Table of Contents

Advertisement

RUNNING FLOOR II

KEITH Manufacturing Co.

www.KeithWalkingFloor.com

World Headquarters

Toll-Free: 800-547-6161

Phone: 541-475-3802

Fax: 541-475-2169

OWNER / OPERATOR MANUAL

©2018 KEITH Manufacturing Co. All Rights Reserved. KEITH, KEITH logo and WALKING FLOOR are registered trademarks of KEITH

Manufacturing Co. Equipment manufactured by KEITH Manufacturing Co. is protected by numerous patents both domestic and foreign.

Original Instructions

®

DX/DXE

10002001

DOC06179 Rev. B

Advertisement

Table of Contents

Summary of Contents for Keith RUNNING FLOOR II DX

- Page 1 OWNER / OPERATOR MANUAL Original Instructions ©2018 KEITH Manufacturing Co. All Rights Reserved. KEITH, KEITH logo and WALKING FLOOR are registered trademarks of KEITH Manufacturing Co. Equipment manufactured by KEITH Manufacturing Co. is protected by numerous patents both domestic and foreign.

-

Page 2: Table Of Contents

RUNNING FLOOR II DX / DXE ® Table of Contents Introduction Declaration of Incorporation KEITH WALKING FLOOR ® Drive Unit Limited Warranty Warranty Registration Card Safety 1.1 General Safety 1.1.1 Intended Function and Expected Use: 1.1.2 Improper Use 1.1.3 Training 1.1.4 Personal Protective Equipment... - Page 3 OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® 3.9 Electric On/Off & Electric Load/Unload - Wireless Remote Control 3.9.1 4 Channel Remote Control Transmitter 3.9.2 4 Channel Remote Control Receiver 3.10 Electric On/Off & Electric Load/Unload - Cabled Remote Control 3.11 Manual Override of Electric Controls Maintenance 4.1 Life Extending Conditions...

-

Page 4: Introduction

DX / DXE ® Introduction We at KEITH Manufacturing Co. are very happy that you have decided to equip your trailer with the KEITH ® RUNNING FLOOR II DX/DXE unloading system. We take great pride in the fact that we manufacture the ®... -

Page 5: Declaration Of Incorporation

This partly completed machinery must not be put into service until the final machinery into which it is to be incorporated has been declared in conformity with the provisions of Directive 2006/42/EC. The person authorized to compile the technical file is: KEITH WALKING FLOOR Europe Harselaarsweg 113 3771 MA Barneveld The Netherlands _________________________________ R. - Page 6 The limited hydraulic warranty period is for (2) two years for the hydraulic parts and components from date of sale by • trailer manufacturer. The Drive system must be installed by your trailer builder according to recommended KEITH installation instructions • and procedures.

- Page 7 Manufacturing Co.’s sole liability under this warranty and the owner’s sole and exclusive remedy is limited to repair or replacement of the defective part(s) at a facility authorized by KEITH Manufacturing Co. This is the owner’s sole and exclusive remedy for all contract claims, and all tort claims including those based on the strict liability in tort and negligence.

-

Page 8: Warranty Registration Card

Model / Serial Number: ________________________________________________________________ Purchased From: ____________________________________________________________________ Type of Material Loaded/Unloaded: ______________________________________________________ I have fully read the KEITH Manufacturing Co. warranty information and fully understand and agree to the terms of the warranty. Name: ___________________________ Date: __________ Signature: __________________________... -

Page 9: Safety

DX / DXE ® Safety 1.1 General Safety 1.1.1 Intended Function and Expected Use: 1.1.1.1. The KEITH RUNNING FLOOR II DX/DX-Europe system is a reciprocating slat ® ® conveyor primarily intended to load, hold, or unload bulk materials. It can also handle unit loads such as pallets by using special handling techniques and possibly additional safety controls. -

Page 10: Training

1.1.6.2. Overheated oil can degrade rapidly. Hot oil and the resulting hot surfaces can cause burns. Do not allow the oil temperature to exceed 140 °F [60 °C]. 1.1.6.3. KEITH recommends some or all of the following temperature control measures depending on the circumstances. High duty cycle systems and hot environments will require more control measures. -

Page 11: Lighting

OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® 1.1.7 Lighting 1.1.7.1. Do not use or service the system in an environment of insufficient light. 1.1.8 Movement Around the System 1.1.8.1. Hydraulic oil can be slippery. Clean up oil spills immediately. 1.1.9 Hydraulic Oil Safety 1.1.9.1. See the MSDS for the oil used in your system for further information about hydraulic oil safety. -

Page 12: Electric Components And Installation

Follow all pipe, tubing, fitting, and hose manufacturer installation and routing guidelines. 1.2.5.2. Hydraulic piping should be supported and isolated from vibration. Contact a KEITH representative for recommendations on installation. 1.2.5.3. Place protective shrouds around the hydraulic tubing in any areas that may have operators or people frequently nearby. -

Page 13: Marking Of Machinery

OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® 1.3 Marking of Machinery 1.3.1 Safety Decals DOC06179 Rev. B... - Page 14 OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® DOC06179 Rev. B...

- Page 15 OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® DOC06179 Rev. B...

- Page 16 OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® DOC06179 Rev. B...

-

Page 17: Serial Plates

OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® 1.3.2 Serial Plates Please fill in the information from the serial plate attached to your drive system. Overtime these plates become difficult to read or even locate and this information is crucial in determining the specific replacement parts for your system. DOC06179 Rev. B... -

Page 18: Specifications

OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® Specifications 2.1 Hydraulic Drive Unit KRFII-3 KRFII-3.5 KRFII-4 Drive Style: 3.0 in 3.5 in 4 in Cylinder Bore Diameter: [76 mm] [89 mm] [102 mm] 6.0 - 10.0 in 6.0 - 10.0 in 6.0 in Cylinder Stroke:... -

Page 19: General Wet Kit Specifications

Suction hose from the reservoir tank to the pump should be no more than 5 ft [1.5 m] in length and a minimum of 2 inch [51 mm] inside diameter. Suction Line: KEITH recommends using SAE100R4 (This type of hose has a spiral wire to keep the hose from collapsing under suction). Hose from wet kit to floor should be 1 in [-16] SAE-100R2. ... -

Page 20: Floor To Wet Kit Connection Diagram

IMPORTANT ® ® , the To ensure proper operation of your KEITH WALKING FLOOR specifications and following diagram must be followed. Failure to ® comply with these instructions may void the KEITH Warranty. Reservoir Return Tank Suction Internal Baffle Pressure... -

Page 21: Operation

OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® Operation 3.1 How It Works Initial Stage All slats are staged together toward the direction of material travel (discharge end). Stage 1 The first group of slats (approximately every 3rd slat) moves under the load. Load does not move. Stage 2 The second group of slats moves under the load. -

Page 22: Oil Flow Diagrams

OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® 3.2 Oil Flow Diagrams DOC06179 Rev. B... - Page 23 OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® DOC06179 Rev. B...

-

Page 24: Component Location Guides

OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® Component Location Guide 3.3 Component Location Guides ® RUNNING FLOOR II Manual Controls (Left Side), Restrictor Valves (If Required) (Front of Trailer) Return Pressure BV Handle On ─► Serial Numbers are Ball Valve ◄─... - Page 25 OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® Component Location Guide ® RUNNING FLOOR II Manual Controls (Right Side), Restrictor Valves (If Required) (Front of Trailer) BV Handle Return Pressure ◄─ On Off ─► Serial Numbers are located underneath Ball Valve front stiffener plate.

- Page 26 OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® Component Location Guide ® RUNNING FLOOR II Electric Controls, Restrictor Valves (If Required) (Front of Trailer) Return Pressure Serial Numbers are Ball Valve located underneath (Electric) front stiffener plate. Restrictor Valve Adapter...

-

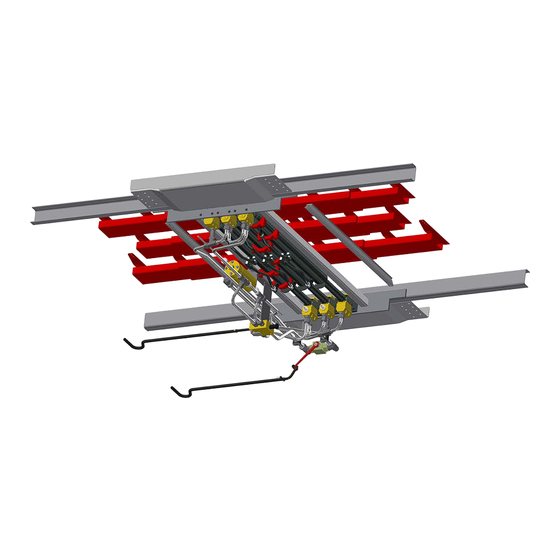

Page 27: Drive Component Identification

OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® 3.4 Drive Component Identification (See RUNNING FLOOR II DX or DXE Parts Catalogs for additional details) ® DOC06179 Rev. B... -

Page 28: Start-Up Operation

3.5 Start-Up Operation 3.5.1 Before initial start-up: • Read through this manual. If there is any confusion, contact a KEITH representative and resolve any concerns before operation of this system (see Contact Information section). • Ensure that the hydraulic reservoir has the recommended amount of oil as well as the correct type of oil (see Specifications section or visit our website for additional details). -

Page 29: Manual Controls

OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® 3.7 Manual Controls 1. Set parking brake on truck and trailer. 2. Open truck or trailer doors fully and secure doors with provided chains or loop rings. ⚠ CAUTION: ALWAYS have doors fully open! Do not, under any circumstances, engage the Power WALKING FLOOR Take Off (PTO) / Pump System or ®... -

Page 30: Electric On/Off, Manual Load/Unload - Wireless Remote Control

OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® 3.8 Electric On/Off, Manual Load/Unload - Wireless Remote Control 3.8.1 4 Channel Remote Control Transmitter EMS - Emergency STOP Status Indicator LED Power ON Key A (ON) ID Plate 1. - Page 31 Remove the yellow key from the transmitter. • Disengage the PTO / Pumping System. • Cut the electric power to the receiver. IMPORTANT NOTE: The KEITH wireless remote control has some built in features: • The floor automatically stops moving if the continuous signal link, between receiver and transmitter, is not detected. •...

-

Page 32: Channel Remote Control Receiver

OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® 3.8.2 4 Channel Remote Control Receiver Function LEDs Power LED Operation LED ID Plate Data LED Frequency LED EMS - Emergency STOP RECEIVER STATUS INDICATOR: Power LED • GREEN = Receiver power is ON Operation LED •... -

Page 33: Electric On/Off & Electric Load/Unload - Wireless Remote Control

OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® 3.9 Electric On/Off & Electric Load/Unload - Wireless Remote Control 3.9.1 4 Channel Remote Control Transmitter EMS - Emergency STOP Power ON Key Status Indicator LED (Load) B A (Unload) C (Right) (Left) D ID Plate... - Page 34 Remove the yellow key from the transmitter. • Disengage the PTO / Pumping System. • Cut the electric power to the receiver. IMPORTANT NOTE: The KEITH wireless remote control has some built in features: • The floor automatically stops moving if the continuous signal link, between receiver and transmitter, is not detected. •...

-

Page 35: Channel Remote Control Receiver

OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® 3.9.2 4 Channel Remote Control Receiver Function LEDs Power LED ID Plate Operation LED Data LED Frequency LED EMS - Emergency STOP RECEIVER STATUS INDICATOR: Power LED • GREEN = Receiver power is ON Operation LED •... -

Page 36: Electric On/Off & Electric Load/Unload - Cabled Remote Control

OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® 3.10 Electric On/Off & Electric Load/Unload - Cabled Remote Control 1. Before operating, follow the Pre-Trip Check List. 2. Open truck or trailer doors fully and secure doors with provided chains or loop rings. -

Page 37: Manual Override Of Electric Controls

OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® 3.11 Manual Override of Electric Controls In the case of a malfunction in the electrical system or loss of the remote control, the electric valves can still be operated by activating the manual override fitted for that purpose. 1. Before operating, follow the Pre-Trip Check List. 2. - Page 38 OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® 6. There are two ways to put the Ball Valve (On/Off) of the drive in ON-position A) Move the red handle to the driver’s side as in image below. (See image below.) The floor will start to move! Take into account that the system can be left-hand (LH) or right-hand (RH) drive. Manual Override - Ball Valve (handle) RH –...

-

Page 39: Maintenance

Inspect cross-drive support bearings, wearpads, tubes and shoes for wear. (See Cross-Drive Wear Component Diagram section). Replace as needed. • Inspect floor wear bearings and seals for excessive wear (especially above the tires). (See Floorings Wear Component Diagrams section) Replace as needed. • Inspect floor slats for wear. If discharge end of slats are worn more than 75% of original thickness rotate all floor slats, end for end, to increase life of the floor. If floor has already been rotated, contact KEITH for replacement slats. DOC06179 Rev. B... -

Page 40: Bolt Torque Requirements

OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® 4.3 Bolt Torque Requirements Description Size Quantity Torque Values 3 in & 3.5 in Cylinder 5/8 in HCS 135 ft-lbs 4 per cylinder Barrel Clamp Bolts [16 mm] HCS [183 N·m] 4 in Cylinder Barrel Clamp Bolts 3/4 in... -

Page 41: Cross-Drive Wear Component Diagram

OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® 4.4 Cross-Drive Wear Component Diagram DOC06179 Rev. B... -

Page 42: Flooring Wear Component Diagrams

OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® 4.5 Flooring Wear Component Diagrams DOC06179 Rev. B... -

Page 43: Troubleshooting

5.3 Adjustments & Repairs See Support and Troubleshooting on our website www.KeithWalkingFloor.com 5.4 Technical Support Please have the following information readily available before contacting KEITH Manufacturing Co. for support: • Model Number (Located on the Serial Plate of the drive unit) •... -

Page 44: Contact Information

OWNER / OPERATOR MANUAL RUNNING FLOOR II DX / DXE ® Contact Information KEITH Manufacturing Co. World Headquarters Parts & Service 401 NW Adler St. P.O. Box 1 Madras, OR 97741 Toll-Free: 800-547-6161 Phone: 541-475-3802 Fax: 541-475-2169 Email: Sales@KeithWalkingFloor.com Canada...

Need help?

Do you have a question about the RUNNING FLOOR II DX and is the answer not in the manual?

Questions and answers