Summary of Contents for Faudi AFGUARD AFG Series

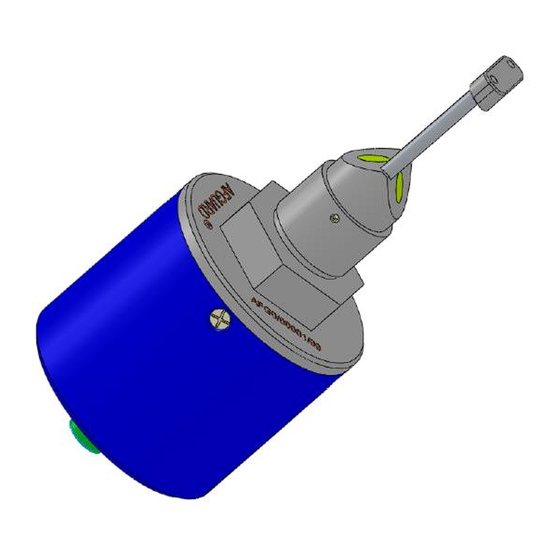

- Page 1 Version 2.2 Operating instructions ® AFGUARD Page: Zone 0/1 type Sensor for the measurement of free water in Jet Fuel FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch...

-

Page 2: Table Of Contents

® Cleaning of the AFGUARD ................29 Accessories ......................30 Connection accessories ..................30 Installation accessories ..................33 Trouble-shooting ....................34 10.1 Trouble-shooting instructions ................34 10.2 Sensor checks ....................34 10.3 Spare parts ......................34 10.4 Return .........................34 FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch... - Page 3 EC-Type Examination Certificate (Original) ............37 12.1 EC-Type Examination Certificate (Tranlsation) ............40 12.2 PESO Certificate for India ...................43 EG-Konformitätserklärung – EC Declaration of conformity ........44 12.3 Issues and solutions....................45 Declaration of decontamination ................47 FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch...

-

Page 4: Safety Instructions

All changes of the standard analyser with parts which are not specified or approved by FAUDI Aviation Sensor GmbH as well as repair and service with not specified parts mean a loss of the Ex-Certificate. -

Page 5: Designated Use

12 of the Operating Instructions) with the packaging and in addition, the shipping documents. No repair is possible without the completed "Declaration of Decontamination"! For optimized shipment – please contact FAUDI-Aviation Shipping department in front of shipment. FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf... - Page 6 This symbol indicates important items of information. Warning! This symbol alerts you to possible faults which can end in explosion. They can cause serious damage to the instrument or to persons if ignored. FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch...

-

Page 7: Identification

It is born according the following attributes Engraved Serial No: AFGX/XXXXX/a Year of construction Serial number (5 digits) 0 = Ex-Version zone 0/1 1 = Non-Ex-Version 2 = Ex-Version zone 2 Name FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch... - Page 8 15 - 30 V DC 4 – 20 mA D 35260 Stadtallendorf www.faudi-aviation.com Signal output Germany ® Picture: Nameplate of a Hazardous area approved version of the AFGUARD hazardous area Zone 2 FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch...

- Page 9 Serie, Non-Ex-Version; Ex-Version Zone 0/1 and Zone 2 Intended use : Civil, Military, Offshore Power supply Direct current voltage: DC 24 V, Measurement ranges: 0 to 50 ppm or 0 to 100 ppm on request Languages: German, English… FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch...

-

Page 10: Scope Of Delivery

Blue cable with Sensor plug connector 10 m length, o Operating Instruction – behind the cover - foam o Calibration protocol If you have any questions, please ask your local supplier or distributor. FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch... -

Page 11: Installation And Dismantling

The original packaging offers the best protection. Also, keep to the approved ambient conditions (see "Technical data"). If you have any questions, please contact your supplier or your sales centre responsible. FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch... -

Page 12: Installation Conditions

Do not mount the AFGUARD overhead. Make sure that there is enough space inside the pipe to prevent contact between the rear wall and the mirror during assembling – space for proper installation. FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch... -

Page 13: Thread For Afguard Installation

AFGUARD uses special threads to be weld into the pipe section. Threads are available in Stainless steel and Aluminium. Ensure to only use FAUDI-Aviation treads as they do have special design. Standard threads do not work with AFGUARD. Welding instruction is part of each thread delivery. -

Page 14: Procedure For Proper Afguard ® Installation

Page: Zone 0/1 type ® 3.3.2 Procedure for proper AFGUARD installation Step 1: Select the best place for installation in the effluent pipe section. Have a look on the assembly area: FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch... - Page 15 AFGUARD® socket stainless steel FAUDI article number: 600355 HSS cylindrical saw 54mm for a hand drilling machine AFGUARD® socket aluminium FAUDI article number: 600356 Please have a look on the welding instruction. FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch...

- Page 16 After welding, it is recommended to thread the socket with a G3/4”-thread cutter. Step 7: Proceed a pressure test to ensure the required PN rating of the pipe section. Step 8: Reassemble the pipe section (ensure to use good working seals). FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch...

- Page 17 Use the special AFGUARD® torque spanner to achieve the recommended torque of 50Nm. Step 10: AFGUARD spanner FAUDI article no 600513 Connect the AFGUARD® to the control system of the truck / tank farm by the use of the blue two wire cable.

-

Page 18: Afguard Orientation In The Pipe Section

820 nF 4 mH Contact FAUDI Aviation highly recommends the use of isolating converters with transmitter supply. Especially for use in hazardous area the use of inherent safe isolating converters is a must. Protection class can be „ia“ or „ib“. -

Page 19: Installing A Measuring Point

This should be done in front of installation. If you are not sure on how to proceed – please call FAUDI Aviation Sensor GmbH. Example: Combination of AFGUARD (Ex ia IIB) together with RN 221N (E+H) -

Page 20: Installation Examples

AFGUARD Page: Zone 0/1 type FAUDI Aviation highly recommends the use of isolating converters with transmitter supply. Especially for use in hazardous area the use of inherent safe isolating converters is a must. Protection classes „ia“ or „ib“ are allowed. -

Page 21: Check Of Correct Assembly

Clean the Sensor and check it carefully. To send the Sensor back for service purposes please fill out the attached declaration of decontamination (chapter 12). Use the original transport box for storage or transport. FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch... -

Page 22: Cabling

Ensure that there is no voltage at the power cable before beginning the connection work. It is only permitted to use the cable specified from FAUDI Aviation Sensor GmbH. For direct connection between the AFGUARD and the recommended isolated converter with transmitter supply FAUDI Aviation Sensor delivers 10 m of two wired cable with isolated plug adapter M12*1. -

Page 23: Operation

The AFGUARD consists of the following functional units: Sensor head with optics and mirror fixed via threaded pins. Housing with electronic and connection adapter for plug connector with three wired cables. FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch... -

Page 24: Mode Of Operation

Fuel with free water: Free water in Jet Fuel as fine dispersed second phase will be detected as scattered light by receiver C. During the whole process the self checking functionality of the electronics is ongoing. FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch... -

Page 25: Signal Output

AFGUARD leaves the factory calibrated for 0 to 50 ppm Jet A1. Other calibration curves could be adjusted in front of use. To optimize the accuracy of measurement FAUDI is going to develop a check tool set for onsite calibration checks. - Page 26 Version 2.2 Operating instructions ® AFGUARD Page: Zone 0/1 type Signal output: ® AFGUARD readout curve depending on calibration status. FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch...

-

Page 27: Commissioning

Cable / Connector damaged – check against cable break No signal: < 3,8 mA: Self check / Sensor damaged ® Between 4..20 mA: AFGUARD submerged in Jet Fuel ® > 20,2 mA: AFGUARD in Air or submerged in Water FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch... -

Page 28: Loop Check

® AFGUARD Page: Zone 0/1 type 7 Loop check FAUDI developed a special device to check the loop behind the AFGUARD to ensure that critical signals from the AFGUARD will be handled as required. ® Test protocol AFGUARD loop test... -

Page 29: Maintenance

Especially when using the AFGUARD together with self-cleaning, hydrophobic coating – avoid contact of optical elements like glass rods or mirror. We offer a special cleaning kit for our AFGUARD. Please contact our Sales Department. FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch... -

Page 30: Accessories

Display for the insitu display of measuring readings. Data log for reading and recording measurement readings. The following types are available: To make installation as easy as possible, FAUDI defined so called bundles that could be used for easy installation. - Page 31 Description: Blue LED warning light 24 V DC IP66 Linked with: Contamination Control System Silver (740000) Light indicator according JIG bulletin 110 to indicate warning and or alarm situation in case of critical levels of free water. FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch...

- Page 32 Loop tester to periodically test the loop of the AFGUARD installation according to JIG requirement. AFGUARD® torque spanner Order reference: 600513 Description: AFGUARD® Torque Spanner To install the AFGUARD sensor with the right torque setting of 50 Nm. FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch...

-

Page 33: Installation Accessories

Please ask for details according the mentioned electronic accessories. Installation accessories Optional torque wrench with spanner insert SW36 Optional ¾“ sleeve for welding into pipe lines (aluminium/stainless steel) Spare gaskets for 3/4“ sleeve connection. FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch... -

Page 34: Trouble-Shooting

No repair without completed "Declaration of Decontamination"! 10.5 Disposal The device contains electronic components and must therefore be disposed of in accordance with regulations on the disposal of electronic waste. Please observe local regulations. FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch... -

Page 35: Technical Data

Materials (in contact with Sensor head: SS 1.4301 medium) Glass rod: optical Glass Sealing: Klingersiel FKM intern G3/4“ Process connections: Thread: Length of thread: 25 mm Wrench size: AF 36 mm FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch... - Page 36 ® AFGUARD Page: Zone 0/1 type Torque setting: < 70 Nm (50 Nm recommended) Cable connection Sensor plug Length of cable Delivered length: 10 m specification: manufacturer Binder Temperature internal compensation FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch...

-

Page 37: Ec-Type Examination Certificate (Original)

Version 2.2 Operating instructions ® AFGUARD Page: Zone 0/1 type 12 EC-Type Examination Certificate (Original) FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch... - Page 38 Version 2.2 Operating instructions ® AFGUARD Page: Zone 0/1 type FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch...

- Page 39 Version 2.2 Operating instructions ® AFGUARD Page: Zone 0/1 type FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch...

-

Page 40: Ec-Type Examination Certificate (Tranlsation)

Version 2.2 Operating instructions ® AFGUARD Page: Zone 0/1 type 12.1 EC-Type Examination Certificate (Tranlsation) FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch... - Page 41 Version 2.2 Operating instructions ® AFGUARD Page: Zone 0/1 type FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch...

- Page 42 Version 2.2 Operating instructions ® AFGUARD Page: Zone 0/1 type FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch...

-

Page 43: Peso Certificate For India

Version 2.2 Operating instructions ® AFGUARD Page: Zone 0/1 type 12.2 PESO Certificate for India FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch... -

Page 44: Eg-Konformitätserklärung - Ec Declaration Of Conformity

Version 2.2 Operating instructions ® AFGUARD Page: Zone 0/1 type EG-Konformitätserklärung – EC Declaration of conformity 12.3 FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch... -

Page 45: Issues And Solutions

® How can I assure that the AFGUARD The marking in vicinity of the screw nut properly installed/positioned? SW36 should be located across to the foot. (BASE) FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch... - Page 46 It is more or less a volume based signal that should be multiplied with the density of particulate matter to have an idea about the mass. FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch...

-

Page 47: Declaration Of Decontamination

............. Description: ............... Reason for Return:: Company data: Company: ............. Contact Person: ............. Street: ............. address: ............. Tel: ............. Fax: ............. E-Mail: ............. Your order no: ............. Place, Date, Signature: __________________________________________________ FAUDI Aviation GmbH, Scharnhorststraße 7 B, D-35260 Stadtallendorf BA_AFGUARD_Ex_rev2.2_Englisch...

Need help?

Do you have a question about the AFGUARD AFG Series and is the answer not in the manual?

Questions and answers