Table of Contents

Advertisement

INSTALLATION AND OPERATION INSTRUCTIONS

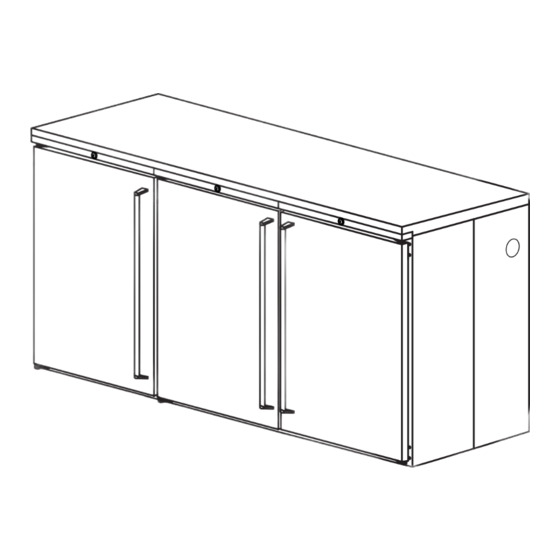

CUSTOM BACK BAR CABINETS – SELF CONTAINED AND REMOTE

US

C

BR72

IMPORTANT INFORMATION

To register your product, visit our web site at

(www.perlick.com). Click on "Commercial", then "Service".

You will see the link to "Warranty Registration Form". You

must complete and submit this form or the installation

date will revert back to the ship Date.

This manual has been prepared to assist you in the

installation of your Cabinet and to acquaint you with its

operation and maintenance.

We dedicate considerable time to ensure that our

products provide the highest level of customer

satisfaction. If service is required, your dealer can provide

you with a list of qualified service agents. For your own

protection, never return merchandise for credit without

our approval.

We thank you for selecting a Perlick product and

assure you of our continuing interest in your

satisfaction.

WARNING: When lifting, the full weight of the

cabinet must be supported. Lift from the cabinet

base and not from the top. Improper lifting can

result in severe damage to the cabinet.

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414.353.7060 • Fax 414.353.7069

Toll Free 800.558.5592 • E-Mail perlick@perlick.com • www.perlick.com

Systems and Products for the Food Service and Beverage Industries Since 1917

BS84

Table of Contents

PREPARING THE CABINET

List of Included Parts ............................................................... 2

Tools Required ............................................................................ 2

Plumbing ...................................................................................... 2

Electrical ....................................................................................... 2

Uncrating and Inspection ...................................................... 2

Placing the Cabinet .................................................................. 2

Leveling the Cabinet ................................................................ 2

Installing Casters or Legs ....................................................... 2

Installing the Base Plate .......................................................... 2

Refrigeration and Temperature Control ............................ 3

Cleaning the Cabinet ............................................................... 3

Cleaning the Condenser ......................................................... 3

Stainless Steel Care Guide ..................................................4/5

Replacement Parts .................................................................... 6

Reversing Door Swing ............................................................. 7

Cleaning Stainless Steel .......................................................... 7

Wiring Diagram (BS Series) .................................................... 8

Wiring Diagram (BR Series) .................................................... 9

MODELS

BR Series

BS Series

Form No. Z2278

Rev. 10.04.10

Advertisement

Table of Contents

Summary of Contents for Perlick BR Series

- Page 1 Cleaning the Cabinet ............... 3 our approval. Cleaning the Condenser ............3 Stainless Steel Care Guide ..........4/5 We thank you for selecting a Perlick product and Replacement Parts ..............6 assure you of our continuing interest in your Reversing Door Swing ............. 7 satisfaction.

-

Page 2: Parts List

24 hours before plugging in and running the unit. Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice Form No.Z2278 Rev. 10.04.10... -

Page 3: Refrigeration And Temperature Control

If defrosting is necessary, turn the control knob to the OFF position until coil is defrosted. Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice Form No.Z2278 Rev. 10.04.2010... -

Page 4: Stainless Steel

After wiping equipment down, allow it to air dry; oxygen helps maintain the stainless steel’s passive film. NEVER use hydrochloric acid (muriatic acid) on stainless steel! Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice Form No.Z2278 Rev. 10.04.10... -

Page 5: Recommended Cleaners For Specific Situations

Use non-chlorinated cleaners with a soft cloth and RINSE, RINSE, RINSE to maintain the natural qualities of your stainless steel equipment! Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice Form No.Z2278... - Page 6 63019-3 63019-3 63019-3 *Replacement Door RND-NL2 RND-NL2 RND-NL2 *Contact Perlick Milwaukee for complete door replacement. Cabinet serial no. required. Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice Form No.Z2278 Rev. 10.04.10...

- Page 7 Reinsert the bottom hinge pin hinge holes. to complete the door switching operation. Step #6 Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice Form No.Z2278 Rev. 10.04.2010...

- Page 8 LIGHT LIGHT EVAPORATOR FAN EVAPORATOR FAN BLACK WHITE THERMOSTAT BLACK POWER CONNECTION CONDENSING UNIT BLACK WHITE GREEN JUNCTION BOX Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice Form No.Z2278 Rev. 10.04.10...

-

Page 9: Field Installed

JUNCTION BOX LOCAL AND NATIONAL ELECTRICAL CODES. CONDENSING UNIT BLACK WHITE GREEN POWER CONNECTION JUNCTION BOX FIELD INSTALLED PRESSURE SWITCH Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice Form No.Z2278 Rev. 10.04.2010...

Need help?

Do you have a question about the BR Series and is the answer not in the manual?

Questions and answers