Summary of Contents for KUHN Quantron S

- Page 1 Complementary instructions RC007BGB B Control box Software version: 3.70 RC007BGB B - English - 11-2009...

-

Page 3: Dear Owner

Designated use of the machine The Quantron S control box is exclusively designed for monitoring the application rate of Kuhn seed drills. Any use outside this application is not permitted. The intended use of the machine includes following all operation, maintenance and repair recommendations given by the manufacturer, and using only genuine spare parts, equipment and accessories, as recommended by the manufacturer. -

Page 4: Table Of Contents

Control box Quantron S $Contents Dear Owner ........................1 Contents..........................2 Control box identification....................5 Front view............................5 Manufacturers' marking ........................6 Safety..........................7 Description of symbols used in this document................7 Safety instructions ...........................8 General description......................10 Description............................10 Technical specifications ........................ 11 Description of control elements....................12 Menu structure..........................14 Assembly and fitting ....................15... - Page 5 Control box Quantron S Machine use ......................... 24 Adjustments before first use......................24 Calibration of forward speed......................25 Preliminary adjustments at work ....................27 Stationary calibration test ......................31 Modification of the parameters ..................... 37 Flow test with regards to an area ....................39 Sowing a seed already stored.......................

- Page 6 Control box Quantron S Alarm messages......................58 Alarm signification .........................58 Deleting a breakdown or an alarm ....................60 Trouble shooting guide....................61 Maintenance and storage ....................63 Connecting diagrams....................64 Limited warranty......................69 Contents...

-

Page 7: Control Box Identification

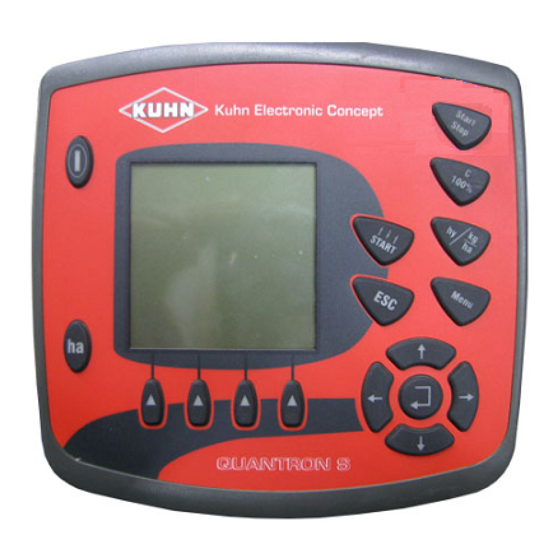

Control box Quantron S $Control box identification 1. Front view Control box identification... -

Page 8: Manufacturers' Marking

Quantron S 2. Manufacturers' marking Please write below the type and serial number of the machine. This information is to be indicated to the dealer for all spare parts orders. Type: QUANTRON S Serial no.: Software version: Control box identification... -

Page 9: Safety

Control box Quantron S $Safety 1. Description of symbols used in this document This symbol indicates a potentially hazardous situation that if not avoided, could result in serious bodily injury. This symbol is used to identify special instructions or procedures which, if not followed strictly, could result in machinery damage. -

Page 10: Safety Instructions

Control box Quantron S 2. Safety instructions Introduction The operator must follow the safety instructions in this manual and in the machine's operator's manual as well as respect the warnings posted on the machine. Any use other than the designated operation is at the risk and responsibility of the operator. - Page 11 Never let anyone operate the machine who is not trained to do so. Should you have any difficulties in understanding certain parts in this manual, please contact your KUHN dealer. Precautions to take before using the control box Place the control box so that it cannot interfere with other tractor controls and be activated inadvertently.

-

Page 12: General Description

Control box Quantron S $General description 1. Description Area of use Connection pin for data transfer 39-pin connector: machine wiring harness connection Power circuit Holder: 2 x M8 General description... -

Page 13: Technical Specifications

Control box Quantron S 2. Technical specifications Operating temperature from -10°C to +60°C Storage temperature up to +85 °C Voltage input 12V, range from 10 V to 16 V Shockproof plastic box, IP65 protection classification Screen 160x 160 pixels CE certification... -

Page 14: Description Of Control Elements

Control box Quantron S 3. Description of control elements Distribution stop/start Delete / rollback Switch between the display of the application Rollback to the tramlining counter rate and the display of the hydraulic valve bank position functions Access to the general menu... - Page 15 Control box Quantron S Display The screen displays information relative to the current machine status, with the possibility to select of modify the values. The main information relative to the machine's use are displayed during work. Description of screen zones...

-

Page 16: Menu Structure

Control box Quantron S 4. Menu structure General description... -

Page 17: Assembly And Fitting

An electric power supply cable for another tractor can be ordered under code 83233002. The cable is connected by the Kuhn dealer to the plus lugs (brown) and the tractor battery earth (blue). For a regular and constant electricity supply for the machines' controls, connect the electricity power cable directly to the battery. -

Page 18: Control Box Connection

- Connect the machines' 39-pin cable. - Connect the control box to the power supply (See chapter Electrical power supply). The Quantron S control box is factory set for the machine supplied. Only connect the supplied control box to the concerned machine. -

Page 19: Putting Into Service

- The control box is properly connected to the tractor. - Minimum voltage: 12 V - Press Quantron S control box Start/Stop button (1). - The start screen appears after a few seconds. - A start menu is displayed during a few seconds. -

Page 20: Access And Menu Navigation

Control box Quantron S 2. Access and menu navigation MENU key (1) - From the work screen, is used to access the menu (see menu tree structure). - From the menu, is used to return directly to the work screen. -

Page 21: Basic Adjustments

Control box Quantron S 3. Basic adjustments Basic adjustments are set in the "System/Test" menu. Brightness/Contrast - Press on the button «F3 (-)» (3), to reduce the brightness (1). - Press on the button «F4 (+)» (2), to increase the brightness (1). - Page 22 Control box Quantron S Info This menu is only used for information purposes. The menu shows how the machine is equipped. - 1: Width of seed drill (m) - 2: Number of low level sensors mounted (1 or 2) - 3: 2 Cylinder for tramlining: The machine is fitted with a second cylinder for tramlining.

- Page 23 Control box Quantron S Display configuration The screen has 2 free display areas. Following values can be displayed: - Working speed (Km/h) - Blower speed - Metering unit "opening position" - Time - Area - Quantity sown "kg trip" - Distance covered "m-trip"...

- Page 24 Control box Quantron S Specific functions Text entry (Example: seed name) Some menus enable creating a name. Entry area Fully deleting a name Keys for navigating in the letter area Key for confirming the letter entry Function key (OK) for confirming the selected...

- Page 25 Control box Quantron S Modifying a letter: - Select the letter in area (1) and position the cursor using keys (6). - Using arrow keys (3), move the cursor on the letter selected in the letter area (7). - Press Enter key.

-

Page 26: Machine Use

Control box Quantron S $Machine use 1. Adjustments before first use Read the operators' manual before using the machine. - Make sure that all requested options are set on the machine. Proceed with the various pre-controls and adjustments indicated in the operators' manual. -

Page 27: Calibration Of Forward Speed

Control box Quantron S 2. Calibration of forward speed Factors such as spinning or soil condition can influence the forward speed measuring and consequently the application rate. - Calibrate the speed sensor for 100m to take sowing conditions into account. - Page 28 Control box Quantron S If the number of impulses is known, it can be entered by hand. - Select the "Machine km/h" submenu. - select Imp/100m (2). - Press Enter key. - Enter the number of impulses. See chapter Entering values using the arrow keys.

-

Page 29: Preliminary Adjustments At Work

Control box Quantron S 3. Preliminary adjustments at work Working mode Drilling can be carried out in MANUAL or AUTOMATIC mode. The normal working mode is the AUTOMATIC mode. The manual working mode can be used for ex. if the speed sensor is faulty. - Page 30 Control box Quantron S Adjusting the blower alarm limit values - Starting from the "main menu", select "hopper configuration". - Select the "blower speed" submenu. - Select value (1). - Press Enter key. - Indicate the minimum speed alarm value (see table for values).

- Page 31 Control box Quantron S Tramlining rhythm Setting the tramlining rhythm according to the wheel track and the treatment width. - Starting from the "main menu", select "hopper configuration". - Press Enter key. - Selecting the "tramlining" sub-menu. - Press Enter key.

- Page 32 Control box Quantron S Example 3: Asymmetrical rhythms - Press on function F2 (6). - With a treatment width of 24 m, the control box calculates the AS 6 rhythm (2) Drilling starts with the rhythm in position 4 (3).

-

Page 33: Stationary Calibration Test

Control box Quantron S 4. Stationary calibration test Before loading the seeds and carrying out the flow test, set the metering unit in the position adapted to the seed variety (small or large seeds). Select type of seed - As from the "main menu", select the "seed settings"... - Page 34 Control box Quantron S - If needed, change the seed name • Select the name line (2). • Press Enter key. We recommend to rename the seed to differentiate the various seeds stored. Machine use...

- Page 35 Control box Quantron S Volume - Select the "Appl. (kg/ha)" submenu. - Press Enter key. - Enter required application rate using the arrow keys. See chapter Entering values using the arrow keys, Page 23. - Confirm entry by pressing Enter key.

- Page 36 Control box Quantron S Carry out the calibration test The metering unit opening is set to determine the density of seeds sown. Carry out regular calibration tests to check that the seed drill is properly adjusted. Carry out the calibration test with the...

- Page 37 Control box Quantron S - Shortly rotate the metering unit in order to fill the cells. - Press on the button Start/Stop. On machine driven hydraulically or electrically, the metering unit will automatically rotate by one turn to fill the cells.

- Page 38 Control box Quantron S The control box calculates the new opening required and displays it on the screen. - Adapt metering unit opening according to the value displayed on the screen (See corresponding manual). In most cases, it is not necessary to adjust the metering unit opening, as the electric or hydraulic drive adjusts the rotation speed.

-

Page 39: Modification Of The Parameters

Control box Quantron S Proceed with a new calibration test After presetting the metering unit opening, run a calibration test to know the exact density of seeds. - Select the "Seed settings" sub-menu. - Press Enter key. - Move browser down to position the cursor on the "Optimize and calibrate"... - Page 40 Control box Quantron S The screen displays: • Metering unit "opening position" • Required small seed slide position • Minimum and maximum application rate values • Minimum and maximum travel speed values Accept - If the possible working zones (outlined values) are convenient, confirm by selecting "Accept".

-

Page 41: Flow Test With Regards To An Area

Control box Quantron S The calibration test is accepted. Settings will be stored in the Private list under the saved name. - Press Enter key. - The machine is ready for work. Optimize and test - Select "Optimize and test". - Page 42 Control box Quantron S - Choose test area using the corresponding key. • Example: F2 for 1/10 ha - Position a container under the metering unit to collect the seeds. - Press Enter key. - Press on the button Start/Stop.

-

Page 43: Sowing A Seed Already Stored

Control box Quantron S 7. Sowing a seed already stored When selecting a seed already stored, the screen displays the latest values stored. - As from the "main menu", select the "seed settings" submenu. - Select the "Seed list privat" sub-menu (1). -

Page 44: Deleting A Seed

Control box Quantron S 8. Deleting a seed A seed stored in the "Seed list privat" can be deleted in the following cases: • The "Seed list privat" is full. • The seed will no longer be sown. - As from the "main menu", select the "seed settings"... -

Page 45: Functioning During Work

Control box Quantron S $Functioning during work 1. Distribution stop/start - Lower the marker and the coulter bar. Sowing start - Start metering unit in the following situations: • Sowing start • Power on. - Press on the button Start/Stop. - Page 46 Control box Quantron S Drilling in field corners To maintain the seed quality in the corners, use the premetering function. - Press 2 times Start/Stop key. The metering unit will run for 6 seconds in a premetering function. Move forward with the tractor while premetering is running.

- Page 47 Control box Quantron S Stopping tramlining temporarily The button "Pause" avoids that the counting is continued whilst going around an obstacle. Condition: the working screen must be displayed. - Press key F1 (1) (REST). If the seed drill is fitted with a circuit selector: - Press on the button hy: The screen displays the hydraulic selector functions.

-

Page 48: Hydraulic Valve Bank

Control box Quantron S 2. Hydraulic valve bank Functions available For Speedliner 3000/4000/6000. - Press on the button hy: The screen displays the hydraulic selector functions. Functions not activated: • (1): The side markers can be controlled by the tractors' hydraulic outlet. -

Page 49: Tramlining Rhythm Adjustment

Control box Quantron S Functions available for the BTFR coulter - Press on the button hy: The screen displays the hydraulic selector functions. • (1): Side marker control • (2): Coulter bar control White background: Functions not activated Black background: Markers (1) and coulter bar (2) can be operated. -

Page 50: Operating Data

Control box Quantron S 4. Operating data This menu is used for saving data of 200 fields. - As from the "Main menu", select the "Field data" menu. Data can be saved either in field file already saved (resuming work that had been stopped) or by creating a new file. - Page 51 Control box Quantron S Starting field data Display of the number of files still available Submenu used for starting the field data Identification area Values saved Display of date and time of drilling start Display of date and time of drilling end...

-

Page 52: Variation Of The Seed Rate

Control box Quantron S Deleting one or several files Deleting a file: - As from the "Field data" menu, select the "Delete file data" submenu. - Press Enter key. - Select the file to delete in the list - Delete the file by pressing Enter key. -

Page 53: Daily Counters

Control box Quantron S 6. Daily counters - Press on the button ha. The screen displays: - Quantity sown (independently from seed variety) (1) - Area sown (2) - Surface covered (3) since the last reset. Deleting the daily counter (4) - Move browser downwards to select the "Delete trip... -

Page 54: System/Test

Control box Quantron S $System/Test 1. Sensor check The "Test/diagnosis" menu monitors and indicates the status of the machine sensors or actors. This menu is only used for information purposes. - As from the "System - Test" menu, select the "Test - diagnosis"... - Page 55 Control box Quantron S Example: Metering unit Sensor short circuit (Function not switched on) Wire cut Sensor function area 3/4 : Sensor is deactivated Sensor is activated Example: Electric motor - Press on the button F1 (2) and keep it pressed down.

-

Page 56: Alarm Configuration

Control box Quantron S 2. Alarm configuration The submenu Alarm configuration allows to deactivate following sensors if they are broken. The machine can continue to work. • Blower • Calibration flap • Low level sensors (UP/DOWN) • Power harrow sensor Only the sensors which are mounted and stored in the menu "Machine options"... -

Page 57: Service: Machine Configuration

Contact your authorised Kuhn dealer to get the password. - (1): The Quantron S control box is factory set for the machine supplied. - (2): This menu is reserved and accessible only by a KUHN technician. -

Page 58: Machine Options

"Machine options". Wrong entries may influence the working quality and even provoke damage the machine. Contact your authorised Kuhn dealer to get the password. (1) Identification area: Check machine name. - Press Enter key. - Enter new designation. (2): Width of seed drill (m) - Press Enter key. - Page 59 Control box Quantron S Move downwards using the arrow key until page 2/2 appears. (1) Check width of mounted metering unit. - There are 2 values possible: 150 mm or 200 mm. - Press Enter button to select one of the 2 possible values.

-

Page 60: Alarm Messages

Control box Quantron S $Alarm messages When an anomaly is detected, an alarm screen is displayed and a permanent buzzer sounds. 1. Alarm signification Description Error messages • Possible causes • The metering unit does not rotate Fault in metering unit! although the machine is lowered. - Page 61 Control box Quantron S Description Error messages • Possible causes Only on machine with 2 low level sensors • Left hopper empty • The blower exceeds maximum authorized speed value. Blower speed too high The alarm disappears automatically if the...

-

Page 62: Deleting A Breakdown Or An Alarm

Control box Quantron S 2. Deleting a breakdown or an alarm An alarm on the screen is simultaneously combined with a sound alarm. Deleting an alarm Look for the cause, and do what is needed. Refer to the seed drill operator's manual. -

Page 63: Trouble Shooting Guide

Control box Quantron S $Trouble shooting guide Problem Cause Remedy - Verify the distance between the sensor The electric or hydraulic drive The control box does not receive and the tips of the metal teeth on the rotates non stop during the pinion. - Page 64 Control box Quantron S Problem Cause Remedy - Check the power connection - Connect wire marked L of wiring The pre-emergence marker harness Y to the solenoid valve. solenoid valve does not Bad connection - The wire marked R of wiring harness Y function.

-

Page 65: Maintenance And Storage

Quantron S $Maintenance and storage The control box does not require any particular maintenance, in the case of a breakdown or a malfunction call your KUHN technician. For any welding operation on the machine, disconnect the electricity supply of the machine... -

Page 66: Connecting Diagrams

Control box Quantron S $Connecting diagrams Connecting diagrams... - Page 67 Control box Quantron S Connecting diagrams...

- Page 68 Control box Quantron S Connecting diagrams...

- Page 69 Control box Quantron S Connecting diagrams...

- Page 70 Control box Quantron S Connecting diagrams...

-

Page 71: Limited Warranty

Control box Quantron S $Limited warranty Limited warranty... - Page 72 Control box Quantron S Limited warranty...

Need help?

Do you have a question about the Quantron S and is the answer not in the manual?

Questions and answers