Table of Contents

Advertisement

Save This Manual for Future Reference

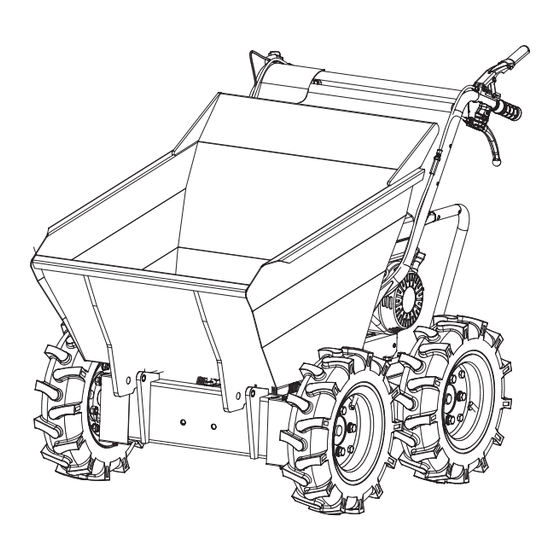

Power Wheelbarrow

Operator's Manual

MODEL NUMBER

YD4103

SERIAL NUMBER

PURCHASE DATE

Both model number and serial

number may be found on the

main label. You should record

both of them in a safe place for

future use.

FOR YOUR SAFETY

READ AND UNDERSTAND THE ENTIRE MANUAL BEFORE OPERATING MACHINE

Tame the Great Outdoors

®

Advertisement

Table of Contents

Summary of Contents for YARDMAX YD4103

- Page 1 Save This Manual for Future Reference Power Wheelbarrow Operator’s Manual MODEL NUMBER YD4103 SERIAL NUMBER PURCHASE DATE Both model number and serial number may be found on the main label. You should record both of them in a safe place for future use.

-

Page 2: Table Of Contents

Up for the job? YARDMAX is. When looking for outdoor power equipment (OPE) to get the job done right, at the right price, YARDMAX delivers the perfect combination of performance and practicality. YARDMAX has a solution that’s right for you. - Page 3 California to cause cancer and birth defects or other reproductive harm. For more information, go to www.P65Warnings.ca.gov. DISCLAIMER YARDMAX reserves the right to discontinue, change, ENVIRONMENTAL and improve its products at any time without notice or obligation to the purchaser. The descriptions and...

-

Page 4: Specifications

SUPPORT Have questions about your YARDMAX equipment? Call us at 844-YARDMAX, email us at support@yardmax.com, or contact us via your favorite social media site. SPECIFICATIONS Model number YD4103 Engine briggs & Stratton Displacement 208cc Torque (ft-lbs, gross) 9.50 Start Type... -

Page 5: Symbols

Power Wheelbarrow Operator’s Manual » SYMBOLS The rating plate on your machine may show symbols. These represent important information about the product or instructions on its use. Keep your hands clear from all rotating Read these instructions carefully. parts. Wear eye protection. Never start or run the engine inside a closed area. -

Page 6: Safety

SAFETY GENERAL SAFETY RULES Always keep hands and feet away from all moving parts during UNDERSTAND YOUR MACHINE operation. Moving parts can cut or crush body parts. Read this manual and labels affixed to the machine to understand its limitations and potential hazards. Always keep hands and feet away from all pinch points. - Page 7 Power Wheelbarrow Operator’s Manual » ENGINE SAFETY Keep grounded conductive objects, such as tools, away from exposed, live electrical parts and connections to avoid sparking or This machine is equipped with an internal combustion engine. Do arcing. These events could ignite fumes or vapors. not use on or near, forest covered, or brush covered land unless the exhaust system is equipped with a spark arrester meeting Always stop the engine and allow it to cool before filling the fuel...

- Page 8 Walk, never run with the machine. Do not operate the machine in confined areas where there may be a risk of crushing the operator between the machine Do not overload the machine capacity. Drive at a safe speed, and another object. adjusting the speed to the slope of the land, the surface conditions of the road, and the weight of the load.

-

Page 9: Unpacking The Container

Power Wheelbarrow Operator’s Manual » UnPACKInG THE COnTAInER Use the screwdriver and hammer to open all the side locks. Remove all the polywood plates. Remove all the loose parts on the bottom pallets. Use scissors or a knife to cut all the straps. (See Figure 1a) Figure 1a When unpacking the shrink wrap around the main body and handlebars, be careful not to cut too deeply or you may sever cables and/or scratch the paint. -

Page 10: Contents Supplied

COnTEnTS SUPPLIED Your YARDMAX power wheelbarrow comes partially assembled and contains the following: Hardware Kit 1. Hopper 7. Hardware Kit, Including: 2. Handlebar M10 X 45 3. Frame M10 X 25 4. Wheels X 16 5. Operator's Manual & Engine Manual Cotter Pin 6. -

Page 11: Assembly

Power Wheelbarrow Operator’s Manual » ASSEMbLY 7.5” Block This power wheelbarrow was partially assembled at the factory. To assemble your machine follow the below instructions. HANDLES Mount the handle frame assembly to the frame and secure it with M10X25 bolts, washers and nuts at the front and M10X45 bolts, washers and nuts at the rear. - Page 12 HOPPER PLOW BLADE (OPTIONAL-SOLD SEPARATELY) Install the two supporting feet to the blade as shown in Install the hopper and fasten the front with two cotter pins (See Figure 4) Fig. 6a, adjust the height and secure them with M12X30 bolts and nuts.

- Page 13 Power Wheelbarrow Operator’s Manual » Fix the blade assembly to the flange bracket with Connect the angle control lever and extension by M20X100 bolt, washer and nut. Do not overtighten, M8X40 bolt, washer and nut. Attach the extension to allowing the blade to rotate freely in both directions. the blade with M8X50 bolt and nut.

-

Page 14: Know Your Machine

KnOW YOUR MACHInE FEATURES AND CONTROLS Engine On/Off Switch Throttle Control Right Steering Lever Clutch Control Lever Left Steering Lever Hopper Release Lever Hopper Gear Selection Lever Wheel Gearbox Choke Control Fuel Shut-Off Valve Recoil Starter Handle ENGINE ON/OFF SWITCH CLUTCH CONTROL LEVER The engine switch enables and disables the ignition Squeeze the control lever, clutch engaged. - Page 15 Power Wheelbarrow Operator’s Manual » Push the lever “A” back towards the hopper to lock it in LEFT STEERING LEVER place. Always lock the hopper prior to transporting it. Operate the lever to turn left. RIGHT STEERING LEVER Operate the lever to turn right. GEAR SELECTION LEVER It controls forward or reverse movements of the machine.

-

Page 16: Operation

OPERATION ADD OIL TO ENGINE IMPORTANT: DO NOT OVERFILL! The engine is shipped without oil. Do not start the This equipment and/or its engine may include engine before adding oil. evaporative emissions control system components, required to meet EPA and/or CARB regulations, that will only function properly when the fuel tank has 1. - Page 17 Power Wheelbarrow Operator’s Manual » OPERATING Remember to be careful when working in adverse weather conditions (ice, heavy rain and snow) or After engine warms up, adjust the throttle to down to on types of ground that could make the machine allow the engine to warm up.

-

Page 18: Maintenance

Adjustment Nut Jam Nut MAInTEnAnCE Jam Nut Regular maintenance and lubrication will help keep your machine in perfect working condition and ensure years of trouble free use. Adjustment Nut Jam Nut PREVENTIVE MAINTENANCE Turn off engine and disengage all levers. Engine must be cool. Inspect the general condition of the unit. - Page 19 Power Wheelbarrow Operator’s Manual » If the above adjustment does not create enough cable tension, adjust the cable tension near the handle by following the below steps. Loosen the jam nut by turning it counter clockwise with 12mm wrench while holding the lock nut in place with 10mm wrench.

- Page 20 LUBRICATION The gearbox is pre-lubricated and sealed at the factory. no need to lubricate until 50 hours use. After first 50 hours use, change all the transmission oil. Capacity is 1.5L. For future use, just check the oil level every 50 hours of working.

-

Page 21: Storage

Power Wheelbarrow Operator’s Manual » STORAGE If the power wheelbarrow will not be used for a period longer than keep the air vents free of obstructions. 30 days, follow the steps below to prepare your unit for storage. Do not use strong detergents or petroleum based 1. -

Page 22: Troubleshooting

TROUbLESHOOTInG Problem Cause Remedy 1. Spark plug wire disconnected 1. Attach spark plug wire securely to spark plug 2. Out of fuel or stale fuel 2. Fill with clean, fresh gasoline 3. Choke not in open position 3. Throttle must be positioned at choke for a cold start Engine fails to start 4. -

Page 23: Parts Diagram

Power Wheelbarrow Operator’s Manual » PARTS DIAGRAM Parts Diagram YD4103PM02 - 1706... - Page 24 Parts Diagram YD4103PM02 - 1706...

-

Page 25: Parts List

Power Wheelbarrow Operator’s Manual » PLOW BLADE (OPTIONAL) PARTS LIST OPTIONAL PLOW BLADE Description Description Description 1* Handle Sleeve 1 13* Connecting bracket 3 25* base 2* nut M12 14* Handle Sleeve 2 26* bolt M8x35 3* Connecting bracket 1 15* Handle Grip 2 27* Connecting bracket 4 4* Washer12... -

Page 26: Yd4103Pm02

PARTS LIST Description Description Description 1 Engine 37 belt Pulley 73 Chasis 2 Handle Sleeve 38 Flat Key b5x40 74 Fender 3 On/OFF Switch 39 belt Shaft 75 Rear Chainwheel 4 Throttle Lever 40 Circlip 8 76 bearing 205 5 Throttle Cable 41 Rockshaft 77 bush 2 6 Locknut M6... - Page 27 Power Wheelbarrow Operator’s Manual » PARTS LIST Description Description Description 109 Seal Fb17X47X7 135 Pin 12x20 161 Clutch Fork Shaft (L) 110 Spring 136 Gear box Case ( R) 162 Cable Connecting Plate Weldment 1 111 Steel ball 6 137 Clutch Fork Shaft ( R) 163 bolt M8X130 112 Gearshift Fork Shaft 138 Plug...

- Page 28 Tame the Great Outdoors ® 844-YARDMAX (844-927-3629) info@yardmax.com...

Need help?

Do you have a question about the YD4103 and is the answer not in the manual?

Questions and answers