Advertisement

Quick Links

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Flowserve ISC1PX

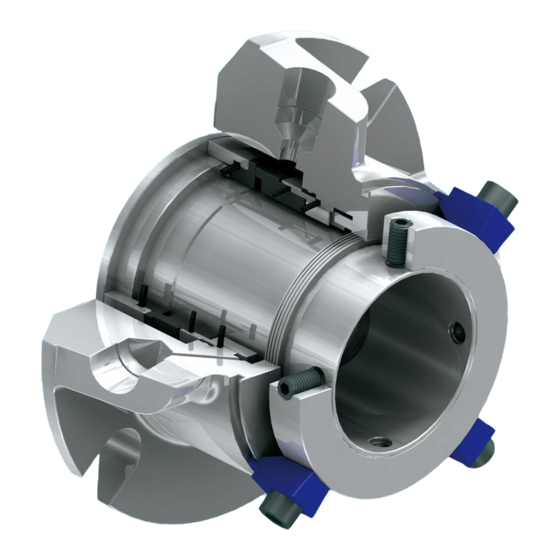

- Page 1 Repair Instructions ISC1PX Single Pusher Seal Experience In Motion...

- Page 2 For assistance with seal failure analysis, please contact your Flowserve representative. Seal Parts that are always replaced Reconditionable Seal Parts •...

-

Page 3: Inspection And Reconditioning

O-ring surfaces to achieve the required surface finish (see 3.2A and 3.3A for the required surface finish). If any parts require machining to correct damage, please contact your Flowserve representative for dimensional requirements, or for any other questions regarding repair. - Page 4 Seal Assembly Instructions 4.1 Tools Required • ", " hex key wrenches (Sizes < 2.625"); ", " hex key wrenches (Sizes 2.625" and larger) • Silicone grease (included in repair kit) • Ethyl alcohol and clean, lint free towel for cleaning seal faces 4.2 As part of the assembly of the seal, there are several blind fits of pins and drive flats.

- Page 5 4.6 Place the seat gasket O-ring Figure 7 13.1 on the O-ring surface of the stationary face 14 , which is the smallest outside Seat Gasket diameter. Place the stationary O-ring 13.1 face with the sealing face down on a clean, flat surface. (Figure 7) 4.7 Align the stationary face drive pins in stator face support 100...

- Page 6 4.12 Place the drive collar 58 onto the end of the sleeve with the “Flowserve” logo facing up. (Figure 12) Align the quarter dog set screws with the smaller holes in the end of the sleeve. On smaller...

-

Page 7: Static Testing

Gasket Static Testing 5.1 Flowserve manufacturing typically air tests the ISC at 25 psig. A pressure drop of less than one pound at 25 psig is acceptable. To static test the seal, bolt it to a single seal test barrel or to the equipment. Secure the cup point set screws to the stub shaft or equipment shaft to prevent deformation of the setting devices due to axial loads. - Page 8 When properly selected, this Flowserve product is designed to perform its intended function safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial service conditions.

Need help?

Do you have a question about the ISC1PX and is the answer not in the manual?

Questions and answers