Subscribe to Our Youtube Channel

Summary of Contents for FRIATEC FRIALEN

- Page 1 FRIALEN ® -Large Pipe Technique for laying large pipes and relining pipe networks Fitting Instructions...

-

Page 2: Table Of Contents

Standard publications and specifications for use Couplers from d 250 mm Saddle parts - Top Loading Pipeline relining Update of these assembly instructions For further information on the processing of FRIALEN ® Safety Fittings, please contact: FRIATEC Aktiengesellschaft Technical Plastics Division P.O.B. -

Page 3: Safety

IMPORTANT! Describes advice and other useful information! Areas of Application FRIALEN ® Safety Fittings are used for weld joints at pressure pipes made of polyethylene in the dimensions SDR 17.6 to SDR 11 for use in gas and water supply, pressure drainage, industry and landfill construction. -

Page 4: Standard Publications And Specifications For Use

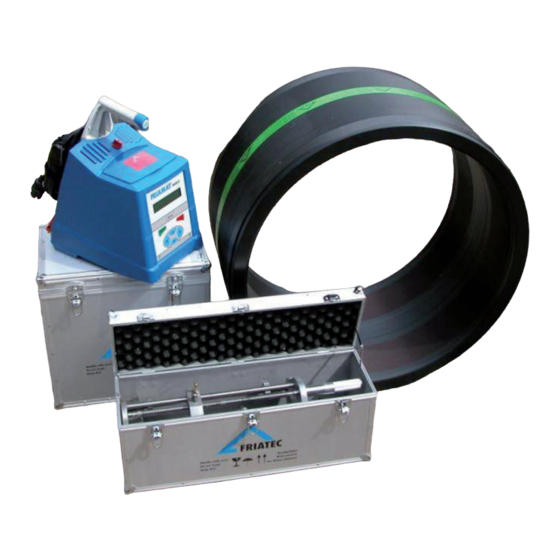

® FRIALEN Safety Fittings consist of PE 100 and meet the requirements according to DIN 16963-5, -7, EN 1555-3, EN 12201-3, EN 13244-3, ISO 8085-3 as well as the DVGW test bases. FRIALEN ® Safety Fittings can ® be fused with FRIAMAT Electrofusion Units at ambient temperatures between - 10 °C and + 45 °C. - Page 5 These data on component traceability can be electronically archived together with the fusion process data. IMPORTANT! Manual electrofusion units (without barcode reader), e.g. FWS 225, are no longer state-of-the art. Processing of FRIALEN ® Safety Fittings with these units is thus no longer possible.

-

Page 6: Couplers From D 250 Mm

The design factor C (calculation coefficient for PE components) depends on the area of application and the specifications (min. 1.25). Fitting material: PE 100 Water ® (FRIALEN standard) SDR Stage maximum operating pressure maximum operating pressure in bar for new: C = 1.25... - Page 7 Measure fusion zone, mark ® with a FRIALEN marker and remove oxide layer Fusion zone: The length of the fusion zone corresponds to half the length of the coupler. At first, remove contaminations from Figure 3 the pipe. A processing allowance of approx.

- Page 8 0.30 - 0.40 FWSG SE 250 - 315 0.25 - 0.35 ® Please note that the indicated wearing margin applies to FRIALEN Safety Fittings. Where appropriate please observe manufacturers’ indications. Filing or sanding are not permitted because contaminations are introduced.

- Page 9 (e.g. moisture, frost formation). Do not touch the fusion zone again after scraping. WARNING! ® FRIALEN Safety Fittings with integrated heating coils guarantee optimal heat transfer through their exposed heating coils and may thus not be scraped at the inside of the fitting.

- Page 10 The cleaning agent must be completely evaporated before starting the fusion process. ® Now, using the FRIALEN marker, re-mark the line (approx. 120 ° distri- buted around the circumference) to show the width of the fusion zone on the pipe since this will have been removed by scraping and cleaning.

- Page 11 (see item 4.9). Before starting the fusion process, check again based on the markings ® whether the position of the pipe insertion end in the FRIALEN Safety Fitting has shifted (correct, if required). WARNING!

- Page 12 Pre-heating for reducing the annular gap between coupler and pipe. WARNING! Only use fusion units which have been approved by the manufacturer ® with regard to their function for the processing of FRIALEN Safety Fittings. See DVS 2207-1. ® ®...

- Page 13 Carrying out the fusion WARNING! Only use fusion units which have been approved by the manufac- turer with regard to their function ® for the processing of FRIALEN Safety Fittings. See DVS 2207-1. ® Use FRIAMAT fusion units only ®...

- Page 14 For fittings with continuous coil, both fitting sides are to be fused simulta- neously (see Figure 11). ® FRIALEN Safety Fittings are equipp- ed with a swell indicator, this only gives an indication that fusion has taken place. This swell indicator...

- Page 15 The obtained actual fusion time is to be compared with the target fusion time on the unit and to be ® noted on the pipe or the FRIALEN Safety Fitting (See Figure 12). With this identification it is ensured that no fusion point is overlooked.

-

Page 16: Saddle Parts - Top Loading

Saddle parts - Top Loading ® FRIALEN TL saddle parts are used with pipes from SDR 17 to SDR 11 from d 250 mm. The processing occurs with the FRIATOP Clamping Unit (Figure 15b). - Page 17 5.1.1 Measuring of fusion zone of the pipes (and the lateral outlet spigot), marking and removing oxide layer The fusion zone: is the area of pipe covered by the saddle; for a side outlet it is the insertion depth on the smooth pipe spigot.

- Page 18 5.1.2 Cleaning The surfaces of the pipes to be fused and the interior surfaces of the ® FRIALEN DAA-TL Pressure Tapping Tees Top-Loading must be absolutely clean, dry and free from any grease. These areas are to be cleaned with a suitable cleaning agent and exclusively with absorbent, lint-free and non-dyed paper directly before the assembly and after scraping.

- Page 19 The fusion fitting is to be removed from the packaging only directly before the planned processing. The packaging protects the fittings against external influences during transport and storage. 5.1.3 Assembly - Place the saddle onto the prepared surface of the pipe. - Fit the adapter of the FRIATOP clamping device (Figure 15a).

- Page 20 The obtained ACTUAL fusion time is to be compared with the target ® fusion time on the unit and to be noted on the pipe or the FRIALEN Safety Fittings. With this identification it is ensured that no fusion point is overlooked.

- Page 21 5.1.5 Tapping and application of the test and operating pressure The following waiting times are to be observed: Diameter Cooling time in minutes for FRIALEN ® in mm Saddle fittings Up to pressurisation via outlet Up to tapping ≥ 250 The cooling time CT stated on the components corresponds to the cooling time until tapping.

- Page 22 O-ring, it is not necessary to apply a great deal of pressure when closing the valve. Install the FRIALEN Installation Kit EBS on the 14 mm square of the DAV-TL and secure the splint against pull out. Set the required overlapping height on telescoping frame.

- Page 23 VAM-RG-TL Valve Tapping Saddles d 250 - 315 (560) 5.2.1 Assembly The preparation of the installation and the fusion process is made ® analogue to the FRIALEN Pressure Tapping Tee (see 5.1.1 to 5.1.4). WARNING! The fusion range of the saddle...

- Page 24 (see Figure 21). SA-TL Spigot Saddles Top-Loading d 250 - 560 5.4.1 Assembly Figure 21 The preparation of the installation and the fusion process is made ® analogue to the FRIALEN Pressure Tapping Tee (see 5.1.1 - 5.1.5). Figure 22...

- Page 25 We recommend the tapping unit of the company of Hütz + Baumgarten, Remscheid (www.huetz-baumgarten.de), especially designed for this purpose. ® Please ask our FRIALEN Application Engineering Department. The manufacturer’s installation instructions are to be observed. VSC-TL Repair Saddle Top-Loading d 250 - 560 5.5.1 Assembly...

-

Page 26: Pipeline Relining

5.6.1 Assembly The preparation of the installation and the fusion process of the tapping ball ® valve AKHP is made as saddle component analogue to the FRIALEN Pressure Tapping Tee (see items 5.1.1 - 5.1.5). INFORMATION: For a leakage-free tapping of pressurised pipings, we recommend the tapping unit of the company of Hütz + Baumgarten, Remscheid... - Page 27 ® The ends of each renovated section of pipeline can be fused with FRIALEN REM Relining Slide-over Couplers. At points where it is scheduled to fuse on a coupler or a saddle the relining pipe should be sized to the nominal inside diameter during the reshaping by fitting half shells.

- Page 28 6.3.3 Pre-heating: Procedure see item 4.8 6.3.4 Support sleeve In case of larger deviations in shape or size on the ends of the pipes in the area of the joint the use of support sleeves is recommended (Figure 26). The fitting can then be used as a slide-over coupler.

- Page 29 Cooling times For cooling times item 4.10 is appli- cable. Relining fittings and clips (top loading) When fitting saddle components (Figure 29) care must be taken with any ovality or flattening of the HDPE pipe. In order to achieve a uniform Figure 29 surface pressure, and thus a proper fusion, the radius of curvature on the inner liner at the site of the proposed...

-

Page 30: Update Of These Assembly Instructions

These technical statements are regularly revised to be up-to-date. The date of the last revision is stated on the document. For an updated version of the operating instructions, please visit our website www.frialen.com on the Internet. You will find the “Download” page on the navigation bar. This page contains our updated operating instructions as pdf documents. -

Page 32: Friatec Aktiengesellschaft

FRIATEC Aktiengesellschaft · Technical Plastics Division P.O.Box 71 02 61 · D-68222 Mannheim Phone: +49 621 486-1486 · Fax: +49 621 479196 E-Mail: info-frialen@friatec.de · www.frialen.com...

Need help?

Do you have a question about the FRIALEN and is the answer not in the manual?

Questions and answers