Summary of Contents for Depa DL25-L

- Page 1 DEPA Air Operated Diaphragm Pumps ® BA-DL-GB/01.19 Air Operated Diaphragm Pumps Operating and Installation Instructions Installation, Operation and Maintenance www.depapumps.com www.cranecpe.com...

- Page 2 Crane Process Flow Technologies GmbH Heerdter Lohweg 63-71 40549 Düsseldorf Düsseldorf, 08/07/2015 Place, date Signature of manufacturer: Hans-Dieter Ptak, Managing Director Information on signatory: This is the translation of the original declaration of conformity for DEPA Air Operated Diaphragm Pumps.

- Page 3 Crane Process Flow Technologies GmbH, The manufacturer Heerdter Lohweg 63-71, 40549 Düsseldorf, www.depapumps.com declares that with the series production pulsation dampers DEPA compressed air diaphragm pumps without air control Designation: DJ/DH*, PD, PH Series: * DHxx-FA in custom design with control block for external air control.

- Page 4 Crane Process Flow Technologies GmbH, Heerdter Lohweg 63- 71, D-40549 Düsseldorf, www.depapumps.com declares that the pump units manufactured in series production Designation: DEPA Air Operated Diaphragm Pumps and DEPA Active Pulsation Dampeners Series: DL, DH, DF, DZ, DJ, DP, DBX* and PD, PH...

- Page 5 The manufacturer Crane Process Flow Technologies GmbH, Heerdter Lohweg 63-71, 40549 Düsseldorf, www.depapumps.com declares that the pump units manufactured in series production Designation: DEPA air operated diaphragm pumps* and DEPA active pulsa- tion dampeners * o nly applies to pumps with internal valve and external sole- noid air valve Series:...

- Page 6 DEPA nopped E4 compound diaphragm, ® EPDM, NBR Supplementary operating manuals: DEPA air operated diaphragm pumps BA-DL-D/12.18 in the design supplied by us, are in compliance with the following applicable regulations: EU Directive: Directive 2014/34/EU for equipment intended for use in poten-...

- Page 7 The manufacturer Crane Process Flow Technologies GmbH, Heerdter Lohweg 63-71, 40549 Düsseldorf, www.depapumps.com declares that the pump units manufactured in series production Designation: DEPA – Air Operated Diaphragm Pumps and DEPA Pulsation Damp- eners Types: DL..SLV, DL..SUV, DL..UEV, DL..SF/SFS, DH..UEV PD..SL, PD..SU, PD..UE, PH..UE Sizes:...

- Page 8 Crane Process Flow Technologies GmbH The manufacturer: Heerdter Lohweg 63-71 40549 Düsseldorf, www.depapumps.com declares that the pump unit manufactured in series production DEPA Air Operated Diaphragm Pumps Designation: DL, DH Series: 15, 25, 40, 50, 80 Sizes: SS, PL Casing material: EPDM, NBR, electr.

-

Page 9: Table Of Contents

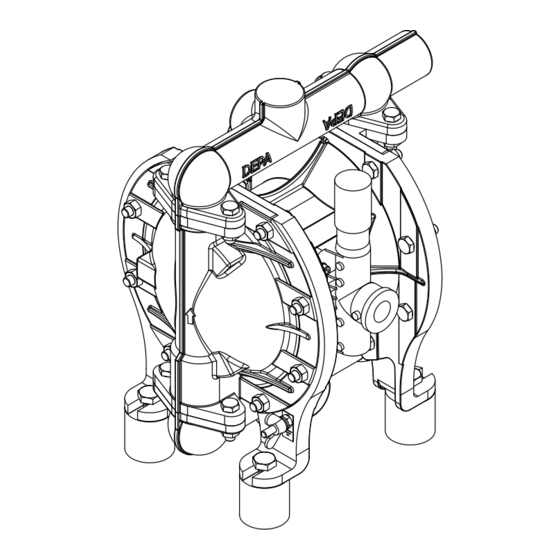

DEPA Air Operated Diaphragm Pumps ® Table of contents Page 1.0. Introduction ............................11 Warranty ..............................11 Transport, unpacking, storage ........................11 Principle of function ..........................12 1.3.1 Functionality ............................. 13 Technical data ............................14 1.4.1 Dimensions, weights and temperatures ....................14 1.4.2... - Page 10 Principle of function ..........................35 Recommended installation schematic ...................... 35 Pulsation damper with diaphragm breakage monitoring ................36 Active pulsation damper with DEPA nopped E4 compound diaphragm ............ 36 Spare parts .............................37 Spare parts storage ..........................37 Ordering spare parts ..........................37 Spare parts kits ............................

-

Page 11: Introduction

Warranty Persons entrusted with the installation, op- The correct function of each DEPA Air Op- eration, maintenance or repair of the pump erated Diaphragm Pump is tested in the must have read and understood these in- factory. -

Page 12: Principle Of Function

DEPA Air Operated Diaphragm Pumps ® n Fasten the lifting tackle so that the Store the pump in a dry place. ■ pump can be safely lifted. Thoroughly clean used pumps before ■ n For pumps DH40-TP/TPL please use storage. -

Page 13: Functionality

By filling the right hand air chamber (dark grey) the right hand diaphragm is pressed towards the outside. The DEPA Air Operated Diaphragm piston rod thereby pulls the left hand Pumps are oscillating positive diaphragm to initial position. Valve ball... -

Page 14: Technical Data

Control air Standard filled with product 8,5 9 Max operating pressure see table 2. DL-PM 2,5 5,5 5,5 DH-PT/-TL dry *) DEPA Air Operated Diaphragm Pumps DH-PT/-TL filled with product are not subject to the pressure DH-TP/-TPL dry equipment directive acc. to article 1, para. 3.10, pressure equipment directive. - Page 15 FKM (Viton®) ● ● ● PTFE ● ● ● nopped E4 PTFE compound ® ● DEPA® Nopped S4 **** ● NRS with core ● EPDM with core ● EPDM Grey with core ● NBR with core ● PTFE with core ●...

-

Page 16: Safety

DEPA Air Operated Diaphragm Pumps ® Safety Danger sources The pump works with pneumatic and hy- draulic energies, which may be under high General information pressure. These instructions were written for the op- Depending on its equipment, the pump may erator and the maintenance and repair per- also work with electric energy. -

Page 17: Unintended Use

DEPA Air Operated Diaphragm Pumps ® Maintenance and repair work Unintended use The operating safety and reliability of the Maintenance and repair work must solely pump can only be assured if it is used for be carried out by qualified and specially in- the purpose it is intended for. The limits structed persons. -

Page 18: Personal Protective Outfit

DEPA Air Operated Diaphragm Pumps ® Moveable parts must be locked in place Danger! before starting work. It must be assured that Be careful when checking for these parts will not start to move while work leaks on pressurized lines. -

Page 19: Installation

DEPA Air Operated Diaphragm Pumps ® must wear ear valves, pressure gauges, flow control defenders. valves and shut-off valves. above 85 dB (A): Room with dangerous Thoroughly examine the alignment of the noise level! Each door pump with the pipelines, in order to avoid must have a clearly strain and premature wear. -

Page 20: Placement And Possible Installations Of The Pump

DEPA Air Operated Diaphragm Pumps ® Pumping combustible liquids. compensators at the suction Experience has shown that and pressure ports of the pump dangerous charges are not (Fig. 3). This will prevent the likely at flow velocities > 7m/s transfer of pulsation shocks (TRGS 727). -

Page 21: Foundations

This causes irregular running of the pump with extreme noise. The results are limited For connection of suction- and discharge power and reduced lifetime of the pump. pipes to DEPA pumps equipped with cylindri- The maximum pre-pressure on the suction cal female thread (shortly signed “G”, stan- side must not exceed 0.7 bar. dard version ISO 228-G) fittings with either cylindrical male thread (none-sealing wit- ■... -

Page 22: Pump On Drum

Fig. 5: Earthing screw 3.10 Pump on drum 3.13 Routing of exhaust air DEPA pumps of type DF can be directly The muffler permanently discharges mounted on drums or containers. For simple relieved compressed air. This air can whirl emptying mount the pump with an adapter up dust and thus generate an explosive on the container. -

Page 23: Operation

DEPA Air Operated Diaphragm Pumps ® 3. Function: 5/2-way valve, monosta- Operation ble, air-spring center posi- tion must be connected. General After the pump stops, the After correct connection of suction and piston rod has no defined pressure line as well as the compressed air position. -

Page 24: Flow Control

Operation of the pump can be electronically Warning! monitored by means of a remote operation During all CIP cleaning indicator. processes the DEPA® Air Operated Diaphragm Pump Diaphragm monitoring - must be running. Otherwise the conductive diaphragm may be excessively... -

Page 25: Diaphragm Break Sensors And Shut Down In Case Of Leaks

DEPA Air Operated Diaphragm Pumps ® chemical attacks and thus the destruction of 4.10 Diaphragm break sensors and the diaphragms when restarting. shut-down in the event of leaks When using diaphragm break sensors, the air supply may be interrupted if there is a 4.13... -

Page 26: Maintenance

2 “Safety”. without being opened. Check all lines and fittings regularly for leaks and externally visible damage! Repair any Note: For repairs use only damage immediately! genuine DEPA spare parts, as otherwise the warranty will Danger! become null and void. Before working with the pump, the pump must be moved from 5.3.1... -

Page 27: Replacement Of Elastomer Components

DEPA Air Operated Diaphragm Pumps ® On plastic pumps turn on the plastic cap first (from DL25). With compound diaphragms, the dia- ■ phragm is unscrewed by hand directly out of the plunger. Pull the piston rod with the second ■ diaphragm out of the central block and disassemble the second diaphragm as described before (Fig. - Page 28 DEPA Air Operated Diaphragm Pumps ® Fig. 8: Removing suction and pressure ports. Fig. 12: Disassembling the air chambers Fig. 13: Assembly of standard diaphragm with inner Fig. 9: Opening the clamp bands. and outer plate Fig. 10: Loosen the diaphragm plate. (Not used for ®...

-

Page 29: Replacement Of The Internal Control Valve

Pumps of series DH-TP/TPL are gener- ■ ally equipped with DEPA nopped E4 ® compound diaphragms. Installation of Fig. 16: Assembly of internal control valve the diaphragm takes place by means of indexing disc and set screw, without... -

Page 30: Replacement Of The External Q-Valve

■ bling the pump (Fig. 18). socket (A) to pump. Special tool is requi- red for (A). 5.3.1.6 Replacement of the outside DEPA Mount the pressure booster (B) to the ■ AirSave System (DL15/25/40) plate (C) using the 4 cheese head ■ Loosen four mounting screws on the... -

Page 31: Replacement Of Diaphragms, Valve Seats And Valve Balls

DEPA Air Operated Diaphragm Pumps ® Fig. 21: Pulling out the diaphragm with piston rod Fig. 22: DH pump with interior control valve We recommend removing and inspecting the 5.3.2.2 Replacement of diaphragms, air control, if the product reach the air area valve seats and valve balls (see 5.3.2.3). -

Page 32: Replacement Of The Airsave Control Valve (M-Valve)

DEPA Air Operated Diaphragm Pumps ® Knock the clamp bands lightly with a 5.3.2.5 Replacement of the AirSave ■ plastic hammer onto the pump chamber control valve (M-valve) for easier settling. ■ Remove AirSave valve and seal Once the clamp bands have settled ■... -

Page 33: Troubleshooting

DEPA Air Operated Diaphragm Pumps ® Troubleshooting Fault Possible cause Remedy Pump running, no delivery Pump draws in air Seal the suction line Suction valve closed Open valves Suction capacity exceeded Change the arrangement Valve ball and seat on suction side worn Replace seats and balls Insufficient pumping capacity Muffler clogged Clean or renew... - Page 34 DEPA Air Operated Diaphragm Pumps ® Fault Possible cause Remedy Pump does not work despite Muffler clogged Clean or renew air supply Air inlet filter clogged Clean or renew Valve balls sticking to Loosen, use PTFE balls valve seat instead Valve balls deformed Chemical attack Change material Mechanical attack...

-

Page 35: Active Pulsation Damper

DEPA Air Operated Diaphragm Pumps ® Active pulsation damper Function The active pulsation dampers are designed for in-line installation. The pressure peaks of the flowing product raise the diaphragm and compromise the air cushion in the air cham- ber. When the displacement pressure in the pipe-... -

Page 36: Pulsation Damper With Diaphragm Breakage Monitoring

5 Needle valve function of the diaphragm monitoring system is not assured (see sketch 4). Sketch 3 Active pulsation damper with DEPA nopped E4 compound diaphragm The DEPA nopped E4 compound dia- ® phragm can also be installed in all active DEPA pulsation dampers. -

Page 37: Spare Parts

DEPA Air Operated Diaphragm Pumps ® Spare Parts Spare parts kits MINI spare part kit Pump type Spare parts storage Pump size Since the extent of the recommended spare parts storage depends on the period of use Item Quan- tity and the different operating conditions for the Diaphragm pumps, you should consult the manufactur- ●... - Page 38 DEPA Air Operated Diaphragm Pumps ® MEDI spare part kits Spare part kit type Pump type DL-PM DL-SA/SX/ DL-PP/PL DL-SLV DL-SUV/ DH-TP/ DH-FA / CA/CX/SS SA/SS Pump size 15/25/40 15/25/40/ 15/25/ 25/40/ 25/40/ 15/25/ 15/25/40/ 50/80 40/50/80 50/80 50/80 40/50...

- Page 39 DEPA Air Operated Diaphragm Pumps ® Spare part kit type M A-valve DL25/40-SS-Q only 78 only DL50/80-SS/HS DEPA E4 ® composite membrane Spare part kit type A 65-1 65-2 51-2 51-1 31T/R 51-3...

- Page 40 DEPA Air Operated Diaphragm Pumps ® Spare part kit group G / P 02PQ 69PQ 30TR Spare part kit type SU / U Internal control valve...

- Page 41 DEPA Air Operated Diaphragm Pumps ® Spare part kit X Applies for DH25/40 für DH25/40 gilt: / for DH25/40 applies: 51-2 51-1 51-3...

-

Page 42: Materials And Pump Coding

DEPA Air Operated Diaphragm Pumps ® Materials and pump coding Series Standard series made of DL 40 PP - E E E cast metal, plastic and stainless steel, polished Cast metal, non metallic flanged design) Drum pump Pump size Double pump Connections G1/2"... -

Page 43: Appendix "Pump Weights In Kg

80, mi- phragms (diaphragm rupture), pump crofilters in the pump inlet are not operation must be stopped immedi- permitted. Multiphase insulating liq- ately. uids must not be pumped with DEPA In explosive environments, the pump must be ® nopped E4 compound diaphragms monitored in the case of incomplete media filling as well as PTFE diaphragms and PTFE (e.g. suction and snore mode), and if there is fluid... -

Page 44: Equipotential Bonding

DEPA Air Operated Diaphragm Pumps ® 10.1.3 Equipotential bonding 10.1.5.1 The level control Earthing of pump and pulsation damper by Earthing must be provided when a means of earthing screw or discharging hoses level control is installed must take place before bringing the pump into the potentially explosive environment. -

Page 45: Maintenance Instructions For Category 1 And 2 Equipment

Pos. 4 Pos. 3 Pos. 7 Pump size Air inlet Air valve Piston Air chamber Clamp band Pos. 2 Pos. 3 Pos.4 Pos. 5 Pos. 7 DL25-L 50 Nm 8 Nm 20 Nm max. 23 Nm DL40-L 50 Nm 8 Nm 90 Nm 20 Nm max. 23 Nm DL50-L 85 Nm 8 Nm... - Page 46 DEPA Air Operated Diaphragm Pumps ® Tightening torques series DH-UE, size 25-50 Pos. 3 Pos. 5 Pos. 4 Pos. 2 Pos. 7 Pump size Air inlet Air valve Piston Air chamber Pump chamber / Pos. 2 Pos. 3 Pos. 4 Pos.

- Page 47 DEPA Air Operated Diaphragm Pumps ® Tightening torques series M, Pos. 6 size 15 Pos. 4 Pos. 1 Pos. 6 Pos. 4 Pos. 7 Pos. 1 Pos. 5 Pos. 7 Pos. 1 Pump size Suction / Discharge Piston Centre block cover Clamp band manifold, Pos.

- Page 48 DEPA Air Operated Diaphragm Pumps ® Tightening torques series P, size 15-80 Pos. 1 Pos. 3 Pos. 6 Pos. 7 Pos. 2 Pos. 4 Pos. 1 Pump size Anchor rod Air inlet Air valve Piston Centre block Clamp band Pos. 1 Pos.

- Page 49 DEPA Air Operated Diaphragm Pumps ® Pos. 1 Tightening torques series P, Typ DH, size 50 Pos. 2 Pos. 6 Pos. 7 Pos. 4 Pos. 1 Pump size Annchor Air inlet Air valve One piece Piston Centre block Pump chamber/...

- Page 50 DEPA Air Operated Diaphragm Pumps ® Tightening torques series M, Type DH-FA /SA/SS Pos. 4 Pos.1 Pos. 7 Size 25-80 Pos.6 Pos.3 Pos.7 Pump size Suction / Discharge External Piston rod Centre block Pump chamber manifold air valve cover Pos. 1 Pos.

- Page 51 DEPA Air Operated Diaphragm Pumps ® Tightening torques series P, type DH-PT/-TL Pos. 1 size 15-40 Pos. 7 Pos. 6 Pos. 4 Pos. 2 Pos. 7 Pos. 1 Pump size Manifold / Air inlet Diaphragm Centre block Pump chamber /...

-

Page 52: Information On The Declaration Of No Objection If Goods Are Returned

Upon our receipt of the filled-out declaration of non-objection, you will receive a return number from us. Please affix the same then to the package so that it is readily visible from the outside. This is the translation of the original operating and installation instructions for DEPA Air Operated Diaphragm Pumps. For the original version in German, please refer to www.cranechempharma.com... - Page 53 ALOYCO • CENTER LINE • DUO-CHEK • FLOWSEAL • JENKINS • KROMBACH • NOZ-CHEK • PACIFIC • STOCKHAM • TRIANGLE DEPA • ELRO • PSI • RESISTOFLEX • RESISTOPURE • REVO • SAUNDERS • XOMOX Crane Process Flow Technologies GmbH, Postfach 11 12 40, D-40512 Düsseldorf, Heerdter Lohweg 63-71, D- 40549 Düsseldorf,...

- Page 54 DEPA Air Operated Diaphragm Pumps ®...

- Page 55 DEPA Air Operated Diaphragm Pumps ®...

- Page 56 DEPA Air Operated Diaphragm Pumps ® Crane Process Flow Technologies GmbH P.O.Box 11 12 40, D-40512 Düsseldorf Heerdter Lohweg 63-71, D-40549 Düsseldorf Phone +49 211 5956-0 infoDus@cranecpe.com www.depapumps.com www.cranecpe.com We reserve the right to change all technical information.

Need help?

Do you have a question about the DL25-L and is the answer not in the manual?

Questions and answers