Table of Contents

Advertisement

Quick Links

Soldering Hints

1

Put leads through mounting holes from the side with

part outline. Ensue component evenly touch PCB.

2

Solder leads at the other side. Solder should fully

fill and cover soldering pads.

Avoid bridges between

neighbering pads.

Cut unused leads

3

flush with cutter.

Step 1

Assembly Main Board and LCD board (follow the order as numbered)

1. Resistors

Note:

Always meter resistor

values before soldering

R7, R36

:

180Ω

R1, R14, R16 100KΩ

:

R8, R12, R13 120Ω

:

R2

1.8MΩ

:

R9, R15, R26 1KΩ

:

R3

200KΩ

:

R10

3KΩ

:

R4

:

2MΩ

R11, R38

:

1.5KΩ

R5

:

20KΩ

R28, R40

:

470Ω

R6

300Ω

:

R37, R39

:

10KΩ

2. HF-Chokes

L1,L3,L4

:

100 H

μ

3. Diodes

Cathode

D1

:

1N5819

D2

:

1N4004

(or 1N4007)

4. Crystal

Y1

8MHz

:

JYE Tech Ltd.

- www.jyetech.com -

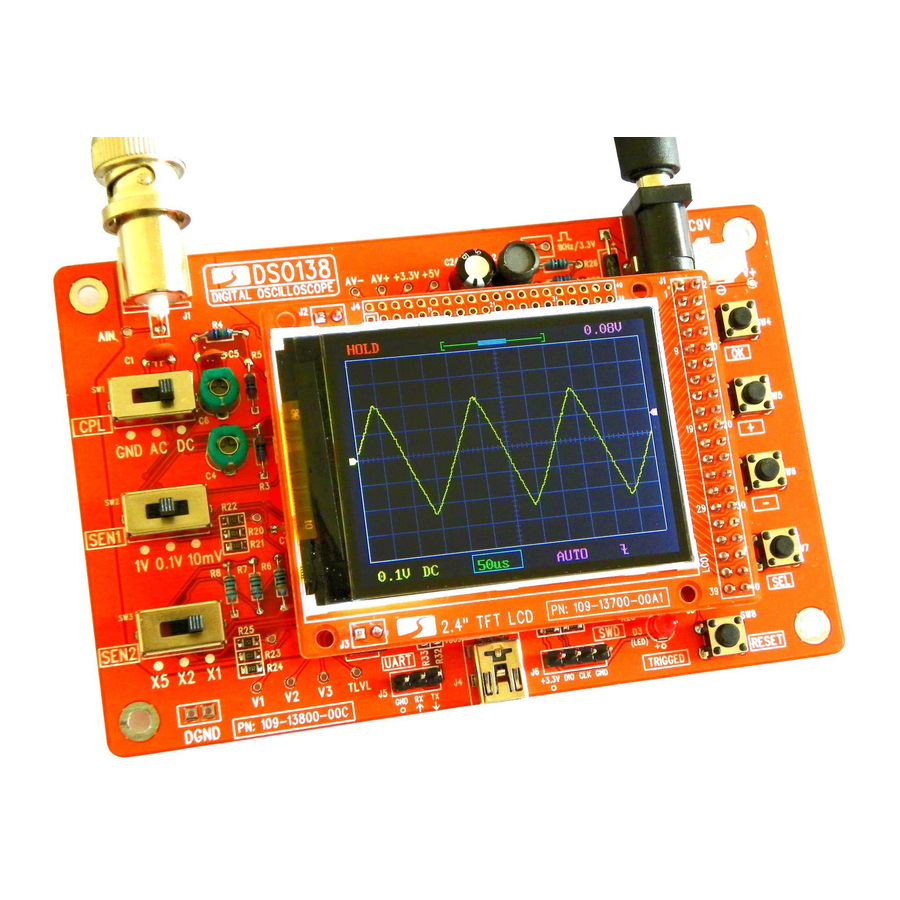

DSO 138 Oscilloscope DIY Kit

User Manual

Tools you need

1

4

Screw driver

Iron (20W)

2

Solder wire

5

Flush cutter

Tweezers

3

Multimeter

6

5. USB Socket *

J4

USB mini -B

:

6. Tact Switches

SW4, SW5,

:

6 X 6 X 5mm

SW6, SW7,

SW8

7. Ceramic Capacitors

C1, C9,

:

μ

0.1 F

C10, C11,

C14, C15,

C16, C17,

C18, C20,

C23

C7, C8

C2

:

330pF

:

120pF

C3

3pF

:

C12, C13

:

22pF

C5

:

1pF

8. LED

Solder positive pole

(the longer lead) to

D3

:

φ3mm, green

the square pad

Rev. 01

Before you start

1

Check part values & quantities against part list

2

Always meter resistor values before soldering

3

Understand all part polarities and orientations

* These parts are optional and not required

for the normal oscilloscope function.

9. Pin header (for power)

Face the opening

outward

2 Pin

J9

:

10. Transistors

Q1

:

8550

Q2

:

9014

11. Regulators

:

79L05

U4

U5

:

78L05

12. Capacitor trimmers

C4, C6

:

13. Power inductor

L2

1mH/0.5A

:

14. Electrolytic capacitors

Solder positive pole

C19, C21,

(the longer lead) to

C22, C24,

the square pad

C25, C26

15. Power connector

16. Pin-header (male) *

J5

17. Pin-header (female)

J7, J8

J3

18. Slide switches

SW1, SW2,

SW3

5 - 30pF

19. BNC connector

:

100 μ /1 6V

F

:

DC005

J10

:

1 X 3 pin

J6

:

1 X 4 pin

:

1 X 2 pin

:

2 X 20 pin

2P3T

:

J1

BNC

:

Page 1

Advertisement

Table of Contents

Summary of Contents for DIY DSO 138

- Page 1 Soldering Hints DSO 138 Oscilloscope DIY Kit 14. Electrolytic capacitors User Manual Put leads through mounting holes from the side with part outline. Ensue component evenly touch PCB. Rev. 01 Solder leads at the other side. Solder should fully Tools you need Before you start fill and cover soldering pads.

-

Page 2: Troubleshooting

20. Test signal ring 21. JP3 22. LCD Board Note: Install to the side 1 ) Make a small ring with a Short JP3 with solder lead cut-off. opposite to LCD panel. 2 ) Solder the ring to the two 2 X 20 pin holes of J2 (as shown in the photo). - Page 3 How to Use Probe Calibration Leave black clip Connect red clip to Because there is always some capacitance between scope input and un-connected test signal output Display and Controls ground probe needs to be calibrated to achieve better measurement results for high frequency signals. This can be done with the help of Trigger Level the built-in test signal.

Need help?

Do you have a question about the DSO 138 and is the answer not in the manual?

Questions and answers