Table of Contents

Advertisement

Quick Links

Read and Understand this manual

Before Operating

FAILURE TO HEED COULD RESULT IN PERSONAL INJURY OR DEATH

Copyright © 2005 by T. R. Metal Crafters Inc. All rights reserved. This manual, or parts thereof (including charts, tables, and

illustrations), may not be reproduced in any form without the prior written permission of the copyright owners.

011205

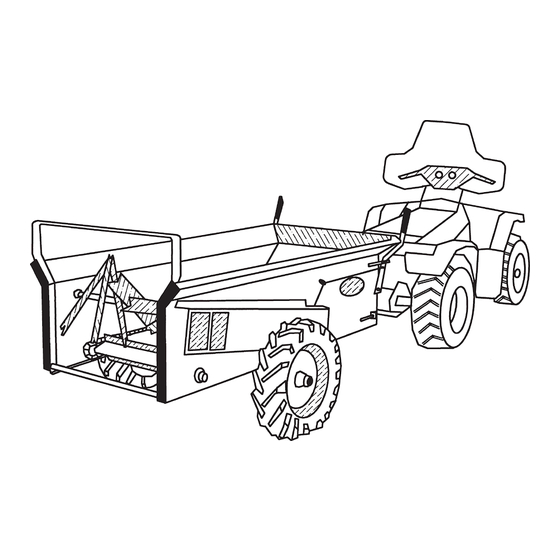

LOYAL MANURE SPREADER

Owner's and Operator's Manual

WARNING: This manure

spreader has rotating parts &

shafts. Use care during

operation and maintenance.

IMPORTANT

This manure spreader was test-run, inspected,

and carefully packaged prior to shipment. Note

any visible damage or shortages on carrier's

delivery receipt before signing. If there is

concealed damage, do not dispose of packing

materials. Contact us immediately so a timely

freight claim can be filed.

If any items covered in this manual are not fully understood by you, contact your dealer or T.R. Metal Crafters,

Inc., 312 E. Industrial Drive, P.O. Box 248, Loyal, WI 54446, (call TOLL FREE 1-800-842-5349) for assistance.

Y70293A

011205

Model MS23A

Read and Understand this manual

Before Operating

Additional Assistance

Operator's

Manual!

Y70293A

Advertisement

Table of Contents

Summary of Contents for Roth Manufacturing MS23A

- Page 1 LOYAL MANURE SPREADER Model MS23A Owner's and Operator's Manual Read and Understand this manual Before Operating WARNING: This manure spreader has rotating parts & shafts. Use care during operation and maintenance. Read and Understand this manual Before Operating FAILURE TO HEED COULD RESULT IN PERSONAL INJURY OR DEATH...

-

Page 2: General Safety Statement

General Safety Statement It is your responsibility as an owner, operator or supervisor to know what specific requirements, precautions and work hazards exist and to make these known to all other personnel working with the equipment or in the area, so that they too may take any necessary safety precautions that may be required. -

Page 3: Foreword

Foreword This Manual is intended to point out some of the basic situations which may be encountered during the normal operation and service of your machine and to suggest possible ways of dealing with these conditions. Additional precautions may be necessary, depending on conditions at the worksite or in the service area. -

Page 4: Table Of Contents

Table of Contents General Safety Statement ........Inside Front Cover Foreword ..................1 Decal Location ................3 Operator Qualifications and Sign Off Sheet ........4 Assembly Instructions ..............5 Safety & Accident Prevention ............6,7 Operating Instructions ..............8 Service and Maintenance ............9, 10 Warranty Registration Card ............ -

Page 5: Decal Location

The Decals Shown On This Page Must Be Displayed As Shown Below FREE REPLACEMENTS ARE AVAILABLE UPON REQUEST Contact T.R. Metal Crafters Inc., 312 E. Industrial Drive, P.O. Box 248, Loyal, WI 54446. (Call TOLL-FREE 1-800-842-5349) Safety decals must be replaced if they are destroyed, missing, painted over, or can no longer be read. New equipment components installed during repair shall be equipped with the same safety decals that were affixed to the original components. -

Page 6: Operator Qualifications And Sign Off Sheet

Operator Qualifications and Sign Off Sheet Operation of this machine shall be limited to competent and experienced persons. In addition, anyone who will operate or work around this machine must use good common sense. In order to be qualified, he must also know and meet all other requirements, such as: Some regulations specify that no one under the age of 18 may operate power machinery. -

Page 7: Assembly Instructions

ASSEMBLY INSTRUCTIONS 1. Remove tongue (1) assembly from shipping skid. 2. Fasten tongue (1) to axle (3) and to spreader box (2) using provided 5/16" fasteners(A) and 3/8" fasteners(B). 3. Unbolt lag screws which secure shipping skid to spreader. 4. Use overhead hoist to lower spreader to ground. NOTE: Spreader weighs 385 lbs. 030104 Y70293A 083101... -

Page 8: Safety & Accident Prevention

Limited Warranty SAFETY & ACCCIDENT PREVENTION T.R. Metal Crafters, Inc. warrants this unit to be free from breakage or malfunctions due to defects in material and/or workmanship under normal farm use and service, for a period of one-year from date of original sale. Should such breakage occur within warranty period, the liability of T.R. - Page 9 ADJUSTMENT INSTRUCTIONS (continued) Latch Adjustment: Symptom: Apron chain is not moving Problem: Improper latch adjustment Solution: Adjust latch as follows. 1) Raise left drive wheel off the ground 2) Remove crank-arm guard 3) Turn left drive wheel by hand, while checking latch (5) engagement into the sprocket tooth (6) 4) Loosen-lightly the four 5/16"...

-

Page 10: Operating Instructions

SERVICE AND MAINTENANCE OPERATING INSTRUCTIONS Disengage apron chain & beater, block wheels, and disconnect WARNING from power source, before adjusting or servicing. Always replace guards before operating manure spreader. If guards or decals become damaged or lost, contact dealer or factory for free replacements. Failure to heed these instructions could result in severe personal injury or death.

Need help?

Do you have a question about the MS23A and is the answer not in the manual?

Questions and answers