Summary of Contents for InstroTek CoreDry

- Page 1 COREDRY ® Rapid Asphalt Drying System OPERATING MANUAL www.InstroTek.com...

- Page 2 © 2018 InstroTek, Inc. CoreDry Operation Manual Version 8...

- Page 3 THE TEST. aware that vapor trap reaches temperatures below freezing. Voltage of 120V is present inside the CoreDry cabinet. DO NOT PROBE INTO THE MAIN CABINET WITH CONDUCTIVE MATERIALS, TOOLS, FINGERS OR HANDS. IF COVER MUST BE REMOVED CONTACT INSTROTEK FIRST.

- Page 4 (InstroTek part number 977.1004 package of 12 filters). Change your exhaust filter on the vacuum pump once a year (InstroTek part number 977.1002, 977.1005, or 977.1006 depending on pump model). Call InstroTek at (919) 875-8371 if you have any questions.

-

Page 5: Table Of Contents

InstroTek 1. Table of Contents **************************************** 1. INTRODUCTION 2. GETTING STARTED 3. MENU FUNCTIONS 4. AGGREGATE TESTING 5. EMULSION TESTING 6. MAINTENANCE 7. TROUBLESHOOTING 8. INDEX 9. WARRANTY... -

Page 6: Introduction

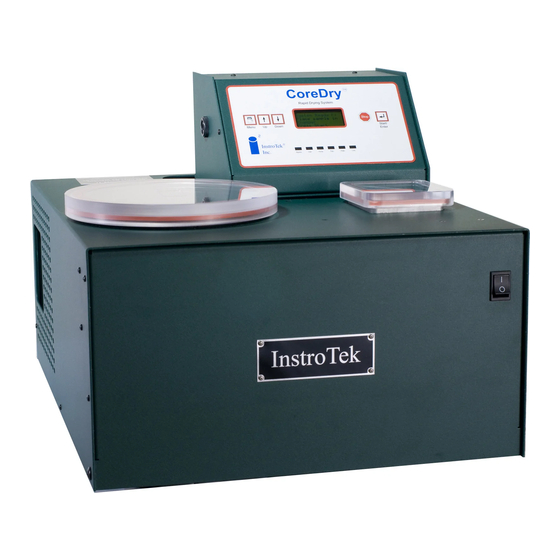

Now you can use the dry weight from the CoreDry to measure your core density in minutes or get a quick measure of your stockpile aggregate moisture content. - Page 7 InstroTek CoreDry Components Sample Cold Trap Chamber with with Lid On/Off Switch CoreDry Front View Oil Fill Plug Power Modules Oil Level Serial Number Site Glass Plate Glass Power Cable Drain Valve CoreDry Back View...

- Page 8 InstroTek Flow Plate & Wire Mesh Sample Flow Plate and Sample Holder Installed in Sample chamber Tank Filters...

-

Page 9: Getting Started

Place the lids on the large and small tanks. 4. Turn on CoreDry: Plug the unit in a wall outlet and flip on the on/off switch to the ON position. The display will indicate the software version once turned on. - Page 10 InstroTek Turn Unit On: Initialization and prep flow chart. CoreDry CoreDry CoreDry Version X.X.X Version X.X.X Version X.X.X System Dry Cold Trap Pressurizing XX T= XX System Ready CoreDry Version X.X.X Start to Begin Cold Trap Cooling = XX Place the sample in the chamber, place the lid firmly on the...

- Page 11 6 mmHg, refer to the trouble shooting section or call InstroTek for service information. Note: When you receive the CoreDry or after transport to other locations, you might have to run the CoreDry several cycles to achieve 6 mmHg.

- Page 12 6. Drying Samples: Note: To speed up the drying process for multiple samples, dry one sample in the CoreDry and place all other samples in front of a fan. a) Make sure the sample is at room temperature or higher.

- Page 13 InstroTek For best results, place the sample on its side. 7. Cold Trap: Liquid and/or ice will accumulate in the cold trap as samples are drying. Between samples, during rotations, and for faster drying, it is best to remove the cold trap lid and the divider plate and wipe out the moisture.

-

Page 14: Menu Functions

InstroTek 3. Menu Functions To access the Menu press the ‘Menu’ Button on the CoreDry Keypad. To cycle through the different menu settings press the Up or Down key to change the menu options. To view or change a menu press ‘Enter’ when a particular menu option is displayed. - Page 15 InstroTek all of the current settings. The screen will scroll every 5 seconds or the Up and Down arrows can be used to navigate through the results. NOTE: Units with serial numbers 499 and below that have been upgraded do not include a Self-Test feature.

-

Page 16: Aggregate Testing

Use the following procedure to dry aggregates and to determine moisture content: 1. Set the CoreDry to program 2 (PR2) by pressing the Menu key. Change the program number to program 2. 2. Remove the wire mesh sample holder and the flow plate from the sample chamber. - Page 17 InstroTek Note: If the maximum number of cycles (20) is reached and the aggregate is still not dry, the unit will display a message prompting the user to turn the sample and restart the drying operations. At this point remove the...

- Page 18 InstroTek Aggregate Sample Fixture Aggregate Fixture with one fastener and lid removed...

-

Page 19: Emulsion Testing

30 minutes using the CoreDry . It enables laboratories to recover the residual asphalt of emulsion to determine the percent residual asphalt without changing the binder properties. - Page 20 10 metal pans and silicone liners (5 for testing and 5 for preparing the next sample) CoreDry control board (necessary for older models) Preparing a Sample 1. Prepare a space with a protective sheet to capture any spills of the emulsion.

- Page 21 InstroTek 4. Spread the emulsion with the included thin-film applicator. Pull the applicator toward your body with a slow smooth motion. The applicator should slide across the surface of the silicon sheet. 5. Once the emulsion is spread, place the silicone sheet back in the metal pan.

- Page 22 8. Place the pan on the rack for drying. 9. Repeat the sample preparation process for the remaining 4 pans. 10. Turn on the CoreDry and select Program`` 5 for drying the emulsion. a. Enter Menu. Select option 1. Program #. Press Enter.

- Page 23 InstroTek 11. Place the rack in the CoreDry. Put the lid on the chamber and press Start. 12. After the samples are dry, remove the rack. Weigh each pan with the dry weight. 13. Calculate the residual content of the emulsion from the average of the total mass.

-

Page 24: Maintenance

3. Slide the unit around so that the back panel can be accessed. 4. Remove the fill cap. Place a 2”-3” block or book under the front of the CoreDry to tilt the drain. Oil Fill Plug Power Oil level... - Page 25 Caution: Carefully remove any spilled oil from the floor to avoid accidents. Only use high-quality synthetic vacuum oil. Vacuum pump oil can be obtained by calling InstroTek at 919-875-8371 or fax 919- 875-8328. The InstroTek part number is 419.0005. Pump Filter Change- Necessary if vacuum does not reach 6 mmHg with tank empty or every 12 months.

- Page 26 Turn CoreDry off and unplug unit from power source. Remove tank and cold trap lids from unit. To remove top cover of CoreDry, unscrew 4 pan head #6 black screws located on outside surface of green top cover (4 screws total 1 on each side at the back edges and 1 on each side in the middle near the bottom).

- Page 27 12. Replace filter stuffing and exhaust cover. Tighten the four bolts that hold the exhaust cover on. 13. Replace top cover of CoreDry. Make sure that wiring and hosing remains undisturbed and is not crimped between base and top cover.

- Page 28 10. Go into Menu option 10 and reset the timer for the Exhaust Filter. Verify Vacuum Pressure Reading (every 6 months) 1. Warm up CoreDry by running the unit empty with both lids on for three separate tests. 2. Dry Cold Trap to make sure there is no moisture inside the Cold Trap.

- Page 29 InstroTek 7. If the two readings are not the same take note of the difference between the Vacuum Gauge and the displayed pressure and contact InstroTek at (919)875- 8371 for instruction on how to adjust pressure offset.

-

Page 30: Troubleshooting

Open CoreDry and make sure no hoses are pinched or loose. Contact InstroTek for troubleshooting help 919-875-8371. CoreDry works but is taking longer time to dry samples than before – Make sure lids, pump fill cap and drain valve are all correctly sealed. - Page 31 InstroTek CoreDry will not release vacuum – Make sure the unit is powered on. Run Self-Test to make sure everything is working within normal parameters. Remove 4 screws, total 1 on each side at the back edge and 1 on each side in the middle near the base.

-

Page 32: Index

InstroTek 8. Index Aggregate Testing ..........12 Aggregate Type ..........13 Auto Mode............6 Busch Pump ............21 Changing Oil ............. 15 Components ............3 Daily Test ............... 7 Drain Valve ............26 Dry Plate ............... 4 Drying Samples............ 8 Emulsion Cleaning .......... - Page 33 InstroTek Preparing a Sample ......... 16 Prep Flow Chart ..........6 Pump Filter ............ 21-23 Quick Start ............5 Self-Test ............10-11, 26 Setup..............5 Tank Filters ..........4-5, 11, 20 Tools Needed ............ 22 Troubleshooting ..........26 Verifying Vacuum Pressure......24 Views..............

-

Page 34: Warranty

Do not ship products back via small parcel carriers i.e. UPS or FedEx. Use a freight shipping company i.e. R&L, UPS Freight or Estes. Call InstroTek, Inc. for shipping details at (919) 875-8371 or fax at (919) 875-8328. - Page 35 InstroTek Contact Information Innovators in Instrumentation Technology www.InstroTek.com | (919) 875-8371 | sales@InstroTek.com Research Triangle Park, NC | Austin, TX | Bensalem, PA | Grand Rapids, MI | Denver, CO | Las Vegas, NV | Concord, CA...

- Page 36 Contact us for top quality, best value and superior service! email: sales@instrotek.com visit: InstroTek.com ª Call a loCaTIon near you: Headquarters: research Triangle Park, nC phone: 919.875.8371 Bensalem, Pa phone: 215.645.1064 Grand rapids, MI phone: 616.726.5850 ª Denver, Co phone: 303.955.5740 austin, TX phone: 512.452.8848...

Need help?

Do you have a question about the CoreDry and is the answer not in the manual?

Questions and answers