Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for REITZ MEE

- Page 1 02/2005 Operating Manual Single stage radial fan Model MEE KONRAD REITZ VENTILATOREN GmbH & Co. KG Konrad Reitz-Straße 1 D-37671 Höxter - Albaxen (Germany) Telephone +49 (0) 52 71 / 964-000 · Telefax +49 (0) 52 71 / 964-119 Email: info@reitz-ventilatoren.de...

-

Page 2: Table Of Contents

Table of contents Safety General ......................1.1 Description of symbols and pictograms ............1.2 Start-up ......................1.2 Servicing ......................1.3 Cleaning ......................1.3 Electrical safety ....................1.4 Description of labels and plates ..............1.5 Application Design conditions................... 2.1 Warranty......................2.1 Description Design ...................... -

Page 3: Safety

The technical design meets DIN 24166 standard “Technical delivery conditions for fans”. It is not allowed to modify the original condition of the fan without the approval of Reitz. The warranty expires when parts other than original Reitz spare parts and/or purchased parts not corresponding to the original parts are used. -

Page 4: Description Of Symbols And Pictograms

1 Safety 1.2 Description symbols pictograms This symbol draws your attention to dangerous situations. operation concerned may endanger persons and cause injuries. This symbol is used to indicate that the work must be carried out by a trained and qualified electrician. This symbol is followed by supplementary information. -

Page 5: Servicing

1 Safety 1.4 Servicing The fan may only be serviced when the electrical system is dead, i.e.: — turn off the electrical machines and ensure that they cannot be switched on again, — wait until the rotor has come to a standstill, —... -

Page 6: Electrical Safety

1 Safety 1.6 Electrical safety The user has to ensure that the fan is only connected and serviced by a qualified electrician in accordance with the rules and regulations applying to electrical equipment. The user must also ensure that the fan is operated in accordance with electro-technical rules and regulations. -

Page 7: Description Of Labels And Plates

1 Safety 1.7 Description of labels and plates The following plates are attached to the fan: Nameplate The nameplate indicates: FAN / Type/ ........…..Serial No. / Year of constr....../ ...…..Com. - No. / ........….. F a n d a t a a t a d e n s i t y o f ρ A = 1 , 2 k g / m 3 ϑ... -

Page 8: Design Conditions

2 Determined use 2.1 Design conditions The fan is designed, tested and delivered in accordance with the instructions given in the order. The instructions indicated in the order have been entered on the fan data sheet of the fan. It is not permitted to change the conditions under which the fan is to be used (e.g. -

Page 9: Description

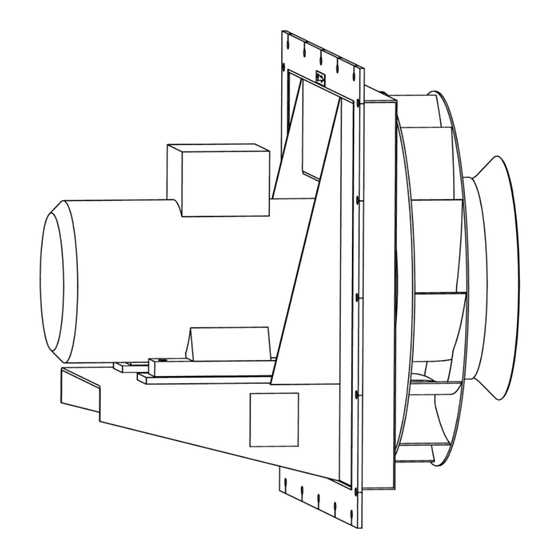

3 Description 3.1 Design The model MEE fan is a welded single-stage radial fan. It is driven directly by the motor shaft on which the impeller is mounted. For special designs please note the information given on the fan data sheet. -

Page 10: Scope Of Supplies

4 Assemblage 4.1 Scope of supplies When delivered the fan and accessories must be checked for damage caused by damaged packing. Immediately report any transport damage to the forwarding agent, insurance company manufacturer. Check that everything indicated on the delivery note has been delivered. -

Page 11: Storage

4 Assemblage 4.3.1 Storage If the fan is not installed and/or put into operation immediately it must be stored in a dry place which is free of vibrations. In case of long-term storage please note the storage and preservation instructions for motors. 4.3.2 Stand-by operation In case of long-term standstill periods, please note the relevant instructions for the storage of motors. -

Page 12: Electrical Connection

4 Assemblage 4.5 Electrical connection The fan may only be connected up to the electrical system by a qualified electrician. The drive motors are usually installed in the manufacturing works. The works warranty does not apply if the customer installs the motors. -

Page 13: Inspection

4 Assemblage 4.6 Inspection 4.6.1 Mechanical testing Check the fan after it has been assembled and installed. — Check the attachment of the fan to the foundation. — Check if the impeller rotates freely (turn it with the hand). — Remove any foreign objects from the fan housing. -

Page 14: Start-Up

5 Start-up 5.1 Putting the fan into operation The fan may only be put into operation by qualified and skilled staff. Before the fan is put into operation the staff must check that the fan is in good working order. The rules and regulations for putting electrical machines into operation must be observed. -

Page 15: Transient Behaviour

5 Start-up 5.3 Transient behaviour 5.3.1 General The fan can only be started when a sufficiently high moment of acceleration is available form the moment it is started up to the moment when nominal speed is reached. It is recommended to start the fan with the damper closed. -

Page 16: Care And Maintenance

6 Care and Maintenance 6.1. Lubrication The fan must be checked at regular intervals (depending on the operating conditions). 6.1.1 Drive motor The motor must be serviced in accordance with the motor’s lubricating instructions. 6.1.2 Shaft seal Lubricate the seal once a month. (use an oil can to pour a small amount of machine oil in the gap between the seal and shaft). -

Page 17: Troubleshooting

6 Care and Maintenance 6.2 Troubleshooting Malfunction Possible cause Action Unsteady operation of fan. Carefully clean impeller. Material sticking to impeller blades. Worn impeller. Replace impeller. Impeller deformed by heat. Replace impeller. Medium escapes at the shaft Seal is faulty or worn. Replace seal. - Page 18 6 Care and Maintenance Troubleshooting (cont’d) Malfunction Possible cause Action Fan does not accelerate. Improper connection of drive Check connection. motor. Motor does not change from star Shorten change-over time to delta connection. from star to delta. Fan operates against insufficient Close dampers or install plant resistance.

-

Page 19: Queries/Sending-Out Of Fitter

(visible/audible). An exact description will allow us to help you more quickly and efficiently. Information sent out by FAX will be very much appreciated. Please contact: KONRAD REITZ Ventilatoren GmbH & Co. KG Montageabteilung P.O. Box 10 05 53 D-37655 HÖXTER - Albaxen...

Need help?

Do you have a question about the MEE and is the answer not in the manual?

Questions and answers