Table of Contents

Advertisement

Quick Links

Plus

C3G

CELL CONTROLLER REL. 1.x e REL. 2.x

OperationS AND

MAINTENANCE MANUAL

Plus

00757045/GB

3UM - C3G

08/0702

Advertisement

Table of Contents

Summary of Contents for Comau C3G Plus

- Page 1 Plus CELL CONTROLLER REL. 1.x e REL. 2.x OPERATIONS AND MAINTENANCE MANUAL Plus 00757045/GB 3UM - C3G 08/0702...

- Page 2 The information provided in this manual is the property of COMAU S.p.A. Any form of reproduction, even partial, is forbidden without the prior written authorization of COMAU S.p.A. COMAU reserves the right to modify the characteristics of the product described in this manual without prior notice.

- Page 3 UPDATING LIST In this issue of the manual, with respect to the previous one, changes to technical contents have been per- formed due to the product updating. The modified sections are listed below. TITLE: C3G Plus CELL CONTROLLER UPDATING CHAPT.

- Page 4 Plus UPDATING LIST UPDATING CHAPT. SUBJECT PAG. No. ACTION 04/0799 Summary Substituted 04/0799 Chapter divider 4 Substituted 04/0799 Safety regulations Substituted Installation I-1¸3-7-10- 04/0799 Substituted 12-14 04/0799 Operator interface 2-3-7-11 Substituted Integration guide 1-11 Substituted 04/0799 Added 04/0799 Emergency Procedures Substituted Maintenance 4-6-9-10-12-...

- Page 5 Plus UPDATING LIST UPDATING CHAPT. SUBJECT PAG. No. ACTION 08/0702 Cover Substituted 08/0702 Back Substituted 08/0702 Preface ii-iii Substituted 08/0702 Summary iv-vi Substituted 08/0702 Installation 2÷20 Substituted 24-25-35-36- 08/0702 Operator interface Substituted 37-59-69 08/0702 Integration guide Substituted 08/0702 Emergency Procedures 1-3-4 Substituted 1-4-5-10-11-...

- Page 6 Plus UPDATING LIST This page has been intentionally blank 08/0702...

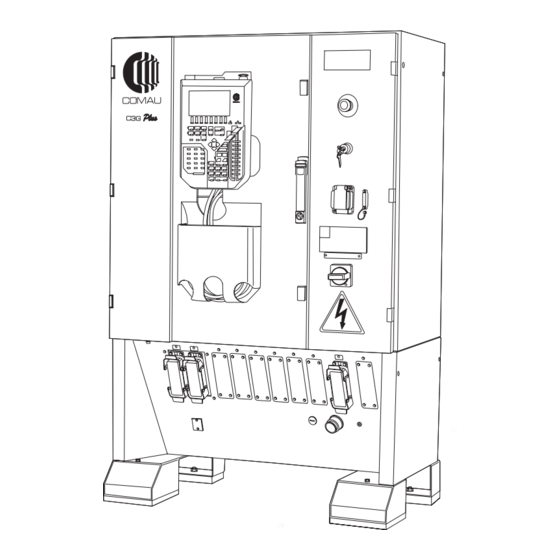

- Page 7 Plus PREFACE Plus VERSIONS SDLP-SDMP-SDHP Plus VERSIONS DDMP-DDHP 05/1199...

- Page 8 Plus PREFACE 序文, 绪言, 前言 This manual refers to the COMAU SYSTEMS robot system consisting of: 由...组成 Plus Rel. 1.X Rel. 2.X cell control unit SDLP 3,8 KVA Power installed SDMP 7 KVA 16,5 KVA SDHP Internal lighting – 230 Vac 6 A, SCHUKO-type service socket –...

- Page 9 · Further courses can be organised to cater for any particular requirements and to provide the technical and practical information required for independent operation of the COMAU robot system, depending on the level of knowledge of the participants. REFERENCE DOCUMENTS...

-

Page 10: Table Of Contents

Plus SUMMARY SUMMARY This manual contains: Page CHAPTER 1 - SAFETY REGULATIONS Responsibility .............................1-1 Safety regulations ............................1-1 CHAPTER 2 - INSTALLATION Installation summary table ..........................2-i Provisions for installation ..........................2-1 Check packing list............................2-1 Acquaintance with operator interface ......................2-1 Connection to power mains ........................2-2 Plus - robot connections ........................2-5 Application Box connections........................2-6... -

Page 11: Table Of Contents

Plus SUMMARY Page PCINT programme ..........................3-15 Plus video on PC ...........................3-18 System commands .............................3-21 Stand-By function ............................3-68 Brake Release Device (C3G-BRD)......................3-69 CHAPTER 4 - INTEGRATION GUIDE Safety signals to remote ..........................4-1 System inputs/outputs ..........................4-4 Input signals from external logic (machine line) ..................4-6 Output signals towards external logic (machine line) ................4-7 24 Vcc power supplies...........................4-8 Procedures for command activation with the controlloer in automatic remote status......4-8... -

Page 12: Table Of Contents

Plus SUMMARY Page CHAPTER 7 - MAINTENANCE General rules for maintenance ........................7-i Preventive maintenance ..........................7-1 Extraordinary maintenance.........................7-3 Plus Main C3G versions SDLP - SDMP - SDHP connections ...............7-5 Plus Main C3G versions DDMP - DDHP connections ................7-14 Diagnostics ............................7-25 Troubleshooting indications........................7-38 Fuses and protections ...........................7-39 Circuit diagrams.............................7-41 Control Unit............................7-43... -

Page 13: Responsibility

Operations and Plus Maintenance Manual SAFETY REGULATIONS INSTALLATION OPERATOR INTERFACE INTEGRATION GUIDE MAIN OPERATIONS FOR SYSTEM USE EMERGENCY PROCEDURES MAINTENANCE SUMMARY Paragraph Page Responsibility Safety regulations... - Page 14 Operations and Plus Maintenance Manual This page has been intentionally blank...

- Page 15 Machine Directive. · COMAU S.p.A. shall not be held responsible for injury or damage resulting from incorrect or im- proper use of the robot system, use of unspecified spare parts and tampering with circuits, com- ponents and system software.

- Page 16 Plus SAFETY REGULATIONS DEFINITIONS - Continued Maintenance and Repairs Maintenance and repair operations refer to periodic checking and/or replacement of parts (me- chanical, electrical, software) or of robot system components and tracing of the causes of any faults and ends with resetting of the robot system to original operating conditions. 2.10 Removal from Service and Dismantling Removal from Service refers to the removal of the robot system (mechanical and electrical) from...

- Page 17 The components of the control unit may be permanently damaged if the connectors are con- nected incorrectly. The C3G Plus internally makes the main safety interlocks (gates, enable button, etc.). Should it be 4.1.21 necessary to connect to the signals provided to make additional external circuits, make sure that these signals are used according to safety regulations.

- Page 18 4.1.26 Only the original disks, supplied by COMAU S.p.A. with the robot, must be used to load or update the system software (e.g. after replacing cards). After loading the software, always run a safety test cycle from outside the protected area.

- Page 19 Plus SAFETY REGULATIONS Automatic Operation 4.3.1 The robot system can only be activated for automatic operation by authorised personnel when the protective barriers are closed and electrically interlocked as specified in the safety standards. 4.3.2 Prior to activating automatic operation, the operator must check the robot system and the pro- tected area to make sure there are no potentially dangerous anomalous conditions.

- Page 20 Before starting to dismantle the robot system components (disassembly, demolition and disposal), contact COMAU, or one of its branches. Depending on the type of robot and control unit, they will provide information regarding the operations to be carried out so as to comply with the current safety regulations, and protect the environment.

- Page 21 4.6.12 Only the original disks, provided by COMAU S.p.A. with the robot, must be used to load software (e.g. after replacing electronic cards). Always run a safety test cycle from outside the protected area, once the software has been loaded.

- Page 22 Plus SAFETY REGULATIONS This page has been intentionally blank 02/1299...

-

Page 23: Provisions For Installation

Operations and Plus Maintenance Manual SAFETY REGULATIONS INSTALLATION OPERATOR INTERFACE INTEGRATION GUIDE MAIN OPERATIONS FOR SYSTEM USE EMERGENCY PROCEDURES MAINTENANCE SUMMARY Paragraph Page Installation summary table Provisions for installation Check packing list Acquaintance with operator interface Connection to power mains Plus - robot connections Application Box connections... - Page 24 Operations and Plus Maintenance Manual This page has been intentionally blank...

-

Page 25: Connection To Power Mains

Plus INSTALLATION Installation Summary Table STEP OPERATION FURTHER REF. DONE Plus PROVISIONS FOR INSTALLATION Technical Specifications CHECK PACKING LIST – ACQUAINTANCE WITH OPERATOR INTERFACE Chapter 3 of manual Plus CONNECTION TO POWER MAINS circuit diagrams Plus - ROBOT CONNECTIONS C3G-MMUX manual Application Box APPLICATION BOX CONNECTIONS manual... - Page 26 Plus INSTALLATION This page has been left intentionally blank 2-ii 01/0498...

- Page 27 Plus INSTALLATION 1. PROVISIONS FOR INSTALLATION Plus To simplify installation operations, the provisions for installation are given in the C3G TECHNICAL SPECIFICATIONS manual which may be supplied in advance of the product (before installation); in any case the above-mentioned manual is also supplied herewith. 2.

- Page 28 Plus INSTALLATION 4. CONNECTION TO POWER MAINS CONNECTION POWER SUPPLY TO CONTROLLER CHECKS BEFORE CONNECTION · The connection cable must meet CEI Std. 2022 and be of the shielded four-core type (three phases plus earth). · The cable cross section must be suited to the power rating of the controller installed. ·...

- Page 29 Plus INSTALLATION OPERATION Connect the power supply cable inserting it in the special cable clamp at the bottom right of the cabin as il- lustrated. The length of the cable inside the cabin must be correct to avoid interfering with already existing cables.

- Page 30 Plus INSTALLATION CHECKS AFTER CONNECTION · The screws of the terminals in which the wires of the power cable have been inserted (phases R-S-T and GND) must be correctly tightened. Try pulling the wires. · The cable clamp must be closed to lock the cable at the controller infeed. Try pulling the cable from out- side the cabin.

- Page 31 Plus INSTALLATION Plus Connection for C3G Versions SDLP - SDMP - SDHP Plus Connection for C3G Versions DDMP - DDHP 08/0702...

- Page 32 Plus INSTALLATION CHECKS AFTER CONNECTION · Make sure connections have been made according to the procedure. · The screws of the terminals into which the connection cables have been inserted must be correctly tight- ened. Try to remove the wires. ·...

-

Page 33: Application Box Connections

Plus INSTALLATION Plus Connect the cables as illustrated (C3G - SMART X1): · During connection avoid kinking the cables. The cable should not be too taut. · The connection between harting connectors (male/female) must take place without forcing to avoid knocking in or breaking the pins. ·... -

Page 34: Connection Of Safety Devices And Cutting Off Commands Leading From The Transfer

Plus INSTALLATION 7. CONNECTION OF SAFETY DEVICES AND CUTTING OFF COMMANDS LEADING FROM THE TRANSFER CONNECTION OF SAFETY DEVICES You are reminded that before performing any type of movement with the robot, the robot system safety de- vices must always be installed and operational. Plus Depending on the type of connection intended to be made to the safety devices, the C3G offers the so-... - Page 35 Plus INSTALLATION If Controller Stop Module C3G-CSM is provided as standard on control unit with 16,5 KVA power and optional on control unit with 7 KVA power, in AUTO LOCAL and AUTO REMOTE states, an emergency stop and/or opening of the safety gates causes controlled stopping of the robot (EN 60204-1), category 1 stop).

- Page 36 Plus INSTALLATION For safety purposes, the interface connectors to the outside must be fitted with a suitable ca- ble clamp, the cables must be screened and the screening appropriately connected to the ground, in order to guarantee electromagnetic compatibility of the system as per directive 89/392.

- Page 37 Plus INSTALLATION DESCRIPTION PIN X30 NOTES Without connecting the power bridge 48-50 (x) (+24 Vcc) Safety circuits power supply connec- supply DRIVE ON is impossi- bridge 49-51 (y) (0 V) tion 15 - 16 Dual channel Safety gates connection 17 - 18 Emergency push-button connection 33 - 34 Dual channel...

- Page 38 Plus INSTALLATION DESCRIPTION PIN X30-2 NOTE The auxiliary contacts of the 6-24 Machine exclusion 1-K123; machine exclusion relays 66-68 machine exclusion 2-K124 are made available. The function of the auxiliary 52-53 Power contactor redundancy contacts power 55-56 (Power contactors machine 2 K121 and contactors K121 and K122 K122) is the same as that of...

- Page 39 Plus INSTALLATION Plus 8. ACTIVATION OF C3G CHECKS BEFORE SWITCHING ON Plus The magnetothermal and differential circuit breaker from which the supply for the C3G is shunted must be closed. Before switching on the controller remove the box containing the floppy disks (operating sys- tem, application programmes, general utility programmes) which is located inside the control- ler.

-

Page 40: Rpt Buffer Battery Connection (When Installed)

Plus INSTALLATION PROBLEMS WHEN THE CONTROLLER IS SWITCHED ON Fault Check Suggestions/Possible causes Presence of mains supply The magnetothermal/differential The PTU4 terminal is off circuit breaker upstream of the Plus is faulty or there is a mains current failure That all the fuses inside the Control- The mains power voltage does ler are intact (See summary table in not correspond to the one for... - Page 41 Plus INSTALLATION Plus 10. C3G - ROBOT OFF LINE FUNCTIONAL CHECK CHECKS BEFORE FUNCTIONAL TESTS · Before moving the robot make sure that the working area is clear of unforeseen obstacles and that there are no persons inside. · Check if the robot calibration position can be reached without knocking any equipment. The calibration position changes depending on the type of robot, therefore refer to the robot literature.

-

Page 42: Turn_Set Operation

Run a continuity test to check that the equipment power supply contacts (safety relay logic) open/close. Refer to step 7 of the installation procedure for the pins involved in the test. Redundancy of power contactors K101 and K102 (K121 and K122 only for C3G Plus versions DDMP-DDHP) (power contactor) ·... - Page 43 Plus INSTALLATION Checking the robot calibration position · If in order to reach the calibration position, the risk exists that the robot may collide with any equip- ment, take the robot close to the calibration indexes (fixed and mobile index) moving the axes indi- vidually;...

- Page 44 Plus INSTALLATION Fault Check Suggestions/Possible causes 3. Checking manual robot movement The axis intended to be moved is Check that: the Enabling Device Incorrect pressing of buttons, keys still button is pressed and the motors or sequence of commands are on DRIVE ON (led on); the but- ton of the axis to be moved is pressed If the clamping brackets for trans-...

-

Page 45: Robot System Integration

Plus INSTALLATION CHECK AFTER TURN_SET At the end of the Turn_set operation the word CAL is shown in the PTU4 status window. PROBLEMS IN EXECUTING THE TURN_SET PROCEDURE Should any difficulty be found in performing the procedure, carefully consult chapter 3 of this manual for further explanations about the commands to be given. -

Page 46: Functional Check Of The Installed Robot System

Plus INSTALLATION 14. FUNCTIONAL CHECK OF THE INSTALLED ROBOT SYSTEM After the integration operations it is necessary to check the functionality of the system completely integrated in the operating system. 功能性,泛函性 · This check must take place systematically (checking all the parts installed) and gradually (proceeding by small steps). - Page 47 Operations and Plus Maintenance Manual SAFETY REGULATIONS INSTALLATION OPERATOR INTERFACE INTEGRATION GUIDE MAIN OPERATIONS FOR SYSTEM USE EMERGENCY PROCEDURES MAINTENANCE SUMMARY Paragraph Page Control panel and serial and parallel interfaces Programming and emergency terminal (C3G-PTU4) C3G-PTU4 display Provision for activating the emergency terminal 3-11 Emergency terminal active keys 3-11...

- Page 48 Operations and Plus Maintenance Manual This page has been intentionally blank...

-

Page 49: Control Panel And Serial And Parallel Interfaces

Plus OPERATOR INTERFACE CONTROL PANEL AND SERIAL AND PARALLEL INTERFACES The push-buttons, selectors, connectors and serial and parallel interfaces are shown in the following figures and described in the table below. Control panel Serial and parallel interfaces (inside cabin) REF. SYMBOL and NAME DESCRIPTION Main circuit breaker... - Page 50 Plus OPERATOR INTERFACE Commands and indicators (continued) REF. SYMBOL and NAME DESCRIPTION COMP: connector Serial communication port for connecting a PC on which it is possible to Plus COM P: install the C3G video/keyboard emulator and download/unload programmes. 25-pin connector (female). COM0: and COM1: con- Serial communication ports available for the connection of a PC or other nectors...

- Page 51 Plus OPERATOR INTERFACE PROGRAMMING AND EMERGENCY TERMINAL (Only for Rel. 1.x) (C3G-PTU4) PTU4 may be installed as programming terminal and also as emergency terminal, on Rel. 1.x version. In the first case it works as system monitor and programming terminal and makes it possible to manually control ro- bot movements, programme the robot or carry out or modify step-by-step movements, while in the second case it works as emergency terminal (only for Rel.

- Page 52 Plus OPERATOR INTERFACE NAME and SYMBOL DESCRIPTION The Command Menu keys (F1 - F8) located below the liquid crystal dis- Function keys play send the corresponding command, displayed on the menu line to the control unit. For example the F1 key enters the CONF command from main menu.

- Page 53 Plus OPERATOR INTERFACE NAME and SYMBOL DESCRIPTION The ALARM key, easily distinguished by the red LED on a yellow back- Video Control Keys ground, resets the alarm status when activated. The LED turns on when alarm occurs. The SHIFT key calls the secondary function of the double function keys, it has no effect if pressed on its own.

- Page 54 Plus OPERATOR INTERFACE NAME and SYMBOL DESCRIPTION The 6/PASTE key enters the numeric value 6. If it is pressed together with Numeric/Edit Keys the SHIFT key, it is used in the editor to insert the programme lines se- (cont.) lected with the MARK and /COPY keys in the correct position of the cur- sor.

- Page 55 Plus OPERATOR INTERFACE NAME and SYMBOL DESCRIPTION Usr - linear movement mode according to the user x, y, z reference tern Single Axis Movement (for example the tern that describes the piece being machined). The first Keys (cont.) three keys allow linear movements in the direction of the three axes of the user reference system (defined by the variable $UFRAME);...

- Page 56 Plus OPERATOR INTERFACE NAME and SYMBOL DESCRIPTION The XTND, JNTP and POS keys make it possible to modify the type of XTND JNTP variable inserted on pressing the REC key in the Editor and EZ environ- ments. Variables of the XTNDPOS, JNTPOS or POSITION type can be selected according to the key that is pressed.

-

Page 57: C3G-Ptu4 Display

Plus OPERATOR INTERFACE C3G-PTU4 DISPLAY The programming terminal display is in the form shown below and it is split into three windows: status win- dow, scroll window, command window. Substantially the display gives the same information displayed on the Plus video emulator of the C3G . - Page 58 Plus OPERATOR INTERFACE Arm: The First Field may have the following values: 1 ® 2 1 ¬ 2 Number of arm selected Synchronised movements for more arms 2 ® 1 2 ¬ 1 C3G MMux device For further information about the meaning of the indication displayed, refer to the specific literature con- cerning the device installed.

-

Page 59: Provision For Activating The Emergency Terminal

Plus OPERATOR INTERFACE PROVISION FOR ACTIVATING THE EMERGENCY TERMINAL (Only for Rel. 1.x) NAME and SYMBOL DESCRIPTION Closing cap for the definition of the PTU4 operating modes. If inserted in CAP FOR CLOSING connector X201, the PTU4 is enabled as programming terminal. If inserted CONNECTORS X201 (ON), in connector X200-X199, the PTU4 is enabled as emergency terminal. -

Page 60: Emergency Control C3G-Emc2

OPERATOR INTERFACE EMERGENCY CONTROL C3G-EMC2 (Only Rel. 2.x) This is an hand-held device which, when interfacing with the controller unit C3G Plus Rel. 2.x, permits the implementation of the emergency terminal function by following the same active modes as described under the paragraphs “Programming and Emergency Terminal”... - Page 61 Plus OPERATOR INTERFACE SAMPLE CONNECTION OF C3G-EMC2 07/1200 3-13...

-

Page 62: Connector For Enabling Device Additional Button

Plus OPERATOR INTERFACE CONNECTOR FOR ENABLING DEVICE ADDITIONAL BUTTON NAME and SYMBOL DESCRIPTION Connector (present on request) for connecting an additional three-position Connector X80 safety switch (Enabling Device) with the same functions as the one on the PTU4 programming terminal. The connector is at the bottom left, cabin front view (below connectors X10 and X30). -

Page 63: Connection Cable For Comp: - Pc Connectors

Plus which the C3G video emulator is installed. If the user has purchased the portable PC from COMAU SYSTEMS, it is provided with the connection cable to be used. If not, the circuit is as shown in the following diagram: 发送... - Page 64 Plus OPERATOR INTERFACE COMMANDS FOR SELECTING AND ISSUING DATA Using the arrow keys on the PC keyboard it is possible to move on the data to be issued (the highlighter moves - - - >). To issue the datum selected press ENTER. E.G.: - - - >...

- Page 65 Plus OPERATOR INTERFACE For displaying special characters on the PC contained in the text of error messages, in the AUTOEXEC.BAT file it is necessary to define the commands “MODE CON CODEPAGE PREPARE=((850)C:\DOS\EGA.CPI)” and “MODE CON CODEPAGE SELECT=850”. In the CONFIG:SYS file define the commands “COUNTRY=039, 850, C:\DOS\COUN- TRY.SYS”...

- Page 66 Plus OPERATOR INTERFACE Plus If the serial port COMP: of the C3G and the serial port of the PC (e.g. COM1) have not been connected, the software download messages are displayed on the display of the PTU4 programming terminal. · Specify the Drive/directory in which the files to be downloaded reside (e.g.: A:\);...

- Page 67 Plus OPERATOR INTERFACE · STATUS WINDOW: displays the following information about system status: Drive: OFF/ON indicates that the robot motors are on or off. State: The First Field indicates the status set by the key selector on the control panel and of the AUTO/MAN key on the programming terminal: ☞...

- Page 68 Plus OPERATOR INTERFACE Ax: indicates the status of the axis selected: ☞ means that axes 1-2-3 are to be calibrated, axes 4-5-6 are calibrated, axes 7-8 ***456— are not present ☞ means that axes 1,2,3,4,5,6 are calibrated, axes 7-8 are not present. 123456—...

-

Page 69: System Commands

Plus OPERATOR INTERFACE SYSTEM COMMANDS This paragraph describes how to enter the different commands and includes a description of each of them. The figure below shows the system command windows on the PC screen and on the programming terminal display. At the end of the paragraph there is a list which summarises the commands. Command window on PC screen Cntrler Io-conf... - Page 70 Plus OPERATOR INTERFACE For many commands including those that require user entry of a parameter, this can be selected using the arrow keys and the ENTER key. Press the HELP key (if the word HELP is present on the line of the com- mand highlighted) in reply to the prompt requiring entry of a parameter (file, programme, I/O point etc.).

- Page 71 Plus OPERATOR INTERFACE Command Recall The up arrow key recalls the last ten parameters that have been entered. This dispenses with the need to enter the same parameter for a series of commands. Command Options Command options are available for some commands. If a command has options, (OPT) appears after the prompt for the last parameter.

- Page 72 Plus OPERATOR INTERFACE CONFIGURE COMMAND Cntrler Io_conf Load Save Configure Display Execute Filer Memory Program Set Utility The CONFIGURE command displays a command menu to configure the system to match user requirements. Calibrate Reten_Mem Turn_set View_cal Cntrler Io_conf Load Save The ARM command displays a command menu to configure the arm to match user requirements.

- Page 73 The CNTRLER command displays a command menu used to set the controller to match user requirements. · Password establishes a system password needed for password protected commands and for access to the Dmon feature for software maintenance (restricted to COMAU). Syntax: CCP password ·...

- Page 74 Plus OPERATOR INTERFACE · Cold restarts the system software and clears the memory. This is particularly useful when the system has been corrupted by some user action. A confirmation is required. Following execution of a command the system I/O ($SDIN [n]/ $SDOUT [n]) are updated to the current system situation. For the user I/O ($DIN [n]/$DOUT [n]), the status of the outputs is reset and the inputs are updated to the current system situation.

- Page 75 Plus OPERATOR INTERFACE - configuration file name - name of the electric gripper, if any, and of its related arm/axis - RAM DISK status (RD has nnn bytes free) - date and time. The screen shown is the one that appears when the controller is switched on. Options: Syntax: Io_conf...

- Page 76 Plus OPERATOR INTERFACE DISPLAY COMMAND Close Fieldbus Input Output Program Vars Configure Display Execute Filer Memory Program Utility The DISPLAY command displays a command menu for opening display windows in the scroll window. These windows show continuously updated information until they are closed with the CLOSE command. Multiple windows can be opened at the same time.

- Page 77 Plus OPERATOR INTERFACE Close Input Output Program Select Total Vars Close Fieldbus Input Output Program Vars The CLOSE command displays a command menu for removing displayed windows from the screen. · Arm closes all ARM windows. Syntax: · Input closes all input windows. Syntax: ·...

- Page 78 Plus OPERATOR INTERFACE Input System Close Fieldbus Input Output Program Vars The INPUT command displays a command menu for displaying the status of user-defined and system inputs. It is possible to associate the command with a HELP string using the HELP10 and HELP102 programmes contained on Floppy disk “2/2 Configuration Tools”;...

- Page 79 Plus OPERATOR INTERFACE Syntax: DOA <string_of_numbers> Example: DOA 17 DOA 17-18-25..27 · DOUT displays user-defined digital output values ($DOUT), where 1 = TRUE and 0 = FALSE. If one of these values is forced, an “F” (forced to false) or “T” (forced to true) will be displayed instead of 0 or 1. Typing an output number, a set of digital outputs is displayed.

- Page 80 Plus OPERATOR INTERFACE - with sets of bits. The $BIT interval required should be specified giving the first and last bits separated by “..”. For example, “DISPLAY VAR BIT” “1..15" displays all the $BITs with an index between 1 and 15. A maximum of 16 bits (on the teach pendant) and 32 bits (for the PCINT) can be displayed at the same time.

- Page 81 Plus OPERATOR INTERFACE FILER COMMAND Copy Delete Edit Print Rename Translate Utility View Configure Display Execute Filer Memory Program Utility The FILER command displays a menu of file management commands. Most of the FILER commands require file names for parameters. A file name consists of the device, name and extension.

- Page 82 Plus OPERATOR INTERFACE Edit The EDIT command invokes the file editor. The file editor can be used to create or modify ASCII files on the RAM DISK. A file name parameter is needed. The asterisk cannot be used. Only the RD (RAM DISK) can be used. If a file extension is not included, the .PDL extension is used.

- Page 83 Plus OPERATOR INTERFACE Rename The RENAME command changes the file name and/or extension of an existing file. The original (source) and a new (destination) file specification are required as parameters. It is possible to use the asterisk for extensions. If no device is specified for the original file, the default device is used. Differ- ent devices cannot be specified for the source and destination files.

- Page 84 Plus OPERATOR INTERFACE · Hidden sets the “hidden” attribute for a file. When this attribute is set, the file cannot be accessed by any command except LOAD. Access is restricted by password. This file is not displayed in the Ram Disk.

- Page 85 Plus OPERATOR INTERFACE · Install makes it possible to install a certain application programme performing all the operations re- quired automatically: identification of the backup device from which to copy the files, installation of the Kermit protocol (if necessary), copy of the installation file of the application programme on the RAM disk and its activation.

- Page 86 Plus OPERATOR INTERFACE MEMORY COMMAND Debug Erase Load Save Teach View Configure Display Execute Filer Memory Program Utility The MEMORY command displays a menu of commands to manage programmes and variables in the main memory (RAM). Only the MEMORY VIEW command is available when memory or system protection is on. Debug The DEBUG command invokes the editor in a display and debug mode only.

- Page 87 Plus OPERATOR INTERFACE · Variable erases one or more variables belonging to the specified programme, which are not linked to a loaded programme. The variable name is required as parameter. To use this command, memory, sys- tem and programme protection must be off. Options: /Noconfirm eliminates the confirmation prompt.

- Page 88 Plus OPERATOR INTERFACE Load Save Debug Erase Load Save Teach View The RLL command displays a menu of commands to load and store a PLC programme code. · Load loads the specified RLL programme from RAM disk to the PLC memory. The asterisk cannot be used.

- Page 89 Plus OPERATOR INTERFACE The TEACH command cannot be used at the same time as the PROGRAM EDIT (DATA mode), MEMORY DEBUG or EZ environment commands when memory, system or programme protection is enabled or if the controller is in FATAL status. Syntax: MT <programme_name>...

- Page 90 Plus OPERATOR INTERFACE User-defined data types are global to the entire system. However, they only exist in memory as long as a programme or programme variables referencing the type are loaded. If a type name is not specified as a parameter, information for all loaded types is displayed. The asterisk can be used.

- Page 91 Plus OPERATOR INTERFACE PROGRAM COMMAND Activate Deactiv Edit State Test View Configure Display Execute Filer Memory Program Utility The PROGRAM command displays a menu of commands to develop and execute programmes. Activate The effect of the ACTIVATE command depends on the holdable/non-holdable programme attribute of the programme specified as parameter: ·...

- Page 92 Plus OPERATOR INTERFACE Edit The EDIT command invokes the programme editor: this is an integrated programming environment which al- lows the programmer to edit, teach points and verify PDL2 programmes. (Refer to the C3G Programming Guide manual). The programme editor works with PDL2 programme code files (.COD) stored on the RAM disk (RD:). A programme name parameter is required and the asterisk cannot be used.

- Page 93 Plus OPERATOR INTERFACE Options: /Cycle /Disable /Fly /Move /Routine /Statement /Update: replaces or activates a programme in memory Syntax: PG <programme_name> Activate Clear_plc Deactiv Restart Sing_scan View Activate Deactive Edit State Test View The RLL command displays a menu of commands to handle PLC programme execution. ·...

- Page 94 Plus OPERATOR INTERFACE · Sing_scan executes the PLC programme loaded in the PLC memory for a single scan. For all timing events, the single scan simulates a 50 msec interval and executes all the ladder rungs as if the above time has elapsed.

- Page 95 Plus OPERATOR INTERFACE Test Break Profile Step Activate Deactiv Edit State Test View The TEST command displays a menu of commands to test any loaded PDL2 programme from outside the programme editor. This is particularly effective for testing multiple programmes. The TEST command cannot be used when memory, system or programme protection is on or when the controller is in the FATAL status.

- Page 96 Plus OPERATOR INTERFACE · Profile displays a menu of commands to monitor performance in terms of CPU time of active programmes. This information is useful when debugging programmes that execute simultaneously. Disable Enable Reset View Break Profile Step · Disable disables the performance calculation. A warning is given if PROFILE is already disabled. Syntax: PTPD ·...

- Page 97 Plus OPERATOR INTERFACE When the step of a programme being executed is changed, the new step takes effect after execution of the current statement. Cycle Disable Move Routine Statement View Break Profile Step · Cycle defines the step as a single cycle within the programme. The CYCLE or BEGIN CYCLE state- ment must be present in the programme.

- Page 98 Plus OPERATOR INTERFACE Options: /Chain displays the chain of calls to routines - routine name - programme to which the routine belongs - line number - frame type reference (main programme, break routine, private, exported) - state /Full displays further information including: - programme attributes - arm number - priority...

- Page 99 Plus OPERATOR INTERFACE SET COMMAND Cntrler Input Output Total_unf Update_io View_io Configure Display Execute Filer Memory Program Utility The SET command displays a menu of commands to change system characteristics. All SET commands are allowed when memory protection is on, but only VIEW can be used also with system protection on. Disable Enable Gen_ovr...

- Page 100 Plus OPERATOR INTERFACE For systems with multiple arms, an arm number parameter is required. An asterisk can be used to indi- cate all arms. Syntax: SAN <arm_num> · Simulate allows programmes to be run simulating the movements without actually moving the arm. All motion calculations are still performed.

- Page 101 Plus OPERATOR INTERFACE · System sets system protection (commands affecting the system cannot be used). Syntax: SCPS · View displays the current default values for the following: - default arm - default communication port - default system device - current protection level - current time and date - default backup device - default PDL2 device...

- Page 102 Plus OPERATOR INTERFACE Syntax: SIFA <index_num> <integer_value> — analogue SIFD <index_num> <forced_value> — digital SIFG <index_num> <integer_value> — group · Unforce remaps a forced logical input back to its original physical configuration. The operator can choose from the submenu to unforce analogue (AIN), digital (DIN) or group (GIN) inputs. A particular input can be specified by its index number.

- Page 103 Plus OPERATOR INTERFACE · A particular output can be specified by its index number. The asterisk cannot be used. Syntax: SOUA <index_num> —analogue SOUD <index_num> —digital SOUG <index_num> —group · View displays the forced outputs. The operator can choose from the submenu to display analogue (AOUT), digital (DOUT) or group (GOUT) outputs.

- Page 104 Plus OPERATOR INTERFACE UTILITY COMMAND Applicatn Communicn Configure Display Execute Filer Memory Program Utility The UTILITY command displays a menu of commands that handle special purpose features of the system. Applicatn The APPLICATN command allows the user to start an application programme. The application programme must be running before this command is issued and must be programmed to handle a call for application aid.

- Page 105 Plus OPERATOR INTERFACE · Tisoft installs the TISOFT protocol on a serial port. This protocol is mainly used to interface with the TISOFT package for PLC that is running on a PC or to link with the TI VPU unit. Syntax: UCMT <port_name>...

- Page 106 Plus OPERATOR INTERFACE COMMAND SUMMARY LIST Example for reading the list: EXECUTE (/CONTEXT) VIEW SIV* F7,F2,F3,* In the first example the command is EXECUTE and it has an option indicated by /CONTEXT. The sequence of keys for issuing the command is E and the sequence of function keys to be used is F3. The example referring to the VIEW command is actually a selection of a submenu of the SET INPUT com- mand and it has no options.

- Page 107 Plus OPERATOR INTERFACE (Main Commands) Character Function Level 3 Level 4 Level 5 Level 1 Level 2 keys keys F2,F2,F5 Select F2,F2,F6 Total F2,F2,F7 Vars F2,F2,F8 Fieldbus F2,F3,* Master F2,F3,F1 Slave F2,F3,F2 Input F2,F4,* F2,F4,F1 F2,F4,F2 F2,F4,F3 System F2,F4,F4 Output F2,F5,* AOUT F2,F5,F1...

- Page 108 Plus OPERATOR INTERFACE (Main commands) Character Function Level 3 Level 4 Level 5 Level 1 Level 2 keys keys Load (/As, /Convert, /Full, /Depend,Nosavevars, F5,F3 /Permanent, /Variables) F5,F4,* Load (/PDL2source) F5,F4,F1 Save F5,F4,F2 Save (/As, /Code, /Overwrite) F5,F5 Teach F5,F6 View F5,F7,* Program (/Nopage, /4)

- Page 109 Plus OPERATOR INTERFACE (Main commands) Character Function Level 3 Level 4 Level 5 Level 1 Level 2 keys keys F7,* F7,F1,* Disable F7,F1,F1 Enable F7,F1,F2 Gen_Ovr F7,F1,F3 (/Increment) F7,F1,F4 Nostroke F7,F1,F5 Simulate F7,F1,F6 Tp_main F7,F1,F7 Unsimul Cntrler F7,F2,* Key_lock F7,F2,F1 Protect SCP* F7,F2,F2,*...

- Page 110 Plus OPERATOR INTERFACE (Main commands) Character Function Level 4 Level 5 Level 1 Level 2 Level 3 keys keys Utility F8,* Applicatn F8,F1 Communicn F8,F2,* Dismount F8,F2,F1 Mount UCM* F8,F2,F2,* Crt_emu UCMC F8,F2,F2,F1 Ddcmp UCMD F8,F2,F2,F2 (/Maint) UCMK F8,F2,F2,F3 Kermit UCMT F8,F2,F2,F4 (/Speed)

- Page 111 Plus OPERATOR INTERFACE COMMAND ANALYTICAL INDEX Character Function Commands keys keys Activate F6,F1 Activate F6,F5,F1 F2,F4,F1 SIFA F7,F3,F1,F1 SIUA F7,F3,F2,F1 SIVA F7,F3,F3,F1 F5,F2,F1 AOUT F2,F5,F1 AOUT SOFA F7,F4,F1,F1 AOUT SOUA F7,F4,F2,F1 AOUT SOVA F7,F4,F3,F1 Applicatn F8,F1 F1,F1,* F2,F1,* F2,F2,F1 F7,F1,* Attribute FUA* F4,F7,F1,*...

- Page 112 Plus OPERATOR INTERFACE Character Function Commands keys keys Deactiv F6,F2 Deactiv F6,F5,F3 Debug F5,F1 Delete F4,F2 F2,F4,F2 SIFD F7,F3,F1,F2 SIUD F7,F3,F2,F2 SIVD F7,F3,F3,F2 Disable PTPD F6,F7,F2,F1 Disable PTSD F6,F7,F3,F2 Disable F7,F1,F1 Disable F7,F6,F1 Dismount F8,F2,F1 Display F2,* DOUT F2,F5,F2 DOUT SOFD F7,F4,F1,F2 DOUT...

- Page 113 Plus OPERATOR INTERFACE Character Function Commands keys keys F6,F5,F4 GOUT F2,F5,F3 GOUT SOFG F7,F4,F1,F3 GOUT SOUG F7,F4,F2,F3 GOUT SOVG F7,F4,F3,F3 Hidden FUAH F4,F7,F1,F1 High FUFH F4,F7,F4,F1 Input F2,F2,F2 Input F2,F4,* Input F7,F3,* Insert PTBI F6,F7,F1,F1 Io_conf F1,F3 Joint F2,F1,F4 Kermit UCMK F8,F2,F2,F3 Key_lock...

- Page 114 Plus OPERATOR INTERFACE Character Function Commands keys keys Program F6,* Program SCPP F7,F2,F2,F3 Protect SCP* F7,F2,F2,* Purge PTBP F6,F7,F1,F2 Readonly FUAR F4,F7,F1,F2 Reboot CCRR F1,F2,F2,F3 Rename F4,F5 Reset PTPR F6,F7,F2,F3 Resolver F2,F1,F6 Restart CCR* F1,F2,F2,* Restart F6,F5,F5 F2,F2,F5 F2,F7 F5,F4,* F6,F5,* Routine PTSR...

- Page 115 Plus OPERATOR INTERFACE Character Function Commands keys keys Test F6,F7,* Time F1,F2,F4 Tisoft UCMT F8,F2,F2,F4 Total F2,F2,F7 Total_unf F7,F5 Tp_main F7,F1,F6 Translate F4,F6 Turn_set F1,F1,F3 Type F5,F7,F2 Unforce SIU* F7,F3,F2,* Unforce SOU* F7,F4,F2,* Unpause F6,F6,F3 Unsimul F7,F1,F7 Update_io F7,F6,* Utility F4,F7,* Utility F8,*...

-

Page 116: Stand-By Function

The value of the $TUNE [27] variable set by COMAU SYSTEMS is 10 seconds; setting this variable to 0, the function is deactivated. -

Page 117: Brake Release Device (C3G-Brd)

Plus OPERATOR INTERFACE BRAKE RELEASE DEVICE (C3G-BRD) This portable device makes it possible to deactivate one robot axis brake at a time. It is connected to: · the 220 Vac mains supply (standard provision) · the motor connector on the X2, X2 EXT and X3 robot base after removing the cable leading from the control system. - Page 118 Plus OPERATOR INTERFACE C3G Plus KIT IVECO Blinker unit and main switch tripping ITEM DESCRIPTION Main switch with tripping coil Blinker Microswitch for blinker Microswitch for tripping coil Keylock selector switch with return spring on the control board 3-70 05/1199...

- Page 119 Plus OPERATOR INTERFACE Wiring diagram GENERAL The kit for the IVECO option includes a blinker, a microswitch and a keylock selector switch. The function of the blinker (H120) is to display the power supply state of the electric equipment within the controller.

- Page 120 Plus OPERATOR INTERFACE This page has been left intentionally blank 3-72 05/1199...

- Page 121 Operations and Plus Maintenance Manual SAFETY REGULATIONS INSTALLATION OPERATOR INTERFACE INTEGRATION GUIDE MAIN OPERATIONS FOR SYSTEM USE EMERGENCY PROCEDURES MAINTENANCE SUMMARY Paragraph Page Safety signals to remote System inputs/outputs Input signals from external logic (machine line) Output signals towards external logic (machine line) 24 Vdc power supplies Procedures for command activation with the controller in automatic remote status Examples of use of system signals dedicated to transfer interface...

- Page 122 Operations and Plus Maintenance Manual This page has been intentionally blank...

-

Page 123: Safety Signals To Remote

Plus INTEGRATION GUIDE SAFETY SIGNALS TO REMOTE Connection to safety interlocks is described in chapter 2, step 7 of the installation procedure. To simplify inte- gration operations and have a complete picture of the signals available to the machine, the connection cir- cuitry of the safety signals and the summary tables are repeated. - Page 124 Plus INTEGRATION GUIDE For safety purposes, the interface connectors to the outside must be fitted with a suitable ca- ble clamp, the cables must be screened and the screening appropriately connected to the ground, in order to guarantee electromagnetic compatibility of the system as per directive 89/392.

- Page 125 Plus INTEGRATION GUIDE SIGNALS DESCRIPTION Safety signals to external equipment that must be used EXTERNAL SAFETY GATES CH1 INPUT to connect the safety gates and all devices that assure EXTERNAL SAFETY GATES CH1 OUTPUT operator safety during the work cycle. EXTERNAL SAFETY GATES CH2 INPUT EXTERNAL SAFETY GATES CH2 OUTPUT Safety signals to external equipment that must be used...

-

Page 126: System Inputs/Outputs

(Enabling Device 2), present on request. ENABLING DEVICE 2 CH1 OUTPUT ENABLING DEVICE 2 CH2 INPUT ENABLING DEVICE 2 CH2 OUTPUT SAFETY SIGNALS ON THE ROBOT PIN X91 ALL COMAU ROBOTS (EXCEPT SIGNALS DESCRIPTION SMART S FAMILY) Emergency signals towards the robot that... - Page 127 Plus INTEGRATION GUIDE 06/0400...

-

Page 128: Input Signals From External Logic (Machine Line)

Plus INTEGRATION GUIDE INPUT SIGNALS FROM EXTERNAL LOGIC (MACHINE LINE) These are controller input signals used to communicate with external equipment (e.g. a PLC). SIGNALS DESCRIPTION When the system is in Remote status, this is a request DRIVE ON (LED A1 SIM, $SDIN[9]) from a remote device to activate the motor start-up cycle. -

Page 129: Output Signals Towards External Logic (Machine Line)

Plus INTEGRATION GUIDE OUTPUT SIGNALS TOWARDS EXTERNAL LOGIC (MACHINE LINE) These are controller output signals used to communicate with external equipment (e.g. a PLC). SIGNALS DESCRIPTION When closed indicates that the control unit has received the DRIVE ON/OFF Drive ON command from the machine line, has carried out (LED C1 SIM, $SDOUT[9]) the motor start-up procedure and is in Drive ON status. - Page 130 Plus INTEGRATION GUIDE 24 Vdc POWER SUPPLIES SIGNALS DESCRIPTION X30-2 + 24 Vdc continuous power supply from the controller. INT. +24V TO EXT. EQUIP. INT. 0 V (+24 Vdc) TO EX. E. Provision for connection of the continuous +24 Vdc +24 Vdc EXTERNAL EQUIPMENT supply from the transfer.

- Page 131 Plus INTEGRATION GUIDE START PROCEDURE The START procedure from remote permits activation of the robot cycle after making all the system checks and checking the DRIVE ON status. This procedure is active only if the status selector on the operator panel is in the Automatic Remote position .

- Page 132 Plus INTEGRATION GUIDE The transfer is informed of the Hold status of the control unit through deactivation of the START/HOLD out- put, i.e. with opening of the contact of the corresponding relay. Also, the LOCAL/REMOTE output is deacti- vated indicating that the system is operating following a local command. The output that indicates hold to the transfer is kept open (HOLD) even when the HOLD command from the operator panel is removed.

-

Page 133: Examples Of Use Of System Signals Dedicated To Transfer Interface

Plus INTEGRATION GUIDE EXAMPLES OF USE OF SYSTEM SIGNALS DEDICATED TO TRANSFER INTERFACE EXAMPLE OF PROGRAMME NUMBER SELECTION FROM REMOTE THROUGH USER-PROGRAMMABLE I/O’s P RO G R . S E L E CT . C H A N G E O F P R O G R A M S T A R T U P D R I V E O N &... - Page 134 Plus INTEGRATION GUIDE EXAMPLE OF STOPPING AND RE-STARTING THE WORK CYCLE FROM REMOTE R E M O T E R E M O T E R E M O T E LO CA L HO LD L O C A L R E M O T E H O L D H O L D...

- Page 135 Plus INTEGRATION GUIDE EXAMPLE OF CHANGING STATUS FROM REMOTE TO LOCAL AND FROM REMOTE TO PROGRAMMING STATUS CHANGE STATUS CHANGE REMOTE TO PRO G RAM MIN G PRO G RAM MIN G R EMO TE REMOTE TO R EMO TE LOCAL ON L O C AL AU TO SELECT...

-

Page 136: Parallel Inputs/Outputs

This paragraph provides information about the parallel I/O’s. Plus IOM MODULE I/O CONNECTION (BASIC CONFIGURATION) SLOT 4 FOR C3G VERSIONS SDLP - SDMP - SDHP AND SLOT 4-6 FOR C3G Plus VERSIONS DDMP - DDHP Plus With the C3G double cabin versions DDMP - DDHP two IOM modules are present at the same time. - Page 137 · output 1 to 16 º &dout[17] to $dout[32]. · Output 16 $dout[32] is not available. IOM SLOT 6 (ONLY FOR C3G Plus VERSIONS DDMP - DDHP) · input 1 to 16 º $din[33] to $din[48]; · output 1 to 16 º $dout[49] to $dout[64].

- Page 138 Plus INTEGRATION GUIDE Plus 24 Vdc SUPPLY INSIDE the C3G JP 200 Plus 24 Vdc SUPPLY INSIDE the C3G OUT 1 to 8 1 2 3 Plus 24 Vdc SUPPLY INSIDE the C3G OUT 9 to 16 1 2 3 JP 201 Plus 24 Vdc SUPPLY OUTSIDE the C3G...

- Page 139 IOM module of slot 6 on connector X30-2. These are respectively on machine 1 and/or 2. BASIC IOM MODULE SIGNAL ALLOCATION ROBOT BASIC IOM MODULE (SLOT 4-6) TRANSFER ALL COMAU ROBOTS SMART S FAMILY EXCEPT SMART S FAMILY SW. ALLOCATION X30 (X30-2)

- Page 140 User available wire 20 User available wire 21 User available wire 22 User available wire 23 User available wire 24 Connectors X90 and X91 for all COMAU Robots except the SMART S family CONNECTOR X91 SIGNAL CONNECTOR X92 +24 VDC...

- Page 141 Plus INTEGRATION GUIDE CONNECTOR X201 CONNECTOR X200 SIGNAL SIGNAL +24 Vdc +24 Vdc 0V (+24Vdc) 0V (+24Vdc) $DIN [9] $DIN [6] $DIN [10] $DIN [14] AVAILABLE $DIN [11] $DIN [12] $DOUT [22] $DIN [13] $DOUT [23] $DOUT [24] $DOUT [17] $DOUT [18] $DOUT [21] $DOUT [19]...

- Page 142 Plus INTEGRATION GUIDE X3/IOM X90/ROBOT INP1 (IOM) OUT1 0 V (+24 Vcc INT) +24 Vcc 1 2 3 24 Vcc EXT JP 200/SDB3 Example of I/O Connection with External 24 Vdc Power Supply MACHINE LINE - ROBOT SIGNALS For the connection of signals from the machine line to the robot it is possible to use the input channels con- nected directly from connector X30 (X30-2) to the connector on the robot and shown in the previous table.

- Page 143 Plus INTEGRATION GUIDE Additional I/O modules 01/0498 4-21...

- Page 144 It should be remembered that for installations in Italy the conductors must comply with CEI 20-22 standards second part; if the COMAU cable is not used, conductors with equivalent electrical characteristics and com- plying with UL 758 VW1 standards must be used.

- Page 145 Plus INTEGRATION GUIDE C3G-IOM (16 INPUT/16 OUTPUT MODULE) This is a slave module of the VME bus. The module can be configured for C3G IOM user or C3G IOMs system I/O’s (special version); in this case it is recognised by the RBC module and mapped in the area of I/O’s not available to the user and the function of each channel is pre-defined univocally.

- Page 146 Plus INTEGRATION GUIDE EXAMPLE OF USE OF THE IOMs MODULE IN HANDLING A MULTI-MACHINE SYSTEM 4-24 01/0498...

- Page 147 Plus INTEGRATION GUIDE C3G-ACI 32 AC INPUT MODULE VME Input module compatible with 110 Vac 32 channel slave type interface, with signalling through activation of LEDs on front panel when an input is present. It may be added on the Control Unit rack starting from the first free slot at the right of the basic configuration modules. TECHNICAL CHARACTERISTICS EXAMPLE OF CONNECTION INPUT...

- Page 148 Plus INTEGRATION GUIDE C3G-DCI 32 DC INPUT MODULE VME Input module compatible with 24 Vdc 32 channel slave type interface, with signalling through activation of LEDs on front panel when an input is present. It may be added on the Control Unit rack starting from the first free slot at the right of the basic configuration modules. All the channels are protected against polarity inversion through double diode.

- Page 149 Plus INTEGRATION GUIDE C3G-DLO 32 DC 0,5 A OUTPUT MODULE VME output module compatible with slave type interface capable of supporting 32 dc Outputs (0.5 A) with signalling through activation of LEDs on the front panel when the outputs are active. It may be added on the Control Unit rack starting from the first free slot at the right of the basic configuration modules.

- Page 150 Plus INTEGRATION GUIDE C3G-DHO 32 DC 2A OUTPUT MODULE VME output module compatible with slave type interface capable of supporting 32 dc Outputs (2 A) with signalling through activation of LEDs on the front panel when the outputs are active. It may be added on the Control Unit rack starting from the first free slot at the right of the basic configuration modules.

- Page 151 Plus INTEGRATION GUIDE C3G-ACO 16 AC 1A OUTPUT MODULE VME output module compatible with slave type interface capable of supporting 16 ac Outputs (1 A) with signalling through activation of LEDs on the front panel when the outputs are active. It may be added on the Control Unit rack starting from the first free slot at the right of the basic configuration modules.

- Page 152 Plus INTEGRATION GUIDE C3G-RLO 16 AC 2A RELAY OUTPUT MODULE VME output module compatible with slave type interface capable of supporting 16 dc or ac outputs (max 2 A), with signalling through ac- tivation of LEDs on the front panel when the outputs are active. It may be added on the Control Unit rack starting from the first free slot at the right of the base configuration modules.

- Page 153 Plus INTEGRATION GUIDE C3G-ADM 2 ANALOG OUT-8 DC INP - 8 DC OUT VME Input/Output module compatible with slave type interface. It comprises 2 analogue output channels, 8 24 VDC digital input chan- nels and 8 24 VDC digital output channels with signalling by LEDs on the front panel when the channels are active. It may be added on the Control Unit rack starting from the first free slot on the right of the basic configuration modules.

- Page 154 Plus INTEGRATION GUIDE EXAMPLE OF CONNECTION CONNECTION OF ANALOGUE OUTPUTS (1/2) The optoisolated section of the analogue outputs requires an external power supply at 24 Vdc which may be connected to the same power supply as the load or separately if high precision of the signal on the load device is required. 1.

- Page 155 Plus INTEGRATION GUIDE CONNECTION OF ANALOGUE OUTPUTS (2/2) 2. Separate power supply This type of connection requires the use of two power supplies. The first connected to the optoisolated section of the ADM module and the second to the load. This solution is recommended when the load device requires high command signal precision.

-

Page 156: Serial Inputs/Outputs

Plus INTEGRATION GUIDE SERIAL INPUTS/OUTPUTS The information needed for the connection and use of modules C3G - PFDP, C3G - EIM, C3G -PLC is given in specific booklets provided only if the controller is fitted with one of these modules. PROGRAMMES CONTAINED IN FLOPPY DISK 3”... - Page 157 Plus INTEGRATION GUIDE HELPIO.COD It permits to configure the help of the command DISPLAY INPUT/OUT- HELPIO.DOC PUT.To this purpose, the program HELPIO.COD has to be modified (by PROGRAM EDIT) and sent to execution (by PROGRAM GO), after loading the program HELPIO2:COD to the memory (by MEMORY LOAD.

- Page 158 Plus INTEGRATION GUIDE This page has been intentionally blank 4-36 06/0400...

- Page 159 Operations and Plus Maintenance Manual SAFETY REGULATIONS INSTALLATION OPERATOR INTERFACE INTEGRATION GUIDE MAIN OPERATIONS FOR SYSTEM USE EMERGENCY PROCEDURES MAINTENANCE SUMMARY Paragraph Page System operating modes System statuses System status in multimachine - multiarm configuration Robot movement in programming status File management between PC and cell controller 5-10 Use of the Floppy Disk unit...

- Page 160 Operations and Plus Maintenance Manual This page has been intentionally blank...

-

Page 161: System Operating Modes

Plus MAIN OPERATIONS FOR SYSTEM USE SYSTEM OPERATING MODES The controller can work in three ways, which can be selected through the status selector on the control panel of the controller: automatic local, automatic remote and programming. The automatic local mode makes it possible to execute production programmes which, as they contain in- structions for robot movement, can be started by pressing the START button on the PTU4 programming ter- minal. - Page 162 Plus MAIN OPERATIONS FOR SYSTEM USE · ALARM: this status is reached following a system alarm. The system starts different actions such as suspending programme execution, deactivating drives, etc. depending on the seriousness of the error. The system current status is displayed on the first status line of the programming terminal (or PC video, if the PCINT tool is used with CRT emulation procedure).

- Page 163 Plus MAIN OPERATIONS FOR SYSTEM USE The conditions that may take the system status from AUTO to HOLD are the following: · switching the control panel status selector on any other position; · pressing the DRIVE OFF or HOLD button on the programming terminal; ·...

-

Page 164: System Status In Multimachine - Multiarm Configuration

Plus MAIN OPERATIONS FOR SYSTEM USE SYSTEM STATUS IN MULTIMACHINE - MULTIARM CONFIGURATION Below is an example in which the controller handles two MACHINES and three ARMS. This example does not cover all the possible configurations, but it shows the statuses of the controller in multi-machine - multiarm handling. -

Page 165: Robot Movement In Programming Status

Plus MAIN OPERATIONS FOR SYSTEM USE ROBOT MOVEMENT IN PROGRAMMING STATUS REFERENCE TERNS A Cartesian reference system, or reference tern, is a geometrical concept which makes it possible to repre- sent an object in space. For example, the corner of a table can be chosen as reference system to represent the table itself. - Page 166 MAIN OPERATIONS FOR SYSTEM USE Now imagine a pen fitted on the robot flange that must write the word COMAU on the table. $BASE transfor- mation defines the point in which the robot base is, the $TOOL movement indicates the pen and the $UFRAME movement indicates the position of the table in relation to the room.

- Page 167 Plus MAIN OPERATIONS FOR SYSTEM USE The procedure for manually moving the arms of a robotised cell differs slightly depending on the configura- tion of the cell controller. The following paragraphs give further details for a few typical situations. MANUAL MOVEMENT OF A SINGLE ARM SYSTEM To perform manual movement of a single arm, simply set the status selector to the programming position choose the most appropriate mode and press the keys keeping the enable button on the...

- Page 168 Plus MAIN OPERATIONS FOR SYSTEM USE MOVEMENT INSTRUCTION IN PROGRAMMING STATUS Programming the movement of a robot requires a certain knowledge about the C3G system and PDL2 pro- gramming language. However, before creating a true programme, it is possible to carry out a few simple movements by the direct execution of an instruction.

- Page 169 Plus MAIN OPERATIONS FOR SYSTEM USE MOVE LINEAR TO POS(100,200,300,0,0,0,’’) linear movement of the arm pre-defined on a Cartesian point of co-ordinates x=100, y=200 and z=300 and tool tern with the same direction as the user tern. MOVE JOINT TO POS(0,0,0,0,180,0,’’) joints type movement of the pre-defined arm on a Cartesian point of co-ordinates x=0, y=0 and z=0 and axis z of the tool tern facing the oppo-...

-

Page 170: File Management Between Pc And Cell Controller

Plus MAIN OPERATIONS FOR SYSTEM USE FILE MANAGEMENT BETWEEN PC AND CELL CONTROLLER Below is a description of the procedures for deleting, displaying and transferring files via PC. To do this it is necessary to use the PCINT programme, which must be installed on the PC; for PCINT programme set up and use, refer to the “PCINT PROGRAMME”... -

Page 171: Use Of The Floppy Disk

Plus MAIN OPERATIONS FOR SYSTEM USE AUTOMATIC FILE TRANSFER FROM PC TO CONTROLLER · Type the FUR command (Filer, Utility, Restore). This command copies in the RAM Disk files coming from the external device (FD COMP: or COM0:) which is recognised automatically. In the case of COM0: Kermit communication protocol must be installed on the PC. -

Page 172: Examples Of The Use Of Digital I/O's And Analogue Outputs

Plus MAIN OPERATIONS FOR SYSTEM USE EXAMPLES OF THE USE OF DIGITAL I/O’s AND ANALOGUE OUTPUTS The examples below are written using PDL2 programming language and may be used in the context of a programme. · DIGITAL INPUTS (e.g. IOM module) WAIT FOR $DIN[1] = ON -- The programme stops waiting for the condition IF $DIN[1] = ON THEN... -

Page 173: Calibration

Plus MAIN OPERATIONS FOR SYSTEM USE CALIBRATION This paragraph describes the calibration and Turn-set procedures that can be carried out using the controller and examines the subject of calibration in detail. The basic concepts, the terminology used and the internal mechanisms for handling axis position information are given below. - Page 174 Recovery of calibration, if necessary, (performed by COMAU SYSTEMS) must be carried out when the robot is started for the first time. Afterwards calibration should not be repeated, unless a component in the kinematic chain has to be replaced due to a mechanical failure or unless a collision damages the structure of the robot.

- Page 175 Plus MAIN OPERATIONS FOR SYSTEM USE The calibration constants are stored in the variable $ARM_DATA[arm_num].CAL_DATA, in the ASCII calibration file, in the C3G.SYS file, in the Flash Eprom on SAU2 or RPT (optional). For robots with particular mechanical structures (e.g. TRICEPT HP1) specific calibration programmes are foreseen.

- Page 176 Plus MAIN OPERATIONS FOR SYSTEM USE · LOSS OF CALIBRATION Events may occur during use of the control unit which cause loss of the calibration constants or of the number of resolver revolutions. If there are no problems, the Ar:CAL message appears in the status window. If Ar:Turn is displayed, an operation to restore resolver revolution is requested.

- Page 177 CALIBR AT ION E R R OR COUNT E R AND E S T ABLIS HE S AXE S EPROM POS IT ION $CAL_DATA (SAU2) CARL C3G Plus SHARED MEMORY $CAL_DATA C A RS C ARL R B C 2 R PT...

- Page 178 CARL/LOADFILE (Configure, Arm, Reten_Mem, Load/Loadfile) ROBOT CALIBRATION The robots are calibrated by COMAU after assembly. Calibration reference indexes and/or notches are in- stalled on the axes. In most applications, these indexes/notches make it possible to bring the robot to its zero position with a sufficient degree of accuracy;...

-

Page 179: Kinematic Compensation Algorithm

.ROB. Each robot has its own specific file, which cannot be used by other robots. · With the C3G Plus cell controller it is possible to have a maximum of 4 Arms per system, each of which has a file which identifies its kinematic model. - Page 180 The approximation in the wrist axes (4 and 6) is due to the need to use inverse kinematic compensation on the final point reached. For further information regarding kinematic compensation please refer to the C3G Plus Pro- gramming Rules and Notes about Working Area manual.

-

Page 181: Cutting Off Alarms Using The Excl Key On Ptu4

Operations and Plus Maintenance Manual PRESCRIZIONI DI SICUREZZA INSTALLATION OPERATOR INTERFACE INTEGRATION GUIDE MAIN OPERATIONS FOR SYSTEM USE EMERGENCY PROCEDURES MAINTENANCE SUMMARY Paragraph Page Cutting off alarms using the EXCL key on PTU4 Use of the PTU4 as emergency terminal Use of the BRAKE RELEASE DEVICE... - Page 182 Operations and Plus Maintenance Manual This page has been intentionally blank...

- Page 183 Normally the cell controller is associated to a robot by COMAU; during installation this asso- ciation must be adhered to (see chapter 2 INSTALLATION). If the controller is connected to...

- Page 184 Plus EMERGENCY PROCEDURES · For single cabin controller versions (SDLP - SDMP - SDHP): remove the closing cap from connector X201 (ON) and insert it in connector X200 (EMC). · For double cabin controller versions (DDMP - DDHP): remove the closing cap from connector X201 (ON) and insert it in connector X200 (EMC) when needing to move MACHINE 1 or X199 (EMC) when intending to move MACHINE 2.

-

Page 185: Use Of The Brake Release Device

Plus EMERGENCY PROCEDURES USE OF THE BRAKE RELEASE DEVICE (C3G-BRD) If the robot is positioned in such a way as not to allow its movement with the normal emergency procedures it is possible to use device C3G-BRD. This device makes it possible to supply the brake of each single axis (one at a time) allowing the movement of the axis itself. - Page 186 Plus EMERGENCY PROCEDURES Connect the brake release device C3G-BRD in the following sequence: a. connect the Harting connector of the device to connector X2, X2 EXT and X3 at the robot base; b. connect the device socket to a 220 Vac power source outside the control unit. X2 EXT 220 Vca C3G-BRD...

- Page 187 Operations and Plus Maintenance Manual SAFETY REGULATIONS INSTALLATION OPERATOR INTERFACE INTEGRATION GUIDE MAIN OPERATIONS FOR SYSTEM USE EMERGENCY PROCEDURES MAINTENANCE SUMMARY Paragraph Page General rules for maintenance Preventive maintenance Extraordinary maintenance Plus Main C3G versions SDLP - SDMP - SDHP connections Plus Main C3G versions DDMP - DDHP connections...

- Page 188 Operations and Plus Maintenance Manual This page has been intentionally blank...

- Page 189 In the event of cable replacement, restore the connections of any screens disconnected previously. · The replaced cable must bear the COMAU code corresponding to the removed one. · Before connecting any cable, always refer to the controller wiring diagrams.

- Page 190 Plus MAINTENANCE This page has been left intentionally blank 7-ii 00/1097...

-

Page 191: Preventive Maintenance

Plus MAINTENANCE PREVENTIVE MAINTENANCE ROUTINE CHECKS In order to ensure correct operation of the controller, the cabin doors must be kept closed. Every six months you are advised to inspect and if necessary, clean the dissipater of the Servo Amplifiers Unit rack SAU2, to be found in the rear controller compartment. - Page 192 Plus MAINTENANCE This page has been left intentionally blank 00/1097...

-

Page 193: Extraordinary Maintenance

Plus MAINTENANCE EXTRAORDINARY MAINTENANCE Extraordinary maintenance summary chart C3G Plus FUNCTIONAL LAYOUTS SDLP-SDMP-SDHP VERSIONS Main C3G Plus connections Power supply distribution Axes control circuit Serial and parallel line connections Internal/external safety device layout System Inputs/Outputs User Inputs/Outputs Plus FUNCTIONAL LAYOUTS... - Page 194 System software loading Subsequent system software loading with same version or later versions Software operations for robot replacement Software operations for controller replacement Software operations for updating characterisation file C3G PTU4 software SPARES High consumption COMAU spares COMAU spares Commercial spares 08/0702...

- Page 195 Plus MAINTENANCE Main C3G Plus Connections AMPLIFIER 放大器 SERVO 侍服 ELECTRO 电板 MECHANICAL 机械的 PROTECTION 保护 RESOLVER 角分器 BOARD 板 THERMAL 热的 OVERTRAVEL 超行程 08/0702...

- Page 196 Plus MAINTENANCE Power Supply Distribution (Page 1 of 2) SOCKET 插座 Only for Rel. 1.x Machine line Robot 04/0799...

- Page 197 Plus MAINTENANCE Power Supply Distribution (Page 2 of 2) AVAILABLE 可用到的 EXTENSION 扩展 00/1097...

- Page 198 Plus MAINTENANCE Axes Control Circuit 00/1097...

- Page 199 Plus MAINTENANCE Serial and Parallel Line Connections Only for Rel. 1.x 04/0799...

- Page 200 Plus MAINTENANCE Internal/External Safety Device Layout (Page 1 of 2) 7-10 08/0702...

- Page 201 Plus MAINTENANCE Internal/External Safety Device Layout (Page 2 of 2) 08/0702 7-11...

- Page 202 Plus MAINTENANCE System Inputs/Outputs excluded SMART H4 (**) X200 on SMART H4 (***) X8 H4 Spot (****) X9 H4 Handling 7-12 04/0799...

- Page 203 Plus MAINTENANCE User Inputs/Outputs excluded SMART H4 (**) for SMART H4 04/0799 7-13...

- Page 204 Plus MAINTENANCE Plus Main C3G Connections DDMP - DDHP Versions 7-14 01/0498...

- Page 205 Plus MAINTENANCE Power Supply Distribution (Page 1 of 2) 01/0498 7-15...

- Page 206 Plus MAINTENANCE Power Supply Distribution (Page 2 of 2) 7-16 01/0498...

- Page 207 Plus MAINTENANCE Machine 1 Axes Control Circuit 01/0498 7-17...

- Page 208 Plus MAINTENANCE Machine 2 Axes Control Circuit 7-18 04/0799...

- Page 209 Plus MAINTENANCE Serial and Parallel Line Connections 04/0799 7-19...

- Page 210 Plus MAINTENANCE Internal/External Safety Device Layout (Page 1 of 2) 7-20 08/0702...

- Page 211 Plus MAINTENANCE Internal/External Safety Device Layout (Page 2 of 2) 08/0702 7-21...

- Page 212 Plus MAINTENANCE System Inputs/Outputs X200 for SMART H4 (**) X8 H4 Spot (***) X9 H4 Handling 7-22 04/0799...

- Page 213 Plus MAINTENANCE User Input/Output IOM Slot 4 excluded SMART H4 (**) for SMART H4 04/0799 7-23...

- Page 214 Plus MAINTENANCE User Input/Output IOM Slot 6 excluded SMART H4 (**) for SMART H4 7-24 04/0799...

-

Page 215: Diagnostics

Plus MAINTENANCE diagnostics 诊断学 DIAGNOSTICS The system with active Control Unit possesses three different diagnostics levels which make it possible to lo- cate any faults: During system start-up the green RUN led of the module on which the fault occurs level 1 (RBC2 or SCC2) flashes emitting a light code referring to the type of fault. - Page 216 Plus MAINTENANCE Primary codes indicate a general type of fault: Intermittence Type of fault Fault at initialisation Diagnostic error Unforeseen asynchronous events Others INITIALISATION FAULT CODES In this case secondary codes are not defined. DIAGNOSTIC ERROR CODES The secondary code represents the diagnostic number concerning the routine that has given a negative result. The values are the following: Intermittence Diagnostic...

- Page 217 If the system start-up sequence is aborted, thus the RUN led of RBC2 or SCC2 flashes, to remedy the fault it is necessary to replace the module with the RUN led that is flashing. The code issued is used by COMAU SYSTEMS to identify the fault and it may be mentioned for subsequent module repair.

- Page 218 Plus MAINTENANCE Meaning Code 0002 0000 OS RAM fault 0004 0000 Program RAM fault 0008 0000 IR RAM fault 0010 0000 Enable RAM fault 0020 0000 ROM fault 0040 0000 Simulated scan fault 0080 0000 Watchdog timer fault 0100 0000 Communication port 1 fault 0200 0000 CPU fault...

- Page 219 “LOCAL DIAGS ON BOARD “RBCO” 00080000, to reset the fault it is necessary to replace the module that failed the test, in this case, RBC2. The code issued is used by COMAU to identify the fault and can be mentioned for subsequent module repair.

- Page 220 Plus MAINTENANCE Level of se- Meaning Effect of Problem Reset Action riousness Fatal Cuts off the supply to Reset re-supplying the the robot motors via control system or using the safety relay on the the CONFIGURE RBC2 board, deacti- CNTRLER RESTART vates all programmes WARM command (DEACTIVATE) and...

- Page 221 Plus MAINTENANCE SAFETY CIRCUIT TEST DEVICES Connector X113 test device: Plus 04/0799 7-31...

- Page 222 Plus MAINTENANCE The connector X113 test device has been developed to allow quick fault-finding on the safety chains; in fact it makes it possible to display the motor switching on chain and the internal and external safety chain through a simplified wiring diagram which represents these circuits and a set of leds which allow quick identification of a fault if it occurs.

- Page 223 Plus MAINTENANCE Meaning of safety chain leds and probable causes MEANING PROBABLE CAUSES internal 24 Vdc present TP12 – TP13 V1 power supply, fuse Off: F116 Flash when the robot motors are switched on failure to close contact Off: of relay K5 (SIM) DBU3 (DBU3-2) dynamic braking OK and power TP11 contactors K101/K102 (K121/ K122) OK...

- Page 224 Plus MAINTENANCE LED LIGHTING UP SEQUENCE When the DRIVES ON button is pressed on PTU4 or from REMOTE the following sequence may be seen on the Connector Test: - leds TP8 - TP11 On - leds TP20 - TP21 - TP30 - TP23 - TP22 - TP24 - TP25 - TP26 - TP27 - TP31 - TP32 On - leds TP8 - TP11 Off FUNCTION OF MICROSWITCHES The first microswitch starting from the top of the connector test device is to check whether the electronics...

- Page 225 Plus MAINTENANCE X30 connector test device: 01/0498 7-35...

- Page 226 Plus MAINTENANCE Plus The X30 connector test device makes it possible to use the C3G controller in the AUTOMATIC/Remote mode without connecting to an external PLC. It also allows connection of all the safety devices (Emergency buttons, Safety gates, others). The device comprises a set of microswitches, signalling leds and two connectors (WEIDMULLER) for con- necting the external safety devices.

- Page 227 Plus MAINTENANCE · TEACH ENABLE This turns on when the status selector is in the PROGRAMMING position (Yellow) - on PROGRAMMING - off AUTOMATIC/Local or AUTOMATIC/Remote · ALARM This turns off when the controller is in an alarm status, it works in all modes (Red) - on NO ALARM PRESENT - off ALARM ·...

-

Page 228: Troubleshooting Indications

Plus MAINTENANCE TROUBLESHOOTING INDICATIONS Alarm/Warning Context Cause/Remedy References · 28707-10: SAU2 Check circuits of Brakes, Motor Circuit diagram Safety chain circuit open Faulty (SFT led on) thermal switch, Overtravel · SAU2 Tables · Consult cause/remedy with PCINT programme · Normal operation Check the safety circuit Use of safety circuit test de- vice (connector X113) -

Page 229: Fuses And Protections

Plus MAINTENANCE FUSES AND PROTECTIONS FUSES TYPE PROTECTION Normal Blow Fuse Optional RPT Module (Robot) 250V 0,5A Normal Blow Fuse Optional RPT Module (Robot) 250V 0,7A Quick-Acting-Fuse 24 Vdc output SIM module 125 V/10kA 5A F1-F2 Quick-Acting-Fuse Outputs 1 to 8 (F1) 125 V/10kA 5A Outputs 9 to 16 (F2) IOM module... - Page 230 RED - ON Protection of 24 Vdc supply for SIM module tripped. Thermal probe S2 warnings (terminal strip X120): With versions DDMP - DDHP of the C3G Plus the thermal probe S2 terminals are in terminal strip X119. TERMINAL WARNING...

-

Page 231: Circuit Diagrams

Plus MAINTENANCE CIRCUIT DIAGRAMS The controller circuit diagrams are gathered in a folder called CONTROL SYSTEM CIRCUIT DIAGRAM which is provided with this Operations and Maintenance manual. The wiring diagrams concerning: Application Box, Robot, fittings/cell outside the controller are provided with the documentation for the robot system, in special folders, separate from the controller circuit diagrams. - Page 232 Plus MAINTENANCE This page has been left intentionally blank 7-42 00/1097...

-

Page 233: Control Unit

Plus MAINTENANCE C3G-PWR3 POWER SUPPLY This is the power supply of the modules in the Control Unit and it generates the output voltages needed to operate the modules and the typical signals required by the specifications of VME standard. It has a recharging circuit for the Control Unit buffer battery. It is inserted in the special slot at the left inside the Control Unit rack and its power rating is 185 W. - Page 234 Plus MAINTENANCE C3G-RBC2 ROBOT CPU At cell level this is the central unit for operating system management and interpretation of the user programmes, trajectories, interfaces. It acts as PLC for the local I/O. It contains a shared memory area accessible from both board and VME bus; if inserted in the first slot it also works as “system controller”...

- Page 235 Plus MAINTENANCE C3G-SCC2 SERVO CONTROL CPU The Servo Control CPU manages axes movement control in a machine receiving the trajectory targets from the RBC module, through the VME bus in the master-slave mode and microinterpolating the trajectories themselves; it sends information about machine status and any alarms to the RBC module, also through the VME bus.

- Page 236 Plus MAINTENANCE 22’ DIFF. 2-AXIS I/O INTERFACE ANNEX Each 22’ DIFF. 2-AXIS I/O INTERFACE annex reads the position and generates the current reference signals for two axes. On a Servo Control CPU module up to four annexes can be installed, for managing a robot with a maximum of eight axes. The annex connects to the SCC2 module through two connectors P1 (analogue signals) and P2 (digital signals).

- Page 237 Plus MAINTENANCE C3G-SIM SYSTEM INTERLOCK MODULE System I/O module which interfaces certain control unit internal assemblies; it manages the I/O to the transfer and implements part of the safety circuits with relay logic. The outputs to the transfer are protected by fuse with specific indication on the monitoring system in the event of breakage. It is a VME bus slave module.

- Page 238 Plus MAINTENANCE Input/Output MODULES · C3G-IOM, 16 Input/16 Output Module · C3G-ACI, 32 AC Input Module · C3G-DCI, 32 DC Input Module · C3G-DLO, 32 DC 0.5 A Output Module · C3G-DHO, 32 DC 2A Output Module · C3G-ACO, 16 AC 1A Output Module ·...

- Page 239 Plus MAINTENANCE C3G-DBU3 DYNAMIC BRAKING UNIT The DBU3 module is a hardware device which increases the safety of the robot. The module cuts in short circuiting the system DC Bus through suitable resistance, offering a braking effect on the axis which would tend to fall in the event of a fault. The DBU3 module is active at DRIVE OFF and also when the robot is in the rest condition, but connected to the controller.

- Page 240 Plus MAINTENANCE C3G-BKM BACKUP MODULE The BKM module is connected to the Control Unit power module (C3G-PWR3) and, in the event of a mains failure, it has the task of keeping the Control Unit rack active for 2 seconds. LAYOUT REPLACEMENTS Specific cautions ·...

- Page 241 Plus MAINTENANCE C3G-MPI MOTORS POLES IDENTIFICATION This circuit allows the system to identify the motor polar pairs installed on board the robot and to automati- cally update a special file containing the machine configuration for the rating of the polar pairs and the result- ing resolver phasing.

- Page 242 Plus MAINTENANCE C3G-RPT RESOLVER POSITION TRACKER (When installed) Intelligent module on board machine which makes the machine itself absolute with regard to the control unit. The RPT module (patented device) based on a microprocessor system with rechargeable backup battery which allows it to work without external power for a maximum of 600 hours, counts the number of motor revolutions for eight machine axes.

- Page 243 ON. The protection fuses inside the module must be replaced only by equivalent ones specified by COMAU; the use of other fuses may cause danger to the operators and control unit malfunctioning for which COMAU undertakes no liability.

-

Page 244: Servo Amplifiers Unit Sau2

Plus MAINTENANCE SERVO AMPLIFIERS UNIT SAU2 The SAU 2 unit is an integrated power unit which has the task of generating controlled terns of sinusoidal currents to drive up to 8 synchronous three-phase brushless motors. It is an intelligent unit controlled by microprocessor which manages the commands and statuses from and for the Servo Control CPU (SCC2) master unit. - Page 245 FRONT PANEL LAYOUT (C3G-SAU2 Model 6) The C3G Plus control with SMART X1 robot requires unit SAU2 model 6 that makes it possible to install just one additional module for the optional axes. This additional module can control an Axis 7 (slide or external axis) or an Axis 8 usually used as motor for the power gripper.

- Page 246 Plus MAINTENANCE FRONT PANEL LAYOUT (C3G-SAU2 Model 1/2/3/4/5/7) Connectors Function Colour Meaning Supplies: 110 Vac auxiliary circuits; ENA1 green Off: indicates that the corre- 24 Vdc brakes circuit, uninterrupted ENA2 green sponding axis is disabled 24 Vdc (the 0 V is shared with the ENA3 green 24 Vdc of the brakes) for releasing...

- Page 247 Plus MAINTENANCE Meaning Connectors Function Colour Off: indicates that the mC is 25-way connector. working correctly Interface to PTU4 emergency termi- On: indicates that the mC is nal (E.M.C.) for: not working correctly - Serial line EIA RS485 (SAU2 green Off: indicates the absence of receives commands and supplies auxiliary 110 Vac current or...

- Page 248 Plus MAINTENANCE SAU2 MAIN COMPONENTS LAYOUT ADDITIONAL AXES If it is decided to add an axis to the configuration of the SAU2 (e.g.: axis 7) a special kit is available including assembly instructions and composed as mentioned in the SAU2 CONFIGURATIONS paragraph. When connecting the power modules the phase sequence necessary is U-V-W When working on the SAU2 follow the rules of safety and the instructions given in the re- placements paragraph.

- Page 249 Plus MAINTENANCE SOFT START CIRCUIT ENABLING/DISABLING On the soft start circuit a switch (SW1) is available which makes it possible to cut off the circuit. Setting the switch to ON the circuit is cut off. The circuit should not normally be cut off. Cutting off is allowed only for fault finding and when considered absolutely necessary.

-

Page 250: System Software Loading

The system software floppy disks are kept in a container inside the controller. Each disk and the box that contains them are labelled with the specific data of the software contained. It is advisable to make a reserve copy of all the disks supplied by COMAU SYSTEMS. PROCEDURE... - Page 251 Plus MAINTENANCE Should the system software loading procedure fail (for instance when inserting the wrong floppy disk), the programming terminal display shows the Bootmon environment. Activate the characters menu pressing the CHAR key on the PTU4 keyboard and then type the com- mand RESET/INIT.

- Page 252 Plus MAINTENANCE SUBSEQUENT SYSTEM SOFTWARE LOADING WITH SAME VERSION OR LATER VERSIONS (2/2) 7-62 00/1097...

- Page 253 Plus MAINTENANCE SOFTWARE OPERATIONS FOR ROBOT REPLACEMENT PRELIMINARY OPERATIONS Replace the robot in compliance with the rules of safety. 01/0498 7-63...

- Page 254 Plus MAINTENANCE SOFTWARE OPERATIONS FOR CONTROLLER REPLACEMENT (1/2) PRELIMINARY OPERATIONS Replace the controller in compliance with the rules of safety. Using the FD (Filer Delete) command erase the backup files of the user programmes from the C3G RAM DISK: COMMAND : FD HELP TYPE : *.bk* or press and select *.bk*...