Advertisement

Quick Links

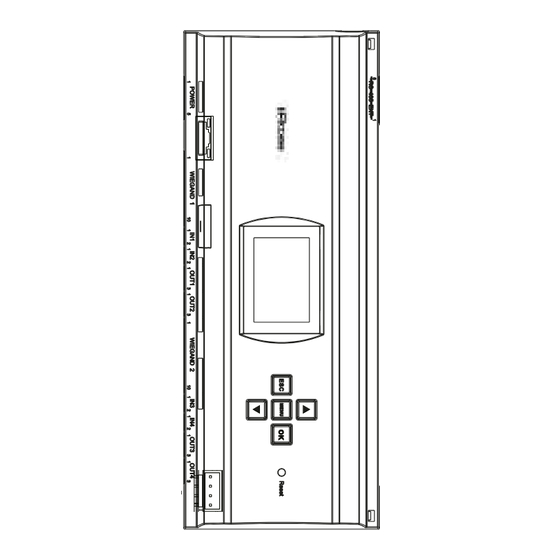

AccessPRO2

1

.Cautions

Please notice the following cautions. Mis-operation may lead to personal injury or

equipment failure:

1 ) Do not energize the system before installation is complete. Never carry out installation

activities when the system is energized.

2) All peripheral devices must be grounded.

3) It is recommended that all wires run through casing pipes which may by PVC or galvanized

ones.

4) It is strongly recommended that the length of exposed part of any connection cable

should not be longer than 4 mm.

Professional clamping tools may be used to

unintentional contact of exposed wires to avoid short-circuit or communication failure.

5) It is recommended that card readers and buttons should be installed at height of 1.4m-1.5m

above ground.

6) It is recommended to use the power supply in case for control panel, and external power

supply for each lock.

2

.Equipment Installation

2

1

Select two of the elliptical holes on

Hang the equipment on the upper

edge of the rear iron cover, and

the rear iron cover. Drill two holes

then press the equipment down.

on the surface for fixing (Which may

be on a distribution cabinet, ceiling

or other weatherproof position).

3

.Lock Connection

1)The access controller provides lock control output. For a lock which should be open when being energized and be closed

when being de-energized, the "COM" and " NO" terminals should be used. For a lock which should be open when being

de-energized and be closed when being energized, the "COM" and " NC" terminals should be used.

2) If the electrical lock is connected to the access control system, you need to parallel one FR107 diode (Equipped

in the package) to prevent the self-inductance EMF affect the system, do not reverse the polarities.

3) Each relay may work under the wet mode or dry mode by setting the jumper terminal. If the 12V power

supply inside the access controller uses external power supply, the output of each relay is under the "wet mode".

If the external power supply uses potential free contacts, the "dry mode" should be used. please refer to

Instructions for Hardware of C4-200/400 Access Controller.

*

It is recommended to short 2-3 ports, the output use the "dry mode", the electronic lock use the external power supply.

1 2 3 4

-

L ock Power

+

Unlock at power on

Diode

+

L ock

-

Unlock at power off

Diode

-

L ock

+

+

L ock Power

-

External power supply for electronic lock

3

1

2

4

Relay

Relay

1

2

4

3

2

1

R elay output por ts and j umper ter minals setting (The second layer of PCB)

Installation and C onnection G uide

V er sion 1. 0.1

D ate: J uly, 201 1

3

Push the equipment backward to hang

the entire equipment onto the rear cover.

FR107

Enlargement of

Lock Ports

NO

COM

NC

FR107

Wet Mode:

1

2

3

4

Dry Mode:

Relay

Distribution

diagram of the

Relay

factory default

jumper cap:

3

4

4

.Equipment Communication

The PC software communicate with the system through two protocols (RS485 and TCP/IP)

for data exchange and remote management. The communication cable should be away

from high-voltage lines as far as possible. Do not keep the communication cable in parallel

with power cords or bind them together.

1) TCP/IP Mode:

TCP/IP Ethernet

avoid

1# Controller

2) RS485 Mode:

G N D

485+

485-

4 3 2 1

1# Controller

Notes:

1) Internationally accepted RVSP (shielded twisted-pair) wires should be used for communication

to

effectively avoid interference.

bus cascade connection.

2) Theoretically, in RS485 communication, one bus may be connected with 64 access controllers.

It is recommended to conenct with no more than 16 devices.

3) The recommended bus length of RS485 communication is less than 600 meters.

4) When the bus is longer than 300 m, to enhance the stability of communication, it is necessary

to change J24 on the first layer of PCB (see the figure below) inthe first and the last units (see

unit 8# as shown in the figure above) to short pins 2-3. This method is equivalent to connect

with a resistance of 120 ohm.

Jumping Terminals

3

1

2

4

Enlargement of J24

Jumping Terminals

2

3

4

1

Terminal R esistance S etting

Jumping Terminals

1 2 3 4

Terminal resistance setting diagram (The first layer of PCB)

PC

Card Reader

S witch

2# Controller

RS485 Ports

485+

485-

485+

G N D

G N D

4 3 2 1

4 3 2 1

2# Controller

8# Controller

RS485 communication wires should be connected by means of

Factory Default Setting

n# Controller

RS485 Convertor

485-

485+

G N D

Serial Bus

485-

PC

RS485

Advertisement

Summary of Contents for AccessPRO AccessPRO2

- Page 1 AccessPRO2 Installation and C onnection G uide .Equipment Communication The PC software communicate with the system through two protocols (RS485 and TCP/IP) V er sion 1. 0.1 D ate: J uly, 201 1 for data exchange and remote management. The communication cable should be away from high-voltage lines as far as possible.

- Page 2 .Terminals Connection Notes: 1) The auxiliary input may be connected to infrared body detectors, smoke detectors, gas detectors, window magnetic alarms, wireless exit switches, etc. 2) The auxiliary output may be connected to locks, monitors, alarms, door bells, etc. 3) The auxiliary input and the auxiliary output is set with iAccess4.0. 4) GPRS, WiFi and the following items indicated with "*"...

Need help?

Do you have a question about the AccessPRO2 and is the answer not in the manual?

Questions and answers