Summary of Contents for Acson international A5MAC 210D

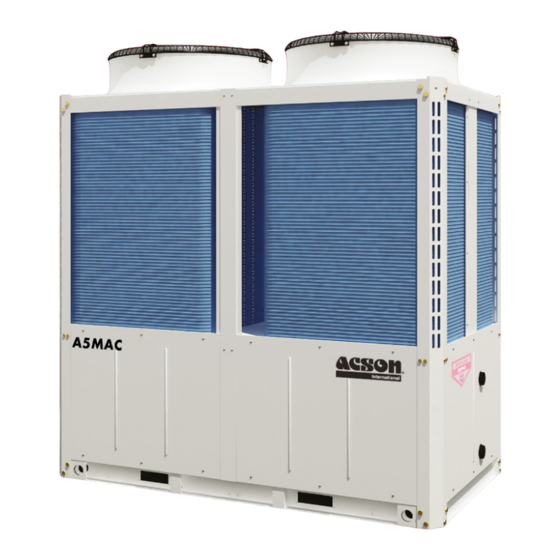

- Page 1 Technical Manual AIR COOLED MODULAR CHILLER A5MAC 210D A5MAC 230D A5MAC 340D A5MAC 450D...

-

Page 2: Table Of Contents

Literature No.: TM-A5MAC-D-201701 Supersedes: - Contents Model Series ................................2 Nomenclature................................2 Overview................................... 2 Features..................................3 ................................5 Dimensions ................................8 Performance Data ..............................10 Water Pressure Drop Curve ..........................13 Sound Data ................................13 Wiring Diagrams ..............................14 Installation ................................19 Water System Installation ............................. -

Page 3: Model Series

Model Series Model Name Max Combination Qty Capacity Range Cooling Capacity: 60kW - 960kW A5MAC210D Cooling Capacity: 205MBH - 3280MBH Cooling Capacity: 65kW - 1040kW Cooling only A5MAC230D Cooling Capacity: 222MBH - 3,552MBH Cooling Capacity: 135kW - 2160kW A5MAC450D Cooling Capacity: 461MBH - 7378MBH Cooling Capacity: 100kW - 1600kW Heat Pump A5MAC340DR... -

Page 4: Features

Features Refrigerant ACSON is committed to protecting the global ecosystem and has developed air-cooled chiller/heat pump with R410A, a new type of refrigerant. Without chlorine, the R410A causes no harm to the ozonosphere (ODP=0). Low Sound Level Thanks to the newly designed spiral blades, the outdoor units feature smooth air flow, signi cantly reducing the turbulence and lowering the air flow sound level. - Page 5 Outstanding Performance A5MAC-D series features leading-edge scroll technology and branded accessories which go through our stringent reliability and compatibility test. Equipped with efficient scroll compressors and precise electronic expansion valves. These units feature high EER and COP, especially at partial loading. Intelligent Control System A5MAC-D features user-friendly intelligent control system.

- Page 6 General Data - R410A MODEL A5MAC210D A5MAC230D A5MAC340DR A5MAC450D 18.5 38.4 28.3 NOMINAL COOLING CAPACITY NOMINAL HEATING CAPACITY RATED POWER INPUT (COOLING) 18.8 19.2 40.3 29.6 RATED POWER INPUT (HEATING) 29.9 Btu/h/W 10.9 11.5 11.4 COP W/W 3.19 3.39 3.35 3.38 RATED RUNNING CURRENT (COOLING) 35.5...

- Page 7 Components Data - R410A MODEL A5MAC210D A5MAC230D A5MAC340DR A5MAC450D TYPE BRAZED PLATE HEAT EXCHANGER PLATE MATERIAL STAINLESS STEEL NOMINAL COOLING WATER FLOW m³/h 10.3 11.2 17.2 23.2 EVAPORATOR NOMINAL HEATING WATER FLOW m³/h 17.2 WATER VOLUME 6.56 10.97 PIPING CONNECTION Rc 2 Rc 2 1/2 UNIT WATER PRESSURE DROP...

-

Page 8: Safety Devices

Electrical Data - R410A MODEL A5MAC210D A5MAC230D A5MAC340DR A5MAC450D RATED RUNNING CURRENT H/L 2.5/1.7 3.96/2.64 FAN MOTOR MOTOR OUTPUT 1300 POLES (H/L) 6/10 FAN SPEED 780/477 920 / 750 RATED RUNNING CURRENT 19.22 20.8 20.8 COMPRESSOR LOCKED ROTOR AMP (LRA) IP/INSULATION GRADE IPX4/F UNIT OPERATING CURRENT... -

Page 9: Dimensions

Dimensions Air-conditioner water outlet Rc2" Modular Air Cooled Chiller/Heat Pump A5MAC210D, A5MAC230D Mounting hole of anchor bolt 14-14x20 地脚螺栓固定孔 14-14x 20 95 0 95 0 101101 14x20 Enlarged drawing for 14x20 地脚螺栓固定孔放大图 Mounting hole of anchor bolt 199 0 84 0 Air-conditioner 空调进水... - Page 10 Modular Air Cooled Chiller/Heat Pump A5MAC340D A5MAC450D RC 2 1/2 Water inlet RC 2 1/2 Water outlet Wiring port Model A(mm) B(mm) Unit: mm A5MAC340DR...

-

Page 11: Performance Data

Performance Data Operating Range A5MAC210/230D Note: Ensure that the water flow is within flow is too small, scale may accumulate and degrade the performance of the unit, cause the antifreeze device to activate, or cause rust points and refrigerant leakage. If the water flow is too large, the unit may be corroded due to water impact. -

Page 13: Water Pressure Drop Curve

Water Pressure Drop Curve A5MAC210/230D Water pressure drop A5MAC210D A5MAC230D 10.5 11.5 12.5 13.5 14.5 15.5 Water flow (m³/h) A5MAC340/450D(R) A5MAC450D A5MAC340DR NOTES: 1) THE WATER PRESSURE DROP OF THE UNIT IS THE TEST RESULT WHEN A PLATE HEAT EXCHANGER AND THE ACCESSORY Y-SHAPED FILTER ARE INSTALLED. -

Page 14: Wiring Diagrams

Wiring Diagrams... -

Page 17: Installation

Installation Working Condition Item Description Power supply voltage 380 - 415V Power supply frequency Rated frequency ± 1% Variations between phases Rated voltage ± 2% Air quality Must not contain solute that can corrode copper, aluminum or iron. Flow rate of chilled water 0.5 - 2.0m/s Pressure of chilled water <... - Page 18 Space Allocated for A Single Chilled Water Unit Deflector ≥ ≥ ≥ ≥ ≥ ≥ ≥ ≥ ≥ ≥ ≥ ≥ ≥ ≥ Front 前面 前面 前面 前面 前面 前面 前面 Back ≥ L3 ≥ L3 ≥ L3 ≥ L3 ≥...

- Page 19 Installing Chiller ■ The user manual, warranty card, accessories, and packing list are place at the right side of the unit. ■ ■ If the unit is installed in a place where it snows during winter, proper measures must be taken to protect the unit against snow and ensure that the unit works properly.

-

Page 20: Water System Installation

Water System Installation Water Quality Requirements Water inside the chilled water system must be clean/soft to prevent formation of scale. Scaling/fouling will degrade performance of the chiller and increase resistance. This will eventually affects both the flow rate and performance of the water pumps. - Page 21 ■ Ensure the flow rate is in the range. Low flow rate will reduce performance of the unit due to scale formation, triggering anti-freeze sensor, and/or refrigerant leakages which caused by corrosion. While flow rate that is too high will cause erosion corrosion. ■...

- Page 22 ■ Illustration for multiple units and constant flow rate chilled water system: Air outlet 排气 Water refill 补水 D N20 DN20 Full 满水 Water 排水 discharge D N20 DN20...

- Page 23 ■ Illustration for multiple unit and variable flow rate system: 排气 排气 排气 排气 排气 排气 排气 排气 排气 排气 补水 补水 补水 补水 补水 补水 补水 补水 补水 补水 DN20 DN20 DN20 DN20 DN20 DN20 DN20 DN20 DN20 DN20 满水...

- Page 24 ■ Installation illustration for multiple unit and variable flow rate system: Exhaust Refill DN20 Full Drain DN20 Electronic 2-way valve Differential pressure sersor Differential pressure bypass valve VFD control cabinet VFD Pump Electronic 2-way valve 1. By default, the unit is set as constant water flow-rate system. SW1.6 on PCB board indicates the water system, OFF is for constant flow-rate system, ON is for variable flow-rate system.

- Page 25 Component Function Electric two-way valve Interworking with the unit Frequency converter Implementing water pump variable frequency Differential pressure sensor Checking pressure difference between water supply and water return, and controlling water pump adjustment Direct digital controller Interfaces implementing the preceding functions are preserved on the unit. For details about wiring, please refer to "Control System Instruction - PCB Instruction".

- Page 26 Application instruction: 1. Set master unit water system to variable flow system. 2. Install electric two-way valve on the terminal side to implement the inter-locking between the electric two-way valve and the fan coil unit. Install an independent water pump for each unit, and configure interworking between the water pump and the unit.

- Page 27 NOTE: PARAMETERS IN THE PRECEDING TABLE MAY VARY BASED ON THE DESIGN MANUAL. FOR DETAILS, SEE THE "HVAC DESIGN MANUAL". Water Storage Tank Volume Calculating is referred to below table Setting temperature of reture water A5MAC 210D A5MAC 230D A5MAC 340D A5MAC 450D (°C)

- Page 28 NOTES: 1. THE TOTAL WATER VOLUME OF THE ENTIRE HYDRAULIC SYSTEM INCLUDES THE WATER IN MAIN PIPE, WATER TANK AND TERMINAL EQUIPMENTS, IN WHICH THE 2-WAY VALVE IS OPEN. 2. IF THE WATER VOLUME (V) WHILE THE UNIT IS RUNNING IS LESS THAN VMIN, IT IS RECOMMENDED TO INSTALL A WATER TANK OF (VMIN-V)L, OR IT WILL CAUSE THE UNIT FREQUENT ON/OFF.

-

Page 29: Commissioning And Operation

Commissioning and Operation Note: Before the commissioning, check that the following conditions are met and read the "Safety Precautions" again. ■ Ensure that the water pump and the unit are connected. Use the PCB controller to switch On and off the pump so that it could cut off the system in the event of abnormalities. -

Page 30: Maintenance

Maintenance Repair Note: Before checking and maintaining the unit, safety precautions need to be adhere. Note: Although the unit go through stringent quality and performance test. The unit must be maintained from time to time. ■ The unit can only be repaired and serviced by specially-trained technicians. After a unit is serviced, safety controls must be checked and analyzed before the unit is turned on. - Page 31 Maintenance The unit need to be checked on a routine basis to maintain optimum performance and minimize breakdown maintenance. The following needs to be checked on a routine basis: Once half a Items Monthly Quarterly Once a year If necessary year 1.

- Page 32 Water Processing Method To ensure effective operation and durability. Cleaning, washing and chemical processing are very important for water systems. Different types of water circuits need to be cleaned in different ways. ■ Close Re-Circulation System Water systems of this type generally require no adjustment to subdue scale, and require no chemical to suppress mud and alga.

-

Page 33: Control System Instruction

Control System Instruction Power Cable Connection Diagram 380-415V/3N/50HZ 380-41 5V/3N~/50H z 380-41 5V/3N~/50H z 380-41 5V/3N~/50H z 380-41 5V/3N~/50H z 380-41 5V/3N~/50H z B reak er with a B reak er with a B reak er with a B reak er with a B reak er with a B rea ker with a B rea ker with a... - Page 34 NOTE: PARTS WITHIN THE DASHED BOX ARE TO BE CONNECTED ONSITE. THE OUTPUT VOLTAGE OF THE MODULE INTERFACE IS 220-240 V. PARTS WITHIN THE REAL-LINE BOX ARE CONNECTED BEFORE DELIVERY. 2WV:WATER SYSTEM 2-WAY VALVE, OV-PUMP: PUMP OVERLAOD PROTECTION, OV-WHEAT: WATER SYSTEM HEATER OVERLOAD PROTECTION, EN-SAVE: 2-WAY VALVE INTERLOCKING OR REMOTE CONTROL SWITCH.

- Page 35 ■ The master unit must set the number of slave unit(s) connected. The slave unit does not have to be set (bits 1~4 of SW2): Address of the SW3 SW4 Address of the SW3 SW4 Address of the SW4 Address of the outdoor unit outdoor unit outdoor unit...

-

Page 36: Wired Controller Instruction

Wired Controller Instruction Dimensions Controller Installation... - Page 37 Functions AC305 is a wall-mounted LCD controller which directly controls air conditioners through keys on its panel. 1) Features Two operation modes: heating/cooling (note: operation modes can only be switched when the unit is off) For air cooled chiller, temperature setting range for inlet water: cooling 10°C - 25°C; heating 25°C - 50°C; For water cooled chiller, temperature setting range for inlet water: cooling 10°C - 25°C (-10°C - 10°C for low water temperature unit);...

- Page 38 The control system has the following functions: Function Function Controlling the 2-way valve of the water system (relevant Timing accessories need to be purchase separately); Anti-freeze protection for plate heat exchanger Protection for Compressors in Operation Alternative defrosting Averaging Workload among Compressors Manual defrosting Failure alarm, viewing and output 2-way Valve Interlock Control...

- Page 39 4) Timer Setting After the “Timer” key is pressed, “Weekday Setting” and “Timer Setting” are displayed at the same time on the LCD, indicating access to the weekday adjustment phase. Press the “▲” or “▼” key to select the weekday of the timer time to be set. After selection, press the “Enter”...

-

Page 40: Error Code

Error Code Controller Stoppage Code Code Symptoms Code Symptoms 00-14 0#...14# communication failure of slave units Main pipe outlet water temperature sensor malfunctioned Compressor no.1 of system no.1 overloaded Inlet water temperature sensor failed Compressor no.1 of system no.2 overloaded Outlet water temperature sensor failed Water pump overload Ambient temperature sensor failed... - Page 41 Code Symptoms Code Symptoms ER24 System 2 high pressure ER50 System 1 suction temperature sensor failed ER25 Anti-freezing protection failure ER51 System 2 suction temperature sensor failed ER26 Electric heater for water system overloaded ER52 System 2 low pressure sensor failed ER27 Ambient temperature too high/low ER53...

- Page 42 Failure Causes and Solutions Failure Code Symptom Possible Cause Solution 1. A/B communication lines of the wired controller and master unit are Check and troubleshoot the incorrectly connected. communication lines. 2. The communication line has broken off. 3. Communication wires between the Rewire the unit, use shielded communication wired controller and the master unit lines or keep the communication lines away...

- Page 43 Failure Code Symptom Possible Cause Solution 1. Check whether the set value of the overload The LED indicator protector current of the water pump is of the unit displays Operating current of the water pump Water pump motor ER18 and the correct according to the wiring diagram motor is too high overloaded...

- Page 44 Failure Code Symptom Possible Cause Solution 1. Return water temperature is set Modify the set temperature of the return The LED indicator too low. water. of the unit displays Anti-freezing ER25 and the protection failed 2. Insufficient water flow rate causing wired controller Check the water system (refer to item 7).

- Page 45 Failure Code Symptom Possible Cause Solution Gently knock the sides of the four-way valve and restart the system. Should the alarm 1. Four-way valve jammed. persist, replace the four-way valve. The LED indicator System 2 suction of the unit displays temperature is too 2.

- Page 46 Failure Code Symptom Possible Cause Solution 1. TH3 temperature sensor is loosen or Check the control module and replug the broken off. temperature sensor. The LED indicator Check whether the resistance of TH3 of the unit displays System 1 middle 2.

- Page 47 Failure Code Symptom Possible Cause Solution 1. TH9 temperature sensor is loosen or Check the control module and replug the broken off. temperature sensor. The LED indicator Check whether the resistance of TH9 System 1 heat 2. TH9 temperature sensor is shorted/ of the unit displays sensor meets specification requirements/ exchanger outlet...

- Page 48 Failure Code Symptom Possible Cause Solution The LED indicator Both SYS1 and SYS2 have failures that of the unit displays No system to startup Query failures to recover SYS1 and SYS2. ER60 and the cannot be recovered automatically. wired controller displays 60 1.

- Page 49 ACSON MALAYSIA SALES & SERVICE SDN.BHD. (129688-D) DAIKIN a member of group Lot 4, Lorong 19/1A, Seksyen 19, 46300 Petaling Jaya, Authorized Dealer : Selangor Darul Ehsan, MALAYSIA. Tel : +603 7964 8200 Sales Fax : +603 7956 9909 Sernice Fax : +603 7956 9907 Acson Careline : 1300 22 3344 Penang : +604-5377 176 Pahang : +609 5178 696...

Need help?

Do you have a question about the A5MAC 210D and is the answer not in the manual?

Questions and answers