Summary of Contents for ontime AVC118

- Page 1 AVC118 ARC VOLTATGE CONTROLLER Instruction Manual Revision 2.0A Mar. 2012 SHENZHEN ONTIME TECHNOLOGY CO.LTD...

- Page 2 When the distance between the torch nozzle and work piece increases, the arc voltage increases, on the opposite, the arc voltage will decrease. AVC118 plasma arc voltage torch height controller will detect the voltage changes, then control the distance between cutting torch and work piece...

- Page 3 SHENZHEN ONTIME TECHNOLOGY CO.LTD IHS (Initial Height Setup) mode: Inductive proximity switch mode. Torch tip ohmic contact mode, only be suited for the plasma power which has less HF and HV interferences and working in dry cutting condition. Arc voltage divider ratio: 1:100.

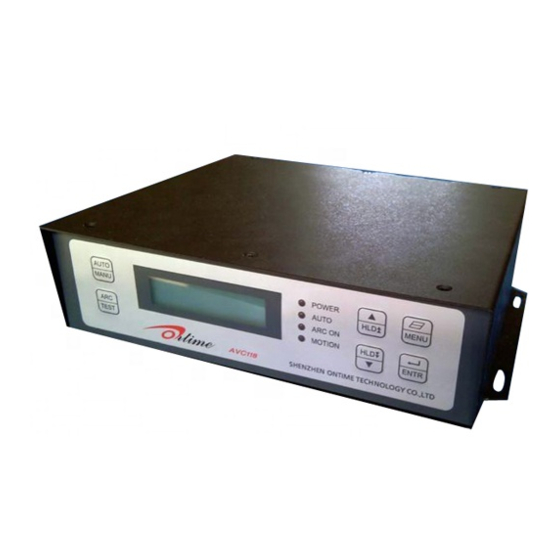

- Page 4 SHENZHEN ONTIME TECHNOLOGY CO.LTD Pictures...

- Page 5 SHENZHEN ONTIME TECHNOLOGY CO.LTD System connection AVC118 Controller SYSTEM START MOTOR Torch ARC VOLT Lifter PLASMA PRO SW SHIELD WORK PIECES GROUND AVC118 controller system connection...

- Page 6 SHENZHEN ONTIME TECHNOLOGY CO.LTD Connectors Terminals outline J1:Connect to CNC controller. J2:Connect to DC24V power supply, lifting motor and limit switches. J3:Connect to the proximity switch and plasma start switch. J4:Connect to the arc voltage sampling terminals. J5:Connect to the torch shield cap signal terminal.

- Page 7 SHENZHEN ONTIME TECHNOLOGY CO.LTD TERMINALS DEFINITION NAME TERMINAL SIGNAL FUNCTION AUTO CNC AUTO THC Enable CNC Torch Up Signal DOWN CNC Torch Down Signal START CUT CNC Start Cutting Signal MOTION Motion Enable to CNC GND of Control Signals UP_LMT...

- Page 8 E-TRODE terminal to the negative terminal of the plasma power. AVC118 has been integrated an isolated arc voltage divider, the divided ratio is 1:100. The arc voltage sense wires should be at least 0.9 mm squared twisted pair wire, rated 600V or greater.

- Page 9 SHENZHEN ONTIME TECHNOLOGY CO.LTD J4 ,J5 connection illustration J4: J5: E_TRODE: ARC VOLT- SHIELD: CAP SHIELD WORK: ARC VOLT+ LEAD LINE...

- Page 10 CNC INTERFACE J1: connected to the CNC control system. Terminal description: J1-1: AUTO Auto height control enable signal from CNC to AVC118 controller. Default definition: HIGH level signal enable auto control, LOW level signal disable auto control. This definition can be reversed by demand when placing order.

- Page 11 SHENZHEN ONTIME TECHNOLOGY CO.LTD CNC should begin the cutting motion. In case of serious error occurred during the plasma cut, this signal will be reset to high level. Active level: LOW. Please refer to the MOTION signal interface circuit illustration.

- Page 12 SHENZHEN ONTIME TECHNOLOGY CO.LTD LIFTER MOTOR AND LIMIT SWITCH Lifter motor: DC shunt motor, 24V DC, power within 60W. Connected terminal: J2-5 and J2-6, if the torch up and down direction is not corresponding to the controller, please exchange the lead wires of the lifter motor.

- Page 13 SHENZHEN ONTIME TECHNOLOGY CO.LTD Proximity switch IHS mode Terminal: J3-1: +12V output, supply for proximity switch. J3-2: proximity switch signal input. J3-3: 0V, ground. Proximity switch type: NPN, normal open, sense distance 2mm. If there is a short wire connected between terminal J3-2 and j3-3, you should remove it before connecting the proximity switch.

- Page 14 SHENZHEN ONTIME TECHNOLOGY CO.LTD Shield cap IHS mode Terminal: J5. Through this lock terminal, Connect the shield cap lead wire (as the Ohmic IHS sensing signal) to the SHELD CAP terminal. The Ohmic IHS sense wire should be at least 0.5 mm squared, rated 1000V or greater.

- Page 15 SHENZHEN ONTIME TECHNOLOGY CO.LTD Operation mode The AVC118 will work in auto mode after power on. This means that the controller will take the responsibility to monitor the arc voltage and modify the torch height correctly during plasma cut. In case of needed, you can Press the AUTO/MANU key to enter into manual operation mode, and it is your responsibility to maintain the torch height correctly.

- Page 16 SHENZHEN ONTIME TECHNOLOGY CO.LTD Arc voltage setup Press the MENU key once while standby, the controller will enter into parameter setup interface, then press UP or DOWN arrow key to select menu items, press the ENTR (enter) key to setup working arc voltage when it displays Arc_Volt information.

- Page 17 SHENZHEN ONTIME TECHNOLOGY CO.LTD You have to setup the initial torch height manually when start arc. Pierce time setup The unit of the pierce time is 0.1s (second). The procedure of the pierce time setup is the same as above.

- Page 18 SHENZHEN ONTIME TECHNOLOGY CO.LTD time. During the IHS test procedure you can press the ENTR key to stop the procedure manually. After the IHS test procedure, press the MENU key to return to standby status while menu item select interface.

- Page 19 SHENZHEN ONTIME TECHNOLOGY CO.LTD Press the MENU key once while standby, the controller will enter into parameter setup interface, then press the UP and DOWN arrow key at the same time for about 3 seconds, then release the key, the controller will enter into inner parameters setup interface.

- Page 20 SHENZHEN ONTIME TECHNOLOGY CO.LTD motor. This parameter defines the upward speed of torch lifting motor during initial height setup procedure. Range: MIN_PWM-MAX_PWM,default:30. IhsDN PWM:The IHS downward PWM value of the lifting motor. This parameter defines the downward speed of torch lifting motor during initial height setup procedure.

- Page 21 SHENZHEN ONTIME TECHNOLOGY CO.LTD Range: 5-50V, default: 15. BRAKE_EN: Motor reverse brake enable control. 0: disable motor brake. 1 : enable brake. Default: 1. AUTO_AMP:Auto amplification value. This parameter defines the sensitivity to the arc voltage deviation. If this value is set too high, the lifter positioning during auto height control will become unstable and prone to oscillation.

- Page 22 Range: MIN_PWM-MAX_PWM, default: 100. ADJ_RANG:Arc voltage intelligent adjustment range. The AVC118 controller has an intelligent arc voltage adjustment function. Supposing the initial arc voltage is set too low, the cutting torch will be also too close to the workpiece, and...

- Page 23 SHENZHEN ONTIME TECHNOLOGY CO.LTD torch nozzle during cutting. The intelligent arc voltage adjustment function make it possible to cut the left part of an whole job without collision temporally, but the user should check the cutting torch immediately after current job.

- Page 24 SHENZHEN ONTIME TECHNOLOGY CO.LTD 0: Disable the pierce procedure. 1: Enable the pierce procedure. default: 1. FAIL_LFT: Torch lifting time after arc off. Unit:0.1second. 0: Disable torch lifting after arc off. Range: 0-100, default: 10. COL_STOP: Torch collision stop enable control.

- Page 25 SHENZHEN ONTIME TECHNOLOGY CO.LTD Range:10-60,default: 20. DEFAULT:Restore default value. When this parameter is set to the value of 18 and press the MENU key to exit, all inner parameters will restore to the default value, and this parameter will restore to...

- Page 26 SHENZHEN ONTIME TECHNOLOGY CO.LTD TROUBLE SHOOTING Error Description Possible cause Corrective action When power on, the Reinstall 1、The IHS proximity torch moves upward proximity switch switch not installed continuously.(if the IHS properly. properly. proximity switch Replace 2、The IHS proximity used )...

Need help?

Do you have a question about the AVC118 and is the answer not in the manual?

Questions and answers

How to change language in avc 118

How to change language

how can i change language it shows strange characters like kvCrcVg instead of Eng