U.S. dollars) company with 60,000 employees.

- Page 15 HYDROFIT™ Owner’s Information Manual HYDROFIT™ Owner’s Information Manual Chapter 2: Performance and Safety Chapter 2: Performance and Safety If anything improper is discovered, corrective action must be taken If anything improper is discovered, corrective action must be taken If anything improper is discovered, corrective action must be taken immediately.

- Page 16 HYDROFIT™ Owner’s Information Manual Do the passengers have enough time to enter and exit before the doors close? There are a number of variables that determine the door’s opening cycle. The minimum time may depend on the number of elevators in the bank and on the distance from a point in the center of the lobby to each elevator.

- Page 17 HYDROFIT™ Owner’s Information Manual with passengers helps to alleviate or avert panic. At these times, information from passengers can be of great assistance to emergency personnel. Is the interior of the elevator adequately lit? Check that all light switches are on, all lamps are lit, and all light diffusers are clean to permit maximum transmission of light.

- Page 18 HYDROFIT™ Owner’s Information Manual Firemen’s Service/Special Emergency Service allows control of elevator operation in the event of fire or other time-sensitive emergencies, particularly where immediate access to specific building areas or floors is necessary. Fireman’s Service has two separate operations, or phases.

- Page 19 Today's elevators provide a safe, rapid means of passenger transportation. In large part, this is due to advances in elevator technology. The intent of the information presented here is to provide you with a general understanding of how your HydroFit™/HydroAccel elevator system is designed and how it operates.

- Page 20 HYDROFIT™ Owner’s Information Manual Elevator Operation In order to gain further understanding of how a HydroFit™/HydroAccel elevator system works, let’s take you through a typical sequence of operation. A passenger registering an elevator call sets into motion a series of actions. The signal is first picked up by the controller, which acknowledges the request by illuminating an indicator on or near the call button.

- Page 21 HYDROFIT™ Owner’s Information Manual The Microprocessor Controller The controller is the central nervous system of the elevator. The controller assembly houses electrical, electronic, and microprocessor components that provide three main areas of control: motion, operation, and door control. It is here that all signals are processed.

- Page 22 HYDROFIT™ Owner’s Information Manual Otis Field Tool (OFT) provides the maintenance mechanic with a quick means of troubleshooting the elevator’s controller. He or she can make parameter changes, monitor elevator car status, and perform routine diagnostics. By manipulating the buttons, the Otis mechanic can toggle through various display functions.

- Page 23 HYDROFIT™ Owner’s Information Manual The third method used to obtain performance information is through the visual means of Light Emitting Diodes, or LEDs. LEDs will turn on or off depending upon the function taking place. The mechanic will use the visual feedback to verify whether or not the function is working properly.

- Page 24 HYDROFIT™ Owner’s Information Manual The ERU not only improves passenger safety, but it also installs quickly with little disruption to building tenants. Your elevator has a supplemental emergency supply of power provided by a 12-volt DC battery unit. It is located within a top-of-car integration box mounted to the top of the elevator car.

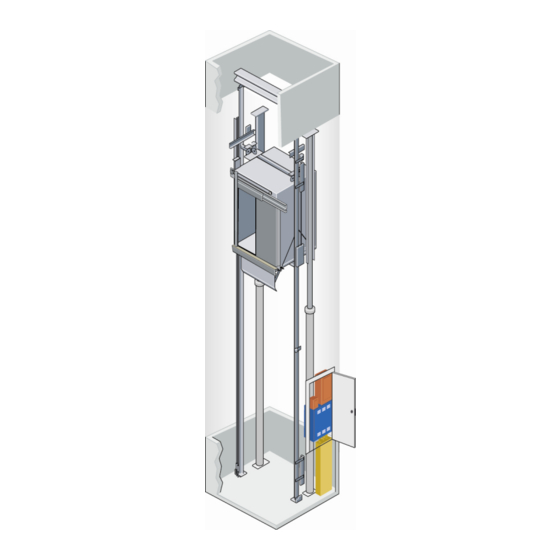

- Page 25 HYDROFIT™ Owner’s Information Manual In the hydraulic elevator, it is the volume of oil being added into the cylinder (and not the pumping action of the pump) that causes the plunger to lift. The pump does not pump pressure, it only produces flow. Pressure results from the restriction of the hydraulic oil to flow.

- Page 26 HYDROFIT™ Owner’s Information Manual HydroFit™ Machine-Roomless Tank The Motor The function of the motor is to provide the necessary torque to the hydraulic pump. The motor has been used for decades to provide efficient, low-maintenance power over long periods of time. Hydraulic elevator motors generally range between 15 horsepower (hp) and 40 hp.

- Page 27 HYDROFIT™ Owner’s Information Manual Solid-State starting uses power semiconductors instead of contactors. Unlike contactors, power semiconductors can be switched on and off at very high speeds and at specific times during the three-phase 60 Hz power cycle. By controlling the semiconductor’s on/off function during the power cycle, the current can be controlled.

- Page 28 HYDROFIT™ Owner’s Information Manual viscosity and the oil cleanliness are important factors for the hydraulic system to operate at peak performance level. The pump is equipped with a strainer to prevent debris from entering the inlet line toward the control valve.

- Page 29 The length of these components depends on the type of hydraulic arrangement: HydroFit™ is a holeless type arrangement; the cylinders are mounted to the building’s foundation (above ground).

- Page 30 HYDROFIT™ Owner’s Information Manual of 90 degrees for six minutes, the system activates an oil recycling operation. The recycle operation starts the motor pump, which brings the oil back to the tank. The operation of the motor pump and the friction of the oil from its own natural resistance to flow causes the oil to heat.

- Page 31 HYDROFIT™ Owner’s Information Manual Limit/Stopping Switches are a backup system to stop the elevator in the unlikely event it should travel beyond the top or bottom landings. This is a safeguard against a communication breakdown in the positioning system. Elevator safety is Otis’...

- Page 32 HYDROFIT™ Owner’s Information Manual The alarm button and emergency stop switch located in the car operating panel are wired into the emergency power circuitry. When operated, an alarm bell located on the car top sounds continuously. Emergency Communication Devices The choice depends on the equipment and services specified for your particular elevator, including: ...

- Page 33 HYDROFIT™ Owner’s Information Manual Access Fixture Assembly Access Fixtures are usually mounted in the entrance jamb and are used by service technicians. They contain keyswitch/es for special operation of zoned access, which allows the elevator to be moved (within defined distance and speed limits) with the landing and car doors open.

- Page 34 HYDROFIT™ Owner’s Information Manual Telephone/Service Cabinet A telephone cabinet is an optional cabinet mounted below the car operating panel and contains a communication device (telephone or intercom provided by others). A service cabinet can contain special keyswitches as ordered. Hands-Free Phone A Hands-Free Phone is a device that helps trapped or disabled passengers call for help.

- Page 35 HYDROFIT™ Owner’s Information Manual Anti-Nuisance If an excessive number of car calls are registered, the elevator will determine whether calls should be canceled. This is a function of passenger load and predetermined weight settings. Automatic Car Return Operation Automatic Car Return Operation causes the car to park at a specified landing when there is no further demand.

- Page 36 HYDROFIT™ Owner’s Information Manual Hall Buttons—Illuminated Hall Fixtures employ mechanical LED illuminated buttons. Hall Button Protection If the hall button communication network link fails, all of the cars in the group enter Hall Button Protection operation. Each car answers all pending car calls. When each car has no further demand, each car travels to the lobby and parks with the doors open.

- Page 37 HYDROFIT™ Owner’s Information Manual Door Time Monitoring When the car door protective device is activated after the car has stopped to answer a hall call, the door open time is reduced from the normal setting for a hall call stop.

- Page 38 HYDROFIT™ Owner’s Information Manual Separate Basement Zone This feature is used where substantial traffic is expected from the basement area (such as would occur in a large basement garage) and there are sufficient elevators in the group to create a single floor lobby zone and a separate basement zone.

- Page 39 HYDROFIT™ Owner’s Information Manual Group: Group Dispatching Features Relative System Response Dispatching Relative System Response (RSR) is a numeric index that indicates the desirability of having a given car respond to a given hall call based on the car’s parameters (position, direction, load, etc.) and the car’s previously assigned demands for service...

- Page 40 HYDROFIT™ Owner’s Information Manual cars travel only to the highest car call and then reverse direction to the lobby. Cars bypass hall calls, stopping only in response to car calls. This operation remains in effect until a car arrives at the lobby.

- Page 41 HYDROFIT™ Owner’s Information Manual remain open until the door close button is activated. When the Phase II keyswitch is in the hold position, the car parks with its door open, the door closed button is disabled, and car calls cannot be registered.

- Page 42 HYDROFIT™ Owner’s Information Manual Card Reader Lockdown When this feature is enabled, the car responds only to hall calls from a card reader. When Card Reader in Hall security is activated, the Card Reader Lockdown feature parks the car at a specified landing and takes it out of service, removing it from group operation.

- Page 43 HYDROFIT™ Owner’s Information Manual Riot Operation This feature is invoked by a keyswitch that prevents cars from returning to the main lobby during periods of riot control. Group: Enhanced Service and Operation Features Attendant Operation Attendant operation is activated from a keyswitch mounted in the car operating panel.

- Page 44 HYDROFIT™ Owner’s Information Manual Express Priority Service (Hospital) A keyswitch initiates Express Priority Service at each landing requiring this service. The car able to respond in the shortest time answers the call after first canceling all registered car calls. When the car reaches the landing, one of the following occurs: ...

- Page 45 HYDROFIT™ Owner’s Information Manual Wild Car Operation Wild Car Operation is an option used when communications carrying registrations for hall calls fails. In that event, all elevators that make up the group complete their car calls until there is no further demand and then each elevator in the group parks at its lobby and takes itself out of service.

- Page 46 HYDROFIT™ Owner’s Information Manual message, and the storage of events and alarms. The personal computer allows display of up to eight 8-car groups on the same monitor. Intercom (Provision) An optional provision is made in the main car operating panel (auxiliary car operating panel if the main car operating panel includes speech synthesis) for a speaker and/or microphone.

- Page 47 HYDROFIT™ Owner’s Information Manual C ar(s) on Firefighters’ Service Phase II. C ar(s) designated by contract to be selected. F irst available car beyond the car(s) designated by contract. If a car selected for normal operation under Standby Power Operation is delayed for 60 seconds, it is placed in a “Not Available”...

- Page 48 Failure to use genuine Otis parts may invalidate any guarantee and may adversely affect the safety of your elevator. Refer to Otis Elevator Company for further information. For safety reasons, only a trained elevator maintenance technician may perform the operations listed in this chapter.

- Page 49 HYDROFIT™ Owner’s Information Manual 2. Ensure ventilation fans and grills are clean and functioning. 3. Keep all parts clean. 4. Ensure cabinet doors are locked shut after inspection. Landing Fixtures Turn off power before working on any fixtures. 1. Check the operation of all fixtures.

- Page 50 HYDROFIT™ Owner’s Information Manual Car Entrance and Operator Do not ride on the car top unless the cart is on inspection operation. Whenever the car is stopped, immediately activate the emergency stop switch. When working on the car doors, ensure the main power is off.

- Page 51 HYDROFIT™ Owner’s Information Manual 3. Investigate any unusual noise, heat, or vibration. 6. Check the condition and adjustment of the cab steadier devices. 7. Check the traveling cables for correct hang and signs of damage. Pit Equipment Do not enter the pit without the power switched off or the pit stop switch activated.

- Page 52 Protect all vulnerable surfaces from damage, especially when an elevator is used for moving furniture or equipment or similar non-passenger activities. Protective pads may be obtained from Otis to protect your elevator. Otis Elevator Company recommends the following cleaning techniques: Glass Clean with a non-abrasive glass cleaner and a soft lint-free cloth.

- Page 53 HYDROFIT™ Owner’s Information Manual Inspection Requirements Controllers Wires. Examine all wiring for breaks, loose lugs, or loose connections. Resistance Tubes. Inspect for loose connections. Examine tubes for breaks in the enamel. Replace broken resistance tubes with tubes of equal value.

- Page 54 HYDROFIT™ Owner’s Information Manual Car Top Fastenings. Check and tighten the fastenings if required. Cab Steadier Plates. Check and tighten cab steadier plates if needed. Roller Guides. Check the roller guides for wear, proper clearances, and adjustments. Plungers. Check seals for leaking.

- Page 55 HYDROFIT™ Owner’s Information Manual Conduit Check the fastenings and ensure the conduit has not pulled out of the fittings and that the duct is securely fastened to the wall. Limit Switches and Cams Rollers. Check the roller guides for wear and replace if they do not engage cams properly.

- Page 56 HYDROFIT™ Owner’s Information Manual Manual Rescue Operation is to be used only after all other means to evacuate trapped passengers have been considered. Basic Escape/Evacuation Rules These rules apply in all cases and must be followed with any type of evacuation.

- Page 57 HYDROFIT™ Owner’s Information Manual A trained mechanic should perform a quick diagnostic check from the machine room to: o Check for power. o Check for blown fuses. o Check for tripped overload. o Check for contact(s) not making.

- Page 58 HYDROFIT™ Owner’s Information Manual Chapter 5: Otis Maintenance and Service Elevator maintenance is more than just returning an elevator to service after an elevator shutdown occurs. Since elevator systems are a significant investment, proper maintenance on this equipment is critical to extend the life of the equipment and reduce the possibility of unscheduled disruptions or shutdowns.

- Page 59 HYDROFIT™ Owner’s Information Manual Because REM constantly monitors an elevator’s performance, it can identify imminent problems that are fixable during a routine maintenance visit. If it finds a major problem, REM automatically sends a message to a customer care center and an Otis service mechanic is dispatched within minutes of the call.

- Page 60 HYDROFIT™ Owner’s Information Manual not only test products, but also perfect installation and service methods before they are implemented. Finally, Otis offers many forms of preventative maintenance programs designed to extend the life of elevator and escalator equipment. Monitoring and maintaining equipment properly also allows for the safest, most reliable performance possible.

Need help?

Do you have a question about the HydroFit and is the answer not in the manual?

Questions and answers

how to change the battery in OTIS elevator