Table of Contents

Advertisement

Table of Content 850600001

...................................................................................................................

.........................................................................................................................

Version Nr. 1-2 - 06.03.2019

...........................................................................................................

........................................................................................................

...................................................................................................

......................................................................................................

................................................................................................................

............................................................................................................

.................................................................................................

......................................................................................................

..........................................................................................

.................................................................................................

............................................................................................................

Doc. Nr. 99850600001

2

2

3

4

7

8

9

10

11

11

12

12

13

1 / 13

Advertisement

Table of Contents

Summary of Contents for Seifert KG 8506-230V

-

Page 1: Table Of Contents

Table of Content 850600001 1. User manual ........................2. Legal regulations ......................3. Safety instructions ......................4. Technical information ....................5. Functional principle ...................... 6. Technical data ........................ 7. Mounting ......................... 8. Wiring diagram ......................9. Taking into operation ....................10. -

Page 2: User Manual

1. User manual This instruction manual contains information and instructions to enable the user to work safely, correctly and economically on the unit. Understanding and adhering to the manual can help one: Avoid any dangers. Reduce repair costs and stoppages. Extend and improve the reliability and working life of the unit. -

Page 3: Safety Instructions

Disregarding the instruction manual Operating error Inappropriate work on or with the unit The use of non-specified spare parts and accessories Unauthorised modifications or changes to the unit by the user or his personnel The supplier is only liable for errors and omissions as outlined in the guarantee conditions contained in the main contractual agreement. -

Page 4: Technical Information

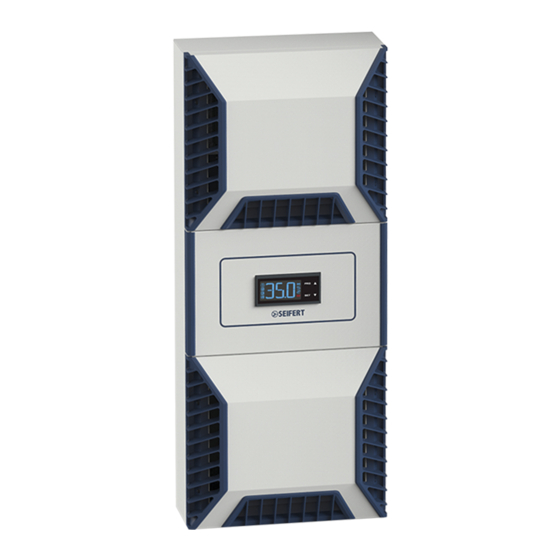

4. Technical information The cooling unit is intended to be used as a complementary accessory to larger industrial equipment. The unit is used where heat needs to be dissipated from electrical control cabinets or similar enclosures in order to protect heat sensitive components. It is not intended for household use. The unit has two completely separate air circuits which ensure that the clean cabinet air does not come into contact with the ambient air which may well be dirty or polluted. - Page 5 Setting cooling set point, St1: 1. Press “SET” and display should show St1 and then the pre-set value of St1. (default: +35°C / +95°F) 2. Reach the desired value by using ▲ or ▼. 3. Press “SET” again to save the new value of St1. Setting heating set point, St2 (only for units supplied with internal heater): 1.

- Page 6 Test function Different test functions can be used depending on the combination of keys pressed. Such tests run for the duration of 4 minutes. “SET+▲” tests Compressor and Ambient Blower relays. “SET+▼” tests Alarms and Heater relays Important Notes Whilst programming, if no button is pressed for 10 seconds, the display starts flashing, and after 1 minute returns to the main display without saving changes.

-

Page 7: Functional Principle

5. Functional principle The cooling unit for enclosures works on the basis of a refrigeration circuit consisting of four main components: compressor (1), evaporator (2), condenser (3) and expansion device (4). The circuit is hermetically sealed and R134a refrigerant circulates inside it (R134a is chlorine free and harmless to the ozone layer). -

Page 8: Technical Data

6. Technical data Order Number 850600001 Cooling capacity 95F/95F 2290 BTU Cooling capacity 95F/122F 1620 BTU EER L35L35 Compressor Rotary Piston Refrigerant / GWP R134a / 1430 Refrigerant charge 4.4 oz. High / low pressure 26 / 6 bar 425 / 88 psig Temperature range 10°C - +60°C Air volume flow (system / unimpeded) -

Page 9: Mounting

7. Mounting The power supply rating on unit rating plate must comply with mains rating. Always disconnect the power supply before opening the unit. The heat load to be dissipated from enclosure should not exceed specific cooling output of the unit at any condition. -

Page 10: Wiring Diagram

8. Wiring diagram Version Nr. 1-2 - 06.03.2019 Doc. Nr. 99850600001 10 / 13... -

Page 11: Taking Into Operation

9. Taking into operation Attention! The unit can be damaged by lack of lubricant. To ensure that the compressor is adequately lubricated the oil, which has been displaced during transport, must be allowed to flow back into it. The unit must therefore be allowed to stand for at least 30 min. before being connected to the mains and taken into operation. -

Page 12: Maintenance & Cleaning

11. Maintenance & Cleaning Always switch power supply off before starting any maintenance on the unit. The cooling unit is generally maintenance free and can be operated without filters in most environments. For units with filters these should be checked, cleaned and if necessary replaced on a regular basis. -

Page 13: Parts Supplied

1 x Signal connector 1 x Female power connector Seifert Systems GmbH Seifert Systems Ltd. Seifert Systems AG Seifert Systems Inc. Seifert Systems Pty Ltd. Haßlinghauser Str. 156 HF09/10 Wilerstrasse 16 75 Circuit Drive 105 Lewis Road Hal-Far Industrial Estate...

Need help?

Do you have a question about the KG 8506-230V and is the answer not in the manual?

Questions and answers