Summary of Contents for Walrus Pump Co., Ltd. HQ Series

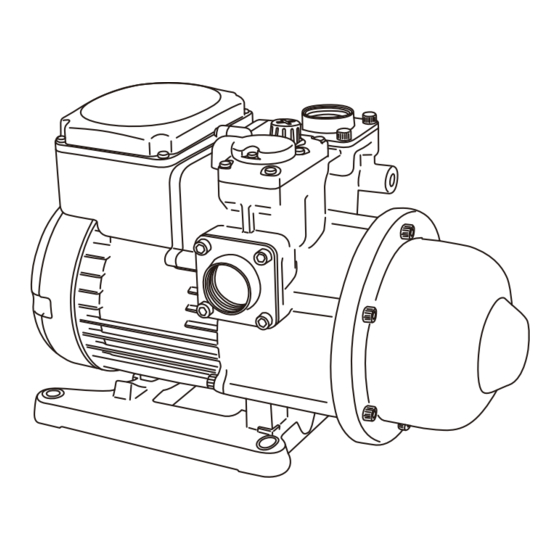

- Page 1 HQ Series HQ Series Electronic Control Pump Instruction Manual “Original Instructions” ISO 9001 Certified WALRUS PUMP CO., LTD.

-

Page 3: Ec Declaration Of Conformity

Walrus Pump Co., Ltd. Address: No.83-14, Dapiantou, Sanzhi Dist., New Taipei City 252, Taiwan Declare that the machinery described: Name : Water Pump Model : HQ Series Conform to the following directive: 2006/42/EC—Machinery directive 2014/35/EU —Low voltage directive 2014/30/EU—EMC (Electromagnetic compatibility) directive... -

Page 4: Operating Conditions

Please read all instructions carefully before installing your new systems, as failures caused by incorrect installation or operation are not covered by the warranty. I. Product The HQ series are designed for the pumping of non-aggressive water, or water not containing solid particles. II. Operating conditions: 1. - Page 5 IV. Piping 1. Flange Installation Reminder Diagonal Hose and flange are at Screw torque is Flange Installation Reminder right angle to a vertical line. 20~25 kgf-cm Forbidden to fasten Forbidden to Hose cant not be lean. only one side of the screw over fasten the screw 2.

-

Page 6: Electrical Connection

V. Electrical connection This mark located outside the connection box is a warning for an electrical hazard. 1. Ensure the mains voltage is the same as the value shown on the motor plate and that the pump is safely connected to ground/earth. 2. -

Page 7: Operation And Maintenance

4. The pump must always be checked for prime if not used for a prolonged period. It is imperative to fill the pump with liquid before operation as dry running causes irreparable damage to the mechanical seal. VIII. Precautions 1. The pump should be shut down and the trouble corrected if the pump is running at speed and found to have any of the following problems: - No liquid discharged - Not enough liquid discharged - Excessive vibration - Motor runs hot... -

Page 8: Noise Level

5. The pump should not be used to transfer toxic or contaminated liquids. Please carefully follow all instructions in the manual as Walrus may refuse to accept the contaminated pump for servic- ing. 6. If the supply cord is damaged, it must be replaced by a special cord or assembly available from the manufacturer or its service agent. -

Page 9: Dimensions (Mm)

4. What is the purpose of the built-in pressure tank? The pressure tank comes from the factory pressurized at approximately 1.0 - 2.5 kg/cm² (with the pump pressure at zero). It is designed to minimize motor startup due to small flow demand or minor leak of the pipeline. -

Page 10: Troubleshooting

XV. Troubleshooting Before starting work on the pump, make sure that the electricity supply has been switched off and that it cannot be accidentally switched on. Problem Cause Remedy a. No power supply 1. pump does not Connect the electricity supply b. -

Page 12: Limited Warranty

Limited Warranty Products manufactured by Walrus Pumps Co (Walrus) are warranted to the first user only to be free of defects in material and workmanship for a period of 12 months from date of installation, but no more than 24 months from date of shipment. Walrus' liability under this warranty shall be limited to repairing or replacing at our election, without charge, FOB Walrus' distribution center or authorized service agent.

Need help?

Do you have a question about the HQ Series and is the answer not in the manual?

Questions and answers

Hi,I have an issue with a customers pump HQ200 not switching off. Iv checked for air and water supply is good. How do I check if it’s a faulty check valve. I disconnected it from the Pcb on the pump and it stopped running every 10 seconds, where as before it never stopped.

To check if the check valve is faulty on a Walrus Pump Co., Ltd. HQ200, follow these steps:

1. Turn off the power supply to the pump.

2. Inspect the check valve for blockages or debris.

3. Clean the check valve if necessary.

4. If the problem persists, replace the check valve with a new one.

If the pump does not stop when water is not consumed, a defective check valve could be the cause.

This answer is automatically generated

Whether motor can **** water from tank bellow 5 feet

The pump is running continuously, off and on

Hi , I just moved in a new built home like 3 months ago, the water pump Booster is Walrus HQ400 , every thing was working as usual with the pump, but since 2 days the Water pump performing a short circle within 15-20 mins even though we are not using the water. It’s just turning on and off . Could you please guide what needs to be done to fix this issue ?