Summary of Contents for Battenfeld PLUS 250/50

- Page 1 Manual Injection moulding machine PLUS Austria Type of machine: PLUS 250/50 Control system: UNILOG 1020 Machine number: 114899-100 Year of manufacture: 1993 Version: PL120102 06/93...

- Page 2 Injection Molding Injection Molding Injection Molding Injection Molding Injection Molding Battenfeld Kunststoffmaschinen Gesellschaft m.b.H. Wr.Neustädter Straße 81 • 2542 Kottingbrunn • Austria Tel. +43 2252 404-0 • Fax +43 2252 404-1062 welcome@battenfeld-imt.com www.battenfeld-imt.com DIN EN ISO 9001...

- Page 3 Structure and Function Structure and function of each individual build group and user UNILOG manual for the control. Operation All important details for user operation of the Battenfeld machine. A: PL120100.IN1 Chapter: INH B: PL120100.IN1 E: 03.93 / T. Weiß...

- Page 4 Table of Contents Maintenance All details for servicing, maintenance and fault-finding. Spare parts / Drawings Detailed description and spare parts lists as well as hydraulic and electrical drawings displaying existing parts. Service Contact addresses of all service partners. 10 Index Dieser Text dient Explanation of the most important machine-related terms.

- Page 5 Table of Contents General Introduction Area of application Explanation of symbols Copyright Statement of delivery Safety Safety regulations Alarm signs General drawing Electrical access protection Hydraulic access protection Mechanical access protection Guarding Safety device for handling unit Safety device supervision Technical Data Dimensions of machine Rating...

-

Page 6: Table Of Contents

Table of Contents Structure and Function Overview of build groups Closing unit 5.2.1 Technical description 5.2.2 Mould fitting 5.2.3 Instructions for fitting - adjustment of fitting height Injection unit 5.3.1 Technical description 5.3.2 Nozzle change 5.3.3 Instructions for setting - nozzle centre 5.3.4 Change and prestressing of synchronous belt 5.3.5... -

Page 7: Table Of Contents

Table of Contents Operation Startup Starting the machine after Emergency Stop Machine shutoff Maintenance General Maintenance schedule Table of hydraulics and lubricants Spare Parts / Drawings Guidelines for ordering spare parts Basic machine data Closing component 8.3.020 Accessories for machine frame 8.3.025 Photoelectric safety device (optional) 8.3.072... - Page 8 Table of Contents Pneumatic system 8.7.380 Material feeder device UNIFEED (optional) 8.7.700 Pneumatic core pull Service Index 10.1 Description of technical terms 10.2 Index Dieser Text dient nur als Hintergrund. Das Kapitel Stichwortver- zeichnis und Glossar zeigt Ihnen die ent- sprechenden Seiten im Text auf und ver- Accessories...

- Page 9 Chapter 1: General 1.1 Introduction This user manual has been written specifically for the personnel in charge of this Battenfeld product moulding machine and should be read, understood and precisely followed by them. The complete technical documentation should always be kept close by the machine;...

- Page 10 General 1.2 Area of application The injection moulding machines of the PLUS series were conceived for the processing of thermoplastics, thermosets and elastomers as well as for LIM. Applications going beyond this definition do not conform to the original intended use of the machine. The manufacturer accepts no liability for defects arising from this type of misuse - the risk is borne solely by the operator.

- Page 11 General 1.4 Copyright The copyright for this user manual rests with Battenfeld Ges.m.b.H. This user manual is destined for the staff in charge of the fitting, operation and supervision of this machine. The technical instructions and drawings contained in it may...

- Page 13 Telefaxtransmission General To: Documentation Department (0)2252 404-402 From: Statement of Delivery ensuring the delivery of the Technical Documentation to the end customer (1) Type of machine Number of machine (2) Address of customer (3) The machine specified in item (1) above was acquired by us. Together with the machine, (number) user manual(s)

- Page 15 For reasons of safety, all unauthorized modifications or changes of the machineand the robot are prohibited and require Battenfeld’s approval. When processing synthetic materials that cause the emission of gases, dust or steam hazardous to human health, the operator of the machine must ensure that appropriate ventilation is provided for the protection of the operating personnel.

- Page 16 Safety The operating enterprise shall ensure that no unauthorized persons on the installation will handle the machine. The machine may be operated only by persons over 18 years of age; with of the necessary technical knowledge; to be expected to comply with their task in a reliable and sensible manner.

-

Page 17: Injection Unit

Safety 2.2 Alarm signs Before putting the installation into operation, always read and familiarize youself with the operating manual, especially chapter 2 “SAFETY”! DANGER OF INJURY! The machine must not be put into operation if the protective guard has been removed! WARNING! HIGH VOLTAGE! Do not activate the master switch if the control box is open! - Page 18 Safety 2.3 General drawing Bild: Pl-0001.TIF Bild: Pl-0002.TIF Bild: Pl-0004.TIF A: PL120100.020 Chapter: 2 B: PL120100.020 E: 03.93 / T. Weiß Page: 4 G: 06.93 / T. Weiß...

- Page 19 Safety 2.4 Electrical access protection The various positions of the protective guard are monitored by means of two guided switches safeguarding the position of the guard. Position - Protective guard closed; Position switch 1 (S 24) actuated. Position switch 2 (S 25) not actuated. Position - Protective guard open;...

- Page 20 Safety Protective guard monitoring device This device monitors the correct functioning of the following elements: a) Alternating operation of position switches (S 24, S 25) b) Limit switch of hydraulic access protection (S 34). c) Guided auxiliary contactors (K 288, K 289) in the valve circuits of the closing unit.

- Page 21 If a machine error has occurred, thereby triggering the mechanical access protection, contact Battenfeld Customer Services or the competent representative office. 2.7 Guarding In order to prevent accidents, the closing unit is completely covered by a guard.

- Page 22 3. Check mechanical access protection Smooth movement of bumper bar on nozzle platen required. If a machine error has occurred, thereby triggering the mechanical access protection, contact Battenfeld Customer Services or the competent representative office. A: PL120100.020 Chapter: 2 B: PL120100.020...

- Page 23 Safety 4. Check operator guard Smooth pivoting movement and stable setting of limit switches required. 5. Check guarding Stable setting of all fastening screws and perfect condition required. 6. Monitoring of safety device for handling unit (optional) All fastening screws must be tight, and the device must be in a satisfactory condition.

- Page 24 Safety A: PL120100.020 Chapter: 2 B: PL120100.020 E: 03.93 / T. Weiß Page: 10 G: 06.93 / T. Weiß...

- Page 25 Technical Data Chapter 3: Technical Data 3.1 Dimensions of machine Please find the dimensions in the enclosed machine drawing at the end of this chapter. 3.2 Rating PLUS 250 PLUS 350 Injection unit Screw diameter (inch) (0,71) (0,87) (0,98) (0,71) (0,87) (0,98) (1,18)

- Page 26 Technical Data Closing unit Closing force (sh tn) (27,5) (38,5) Opening force (sh tn) (3,087) (3,087) Space between the bars (inch) (10,630) (10,630) Tiebar diameter (inch) (2,362) (2,362) 470 x 280 470 x 280 Size of nozzle platen (inch) (18,504 x 11,024) (18,504 x 11,024) 450 x 259 450 x 259...

- Page 27 Technical Data 3.3 Diagram / Injection pressure Injection component 50 Screw D = 18 mm (0,709 inch) 2431 bar (35250 psi) Screw D = 22 mm (0,866 inch) 1627 bar (23590 psi) Screw D = 25 mm (0,984 inch) 1260 bar (18270 psi) p [%] Bild: PL-0015.WMF...

- Page 28 Technical Data Injection component 75 Srew D = 18 mm (0,709 inch) 3038 bar (44050 psi) Screw D = 22 mm (0,866 inch) 2034 bar (29500 psi) Screw D = 25 mm (0,984 inch) 1575 bar (22840 psi) Screw D = 30 mm (1,181 inch) 1094 bar (15860 psi)

- Page 29 Technical Data 3.4 Diagram / Injection velocity These technical data refer only to the injection flow directed to atmosphere. / sec / sec (inch / sec) (inch / sec) Screw D = 30 Screw D = 25 Bild: PL-0017.WMF Bild: PL-0017.WMF (6,10) (4,27) (5,49)

- Page 30 Technical Data 3.5 Diagram / Injection volume (inch (inch Screw D = 30 Screw D = 25 Bild: PL-0017.WMF Bild: PL-0017.WMF (4,27) (3,05) (3,84) (2,75) (3,42) (2,44) (2,99) (2,14) (2,56) (1,83) (2,14) (1,53) (1,71) (1,22) (1,28) (0,92) (0,85) (0,61) s [%] s [%] (0,43) (0,31)

- Page 31 Technical Data 3.6 Diagram / Injection stroke (inch) Spritzaggregat 50 Spritzaggregat 75 Bild: PL-0017.WMF (3,94) (3,54) (3,15) (2,76) (2,36) (1,97) (1,57) (1,18) (0,79) s [%] (0,39) 3.7 Diagram / Screw torque screw torque 400 min-1 (stand.) screw torque 320 min-1 (aux.) Bild: PL-0018.WMF min-1 40 80 120 160 200 240 280 320...

- Page 32 Technical Data 3.8 Diagram / Closing pressure (shtn) (shtn) Plus 250 Plus 350 Bild: PL-0018.WMF Bild: PL-0018.WMF (27,5) (38,5) (24,8) (34,7) (22,2) (30,9) (19,3) (27,0) (16,5) (23,2) (13,8) (19,3) (11,0) (15,4) (8,2) (11,6) (5,5) (7,7) (2,8) (3,9) 10 20 30 40 50 60 70 80 10 20 30 40...

- Page 33 Technical Data 3.10 Diagram / Closing stroke (inch) Plus 250 Plus 350 Bild: PL-0017.WMF (7,87) (7,09) (6,30) (5,51) (4,72) (3,94) (3,15) (2,36) (1,57) s [%] (0,79) 3.11Fitting dimensions of machine Please find data in the enclosed platen diagram at the end of this chapter.

- Page 34 Technical Data Since the measuring precision of the injection pieces, the additional load for the mould and the mould functions (in case of complicated designs, such as multiplate moulds, slide moulds etc) are influenced by the degree of deflection of the platens, the observance of these standard values ensures that inacceptable overloading of the closing unit and mould is excluded.

- Page 39 Transport - Siting Chapter 4: Transport - Siting 4.1 Spatial requirement plan 2348 Bild: PL-0005.TIF At least 600 mm (23.62 in.) of clearance should be left around the injection moulding machine for maintenance works. 4.2 Transport of machine The machine frame contains four clearance holes (D = 50 mm);...

- Page 40 Transport - Siting (2248 lb) (2,56 inch) Bild: PL-0006.TIF A: PL120100.040 B: PL120100.040 Chapter: 4 E: 03.93 / T. Weiß Page: 2 G: 06.93 / T. Weiß...

- Page 41 Transport - Siting 4.3 Siting of machine No special foundation is required for siting the machine. The machine frame contains borings (3 x M 16) for fastening the vibration-absorbing elements. The machine must be balanced properly before startup. 4.4 Oil filling The combined filling and ventilation aperture becomes accessible by screwing off the cover sheet at the back of the machine.

- Page 42 Transport - Siting 4.5 Table of hydraulic oils and lubricants Pneumatic Lubricating point Hydraulic installation Greasing points control device acc. to DIN HLP 68 DIN 51524 T 2 K 2 K DIN 51825 HL 10 DIN 51524 T 2 Agip OSO 10 Agip OSO 68 Agip GR MU 2 Agip Radula 10...

- Page 43 Transport - Siting 4.6 Connection to cooling water distributor The cooling water distributor is situated at the back of the machine. The connection diametre is R 1/2". 4.7 Oil cooler fitting The oil cooler is connected to the 2nd cooling water distribution circuit.

- Page 44 Transport - Siting 4.8 Connection to power line This injection moulding machine may only be connected to a ATTENTION power supply network corresponding to the specifications of the rating plate (control box) with respect to type of current, voltage and frequency. The PLUS-series will be constructed with two different voltages.

- Page 45 Transport - Siting Basically, two types of electrical connection are possible: Direct connection The machine is connected via the master switch. Please observe the correct phase-sequence (clockwise rotation). The master switch is also equipped with a leading switching contact N for all-polo separation. The cable link is provided by one of two PG 29 inputs located at the side of the control box.

- Page 46 Transport - Siting 9. Type of design Open design (including star-point and grounding) on terminals, angles for securing the machine to the ground, fully impregnated under vacuum conditions. 10. Short circuit voltage max. 4% 11. Insulation class E or F (with excess temperatures of 75°K or 100°K) 12.

-

Page 47: Hydraulic Unit

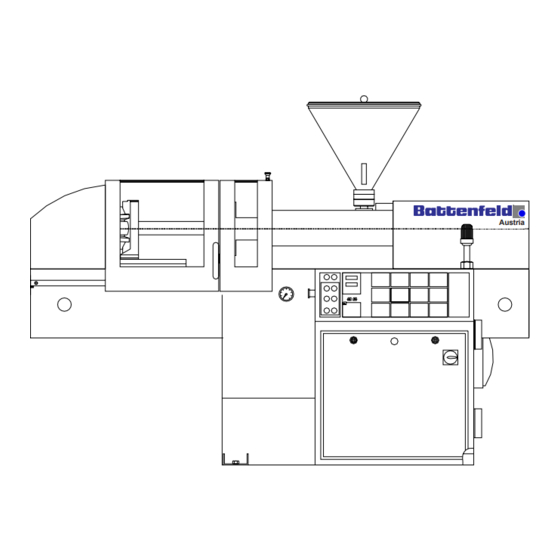

Structure and Function Chapter 5: Structure and Function Overview of build groups 5.2 Closing unit 5.3 Injection unit 5.4 Hydraulic unit 5.5 Electric unit 5.6 Pneumatic unit (optional) 5.7 Control Bild: PL0008.TIF A: PL120100.051 B: PL120100.051 Chapter: 5.1 E: 03.93 / T. Weiß Page: 1 G: 06.93 / T. - Page 48 Structure and Function A: PL120100.051 B: PL120100.051 Chapter: 5.1 E: 03.93 / T. Weiß Page: 2 G: 06.93 / T. Weiß...

- Page 49 Structure and Function 5.2 Closing unit 5.2.1 Technical description The closing unit mainly consists of a cast iron closing plate (Item 1) with an integrated hydraulic ejector (Item 2), a cast iron nozzle plate (Item 3) with a clearance (Item 4), which doubles as an injection protection for the injection equipment.

- Page 50 Structure and Function Description of function: The unit is linked to the machine frame via a nozzle plate. The standard version of the closing plate is supported so that the weight forces are transmitted to the machine frame. ATTENTION! The sliding plates of the closing platen must be lubricated every 2,500 working hours.

- Page 51 Structure and Function 5.2.2 Mould fitting The mould is inserted into the closing unit from above by means of a suitable hoisting device. An eccentric ring (D=110 f7; 4,33 inch) is used to position the mould close to the nozzle plate.

- Page 52 Structure and Function number. Adjust the fastening nuts. 5. Withdraw the closing platen (Item 4) towards the fastening nut until the limit stop is reached. Make sure that the markings match. 6. Pull back closing plate to nut until limit stop is reached. 7.

- Page 53 Structure and Function 5.3 Injection unit 5.3.1 Technical description The injection unit consists of a plastification unit (Item 1), a holding device for the platification unit (Item 2), a fastening nut for the screw cylinder (Item 3), a metering drive unit including a hydraulic motor (Item 4), a cylinder block (Item 5) with an integrated nozzle drive cylinder (Item 6), an injection cylinder (Item 7) and the guiding roller (Item 8).

- Page 54 Structure and Function Description of function: The injection unit is set between the two closing cylinders by means of the guiding rollers and the two nozzle drive cylinders. The nozzle drive cylinders are directly connected to the closing cylinders and have the form of double-action hydraulic cylinders.

- Page 55 Structure and Function In the factory, the nozzle centre is set at the centre of the nozzle plate. If it becomes necessary, however, to correct the nozzle centre (e.g. exchange of the injection unit), observe the following steps: 1. Measure the deviation of the nozzle centre from the diameter of the eccentric ring both horizontally and vertically.

- Page 56 Structure and Function 5.3.4 Change and prestressing of synchronous belt 1. Uncouple screw and move injection cylinder to rear end position. 2. Loosen fastening screws (Item 1; 3x) and hand-tighten so that no gap can form between the guiding platen (Item 2) and hydraulic motor.

- Page 57 Structure and Function Preconditions: 1. Eject residual material from screw cylinder. 2. Heat screw cylinder to last preset material temperature, disconnect and dismount heater bands and thermocouples. Process: Bild: PL-0012.TIF 1. Pull back nozzle drive cylinder to rear limit stop. 2.

- Page 58 Structure and Function A: PL120101.053 B: PL120100.053 Chapter: 5.3 E: 03.93 / T. Weiß Page: 6 G: 06.93 / T. Weiß...

-

Page 59: Oil Tank

Structure and Function 5.4 Hydraulic unit 5.4.1 Pump element A continuously active electric motor is mounted with the pump. This electric motor drives the hydraulic pressure pump via the coupling. The hydraulic pressure pump is a variable capacity pump connected to the central hydraulic block by means of tubing. -

Page 60: Oil Cooler

Structure and Function Attention: In order to safeguard the operational safety and long material life of the machine, only original filter elements may be installed (Hydac 0165R010BN/HC; item No. MB628). 5.4.4 Oil cooler An oil suction cooler installed inside the oil tank ensures adequate cooling of the hydraulic oil. -

Page 61: Relief Valve Amplifier

Structure and Function After selecting a pressure of appr. 70 bar (1015 psi) and a material quantity of appr. 50%, the “Withdraw nozzle” movement adjusts the p setting of the output regulation of the variable capacity pump. The control block connection points MPP (pressure before quantity decrease) and MPS (pressure after quantity decrease) are used as measuring points. - Page 62 Structure and Function Speed setting is done by means of a proportional choker valve, which is activated by the proportional amplifier. For speed setting, the following steps have to be taken in that order: a) Set the “Dither” potentiometer at 50% (clockwise direction, 50% are 10 rotations = original manufacturer’s setting).

-

Page 63: Setting For Maximum Pressure Protection For

Structure and Function Pressure setting is done by means of a proportional pressure control valve which is activated by the proportional amplifier. For pressure setting, the following steps have to be taken in that order: a) Set the “Dither” potentiometer at 50% (clockwise direction, 50% are 10 rotations = original manufacturer’s setting). - Page 64 Structure and Function This setting is only necessary if the pump type plate does not give 210 bar for DR. ATTENTION ! For “Withdraw nozzle” movement set pressure at 100% and speed at 70%. Initiate “Withdraw nozzle” movement and set “Amplifier” potentiometer at a pressure of 220 bar (3190 psi).

- Page 65 Structure and Function the required hydraulic valves and the consumer’s terminals (2 x R1/4"). This function module is mounted on the left connecting wall of the piece ejection shaft. The delivery package does not include a connection to the mould core pull cylinder. Furthermore, it must be borne in mind that the available hydraulic pressure is 210 bar (3045 psi).

- Page 66 Structure and Function A: PL120101.054 B: PL120100.054 Chapter: 5.4 E: 03.93 / T. Weiß Page: 8 G: 06.93 / T. Weiß...

-

Page 67: Pneumatic Unit

Structure and Function 5.5 Pneumatic unit 5.5.1 Material feeder device UNIFEED (optional) 1) Area of application The material feeder device was conceived for use with a plastics processing machine; it is installed directly above the screw cylinder (instead of the hopper). This device is characterized by high operational reliability since it does not contain any movable components;... - Page 68 Structure and Function Bild: PL-A0043.TIF Bild: PL-0032.TIF A: PL120000.055 B: PL120000.055 Chapter: 5.5 E: 06.93 / T. Weiß Page: 2 G: 06.93 / T. Weiß...

- Page 69 Structure and Function 3) Processing of reclaimed material The UNIFEED device is principally suited for feeding regenerated material together with new granulated material. However, the grain size must not exceed 3-4 mm (0.12-0.16 inch). It must be said that a higher degree of contamination entails increased clogging of the filter;...

- Page 70 Structure and Function 5) Air consumption Q in case of 100% action time Q in case of 50 kg (115 lb) of material per hour Q in case of 35 kg (80 lb) of material per hour Bild: PL-0035.WMF Air consumption Q n / min Pneumatic pressure (abs.) (44)

-

Page 71: Pneumatic Core Pull

Structure and Function 5.5.2 Pneumatic core pull (optional) The pneumatic core pull consists of an electrical 4/2 pulse valve including all service connections for a plastic pipe, NW This functional module is installed on the left connecting wall of the ejector shaft. The hook-up to the core pull cylinder supplied by the manufacturer is not part of the delivery package. - Page 72 Structure and Function A: PL120000.055 B: PL120000.055 Chapter: 5.5 E: 06.93 / T. Weiß Page: 6 G: 06.93 / T. Weiß...

-

Page 73: Electric Unit

Structure and Function 5.6 Electric unit 5.6.1 Electric drive The pump unit is driven by a 4-pole three-phase asynchronous motor. Bild: Pl-0026.DRW The drive motor is coupled directly to the hydraulic pump and connected in accordance with the operating voltage of the relevant circuit ( Y or ). -

Page 74: Control Box

Structure and Function 5.6.2 Control box The control box is easily accessible; it is located at the front of the machine and contains the majority of the electrical devices necessary for operation. Front view of control box: Bild: Pl-0022.TIF EMERGENCY STOP button Manual control panel Input panel Auxiliary control panel... - Page 75 Structure and Function Right-hand view of control box: Combined cycle counter and time meter Outlet filter Inlet filter Main input point, top Main input point, bottom Type plate Rating plate Left-hand view of control box: EMERGENCY STOP button Socket holding plate Device for switching to follow-up pressure, depending on the pressure inside the mould (optional)

- Page 76 Structure and Function Back view of control box: Bild: Pl-0025.TIF Cable outlets Socket heater band - nozzle Socket heater band - zone 1 Socket heater band - zone 2 Reserve Cable thermocouple sensor - nozzle (optional) Cable thermocouple - zone 1 Cable thermocouple - zone 2 Reserve A: PL120100.056...

- Page 77 Structure and Function 5.7 Control 5.7.1 Description of electronic system General The real-time control system UNILOG 1020 is the centre of all control tasks required to run the machine properly. The control system consists of two system units: a) operating unit for the display and presetting of all process- relevant data.

- Page 78 Structure and Function Description of individual components 3.1 Operating unit (CTD) The operating unit provides all necessary functions for the communication of operator and machine. All information items are represented by symbols, i.e. are independent of language. The unit consists of the following areas: a) Set value input panel for displaying and inputting individual set values.

-

Page 79: Operation

Structure and Function Digital output card CA 16 For outputting 16 digital signals with a maximum capacity of 2.5 A. Each output is tested for overload and short-circuiting. If this monitoring function reacts, all output cards of the control system are deactivated. An LED indicates the defective output card. - Page 80 Structure and Function A: PL120100.057 B: PL120100.057 Chapter: 5.7 E: 03.93 / T. Weiß Page: 4 G: 06.93 / T. Weiß...

-

Page 81: Startup

Operation Chapter 6: Operation 6.1 Startup The machine is switched on by pressing the master switch on the control box door. If possible, the master switch should always be activated without load, i.e. first press master switch before switching on the heating. Press the red EMERGENCY STOP button located on the side of the control box and release by rotating in direction of arrow (to check EMERGENCY STOP circuit). -

Page 82: Starting The Machine After Emergency Stop

Operation 6.2 Starting the machine after EMERGENCY STOP After pressing the EMERGENCY STOP button, eliminate the malfunction or error or external cause of EMERGENCY STOP (i.e. peripheral device, e.g. robot) and unlock the EMERGENCY STOP button by rotating it in the direction of the arrow. -

Page 83: Maintenance

Maintenance Chapter 7: Maintenance 7.1 General The machine will only work properly and without hitches if it is regularly serviced. We recommend cleaning the machine every day to remove impurities and to clean it thoroughly each week. The protecting guard and control panel must always be kept free of any type of impurity. - Page 84 Maintenance 7.3 Table of hydraulic oils and lubricants Pneumatic Lubricating point Hydraulic installation Greasing points control device acc. to DIN HLP 68 DIN 51524 T 2 K 2 K DIN 51825 HL 10 DIN 51524 T 2 Agip OSO 10 Agip OSO 68 Agip GR MU 2 Agip Radula 10...

-

Page 85: Spare Parts / Drawings

In addition, an acknowledgement number (RM Nr.:) is featured above the DOK number. When ordering, please contact either your authorized BATTENFELD dealer or BATTENFELD Austria (see addresses and phone numbers in chapter 9). To avoid any possible misunderstanding, please always give the machine number when ordering spare parts. - Page 86 Spare Parts / Drawings A: PL120100.080 B: PL120100.080 Chapter: 8 E: 03.93 / T. Weiß Page: 2 G: 05.94 / G. Krajnik...

- Page 87 Customer Service Contact Injection Molding Injection Molding Injection Molding Injection Molding Injection Molding BATTENFELD INTERNATIONAL contact 1 0 7 W T 1...

- Page 88 Customer Service Contact Service Battenfeld Spritzgießtechnik bietet seinen Kunden ein umfangreiches und effizientes Serviceportfolio an. Schnell, zuverlässig und kompetent betreuen die Servicestellen unsere Kunden in mehr als 80 Ländern der Welt. Servicevereinbarungen Kalibrier-Service Basis-Service Standard-Service Full Service Vorbeugende Instandhaltung •...

- Page 89 Customer Service Contact Maschinen-Upgrades • Steuerungsmodernisierung • Software-Upgrades • Nachrüstung von Zusatzspritzaggregaten für Mehrfarbentechnik • Nachrüstung von Beistellaggregaten auch an Fremdmaschinen • Optionsnachrüstungen (z. B. Kernzüge, Airmould®, Hilfsachsen für Roboter, EUROMAP- Schnittstellen etc.) Starke Partner Bei Bedarf ermöglichen wir unseren Kunden den Kontakt zu Partnern unseres weltweiten Netzwerkes aus den Bereichen •...

- Page 90 Tel.: 0043-2252-404-6219 Fax: 0043-2252-404-6202 e-Mail: markus.gaisch@battenfeld-imt.com Training Tel.: 0043-2252-404-7410 Fax: 0043-2252-404-7505 e-Mail: karin.stefan@battenfeld-imt.com Australia (VAU) Battenfeld Australia Pty. Ltd. 3, Phoenix Court Braeside, 3195 Melbourne / Australia Postal address: P.O.Box 614 Mordialloc, 3195 Melbourne / Australia Tel.: 0061-3-9587-5211 Fax: 0061-3-9587-5224 e-Mail: service@battenfeld.com.au...

- Page 91 Further Straße 27 A-2564 Weißenbach Tel.: 0043-2674-87427 0043-2674-87413 Fax: 0043-2674-874135 e-mail: fr0198@aol.com Brasilia (VBR) Battenfeld do Brasil Ltda. R. Seranouch Magdesian, 489 (antiga R. Arnaldo de Oliveira Barreto) 06210-130 Osasco-SP / Brazil Tel.: 0055-11-3699-2883 Fax: 0055-11-3699-2883 e-Mail: battenfeld.brasil@vbr.battenfeld.com Canada (VCA) Battenfeld Canada Co.

- Page 92 AI-LE Building 10H ShanghaiTel.: 0086-21-64866856 0086-21-64866857 0086-21-64863796 Fax: 0086-21-64866858 e-Mail: royaland@value-net.com.cn Agency for: Guangdong (VHK) Battenfeld Hong Kong Ltd. 2/Fl., No. 18 Dai Fat Street Tai Po Industrial Estate Tai Po, N.T. HONG KONG Tel.: 00852-2666-9140 Fax: 00852-2665-2526 e-Mail: bathk@hk.super.net Croatia Fokuma Planungs- u.

- Page 93 Smid Spol. sro. Ke Kastanku 236 CZ-252 18 Uhonice / Tschechische Republik Tel.: 00420-311-670253 Fax: 00420-311-670795 e-Mail: zastoupeni.battenfeld@pvnet.cz Danmark (VDK) Battenfeld Danmark AS Stengaardsvej 7 4340 Toelloese / Danmark Tel.: 0045-59185949 Fax: 0045-59186922 e-Mail: hagemann.k@battenfeld.dk England (VUK) Battenfeld U.K. Ltd.

- Page 94 Customer Service Contact Germany Battenfeld Kundendienst GmbH&Co.Kg Scherl 10 58540 Meinerzhagen - Deutschland Head Customer Service:++49 (0) 2354/72-120 Sekretary: ++49 (0) 2354/72-121 Fax:++49 (0) 2354/72-129 e-Mail: karina.reitz@battenfeld-imt.com Head Technical Customer Service Team National 1 Tel.: ++49 (0) 2354/72-161 Fax: ++49 (0) 2354/72-139 e-Mail: michael.hinz@battenfeld-imt.com...

- Page 95 General Plastics Ltd. Representatives - Importers Laskaridou 143 Kallithea 17675 Athens / Greece Tel.: 0030-1-9567885 Fax: 0030-1-9560137 Hong Kong (VHK) Battenfeld Hong Kong Ltd. Units 910-911 No. 1 Hung To Road Kwun Tong Kowlon Tel.: 00852-2666-9140 Fax: 00852-2665-2526 e-Mail: bathk@hk.super.net...

- Page 96 #302 940-2, Siheung 3-Dong Geumchun-Gu SEOUL SÜDKOREA 153-861 Tel 0082-2-8931294 Fax 0082-2-8931293 e-Mail: insook@bestoncorp.co.kr Malaysia (VSI) Battenfeld Injection Moulding Technology (S) Pte. Ltd. Blk. 196, Pandan Loop #01-16 Pantech Industrial Complex SGP 128384 / SINGAPORE Tel.: 0065-773-0821 Fax: 0065-773-2427 e-Mail: batasean@singnet.com.sg Mazedonia Fokuma Planungs- u.

- Page 97 Adamowizna 151 05-825 Grodisk Maz / Polen Tel: 0048 22 724 38 07 Fax: 0048 90 213 014 e-Mail: battenfeld@hot.pl Portugal (VES) Battenfeld Iberica S.A. Poligono Industrial La Ferreria Avda. La Ferreria 29 E-08110 Montcada i Reixach Espagna Tel.: 0034-93-5646053...

- Page 98 00421-905821858 e-Mail: fr0198@aol.com Slovakia Fokuma spol. s.r.o. Gogolova 18 SK-85202 Bratislava / Slowakei Tel/Fax: 00421-7-638-11-858 Spain (VES) Battenfeld Iberica S.A. Poligono Industrial La Ferreria Avda. La Ferreria 29 ES-08110 Montcada i Reixach / Espagna Tel.: 0034-93-5646053 Fax: 0034-93-5646600 South Africa D.K.

- Page 99 Yenibosna 34520 Istanbul Turkey Tel.: 0090-212-5522361 Fax: 0090-212-5529670 e-Mail: meltemltd@turk.net USA (VUS) Battenfeld of America, Inc. 1620 Shanahan Drive 60177 SOUTH ELGIN, IL Tel. 001 – 847-5310015 Fax. 001 – 847-5310029 e-Mail: batserve@aol.com Yugoslavia Fokuma Planungs- u. Vertriebsges.m.b.H. Further Straße 27, A-2564 Weißenbach Tel.:...

- Page 100 Customer Service Contact contact 1 0 7 W T 1...

-

Page 101: Screw Cylinder

Dieser Text dient nur als Hintergrund. Das Kapitel Stichwortver- zeichnis und Glossar zeigt Ihnen die ent- Index sprechenden Seiten im Text auf und ver- Chapter 10: Index 10.1 Description of technical terms Closing force The closing force can be established and maintained both mechanically and hydraulically. - Page 102 Dieser Text dient nur als Hintergrund. Das Kapitel Stichwortver- zeichnis und Glossar zeigt Ihnen die ent- sprechenden Seiten Index im Text auf und ver- Injection The screw rotation stops after the plastification process. The forward axial movement of the screw (in the direction of the mould) transports (injects) the melted moulding material into the mould cavity.

- Page 103 Dieser Text dient nur als Hintergrund. Das Kapitel Stichwortver- zeichnis und Glossar zeigt Ihnen die ent- Index sprechenden Seiten im Text auf und ver- Nozzle The front end of the screw cylinder is a nozzle, providing a link between the screw cylinder and the mould. Nozzle plate The nozzle and closing plates are equipped with centering bores to hold the eccentric rings of the mould.

- Page 104 Dieser Text dient nur als Hintergrund. Das Kapitel Stichwortver- zeichnis und Glossar zeigt Ihnen die ent- sprechenden Seiten Index im Text auf und ver- Screw cylinder The screw cylinder consists of a thick-walled steel tube heated by electrical heater bands. Screw drive The rotating screw is usually driven by a hydraulic motor.

Need help?

Do you have a question about the PLUS 250/50 and is the answer not in the manual?

Questions and answers