Summary of Contents for Incon 1250-LTC

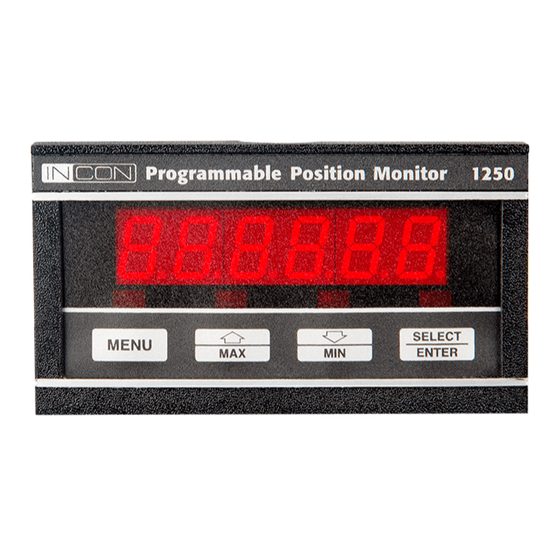

- Page 1 INSTALLATION AND PROGRAMMING MANUAL FOR MODEL 1250-LTC PROGRAMMABLE POSITION MONITOR Solid State Indicator for SynchroTransmitter 000-2072 Rev. C...

- Page 2 PO Box 638 Saco, Maine 04072 USA Phone: 207-283-0156 FAX: 207-283-0158 Toll Free: Technical Service & Sales 800-872-3455 Web Site: www.incon.com E-mail: sales@incon.com This manual applies to all INCON model 1250-LTC monitors Copyright 2008, Intelligent Controls, Inc. All rights reserved...

-

Page 3: Table Of Contents

TABLE OF CONTENTS Section: Page: List of Figures…………………………………………………………………… 4 List of Tables……………..……………………………………………………… 4 Introduction……………………………………………………………………... 5 1.0 Installation……………………………………………………………..…… 5 - 8 2.0 Programming…………………………………………………………..…… 9 – 33 2.1 Front Panel Programming…………………………………………….. 9 2.2 Serial Port Programming – ASCII …………………………………… 13 - 17 2.3 Serial Port Programming –... -

Page 4: List Of Figures

LIST OF FIGURES Figure: Page: Mechanical Dimensions…………………………………………………………… 6 Field Wiring Diagram…………………………………………………………….. 6 Field Wiring Diagram with 4-20mA Option.…………………………………….. 7 Simplified Programming Flowchart…...…………………………………………. 12 Serial Data Dump Example……………………………………………………….. 17 Base 1 Uni-Polar Mode Analog Output………………………………………….. 35 Base 0 Uni-Polar Mode Analog Output………………………………………….. 36 Bi-Polar Mode Analog Output……………………………………………………... -

Page 5: Introduction

The INCON 1250-LTC series is unique in its capability to monitor up to 40 user- definable position segments. It is specifically designed for monitoring power transformer load tap changer position, where the desired readout is in whole tap numbers. -

Page 6: Mechanical Dimensions

Figure 1.1 Mechanical Dimensions Figure 1.2 Field Wiring Diagram... - Page 7 Figure 1.3 Field Wiring Diagram with 4-20mA Output Table 1.1 Terminal Functions Terminal Function Terminal Function Analog Output + Analog Output – Program Mode Inhibit (Spare) Inhibit Return R1 * Line L1 * R2 * Line L2 * Chassis Ground * Terminals E &...

- Page 8 (See Figure 1.3, page 7). 4) When additional remote indication is needed, several 1250-LTC’s may be wired in parallel to the same transmitter. The 1250-LTC can also be connected via its serial port to the INCON model RD-4 Remote Display unit.

-

Page 9: Programming

2.0 PROGRAMMING The Model 1250-LTC has three methods of programming: numeric menu (traditional 1250); alphanumeric menu; and serial port programming commands. The 1250-LTC can be ordered with either RS-232 or RS-485 serial port hardware. The serial programming commands can be in the form of ASCII characters or MODBUS packets, depending upon the position of DIP switch #2. - Page 10 Num- Alpha-numeric Function: Default Programmable eric Protocol Value: Range: OP 19 dEGrE Displays absolute synchro position in degrees with one decimal place resolution OP 20 tAPS Number of taps 2 to 40 OP 21 d SEG Degrees per tap 10.000 -99999 to +99999 OP 22 Number of neutral taps...

- Page 11 Num- Alpha-numeric Function: Default Programmable eric Protocol Value: Range: OP 60 Aut27 Auto-Reset after “FA 27” Unstable On or OFF Synchro Signal Error (page 50) OP 61 27rLY Selects which relay will assert when the OFF, LO, HI “FA 27” error is active OP 62 OtGLt Sets On-Tap guard band limit (Degrees)

-

Page 12: Simplified Programming Flowchart

Num- Alpha-numeric Function: Default Programmable eric Protocol Value: Range: OP 88 PtrSt Resets the “Pass-Through-Neutral” rESEt counter & alarm OP 90 1dCLt Sets the limit for number of consecutive 2 to 30 tap changes in One Direction OP 91 1drLY Selects which relay will assert when the OFF, LO, HI “One Direction Change”... -

Page 13: Serial Port Programming - Ascii

The terminal must have the proper Comm port settings to communicate to the 1250-LTC (see Sections 3.3 and 3.4, pages 46 - 47). See Table 2.2 for a full listing of all Serial Programming Commands and syntax. - Page 14 Command Syntax: Function: Explanation: DEGSEG◊n.nnnn Set degrees per segment n= a floating point number, 5 digits max, average number of degrees between taps NEUTRALS◊n Set number of neutral taps n= an integer from 0 to 8 NSTART◊nn Set lowest neutral tap number n= an integer, any valid tap number SETTAP◊nn Set present tap position...

- Page 15 Command Syntax: Function: Explanation: OTGDLMT◊nn.n Sets the On-Tap guard band n= a number of degrees from 0.0 to 99.9 limit in DEGREES with one tenth degree resolution OTRLY◊LO Selects which relay is associated Choose “OFF”, “LO” or “HI” relay to with the On-Tap alarm assert when the alarm limit is reached OTDVTN...

- Page 16 HELP◊(command) Provides on-line help on the An explanation of a command and the specific command entered or proper entry syntax is given. If no lists all available commands command is entered, all commands will be listed with syntax but no explanations To prevent accidental or unwanted changes to the program parameters, a jumper wire may be installed across terminals 3 &...

-

Page 17: Serial Data Dump Example

Site ID: Maplewood Sub LTC #2 INCON 1250-LTC Firmware Revision X.xx Copyright 2007 Present Tap: Total Tap Changes: 5729 Low Draghand: -7 35.4 Days Since LAST Visit High Draghand: 8 17.6 Days Since LAST Visit ALARMS: Since activated - Days:... -

Page 18: Serial Port Programming - Modbus

MODBUS communication software and serial port hardware to the 1250-LTC’s serial port cable. The computer must have the proper Comm port settings to communicate to the 1250-LTC (see Section 3.3, page 46). See Table 2.3 for a full listing of all MODBUS Registers, the definition and binary format for each. -

Page 19: Modbus Packet Format - Read

(read multiple registers) and “16” (write multiple registers). By supporting these two commands the 1250-LTC is in level 0 compliance. Using these two commands it is possible to configure the 1250-LTC as well as monitor it for current position. MODBUS RTU command and response packets are formatted as follows: 2.3.1 MODBUS Packet Format - Read... -

Page 20: Modbus Packet Format - Write

2.3.2 MODBUS Packet Format - Write Write to Holding Registers: GAP = A gap in transmission of 3.5 character frames indicates to the slaves that a new packet is to follow. No transmission gaps within a packet may exceed 1.5 character frames. Byte 1 = Device Address: Address 0 is a broadcast address that all units respond to regardless of programmed address. -

Page 21: Modbus Packet Format - Error Exception Response

2.3.3 MODBUS Packet Format – Error Exception Response When the master sends a command, the MSB bit in the Function Code is always clear. When a slave responds to the command, the slave leaves the MSB bit in the Function Code clear if the response is a normal response and sets MSB bit on if the response is an error exception response. - Page 22 Table 2.8 RS-485 MODBUS Register Definitions Register Class & Type Function: Binary Format: Address: Decimal [hex] 40001 Class: Setup / run 000000000000000s Configuration mode select [0000] LSB (s) Type: 0 – run mode Read\write 1 – setup mode This bit must be 1 before any program parameter can be changed 40002 Class:...

- Page 23 Register Class & Type Function: Binary Format: Address: Decimal [hex] 40519 Class: State Low tap tttttttt0000nnnn draghand [0206] Type: Read-only [“0000” are unused bits] “t”= 8-bit tap number “n”= 4-bit neutral number (both in binary) 40520 Class: Draghand 000000000000000s Configuration counter start [0207] visit...

- Page 24 Register Class & Type Function: Binary Format: Address: Decimal [hex] 40801 Class: On-tap alarm 000000000000000s AlarmClearing, state [0320] AlarmStatus LSB (s) 0 – OK Type: 1 – ALARM Read\write, Write 0 to clear 40802 Class: One-direction 000000000000000s AlarmClearing, alarm state [0321] AlarmStatus LSB (s)

- Page 25 Register Class & Type Function: Binary Format: Address: Decimal [hex] 40807 Class: Total tap change 000000000000000s AlarmClearing, alarm state [0326] AlarmStatus LSB (s) 0 – OK Type: 1 – ALARM Read\write, Write 0 to clear 40808 Class: Low tap alarm 000000000000000s AlarmClearing, state...

- Page 26 Register Class & Type Function: Binary Format: Address: Decimal [hex] 40839 Class: AlarmStatus Days since dddddddddddddddd asserting Total [0346] Type: Read-only tap changes “d” = 10ths of a day alarm 40840 Class: AlarmStatus Days since dddddddddddddddd asserting Low [0347] Type: Read-only tap alarm “d”...

- Page 27 Register Class & Type Function: Binary Format: Address: Decimal [hex] 44097 Class: Operating mode 00000000000mmmmm Configuration [1000] LSBs (mmmmm) Type: (see list of modes on page 34) Read\write 44353 Class: Number of taps 000000000nnnnnnn Configuration [1100] 7-bit number (in binary) Type: Read\write 44354,...

- Page 28 Register Class & Type Function: Binary Format: Address: Decimal [hex] 45121 Class: Display blank 000000000000000b Configuration [1400] LSB(b) Type: 0 = disabled Read\write 1 = enabled [display will blank] 45122 Class: Menu mode 000000000000000m Configuration [1401] LSB (m) Type: 0= numeric Read\write 1=alphanumeric 45155...

- Page 29 Register Class & Type Function: Binary Format: Address: Decimal [hex] 45635 Class: Word length 000000000000000w Configuration [1602] LSB (w) Type: 0 = 7 bits Read\write 1 = 8 bits 45636 Class: Parity 00000000000000pp Configuration [1603] LSBs (pp) Type: 00 = none Read\write 01 = even 10 = odd...

- Page 30 Register Class & Type Function: Binary Format: Address: Decimal [hex] 46145 Class: On-tap guard dddddddddddddddd Configuration band limit [1800] “d” = tenths of a degree Type: (in binary) Read\write 46146 Class: On-tap alarm 00000000000000 rr Configuration relay [1801] LSBs (rr) Type: 00 –...

- Page 31 Register Class & Type Function: Binary Format: Address: Decimal [hex] 46657 Class: Pass-through- dddddddddddddddd Configuration neutral limit [1A00] “d” = tenths of a day Type: (in binary) Read\write 46658 Class: Pass-through- 00000000000000 rr Configuration neutral counter [1A01] alarm relay LSBs (rr) Type: 00 –...

- Page 32 Register Class & Type Function: Binary Format: Address: Decimal [hex] 47938 Class: Tap change 00000000000000 rr Configuration acknowledge [1F01] relay LSBs (rr) Type: 00 – OFF Read\write 01 – LO Relay 10 – HI Relay 47939 Class: Acknowledge 000000000sssssss Configuration relay delay time [1F02] “s”...

- Page 33 Register Class & Type Function: Binary Format: Address: Decimal [hex] 48706 Class: State Tap number ssssssssssssssss corresponding [2201] Type: Read-only to Tap index Signed 16-bit word select 48707 Class: State Neutral number uuuuuuuuuuuuuuu corrresponding [2202] Type: Read-only to Tap index Unsigned 16-bit word select 48708...

-

Page 34: Operating Modes

2.4 Operating Modes: The model 1250-LTC has six operating modes. Each mode causes the 1250-LTC to function differently. Determine which of the following operating modes is best suited to your application. The proper mode will depend upon the desired numbering of the taps and where... -

Page 35: Base 1 Uni-Polar Mode Analog Output

Modes 16 & 17: Base 1 Uni-polar Segmented These modes are used for LTC monitoring when the lowest tap number is 1. There may be multiple neutral taps. They can be located anywhere between the lowest and highest taps as long as they are grouped together in one section. Mode 16 has a linear analog output that continuously varies with LTC shaft position. -

Page 36: Base 0 Uni-Polar Mode Analog Output

Modes 18 & 19: Base 0 Uni-polar Segmented These modes are used for LTC monitoring when the lowest tap number is 0. There may be multiple neutral taps, but they can only be located at tap 0. Mode 18 has a linear analog output that continuously varies with LTC shaft position. -

Page 37: Bi-Polar Mode Analog Output

Modes 20 & 21: Bi-polar Segmented These modes are used for LTC monitoring when the neutral tap(s) are in the center of the dial and there is an equal number of raised and lowered taps. There may be multiple neutral taps, but they can only be located at tap 0. Mode 20 has a linear analog output that continuously varies with LTC shaft position. -

Page 38: Programming Notes

2.5 Programming Notes: If the Degrees Per Tap value is not known, the 1250-LTC can be used to determine this value. Follow these steps to determine the Degrees Per Tap value: 1) Enter the Programming Menu and select OP 19 (Degrees Mode) and press the ENTER key. -

Page 39: Options

If the presence of high voltage AC “ripple” is found on the analog output terminals, it is generally not a problem with the 1250-LTC itself. Check the isolation of all field wiring with respect to earth ground. All wiring should be completely isolated from ground. See Section 3.5, page 48 Input Isolation Option. -

Page 40: High / Low Relay Limits

3.2 High / Low Relay Limits Option “-R” In the 1250-LTC, the High / Low Relays serve as alarm annunciators for the many programmable limits associated with expanded LTC monitoring. The (two) relays are normally open, dry contacts. Each relay may have one or more of the alarm limits assigned to it. -

Page 41: Tap Change Acknowledgement

Use the OP 5, tCrLt, ACKHOLD command to set the duration time. 3.2.2 High Tap Relay and Low Tap Relay The 1250-LTC can close a relay contact when the LTC moves beyond programmable upper and lower position limits. When the LTC tap position value reaches the Low Relay limit, the assigned Low Tap Relay turns on, the appropriate Relay LED will light up, and the alarm code “LOtAP”... -

Page 42: Total Tap Change Count

3.2.3 Total Tap Change Count Relay The 1250-LTC can count the number of tap position changes and turn on a relay and LED when a programmed limit (10 to 999,990 counts) is reached. The alarm code “ttCLt” will also be displayed momentarily. The counter can be pre-set to any number. A date can be entered for reference purposes when the count is preset. -

Page 43: On-Tap Example

Figure 3.2 On-Tap Example Figure 3.1 is an example of an LTC with 10.0 degrees per tap position. This LTC should stop at the “zero degrees” center point on every tap, plus or minus a programmable tolerance (“Guard Band”) of 1.5 degrees (green area). If the LTC ever stops more than 1.5 degrees from the center (red area) of any tap, the On-Tap Alarm Relay will be asserted and an LED will flash. -

Page 44: Up-To & Down-To Count

LTC’s the contact surface used in changing Up-To a tap is different than the surface used in changing Down-To the same tap. As the 1250-LTC is monitoring the movement of the LTC, it will keep a log of how many times the LTC changes Up-To and Down-To each tap. -

Page 45: One-Direction Change Count

– especially in the case of parallel transformers. As the 1250-LTC monitors LTC position, it can be programmed to assert an alarm relay if it sees the LTC move too many taps consecutively in one direction, up or down. A... -

Page 46: Serial Rs-232

RS-232 port for the current position. This is done by first instructing the 1250-LTC to latch the current position by transmitting an asterisk (*) to the unit. The position is then extracted, one character at a time, by transmitting the digits 0 through 6. Zero causes the sign character to be transmitted, 1 through 6 causes each position digit to be sent. -

Page 47: Serial Rs-485

MODBUS is the most likely protocol to use for a 1250-LTC equipped with RS-485, but the 1250-LTC with RS-485 will operate in all of the same serial modes listed above in Section 3.3. Certain restrictions apply due to the nature of the half-duplex configuration: The device communicating to the 1250-LTC must be able to turn off its transmitter very quickly so that the 1250-LTC can respond over the same transmission lines. -

Page 48: Input Isolation

Isolation Option will prevent AC voltage from becoming impressed upon the 1250-LTC’s analog output signal to that device. (See Note at the end of Section 3.1, page 39) This option consists of two signal isolation transformers installed in the signal input circuitry. -

Page 49: Analog Output Adjustment Pots

The 1250-LTC has the capability to delete all user-programmed values and restore all factory default program values. This “cold boot” is accomplished by pressing the “MENU” key while turning on the power to the 1250-LTC. There is no way to undo the effects of a cold boot. -

Page 50: Error Codes

5.0 ERROR CODES Table 5.1 Error Codes DISPLAY DESCRIPTION FA 2 Watchdog Re-start (Processor Crash If condition recurs, call the factory.) Memory Error at start-up FA 3 (User programming is erased, factory program defaults are re-loaded.) Keyboard Error at start-up FA 5 (UP or Down Key, or more than one key is being pressed during power-up.) FA 20... -

Page 51: Specifications

6.0 SPECIFICATIONS (All values are typical, unless otherwise specified) ENCLOSURE: RECTANGULAR PANEL MOUNTED INSTRUMENT MATERIAL PLASTIC SIZE 89mm W X 41.3mm H X 178mm D BEZEL 112mm W X 62mm h X 17.5mm D MOUNTING INTEGRAL SNAP-IN TABS POWER INPUT: CONNECTOR SCREW TERMINALS L1, L2, GND VOLTAGE... - Page 52 Model 1250-LTC Installation & Programming Manual...