Table of Contents

Advertisement

Quick Links

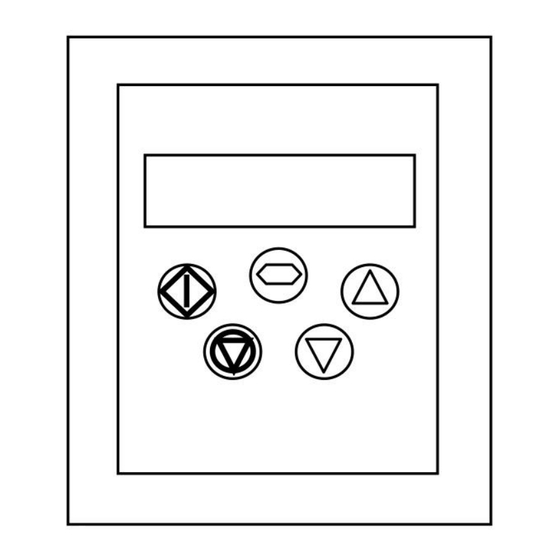

OPTIPORT E-2

Remote Keypad Option Module

User Guide

Installation and Operating Instructions

DECLARATION

All rights reserved. No part of this User Guide may be reproduced or

transmitted in any form or by any means, electrical or mechanical

including photocopying, recording or by any information storage or

retrieval system without permission in writing from the publisher.

Copyright Invertek Drives Ltd © 2007

The manufacturer accepts no liability for any consequences resulting

from inappropriate, negligent or incorrect installation, or adjustment of

the optional operating parameters of the drive or from mismatching of

the drive to the motor.

The contents of this User Guide are believed to be correct at the time

of printing. In the interests of a commitment to a policy of continuous

improvement, the manufacturer reserves the right to change the

specification of the product or its performance or the contents of the

User Guide without notice.

WARRANTY

All Invertek Drives Ltd (IDL) products carry a 2-year warranty, valid

from the date of manufacture. This date is clearly visible on the rating

label.

Complete Warranty Terms and Conditions are available upon request

to your IDL Authorised Distributor.

SAFETY

Optiport E-2 is designed to be used in conjunction with the Optidrive E-

2 variable speed drive and is intended for professional incorporation

into complete equipment or systems. The Optiport E-2 can be used to

control the operation of the Optidrive E-2 range. The drive must be

installed correctly to prevent a safety hazard. The Optidrive E-2 uses

high voltages and currents, carries a high level of stored electrical

energy, and is used to control mechanical plant that may cause injury.

Close attention is required to system design and electrical installation to

avoid hazards in either normal operation or in the event of equipment

malfunction.

System design, installation, commissioning and maintenance must be

carried out only by personnel who have the necessary training and

experience. They must read carefully this safety information and the

instructions in this and the Optidrive E-2 User Guide and follow all

information regarding transport, storage, installation and use, including

the specified environmental limitations.

Please read the IMPORTANT SAFETY INFORMATION below, and

all Warning and Caution boxes elsewhere.

SAFETY NOTICES

is given where there is a hazard that could lead to injury or

WARNING

death of personnel.

is given where there is a hazard that could lead to damage

CAUTION

to equipment.

Dr David Jones, R&D Director

IMPORTANT SAFETY INFORMATION

Safety of machinery, and safety-critical applications

The level of integrity offered by the Optiport E-2 / Optidrive E-2 control

functions – for example stop/start, forward/reverse and maximum

speed, is not sufficient for use in safety-critical applications without

independent means of protection. All applications where malfunction

could cause injury or loss of life must be subject to a risk assessment

and further protection provided where needed.

Within the European Union, all machinery in which this product is used

must comply with Directive 89/392/EEC, Safety of Machinery. In

particular, the electrical equipment should comply with EN60204-1.

CONFORMITY WITH STANDARDS FOR OPTIDRIVE

•

CE-marked for Low Voltage Directive.

•

EN61000-4 EMC Generic Emissions Standard, Industrial Level.

•

EN61000-2 EMC Generic Immunity Standard, Industrial Level.

•

Enclosure ingress protection, EN60529, NEMA 250.

•

Flammability rating according to UL 94.

GENERAL SPECIFICATION

Signal Interface:

Standard 6-way RJ45 connector

Supply Input:

10V ... 36V DC, 30mA

RS485 signal:

industry standard 2-wire +5V differential

Environmental:

Operational

0 ... 50 °C

Storage

-40 °C ... 60 °C

Relative Humidity

< 95% (non condensing)

Protection rating:

IP54

Max cable length:

20m (unscreened, total length)

100m (screened, twisted pair, total length)

MECHANICAL INSTALLATION

WARNING

• When installing the Optiport E-2, all Optidrives should be

disconnected and ISOLATED before attempting any work. High

voltages are present at the terminals and within the drive for up to 10

minutes after disconnection of the electrical supply. The Optidrives

should be installed by qualified electrical persons and in accordance

with local and national regulations and codes of practice.

• Refer to the Optidrive E-2 manual for further details.

CAUTION

• Carefully inspect the Optiport before installation to ensure it is

undamaged.

• Store the Optiport in its box until required. Storage should be clean

o

o

and dry. Temperature range -40

C to +60

C.

• Install the Optiport on a flat, flame-resistant vibration-free surface.

• Flammable material should not be placed close to the Optiport.

DIMENSIONS

81

66

3

23

Unit: mm

55

THROUGH PANEL MOUNT

The panel on to which the Optiport E-2 is to be mounted should be cut

out in accordance with the diagram below.

70

Cut Out

55

Unit: mm

Panel

ELECTRICAL INSTALLATION

Electrical Interface

The Optiport E-2 is uses a standard RJ45 8-Way connector as its

electrical interface, which provides a simple solution for the user to

setup their system using a standard RJ45 8-Way data cable. The

signal layout of the connector is as follows :

NC

NC

0V

RS485 - / Optibus

RS485 + / Optibus

+24V

NC

NC

RJ45 Interface Signal Layout

Cable Requirements

Standard 8-way data cables with plugs are available from Invertek

Drives Ltd on request.

If the data cable is made up on site, ensure that the connection pin

out is correct : Pin 1 to Pin 1, Pin 8 to Pin 8 etc.

1

8-way ribbon cable with leader

CAUTION

65

Incorrect cable connection may damage the drive. Extra care should

be taken when using third party cable.

The Optidrive E-2 provides the +24V power supply to the Optiport E-2

via RJ45 connection. Once the physical connection has been setup,

the system is ready to operate. See picture blow:

RJ45 Interface

Electromagnetic Compatibility (EMC)

Optidrive is designed to high standards of EMC. EMC data is provided

in a separate EMC Data Sheet, available on request. Under extreme

conditions, the product might cause or suffer disturbance due to

electromagnetic

interaction

with

other

equipment.

responsibility of the installer to ensure that the equipment or system

into which the product is incorporated complies with the EMC

legislation of the country of use. Within the European Union,

equipment into which this product is incorporated must comply with

89/336/EEC, Electromagnetic Compatibility.

When installed as recommended in this User Guide, the radiated

emissions levels of all Optidrives are less than those defined in the

Generic radiated emissions standard EN61000-6-4. The conducted

emission levels are less than those defined in the Generic radiated

emissions standard EN61000-6-4 (class A) for the specified motor

cable lengths.

1

It

is

the

Advertisement

Table of Contents

Summary of Contents for Intertek OPTIPORT E-2

- Page 1 Directive 89/392/EEC, Safety of Machinery. In the drive to the motor. The panel on to which the Optiport E-2 is to be mounted should be cut particular, the electrical equipment should comply with EN60204-1. out in accordance with the diagram below.

- Page 2 OI-b Brake channel over current If the Optiport E-2 doesn’t find the drive in the network, i.e. there is only OL-br Brake resistor overload one drive in the network and its address is not equal to 1, the Optiport...

Need help?

Do you have a question about the OPTIPORT E-2 and is the answer not in the manual?

Questions and answers