Summary of Contents for ESAB Aristo 1000

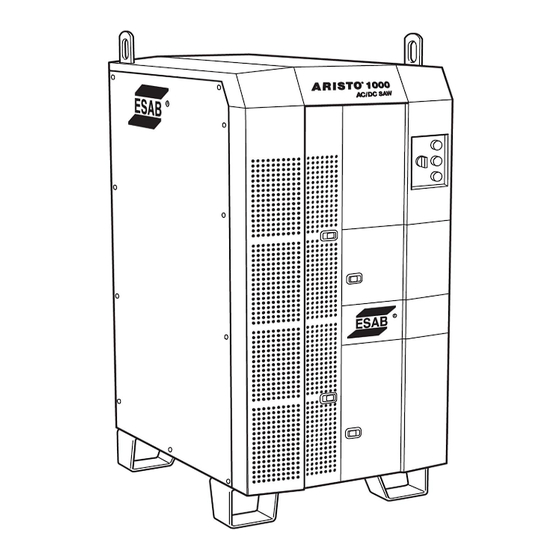

- Page 1 Aristo® 1000 AC/DC SAW Instruction manual Valid for: serial no. 336-xxx-xxxx 0462 985 101 GB 20170207...

-

Page 3: Table Of Contents

FAULT-TRACING................... 18 ORDERING SPARE PARTS ................19 CABLE ROUTING REQUIREMENTS ..............CLEANING......................DIAGRAM ......................ASSEMBLY INSTRUCTIONS ................CONNECTION INSTRUCTION................ORDERING NUMBERS ..................WEAR PARTS....................... ACCESSORIES ....................Rights reserved to alter specifications without notice. 0462 985 101 © ESAB AB 2017... -

Page 4: Safety

Data Sheets (SDSs). Safety precautions Users of ESAB equipment have the ultimate responsibility for ensuring that anyone who works on or near the equipment observes all the relevant safety precautions. Safety precautions must meet the requirements that apply to this type of equipment. The following recommendations should be observed in addition to the standard regulations that apply to the workplace. - Page 5 • Protect your eyes and body. Use the correct welding screen and filter lens and wear protective clothing. • Protect bystanders with suitable screens or curtains. NOISE - Excessive noise can damage hearing Protect your ears. Use earmuffs or other hearing protection. 0462 985 101 - 5 - © ESAB AB 2017...

- Page 6 For further information contact the nearest ESAB dealer. ESAB has an assortment of welding accessories and personal protection equipment for purchase. For ordering information contact your local ESAB dealer or visit us on our website. 0462 985 101 - 6 -...

-

Page 7: Introduction

2 INTRODUCTION INTRODUCTION Aristo 1000 is a welding power source intended for high productivity submerged arc welding with direct current (DC) or alternating current (AC). The power source has many setting options for those who want to optimise their welding process. -

Page 8: Technical Data

Mains supply, S sc min Minimum short circuit power on the network in accordance with IEC 61000-3-12. 0462 985 101 - 8 - © ESAB AB 2017... -

Page 9: Installation

. Refer to the technical data in the scmin TECHNICAL DATA chapter. NOTE! The power source can be powered from a generator. For more information, contact authorised ESAB service personnel. Lifting instructions 0462 985 101 - 9 - © ESAB AB 2017... -

Page 10: Location

(9.86") all the way around. When installing the power source on the floor, see the dimensions according to the hole pattern in the "ASSEMBLY INSTRUCTIONS" appendix to this manual. 0462 985 101 - 10 - © ESAB AB 2017... -

Page 11: Example Of Welding Equipment

9 Measurement cable, speed 2 Control unit 6 Measurement cable, 10 Motor cable workpiece 3 Control cable 7 Workpiece 11 Measurement cable, welding voltage 4 Welding power source 8 Welding cable 0462 985 101 - 11 - © ESAB AB 2017... -

Page 12: Cable Routing

4 INSTALLATION Cable routing *Recommended 3 Control cable 5 Return cable 6 Measurement 8 Welding cable cable, workpiece For more information regarding cable routing, see the "CABLE ROUTING REQUIREMENTS" appendix. 0462 985 101 - 12 - © ESAB AB 2017... -

Page 13: Mains Power Supply

80 A 80 A 80 A 63 A 63 A NOTE! The fuse sizes as shown above are in accordance with Swedish regulations. Use the welding power source in accordance with the relevant national regulations. 0462 985 101 - 13 - © ESAB AB 2017... -

Page 14: Operation

Position 1, ON / OFF of mains voltage controlled from remote control unit • Position 2, ON / OFF blocked • Position 3, ON / OFF controlled using button 3 and 4 0462 985 101 - 14 - © ESAB AB 2017... -

Page 15: Connection Of Welding And Return Cable

A fault code appears in the control unit (PEK) settings panel. The overheating protection resets automatically and the welding process can be restarted when the temperature has fallen. 0462 985 101 - 15 - © ESAB AB 2017... -

Page 16: Maintenance

Release the dust filter according to the illustration. Blow the filter clean using compressed air (reduced pressure). Reinstall the filter. Ensure that the filter with the finest mesh is placed towards the grille. 0462 985 101 - 16 - © ESAB AB 2017... - Page 17 6 MAINTENANCE Replacing and cleaning the air filter Release the air filter according to the illustration. Clean the filter using soap and water Reinstall the filter. 0462 985 101 - 17 - © ESAB AB 2017...

-

Page 18: Fault-Tracing

• Check that the welding current supply and return cables are correctly connected. • Check that the correct current value is set. • Check that the correct filler material (wire and powder) is used. 0462 985 101 - 18 - © ESAB AB 2017... -

Page 19: Ordering Spare Parts

Spare parts and wear parts can be ordered through your nearest ESAB dealer, see the back cover of this document. When ordering, please state product type, serial number, designation and spare part number in accordance with the spare parts list. -

Page 20: Cable Routing Requirements

CABLE ROUTING REQUIREMENTS CABLE ROUTING REQUIREMENTS *Recommended *Recommended 0462 985 101 - 20 - © ESAB AB 2017... - Page 21 CABLE ROUTING REQUIREMENTS 0462 985 101 - 21 - © ESAB AB 2017...

- Page 22 CABLE ROUTING REQUIREMENTS 0462 985 101 - 22 - © ESAB AB 2017...

- Page 23 CABLE ROUTING REQUIREMENTS 0462 985 101 - 23 - © ESAB AB 2017...

-

Page 24: Cleaning

CLEANING CLEANING 0462 985 101 - 24 - © ESAB AB 2017... -

Page 25: Diagram

DIAGRAM DIAGRAM 0462 985 101 - 25 - © ESAB AB 2017... -

Page 26: Assembly Instructions

ASSEMBLY INSTRUCTIONS ASSEMBLY INSTRUCTIONS 0462 985 101 - 26 - © ESAB AB 2017... -

Page 27: Connection Instruction

CONNECTION INSTRUCTION CONNECTION INSTRUCTION 0462 985 101 - 27 - © ESAB AB 2017... -

Page 28: Ordering Numbers

Spare parts list Aristo® 1000 AC/DC SAW 0740 801 030 Installation manual For tandem and parallel connection of Aristo® 1000 AC/DC SAW Technical documentation is available on the Internet at: www.esab.com 0462 985 101 - 28 - © ESAB AB 2017... -

Page 29: Wear Parts

WEAR PARTS WEAR PARTS Ordering no. Denomination 0458 398 003 Dust filter 0441 828 003 Air filter 0462 985 101 - 29 - © ESAB AB 2017... -

Page 30: Accessories

Welding automat A6 Mastertrac 0449 270 900 Welding head A6 SF F1 SAW 0148 140 880 Flux recovery unit For more information regarding components for the A2 / A6 system, see separate brochures. 0462 985 101 - 30 - © ESAB AB 2017... - Page 31 ACCESSORIES 0462 985 101 - 31 - © ESAB AB 2017...

- Page 32 ESAB subsidiaries and representative offices Europe THE NETHERLANDS North and South America SOUTH KOREA ESAB Nederland B.V. ESAB SeAH Corporation AUSTRIA Amersfoort ARGENTINA Kyungnam ESAB Ges.m.b.H Tel: +31 33 422 35 55 CONARCO Tel: +82 55 269 8170 Vienna-Liesing Fax: +31 33 422 35 44...

Need help?

Do you have a question about the Aristo 1000 and is the answer not in the manual?

Questions and answers

Hi. The welder (aristo 1000) was welding good, then stopped with fault code F004, can't get goin again. What is (start weld time out) ? How do I fix the problem ?