Subscribe to Our Youtube Channel

Summary of Contents for Howden Roots Tri-RAM 617

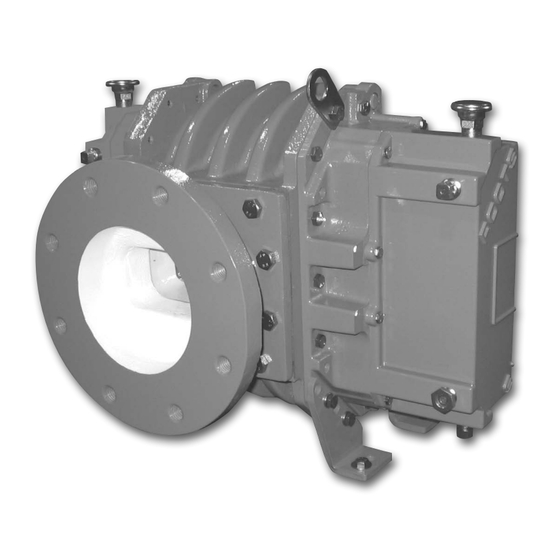

- Page 1 Roots Tri-RAM Tri-lobe Blowers Installation Operation & Maintenance Manual...

-

Page 2: Table Of Contents

NOTE: Information in this manual is correct as of the date to persons working on or near the equipment of publication. Howden reserves the right to make design or during both installation and operation. See SAFETY material changes without notice, and without obligation to make PRECAUTIONS. -

Page 3: Safety Precautions

Safety Precautions CAUTION: Never cover the blower inlet with your hand or other part of body. It is important that all personnel observe safety precautions to minimize the chances of injury. Among many consider- • Stay clear of inlet and discharge openings. ations, the following should be particularly noted: •... -

Page 4: Installation

Installation cylinder adjacent to the headplates. Either method prevents strain on the extended drive shaft. Roots blowers & exhausters are treated after factory assembly to protect against normal atmospheric corrosion. The maxi- Packaged Units: When the unit is furnished mounted on a mum period of internal protection is considered to be one year baseplate, with or without a driver, use of lifting slings passing under average conditions, if shipping plugs &... - Page 5 problems caused by unit speed being too low. Make sure It is possible for a base-mounted assembly to become twisted during shipment, thus disturbing the original align- the drive speed selected is within the allowable range for the ment. For this reason, make the following checks after the specific unit size, as specified under Table 1, page 13.

- Page 6 Fig. 1 - Acceptable Blower Drive Arrangement Options Acceptable Unacceptable Top Shaft Top Shaft DISCHARGE INLET DISCHARGE INLET Motor on Inlet Side of Blower (Top Shaft) Motor on Discharge Side of Blower (Top Shaft) DISCHARGE INLET DISCHARGE INLET Bottom Shaft Bottom Shaft Motor on Discharge Side of Blower (Bottom Shaft) Motor on Inlet Side of Blower (Bottom Shaft)

-

Page 7: Lubrication

Lubrication Due to sludge build-up and seal leakage problems, High ambient temperatures contribute to increased lubrication Roots recommendation is DO NOT USE Mobil SHC sump temperatures. In situations such as blowers in a enclo- synthetic oils in Roots blowers. sure, blowers exposed to radiant heat from other sources, blowers installed in areas with poor air circulation or ambient LUBRICATION: For Units with Splash Lubrication on temperatures above 80°F the lubrication sump temperature... -

Page 8: Operation

Operation ture rise across the blower exceeds the limit specified in this manual, shut down and investigate conditions in the piping Before operating a blower under power for the first time, system. Refer to the TROUBLESHOOTING CHECKLIST recheck the unit and the installation thoroughly to reduce the for suggestions on various problems that may appear. -

Page 9: Troubleshooting

Troubleshooting Checklist Trouble Item Possible Cause Remedy No flow Speed too low Check by tachometer and compare with published perfor- mance. Wrong rotation Compare actual rotation with Figure 1, change driver if wrong. Obstruction in piping Check piping, valves, silencer to assure open flow path. Low capacity Speed too low See item 1, if belt drive, check for slippage and re-adjust ten-... -

Page 10: Inspection & Maintenance

Inspection & Maintenance A good program of consistent inspection and maintenance Oil seals should be considered expendable items, to be is the most reliable method of minimizing repairs to a blower. replaced whenever drainage from the headplate vent cavity A simple record of services and dates will help keep this becomes excessive or when the blower is disassembled for work on a regular schedule. -

Page 11: Figures

Figure 2 - Allowable Overhung Loads for V-belt Drives for Tri-RAM Blowers - Models 409 thru 832 Dimen- Allowable Sheave Sheave Model sion A Shaft Load Diameter Width Inch (mm) • Inch (mm) Inch (mm) • 409, 413, 5,100 1.90 (48.3) 7.1 (180) 3.06 (78) (58.9) -

Page 12: Figures

Figure 4 - Gas Blower Installations with Accessories 1. Standard Arrangement (3-way universal) External Sight Glasses (37) and Breathers (21) must be relocated as shown. Feet (76 and 77) and Lifting Lugs (63) must be relocated as shown. DISCH INLET TOP DRV, L.S. -

Page 13: Tables

Table 1 - Tri-RAM Maximum Allowable Operating Conditions Temperature Rise Delta Pressure Inlet Vacuum Speed Model F° C° mbar INHG mbar 4750 1034 4750 1034 4400 3560 1034 3560 3050 1034 3050 2670 1034 2670 Table 2 - Recommended Oil Grades Use a good grade of industrial type non-detergent, rust Ambient* inhibiting, anti-foaming oil and of correct viscosity per Table... - Page 14 Specified Lubricants Tri-RAM Blowers Parts List - Models 409 through 621 Roots Synthetic Oil: ISO-VG-320 Grade Item Num- Part Name Quantity Part Number Headplate Quart 813-106-004 Gearbox Gallon 813-106-005 Timing Gears Case (12 qts) 813-106-007 End Cover Gasket – Gearbox/Cover Roots Synthetic Oil: ISO-VG-220 Grade Shims Part Number...

- Page 15 GEA19684 ISRB_2008 rev._11.15...

- Page 16 GEA19684 ISRB_2008 rev._11.15...

-

Page 17: Parts List

Specified Lubricants Tri-RAM Blowers Parts List - Models 722 and 728 Roots Synthetic Oil: ISO-VG-320 Grade Item Num- Part Name Quantity Part Number Headplate Quart 13106004 Gearbox Gallon 13106005 Timing Gears Case (12 qts) 13106007 End Cover Roots Synthetic Oil: ISO-VG-220 Grade Gasket –... -

Page 18: Assembly Drawings

GEA19684 ISRB_2008 rev._11.15... - Page 19 Specified Lubricants Tri-RAM Blowers Parts List - Models 826 and 832 Roots Synthetic Oil: ISO-VG-320 Grade Item Num- Part Name Quantity Part Number Headplate Quart 13106004 Gearbox Gallon 13106005 Timing Gears Case (12 qts) 13106007 End Cover Roots Synthetic Oil: ISO-VG-220 Grade Gasket –...

- Page 20 GEA19684 ISRB_2008 rev._11.15...

- Page 21 GEA19684 ISRB_2008 rev._11.15...

- Page 22 Howden Roots 900 W. Mount St. Connersville Indiana 47331 Tel: +1 765 827 9200 Web: www.howden.com ©Howden Group Limited. All rights reserved. 2015. GEA19684 ISRB_2008 rev._08.12 Howden and the flying H logo are registered trade marks belonging to Howden Group Limited.

Need help?

Do you have a question about the Roots Tri-RAM 617 and is the answer not in the manual?

Questions and answers