Table of Contents

Advertisement

IM279-TS

LT- 7 TRACTOR TROUBLESHOOTING

JUNE 1995

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However, your

overall safety can be increased by

proper installation ... and thought-

ful operation on your part. DO

NOT INSTALL, OPERATE OR

REPAIR

THIS

EQUIPMENT

WITHOUT READING THIS MAN-

UAL AND THE SAFETY PRE-

CAUTIONS

CONTAINED

THROUGHOUT.

And,

most

importantly, think before you act

and be careful.

TROUBLE SHOOTING GUIDE

World's Leader in Welding and Cutting Products

Premier Manufacturer of Industrial Motors

Sales and Service through Subsidiaries and Distributors Worldwide

22801 St. Clair Ave. Cleveland, Ohio 44117-1199 U.S.A. Tel. (216) 481-8100

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Lincoln LT-7

- Page 1 IM279-TS LT- 7 TRACTOR TROUBLESHOOTING JUNE 1995 Safety Depends on You Lincoln arc welding and cutting equipment is designed and built with safety in mind. However, your overall safety can be increased by proper installation ... and thought- ful operation on your part. DO...

- Page 2 Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199. BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

- Page 3 SAFETY ARC RAYS can burn. ELECTRIC SHOCK can kill. 3.a. The electrode and work (or ground) circuits 4.a. Use a shield with the proper filter and cover are electrically “hot” when the welder is on. plates to protect your eyes from sparks and Do not touch these “hot”...

- Page 4 SAFETY WELDING SPARKS can CYLINDER may explode cause fire or explosion. if damaged. 6.a. Remove fire hazards from the welding area. 7.a. Use only compressed cylinders If this is not possible, cover them to prevent containing the correct shielding gas for the the welding sparks from starting a fire.

-

Page 5: Table Of Contents

• Never work on the inside of the machine without removing the input power. You can receive a life threatening electrical shock if you fail to do this. Only qualified technicians should perform installation, maintenance, and troubleshooting work on the machine. LT-7 TRACTOR... -

Page 6: Theory Of Operation

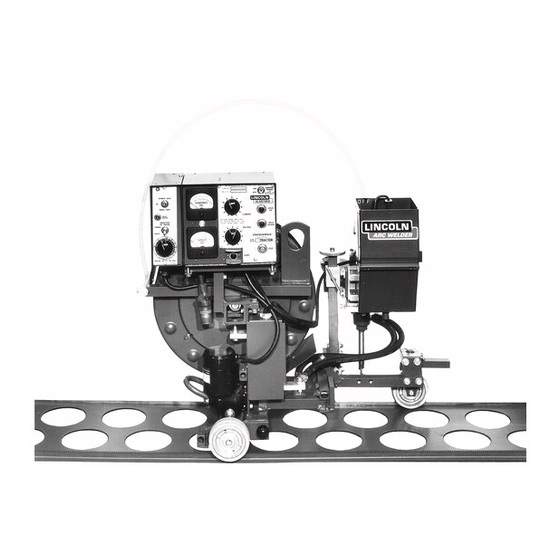

The LT-7 tractor is a compact, lightweight, DC, single arc tractor. It is capable of operating with 3/32” through 3/16” electrode with a current carrying capacity of 1000 amps. The LT-7 has a travel range from 6 to 70 inches per minute. -

Page 7: Control Logic And Travel Boards

Reed switch 4CR protects the internal grounding el motor to satisfy the control settings. wire circuitry. In the event that abnormally high current NOTE: Unshaded areas of the Block Logic Diagram are the subject of discussion LT-7 TRACTOR... -

Page 8: Variable Voltage Board

The variable voltage board also generates a low volt- age which is applied to the electrode during the inch NOTE: Unshaded areas of the Block Logic Diagram are the subject of discussion LT-7 TRACTOR... - Page 9 NOTES LT-7 TRACTOR...

- Page 10 How To Use Troubleshooting Guide WARNING Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual.

-

Page 11: Troubleshooting And Repair

CAUTION complete. Sometimes machine failures appear to be due - If you return a PC board to The Lincoln to PC board failures. These problems can Electric Company for credit, it must be in the sometimes be traced to poor electrical con- static-shielding bag. -

Page 12: Troubleshooting Guide

Replace. CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for electrical technical troubleshooting assistance before you proceed.Call 216-383-2531 or 1-800- 833-9353... -

Page 13: Troubleshooting Guide

#532. See wiring diagram. CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for electrical technical troubleshooting assistance before you proceed.Call 216-383-2531 or 1-800-... - Page 14 •A defective control board. CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for electrical technical troubleshooting assistance before you proceed.Call 216-383-2531 or 1-800-...

- Page 15 See wiring diagram. CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for electrical technical troubleshooting assistance before you proceed.Call 216-383-2531 or 1-800-...

- Page 16 • A defective power source. CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for electrical technical troubleshooting assistance before you proceed.Call 216-383-2531 or 1-800-...

- Page 17 CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for electrical technical troubleshooting assistance before you proceed.Call 216-383-2531 or 1-800- 833-9353...

- Page 18 CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for electrical technical troubleshooting assistance before you proceed.Call 216-383-2531 or 1-800- 833-9353...

- Page 19 CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for electrical technical troubleshooting assistance before you proceed.Call 216-383-2531 or 1-800-...

- Page 20 CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for electrical technical troubleshooting assistance before you proceed.Call 216-383-2531 or 1-800-...

- Page 21 See wiring diagram. CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for electrical technical troubleshooting assistance before you proceed.Call 216-383-2531 or 1-800-...

- Page 22 3. The control board may be faulty. CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for electrical technical troubleshooting assistance before you proceed.Call 216-383-2531 or 1-800-...

- Page 23 CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for electrical technical troubleshooting assistance before you proceed.Call 216-383-2531 or 1-800- 833-9353...

- Page 24 CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for electrical technical troubleshooting assistance before you proceed.Call 216-383-2531 or 1-800- 833-9353...

- Page 25 CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for electrical technical troubleshooting assistance before you proceed.Call 216-383-2531 or 1-800- 833-9353...

- Page 26 CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for electrical technical troubleshooting assistance before you proceed.Call 216-383-2531 or 1-800- 833-9353...

- Page 27 Replace relay. CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for electrical technical troubleshooting assistance before you proceed.Call 216-383-2531 or 1-800-...

- Page 28 3. The travel board may be faulty. CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for electrical technical troubleshooting assistance before you proceed.Call 216-383-2531 or 1-800-...

- Page 29 3. The travel board may be faulty. CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for electrical technical troubleshooting assistance before you proceed.Call 216-383-2531 or 1-800-...

-

Page 30: Pc Board Status Lights

PC BOARD STATUS LIGHTS Table B.1 is a summary of the on/off states of the LED’s on the Control Board, Logic Board and Voltage Board for various conditions of the LT-7. Table B.2 lists the functions that these LED’s indi- cate. - Page 31 B-22 B-22 TROUBLESHOOTING AND REPAIR L5927 LOGIC FIGURE B.1 Logic P.C. Board LED Locations L5394 VARIABLE VOLTAGE FIGURE B.2 Voltage P.C. Board LED Locations L6959 CONTROL FIGURE B.3 Control P.C. Board LED Locations LT-7 TRACTOR...

- Page 32 B-23 B-23 NOTES LT-7 TRACTOR...

-

Page 33: Wire Drive Motor Test

TROUBLESHOOTING AND REPAIR WIRE DRIVE MOTOR TEST WARNING Service and repair should only be performed by Lincoln Electric factory trained personnel. Unauthorized repairs performed on this equipment may result in danger to the technician or machine operator and will invalidate your factory warranty. - Page 34 TEST POINTS RESISTANCE DC VOLTAGE Lead #539 to #541 4 to 5 ohms 0 to 90VDC Armature Lead #626 to #627 750 to 850 ohms 90 to 120VDC Field Winding All leads 500,000 ohms min. NONE motor shell LT-7 TRACTOR...

-

Page 35: Travel Motor Test

TROUBLESHOOTING AND REPAIR TRAVEL MOTOR TEST WARNING Service and repair should only be performed by Lincoln Electric factory trained personnel. Unauthorized repairs performed on this equipment may result in danger to the technician or machine operator and will invalidate your factory warranty. - Page 36 Lead #559 to #561 27 ohms* 0 to 90VDC* Armature* Lead #546 to #547 500 to 650 ohms* 90 TO 110VDC* Field Winding* All leads to motor 500,000 ohms min. NONE shell *DENOTES OLDER UNITS WITH FIELD WINDING LT-7 TRACTOR...

- Page 37 B-28 B-28 TROUBLESHOOTING AND REPAIR TRAVEL MOTOR TEST ( continued ) #594 #595 FIGURE B.5 Travel Motor Connector Pins #559 #647 #561 #646 FIGURE B.6 Travel Motor Connector Pins (Older Units with Powered Field.) LT-7 TRACTOR...

- Page 38 B-29 B-29 NOTES LT-7 TRACTOR...

-

Page 39: Wire Drive Motor Removal And Replacement

WIRE DRIVE MOTOR REMOVAL AND REPLACEMENT WARNING Service and repair should only be performed by Lincoln Electric factory trained personnel. Unauthorized repairs performed on this equipment may result in danger to the technician or machine operator and will invalidate your factory warranty. - Page 40 Note: The inspection cover plate has to be remove (Step #5) to gain access to the two socket head cap screws. 7. Carefully remove the motor(with pinion gear) from the gear box assembly. LT-7 TRACTOR...

-

Page 41: Diagrams

DIAGRAMS CONNECTION SCHEMATIC - M15342 LT-7 TRACTOR... - Page 42 DIAGRAMS CONTROL BOX WIRING DIAGRAM- L7460 3 AMP CIRCUIT BREAKER LT-7 TRACTOR...

- Page 43 NOTES LT-7 TRACTOR...

Need help?

Do you have a question about the LT-7 and is the answer not in the manual?

Questions and answers