Summary of Contents for Atrump K5V

- Page 1 OPERATING MANUAL HEALTH AND SAFETY GUIDANCE NOTES MODEL: K5V DATE: 2002/10/01 VERSION: 6...

-

Page 2: Table Of Contents

1. Operating safety guidelines 1.1 Operating safety precautions 1.2 Machine operators precautions 1.3 Warning signs and marks on the machine 1.4 Safety devices and inspection 2. Machine specifications 2.1 Specification 3. Names of machine parts 3.1 Headstock 3.2 Machine body 4. - Page 3 7.3 Floor space 8. Precision alignment 9. Trouble shooting 9.1 Dismantling of motor 9.2 Replacement of speed change belt 9.3 Replacement of brake block 9.4 Replacement of timing belt 10. Adjustment 10-1 10.1 Adjustment of backlash of leadscrew 10-1 10.1.1 Adjustment of cross leadscrew 10-1 10.1.2 Adjustment of backlash of longitudinal leadscrew 10-2...

- Page 4 13. Summart of the electrical 13-1 13.1 Electrical components and layout 13-1 13.2 Control panel, switches and symbols 13-2 13.3 Power circuit 13-3 13.3.1 Wiring diagram for standard electric box three phase 13-3 13.3.2 Wiring diagram for simple electric box three phase 13-4 Power circuit (ce option) 13.3.3...

-

Page 5: Operating Safety Guidelines

1. OPERATING SAFETY GUIDELINES 1.1 OPERATING SAFETY PRECAUTIONS a. The operator must be a technician who is trained in the operation and familiar with the manual. b. Never lay anything on the working surfaces of the machine, where it may foul with rotating or moving parts. -

Page 7: Safety Devices And Inspection

FIG1-2 1.4 SAFETY DEVICES AND INSPECTION... -

Page 8: Machine Specifications

SPINDLE GUARD (CE OPTION) CHIP TRAY FIG1-3 2. MACHINE SPECIFICATIONS... -

Page 9: Specification

2.1 SPECIFICATION WORK TABLE STD. 1320 x 280mm (52”x11”) OPT. 1475 x 280mm (58”x11”) X AXIS TRAVEL STD. 940mm (37”) OPT. 1094mm (43”) Y AXIS TRAVEL 395mm (15 - 9/16”) Z AXIS TRAVEL 500mm (19 - 5/8”) QUILL DIAMETER Ø105mm (4 .14”) QUILL TRAVEL 153mm (6”) QUILL FEED... -

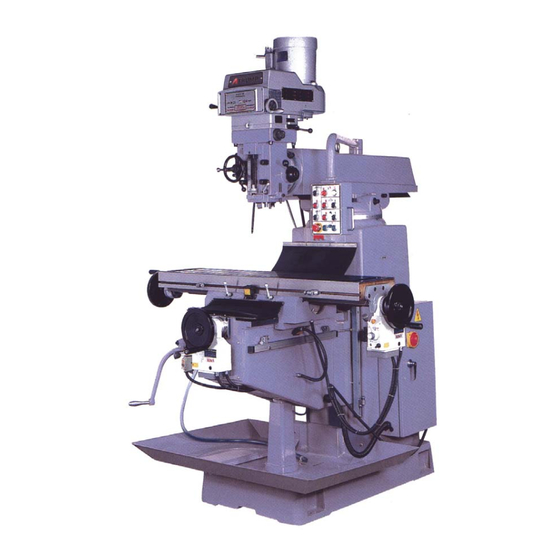

Page 10: Headstock

FIG3-1 Milling head stock Turret Culumn Work table Saddle Knee Operating plate 3.1 HEADSTOCK... -

Page 11: Machine Body

SPEED SELECTOR HANDLEEWHEEL HI-LOW SPEED SELECTOR FEED REVERSE KNOB QUILL FEED LEVER FEED REVERSE QUILL FEED LEVER KNOB HANDLEWHEEL QUILL LOCK FEED CONTROL LEVER MICROMETER ADJUSTING NUT FIG3-2 3.2 MACHINE BODY (1) COLUMN, TURRET AND RAM... -

Page 12: Position And Noise Level

RAM LOCK LEVER RAMPINION COULUMN TURRET FIG3-3 GIBBOLT (2) WORK TABLE, SADDLE AND KNEE WORK TABLE LOCK LEVER WORK TABLE HANDLE WHEEL SADDLE LOCK LEVER HANDLE WHEEL SADDLE ELEVATING CRANK KNEE FIG3-4 4. POSITION AND NOISE LEVEL 4.1 OPERATOR POSITION AND NOISE LEVER... -

Page 13: Spindle Noise Detail

Noise Level: Less Than 82 dB At a distance of 1 meter from the sun face of the machinery and at a height of 1.6 meter from floor. FIG4-1 4.2 SPINDLE NOISE DETAIL Spindle Nose Detail... -

Page 14: Lubrication

FIG4-2 5. LUBRICATION 5.1 HEADSTOCK LUBRICATION... -

Page 15: Machine Table Lubrication

FIG5-1 ITEM LUBRICANTS QTY. TIME POSITION KUO-KUANG R68 FULL TWICE COUNTER SHAFT GEAR ESSO FEBIS K53 DAILY WORM GEAR CRADLE COSMO CHASSIS FULL ONCE BULL GEAR BEARING GREASE NO. 3 WEEKLY SLEEVE COSMO CHASSIS FULL ONCE HEAD STOCK MATCHING GREASE NO.3 WEEKLY QUILL HOLES 5.2 MACHINE TABLE LUBRICATION... -

Page 16: Instruction In Operations

SLIDING SURFACE WORK TABLE SLIDING SURFACE KNEE FIG5-2 POSITION: LUBRICATION OF WORK TABLE, KNEE, SLIDING SURFACE AND LEADSCREWS MAY BE EFFECTUATED BY MEANS OF THE HAND CRANK PUMP ON THE LEFT SIDE OF KNEE. METHOD: 3 TO 5 TIME DAILY BY PULLING TWICE EACH TIME. LUBRICANT: KUO KUANG R-68 GULFWAY 52... -

Page 17: Spindle Switch

6.1.1 SPINDLE SWITCH: Motor turning is controlled by the push button (vied the figure in the right). When the high-low speed change lever (vice FIG6-1,) is placed at the high gear position and the switch is on CW, the motor turns clockwise. When the switch is on CCW, the motor turns counterclockwise. -

Page 18: Automatic Feed

Feed control lever (F) must be pulled from (F1) to (F2). This is to engage the overload clutch. Turn the feed hand wheel (E) clockwise for quill downward feed, and vice-versa. FIG6-3 6.1.6 AUTOMATIC FEED: For automatic feeding, please take the following steps (Vide Figure 3,): a. -

Page 19: Speed Change Of Spindle

FIG6-4 6.1.7 SPEED CHANGE OF SPINDLE (1) Speed change By means of the variation of one set of slicking belt pulley and counter 1 shaft gear (high or low speed), the spindle revolution speed is changed accordingly. Change of high and low speeds: The speed change may be effectuated by the chosen high and low speed lever (FIG6-5 (J) ). -

Page 20: Headstock Tilting

to safeguard the speed rapidly to safeguard the service life of the internal mechanism. d. It takes roughly 10 to 15 minutes to change from low speed to the high one, and viceversa. 6.1.8 HEADSTOCK TILTING Cross tilting (FIG6-6:) Loosen evenly the four lock nuts and turn the worm shaft (S) until the desired angle is... -

Page 21: Machine Body Operations

secured. Then lock up the lock nuts evenly. NOTE :a. If the adjustment angle is larger than 30 degrees, the safety pin (T) must be drawn out. there is no need to pull the pin out for any angle less than that. b. -

Page 22: Zero Positioning Of Dial Ring Of Table Feed

a. Loosen the two ram lock levers (A) b. Swivel the ram pinion handle (B), and the ram can be moved. c. When it moves to the desired position, lock up (A). (2). Ram swiveling: Loosen the four locking bolts (C). And force the cross srm to turn until the desired angle is obtained. -

Page 23: Setting Of Sliding Surfaces Of Work Table, Saddle And Knee

6.2.3 Setting of sliding surfaces of work table, saddle and knee: All non-feed sliding surfaces shall be secured and set to prevent slipping and increase machine body's rigidity. The sliding surface setting levers (as shown in FIG6-9) are clockwise for setting and counterclockwise for release. FIG6-8 SADDLE LOCK LEVER WORK TABLE... - Page 24 (3) After packing, transport may be made by hoisting with a reinforced cable (FIG7-2) REMARKS: (1) Always ensure capacity of equipmentis adequate before attempting to lift. (2) When the machine is being hoisted, keep the personnel afar. (3) Hoisting by eye bolt should be used as less as possible. (4) To hoist the unpacked case by reinforced cable, the motion shall observe strictly the instruction appeared on the side of the wooden case.

-

Page 25: Cautions For Unpacking

FIG7-2 7.2 CAUTIONS FOR UNPACKING: a. To transport the machine, it is necessary to support the machine with the rated case or pallet to avoid moisture. In case of damage by moistening, please contact our agent or transporter. b. After unpacking, check and see if all tools and accessories are intact, otherwise, please contact our agent. -

Page 26: Precision Alignment

FIG7-3 8. PRECISION ALIGNMENT... -

Page 27: Trouble Shooting

Precision of a machine dominates the processing quality. To produce the quality work piece, precession of each and every components is a top priority. In order to maintain the primary machine precision following a long-term operation, regular precision alignment is indispensable to the upgrading of work quality. Beside, it may extend machine service life. -

Page 28: Dismantling Of Motor

9.1 DISMANTLING OF MOTOR (AS SHOWN IN FIG9-1) a. Start the motor and turn the speed change hand wheel (A) to the position of 60 rpm appeared on the indicator to lower down the stationary motor vari-disc to the lowest position. - Page 29 a. Refer to step A to E of motor dismantling. b. Take off draw bar (I). c. Dismantle the three hexagonal concave bolts (J) and use two of them (J) to lift the bearing housing (K). d. Remove from atop the two hexagonal concave bolts (L), fixing the speed change plate, and take off the bolt sleeves (M).

-

Page 30: Replacement Of Brake Block

9.3 REPLACEMENT OF BRAKE BLOCK (FIG9-3) a. Refer to step a to e on motor dismantling. b. Refer to step B to G on replacement of speed change belt to dismantle the upper belt housing. c. As shown in FIG9-4, take off the connected gear housing (R) and the four hexagonal concave bolts (V) bottom belt housing (T1). -

Page 31: Replacement Of Timing Belt

9.4 REPLACEMENT OF TIMING BELT a. Refer to step A to E of motor dismantling b. Refer to step B to G speed change belt replacement to take off the dismantling of bottom belt housing and change the timing belt as shown in FIG9-4. c. -

Page 32: Adjustment

10. ADJUSTMENT 10.1 ADJUSTMENT OF BACKLASH OF LEADSCREW After a certain period of time, a clearance is developed between the lead screw and its nut due to friction. Positioning accuracy will become impossible. Therefore, the nut must be adjusted so as to keep a proper tension between itself and the lead screw. 10.1.1 Adjustment of cross lead screw a. -

Page 33: Adjustment Of Backlash Of Longitudinal Leadscrew

10-1 10.1.2 Adjustment of backlash of longitudinal leadscrew: a. Move the work table to the center of saddle. b. Insert the large end of backlash adjustment tool into the left side of saddle. Turn the locking nut (J) Counterclockwise one round. Reverse the end of adjustment tool and insert the small end into same position and turn the leadscrew adjusting nut (K) clockwise. -

Page 34: Adjustment Of Saddle Gib

e. Replace the excessive worn-out gib whenever necessary. 10-2 FIG10-3 10.2.2 Adjustment of saddle gib (vide FIG.10-4): Saddle gib is attached to the position between the left side of saddle and knee dovetail. a. Loosen the saddle lock bolt (A) b. -

Page 35: Adjustment Of Knee Gib

10-3 FIG10-4 10.2.3 Adjustment of knee gib (vide FIG.10-5): The knee gib is attached to the position the left side of knee and column dovetail. The adjustment can be performed as follows: a. Loosen the knee clamp lever (G) (vide FIG.10-6). b. -

Page 36: Adjustment Of Ram Gib

10-4 10.2.4 ADJUSTMENT OF RAM GIB: The ram gib is attached between the ram and turret dovetail. when the ram sliding is too tight or loose, adjustment may be effectuated by means of the bolt as follows: a. Loosen ram lock lever (C). b. - Page 37 FIG10-7 10-6...

-

Page 38: Maintenance

11. MAINTENANCE: "Maintenance is more important than repair; and repair is better than purchase". Under long-tem operations, if the machine has not been properly maintained and operated, its service life shall be greatly reduced. The work piece quality is therefore affected, and the efficiency, decreased. -

Page 39: Head Stock Upside

12. PARTS LSIT: 12.1 HEAD STOCK UPSIDE (1) 12-1... - Page 40 HEAD STOCK UPSIDE (1) PARTS LIST PART NO. DESCRIPTION K 2 - V 0 0 2 - 0 0 B E L T H O U S I N G B A S E 2-1. Ø 1 / 2 x Ø 1 / 4 P O L L P I N 2-2.

-

Page 41: Head Stock Upside

12.2 HEAD STOCK UPSIDE (2) 12-3... - Page 42 HEAD STOCK UPSIDE (2) PARTS LIST PART NO. D E S CRI P T I O N K 5 - V 0 0 3 - K 0 G E A R H O U S I N G K 5 - V 0 0 4 - 0 0 F I X E D CL U T CH BRA CK E T M 8 x 2 0 S O CK E T CA P S CRE W...

- Page 43 12.3 HEAD STOCK UPSIDE (3) 12-5...

-

Page 44: Head Stock Upside (3)

HEAD STOCK UPSIDE (3) PARTS LIST PART NO. DESCRIPTION K 5 - V 0 0 1 - K 0 BE L T H O U S I N G A S S E M B L Y 1-1. B R A N D P L A T E K 3 - V 0 0 6 - 0 0 MO T O R P U L L E Y C O V E R K 5 - V 0 0 7 - 0 0... - Page 45 12.4 HEAD STOCK INFRASTRUCTURE (1) 12-7...

-

Page 46: Head Stock Infrastructure (1)

HEAD STOCK INFRASTRUCTURE (1) PARTS LIST N O . P A R T N O . D E S C R I P T I O N Q T Y K 5 - A 0 4 2 - 0 0 SHIFT CRANK 42-1. - Page 47 12.5 HEAD STOCK INFRASTRUCTURE (2) 12-9...

-

Page 48: Head Stock Infrastructure (2)

HEAD STOCK INFRASTRUCTURE (2) PARTS LIST N O . P A R T N O . D E S C R I P T I O N Q T Y K 2 - A 0 5 3 - 0 0 F E E D RE V E RS E BE V E L P I N I O N K 2 - A 0 5 4 - 0 0 BE V E L G E A R BE A RI N G... - Page 49 12.6 HEAD STOCK INFRASTRUCTURE (3) 12-11...

-

Page 50: Head Stock Infrastructure (3)

HEAD STOCK INFRASTRUCTURE (3) PARTS LIST N O . P A R T N O . D E S C R I P T I O N Q T Y H N - 5 / 8 N U T K 5 - A 0 7 1 - 0 0 1 / 2 "... - Page 51 12.7 HEAD STOCK INFRASTRUCTURE (4) 12-13...

-

Page 52: Head Stock Infrastructure (4)

HEAD STOCK INFRASTRUCTURE (4) PARTS LIST N O . P A R T N O . D E S C R I P T I O N Q T Y 6 4 . 3 / 8 " x 3 / 4 " S O CK E T CA P S CRE W 6 5 . - Page 53 12.8 COLUMN ASSEMBLY 12-15...

-

Page 54: Column Assembly

COLUMN ASSEMBLY PARTS LIST N O . P A R T N O . D E S C R I P T I O N Q T Y K 5 - C 0 0 1 - 0 0 W E A R G E A R M 1 0 x 9 0 S O CK E T CA P S CRE W 5 / 8 "... - Page 55 12.9 KNEE ASSEMBLY 12-17...

-

Page 56: Knee Assembly

KNEE ASSEMBLY PARTS LIST N O . P A R T N O . D E S C R I P T I O N Q T Y K 5 - C 0 6 2 - 0 1 K N E E M 6 x 8 O V A L H E A D S C R E W K 5 - C 0 9 6 - 0 0... - Page 57 12.10 TABLE, SADDLE ASSEMBLY 12-19...

-

Page 58: Table, Saddle Assembly

TABLE, SADDLE ASSEMBLY PARTS LIST PART NO. DESCRIPTION 0 1 . K 5 - C 0 2 3 - 2 0 1 1 "X52" TABLE K 5 - C 0 2 3 - 8 0 1 1 "X58" TABLE 0 2 . K 2 - D 0 2 9 - 0 0 C H OCK PLUG 0 3 . -

Page 59: Spindle Guard (Ce Option)

12.11 SPINDLE GUARD (CE OPTION) 12-21... -

Page 60: Summart Of The Electrical

13.SUMMART OF THE ELECTRICAL 13.1 ELECTRICAL COMPONENTS AND LAYOUT 13-1... -

Page 61: Control Panel, Switches And Symbols

13.2 CONTROL PANEL, SWITCHES AND SYMBOLS( CE OPTION) 1. Spindle forward 2. Spindle stop 3. Spindle reverse 4. Emergency stop 5. X,Y axis auto feed 6. Z axis rapid to up 7. Z axis rapid to down 8. Coolant pump switch 9. -

Page 62: Power Circuit

13.3 POWER CIRCUIT 13.3.1 WIRING DIAGRAM FOR STAND ARD ELECTRIC BOX THREE PHASE 13-3... -

Page 63: Wiring Diagram For Simple Electric Box Three Phase

13.3.2 WIRING DIAGRAM FOR SIMPLE ELECTRIC BOX THREE PHASE 13-4... -

Page 64: Power Circuit (Ce Option)

13.3.3 POWER CIRCUIT (CE OPTION) 13-5... - Page 65 13-6...

- Page 66 13.4 SCHEDULE OF ELECTRICAL EQUIPMENT (CE OPTIION) MANUFACTU SCHEDULE OF ELECTRICAL SHEET RER EXTRON EQUIPMENT ORDER TYPE SEE ALSO LIST DRAWN ITEM DESCRIPTION AND TECHNICAL SUPPLIERS DESIGNATION FUNCTION DATA QTY SUPPLIER REFERENCE REMARKS MAIN POWER SWITCH 600V 20A 194L-A20 IEC-947-3 VDE 0660 AC 600V T-400VA...

- Page 67 CABLE PVC CABLE-WIRE 1 TONG-WU CNS 3301 0x4C(37/0.26)16A 4398 3. 25x4C(50/0.18)11A AMBIENT TEMP C3342 、 3401 õC~60õC) MAX 600V SPINDLE MOTOR Z AXIS MOTOR PUMP MOTOR X AXIS POWER FEED ALIGN CE-235 Y AXIS POWER FEED AC 110V 50/60HZ ALIGN CE-250 Z AXIS POWER FEED ALIGN...

Need help?

Do you have a question about the K5V and is the answer not in the manual?

Questions and answers