Table of Contents

Advertisement

Quick Links

"Teamwork & Communication"

Model FF-1600

without Heat

Operating Manual

17942C-1

January 7, 2000

Issue 1

®

GUSMER CORPORATION

A Subsidiary of Gusmer Machinery Group, Inc.

One Gusmer Drive

Lakewood, New Jersey, USA 08701-8055

Toll Free 1-800-367-4767 (USA & Canada)

Phone: (732) 370-9000

Fax: (732) 905-8968

®

Copyright 2000, GUSMER CORPORATION

http://www.gusmer.com

NOTICE: This manual contains important information for your GUSMER equipment. Read and retain for future reference.

Advertisement

Table of Contents

Summary of Contents for GUSMER ff-1600

- Page 1 One Gusmer Drive Lakewood, New Jersey, USA 08701-8055 Toll Free 1-800-367-4767 (USA & Canada) Phone: (732) 370-9000 Fax: (732) 905-8968 ® Copyright 2000, GUSMER CORPORATION http://www.gusmer.com NOTICE: This manual contains important information for your GUSMER equipment. Read and retain for future reference.

- Page 2 All statements, information and data given herein are believed to be accurate and reliable but are presented without guarantee, warranty or responsibility of any kind expressed or implied. Statements or suggestions concerning possible use of GUSMER equipment are made without representation or warranty that any such use is free of patent infringement, and are not recommendations to infringe any patent.

-

Page 3: Table Of Contents

Operating Manual General Safety Information CONTENTS LIST OF FIGURES ......................4 WARRANTY........................5 GENERAL SAFETY INFORMATION................6 ..................6 CCEPTABLE QUIPMENT ................7 PERATIONAL AFETY ROCEDURES DESCRIPTION OF CONTROLS ...................8 SPECIFICATIONS......................10 INITIAL MACHINE SET-UP ..................11 ........................13 URGE NORMAL OPERATING PROCEDURES ..............14 ..................14 AILY TART ROCEDURE ...................14 AILY ROCEDURE... -

Page 4: List Of Figures

Model FF-1600 with out Heat LIST OF FIGURES 17000C-1 P ............8 IGURE ODEL ROPORTIONING ................. 12 IGURE ONNECTION OCATIONS (A) ................12 IGURE ONNECTION (B) ................12 IGURE ONNECTION ................13 IGURE OCATION 6. P ..............16 IGURE ROPORTIONING... -

Page 5: Warranty

Gusmer through the sale, lease, or rental of Product in no way expresses or implies a license for the use of, nor encourages the infringement of any patents or licenses. -

Page 6: General Safety Information

Under no circumstances should any acid or corrosive chemicals be used in the unit. Consult GUSMER if there is any doubt about the compatibility of the chemical system to be used in this equipment. -

Page 7: Operational Safety Procedures

Operating Manual General Safety Information Operational Safety Procedures This safety information will not be repeated in the text of this manual. The symbols pertaining to this information will appear where appropriate to alert the operator to potential hazards. WARNING: T HE SOVENTS AND CHEMICAL USED WITH THIS EQUIPMENT EXPOSE THE OPERATOR TO CERTAIN HAZARDS DEQUATE PERSONAL PROTECTIVE MEASURES MUST... -

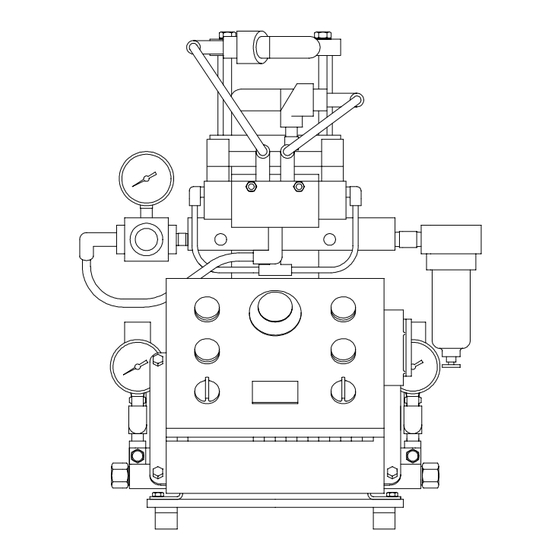

Page 8: Description Of Controls

Model FF-1600 with out Heat DESCRIPTION OF CONTROLS Figure 1 Model 17000C-1 Proportioning Unit MAIN SWITCH- Controls power to all circuits. • OFF- Main Power is off. • POWER- Turn the Main Switch to this position. To supply Main Power to the Console. - Page 9 Operating Manual Initial Machine Set-up AIR PRESSURE GAUGE- Displays the air pressure in the air drive system during the up and downstroke. MAIN AIR FILTER- Filters the system air supply. (3/8 NPT Female) ISOCYANATE PRESSURE GAUGE- Displays the pump out put pressure in the Isocyanate proportioning system.

-

Page 10: Specifications

Model FF-1600 with out Heat SPECIFICATIONS 26 scfm @100 psi (12 liters/sec @7 bars) 2 amps @ 110 volts, 50/60 Hertz single phase, AC. Electric Maximum Output 16 lbs/min. (7.25 kg/min) Maximum Pressure 1600 psi (108 bars) @ 100 psi Air... -

Page 11: Initial Machine Set-Up

Operating Manual Initial Machine Set-up INITIAL MACHINE SET-UP WARNING: P ROPER PROTECTIVE GEAR AS SPECIFIED BY THE CHEMICAL AND SOLVENT SUPPLIER MUST BE WORN WHEN SERVICING OR OPERATING THIS EQUIPMENT T INCLUDES BUT IS NOT LIMITED TO GLOVES EYE PROTECTION AND RESPIRATORY PROTECTION EFER TO ENERAL... -

Page 12: Figure 2 Hose Connection

A liberal amount of duct not separate the hoses until they tape can be used in this area to make the bundle as compact as possible. Gusmer are ready for coupling to the recommends the installing of the optional scuff jacket to protect the hose insulation proportioning unit. -

Page 13: Air Purge

Operating Manual Initial Machine Set-up Connect the air hose adapter between the Proportioning Unit and hoses. Connect the coupling block to the gun hose and see that the manual valves are closed. Air Purge Prior to operation, it is necessary to purge the entire system of air and mineral oil left over from the functional testing of the equipment. -

Page 14: Normal Operating Procedures

Model FF-1600 with out Heat NORMAL OPERATING PROCEDURES Daily Start-up Procedure Check the condition of the Isocyanate lube cup and service as required. Adjust the packing. The packing nut on the Proportioning Unit is adjustable and will require tightening when the pump lube is changed. -

Page 15: Troubleshooting Procedures

Certified Gusmer Technician. GUSMER maintains a competent staff of Technical Representatives and authorized Distributors who can resolve almost any problem you may encounter with GUSMER equipment. Feel free to call on these people for assistance when you need it. -

Page 16: Proportioning System

Model FF-1600 with out Heat Proportioning System Figure 6. Proportioning Pump Features To avoid unnecessary repairs, try the recommended solutions in the order given for each problem. Before assuming there is a problem, determine that all circuit breakers, switches, and controls are properly set. - Page 17 The most common causes of cavitation are as follows: The Transfer Pump can not handle the supply requirement. A GUSMER 2:1 Transfer Pump is recommended for use with this Proportioning Unit. Also recommended is a minimum of 3/4” diameter supply hose, as short as practical.

- Page 18 Model FF-1600 with out Heat LEAKING INLET CHECK VALVE - An inlet check valve and/or leaking seat that does not properly seal will permit some of the proportioned material to flow back towards the supply drum. When this happens the proper volume of material will not pump during the discharge stroke and an off-ratio condition will result.

-

Page 19: Maintenance

Operating Manual Maintenance MAINTENANCE To realize the full productivity of the Proportioning Unit it is necessary to perform maintenance on a daily or periodic basis. WARNING: W HENEVER WORKING ON THE EQUIPMENT WEAR EYE AND SKIN PROTECTION TO GUARD AGAINST EXPOSURE TO THE CHEMICALS AND SOLVENTS IN USE LWAYS WORK IN A WELL VENTILATED AREA TO PREVENT EXPOSURE TO HARMFUL FUMES AND VAPORS NFORMATION CONCERNING THE TOXICITY AND PROPER HANDLING PROCEDURES OF YOUR... -

Page 20: Inlet Filter Screen

Model FF-1600 with out Heat Inlet Filter Screen A filter screen in each Proportioning Pump filters out solid matter that could adversely effect the operation of the valve balls in the pump base. You will note that the Daily Start-up Procedure indicates these screens should be inspected daily. -

Page 21: Proportioning Pumps

Operating Manual Maintenance Proportioning Pumps Disassemble and clean both Proportioning Pumps annually. Inspect the pistons and cylinders for mars or scratches, which may cause leakage or damage to the packings, and replace as necessary. As a preventative maintenance precaution, replace the piston and cylinder packings on an annual basis. -

Page 22: Notes

Model FF-1600 with out Heat NOTES 17942C-1, Issue 1... -

Page 23: Instruction Manual Discrepancy Report

Date of Issue Page Number Discrepancy Instructions: Complete the above fields of the form by following the instructions listed on the reverse side of this sheet and mail to: Gusmer Corporation One Gusmer Drive PO Box 2055 Lakewood, NJ 08701 01/07/00... - Page 24 Model FF-1600 with out Heat Field Field Title Description Number Date Enter date report is submitted. Name Enter name of person making report. IM Number Enter the Part Number of the Instruction Manual from the title page. Issue Number Enter the Issue number of the Instruction Manual from the title page. If there is no issue number enter NONE.

Need help?

Do you have a question about the ff-1600 and is the answer not in the manual?

Questions and answers

caudal de Inyeccion normal (gr/min)

The normal injection flow rate for the GUSMER FF-1600 is 16 lbs/min, which is approximately 7250 grams/min.

This answer is automatically generated

cuánto aire requiere

The air requirement for the GUSMER FF-1600 is 26 scfm at 100 psi (12 liters/sec at 7 bars).

This answer is automatically generated