Advertisement

INSTALLATION AND SERVICE MANUAL

Please fill in for future reference:

MODEL: ___________________________

SERIAL NUMBER: ____________________

DATE PURCHASED: ___________________

* Please fill out the warranty registration

card included with this product or online at:

www.mdminc.com

XXXXXXXXX

S/N: XXXX-XXXXXX

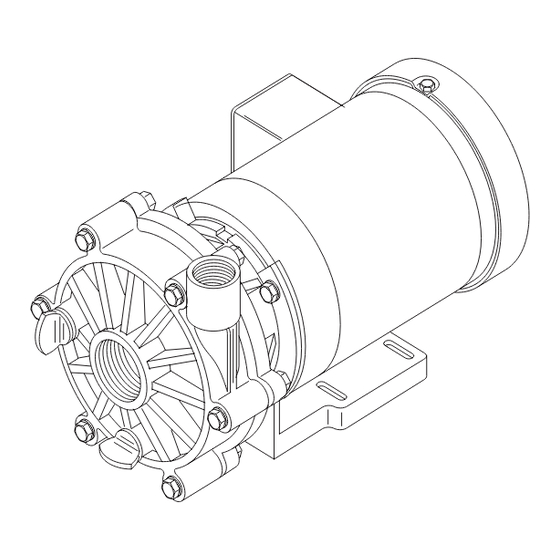

TYPE: END-SUCTION CENTRIFUGAL

MOTOR: NEMA C FACE, 56J

PORT SIZE: 1 1/2" FNPT INLET & DISCHARGE (ADVANCE 1000)

1 1/2" FNPT INLET & 3/4" FNPT DISCHARGE (ADVANCE 3000)

HORSEPOWER: 1/8 HP THROUGH 3 HP

MATERIAL: 30% GLASS-FILLED NORYL

40% GLASS-FILLED POLYPROPYLENE.

WARNING: Please read completely before you install or operate your new pump! Do NOT allow this pump to become submerged!

Never run dry - Never reverse rotation. Use of a phase rotation meter is highly recommended to prevent damage to the pump.

Never exceed an internal case pressure of: 65 PSI Max Polypropylene 100 PSI Max Noryl

Corrosion-resistant, non-metallic pumps.

Proudly Made in the USA

ADVANCE 1000

OR

®

1000 & 3000

HARDWARE: STAINLESS STEEL

SEAL OPTIONS: STAINLESS STEEL WITH VARIOUS

ELASTOMERS, NON-METALLIC IMPENATRA

WITH MULTIPLE CONFIGURATIONS FOR CHEMICAL

COMPATIBILITY.

OTHER OPTIONS: EXTENSION COUPLED, PEDESTAL MOUNTED AND LONG

COUPLED WITH PEDESTAL MOUNTED PUMP ON FIBER-

GLASS BASEPLATE. PUMP ENDS ALSO AVAILABLE.

.

®

ADVANCE 3000

SEAL

®

© 2018 MDM INC.

Advertisement

Table of Contents

Summary of Contents for MDM INC. Advance 1000

- Page 1 ADVANCE 3000 TYPE: END-SUCTION CENTRIFUGAL HARDWARE: STAINLESS STEEL MOTOR: NEMA C FACE, 56J SEAL OPTIONS: STAINLESS STEEL WITH VARIOUS PORT SIZE: 1 1/2” FNPT INLET & DISCHARGE (ADVANCE 1000) ELASTOMERS, NON-METALLIC IMPENATRA SEAL ® WITH MULTIPLE CONFIGURATIONS FOR CHEMICAL 1 1/2” FNPT INLET & 3/4” FNPT DISCHARGE (ADVANCE 3000) HORSEPOWER: 1/8 HP THROUGH 3 HP COMPATIBILITY.

-

Page 2: Installation

1000 & 3000 We congratulate you on your choice of the Advance Centrifugal Pump! It has been carefully designed using the advantages of today’s technology and carefully constructed to give you the dependability of yesterday. To insure proper performance, we urge you to carefully follow the instructions in this manual. If you have any questions, call your nearest distributor or MDM for assistance. -

Page 3: Pump End Assembly

1000 & 3000 PUMP END ASSEMBLY Electrically, connect the motor so that the impeller will rotate CCW when facing the pump with the motor toward the rear. Warning: Incorrect rotation will damage the pump and void the warranty. For 3 phase power, electrically check rotation of impeller with volute disassembled from bracket If pump end is assembled and rotation is incorrect, serious damage to pump end assembly can occur even if the switch is “quickly bumped.”... -

Page 4: Maintenance

1000 & 3000 WARNING: EYE PROTECTION IS STRONGLY RECOMMENDED MAINTENANCE *The pump must be drained before servicing or if stored below freezing temperatures. Periodic replacement of seals may be required due to normal carbon wear. Lubrication Motor - Permanently Lubricated ball bearings - no service required. Rotary Seal - Requires no lubrication after assembly. -

Page 5: Tools And Materials

PUMP NUT DRAIN PLUG & O-RING 9.05” 3.13” 2.99” Note: These part numbers are only for standard DISCHARGE 0.75” FNPT models within the Advance 1000 and Advance 3000 series. 8.39” TOOLS & MATERIALS 1/4”FNPT DRAIN QTY TOOLS / MATERIALS USAGE PLUG 4.02”...

Need help?

Do you have a question about the Advance 1000 and is the answer not in the manual?

Questions and answers