Conmet PreSet Installation Instructions

Seal & spacer

Hide thumbs

Also See for PreSet:

- Installation instructions manual (2 pages) ,

- Service manual (76 pages)

Table of Contents

Advertisement

Quick Links

PreSet

/ PreSet Plus

®

Seal & Spacer

Installation Instructions

Replace the seal any time the hub is removed from the spindle.

If the spacer has seen duty service, replace the spacer. A new

spacer will ensure proper bearing adjustment is maintained. This

kit contains one wheel seal and one bearing spacer for selected

specific axle type.

Hazard Alert Messages

A Danger alert indicates a hazardous situation which if not

avoided, will result in death or serious injury.

A Warning alert indicates a hazardous situation which if not

avoided, could result in death or serious injury.

A Caution alert indicates a hazardous situation which if not

avoided, could result in minor or moderate injury.

A note includes additional information that may assist the

technician in service procedures.

Prior to installing the bearing spacer in this kit, verify the

hub is a ConMet PreSet or PreSet Plus. Only ConMet PreSet

and PreSet Plus hubs are designed to fit these components

and function properly. Use of this bearing spacer in hubs

other than ConMet PreSet or PreSet Plus could result in

catastrophic wheel end failure.

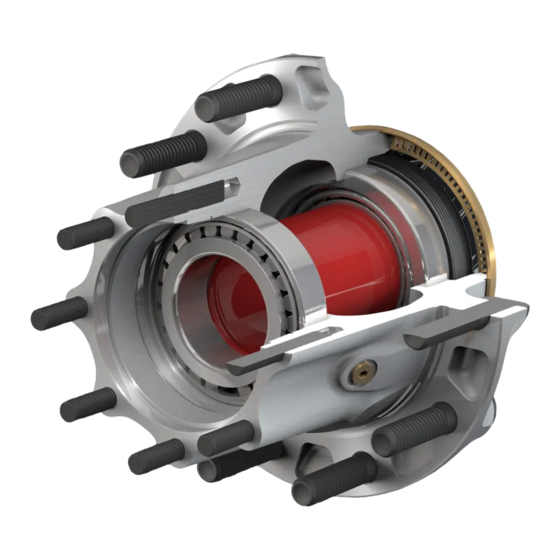

PreSet Plus hubs with an integrated spindle nut were introduced

in 2013. If your hub is equipped with the integrated PreSet Plus

spindle nut (see Figure 1), make note of the different require-

ments in the following instructions.

PreSet Plus

hubs feature

an integrated

spindle nut

held in place

with a retaining ring.

Figure 1

PreSet Plus

Part No. 10081721 Rev. A 11-2017

©2017 Consolidated Metco Inc.

Disassembly

1. Remove the spindle nut system.

a. If equipped with a one-piece or multi-piece spindle nut,

follow the manufacturer or OEM guidelines for removal.

®

b. If equipped with a PreSet or PreSet Plus spindle nut, remove

the red locking ring from the spindle nut assembly. Use

caution not to damage the locking ring.

c. For the PreSet spindle nut, remove the spindle nut and slide

the hub off of the spindle.

d. For the PreSet Plus spindle nut, use a breaker bar to

loosen the spindle nut. Be aware that PreSet Plus spindle nut

installation torque is 300 ft-lbs for steer hubs and 500 ft-lbs for

drive and trailer hubs. After the spindle nut is initially loosened

with a breaker bar, loosen the spindle nut to remove the hub

from the spindle. The internal spiral snap ring will act as a hub

puller and will aid in removal of the hub from the spindle. Do

not exceed 50 ft-lbs of torque when removing the hub from

the spindle. If the hub will not come off without exceeding this

torque value, remove the spiral snap ring and the spindle nut

assembly and use a conventional hub puller to remove the hub

from the spindle.

e. If part of the seal remains on the spindle, carefully remove

the part of the seal that remains on the seal journal.

2. Remove the outer bearing cone from the hub assembly

being careful not to drop it.

3. Place the hub on its outboard end and remove and discard

the seal.

INNER

BEARING

CONE

SPACER

Figure 2

4. Remove the inner bearing cone and spacer from the hub

assembly (see Figure 2).

Reassembly

1. Place the hub, seal end up, on a clean work surface.

2. Visually inspect the inner bearing cup and cone for signs of

heat, wear or damage. Reference TMC RP644 for proper compo-

nent inspection procedures.

3. Lubricate the inner bearing cone with the same lubricant as

will be used in the hub and install it into the inner bearing cup

(see Figure 3).

If during any bearing inspection there is an indication that the

existing bearing must be replaced, bearing cups and cones must be

®

replaced as a set. You must only replace bearings with ones approved

106922a

for use in PreSet hubs. Non-approved bearings could result in

excessive preload or endplay.

5701 SE Columbia Way, Vancouver, WA 98661 (800) 547-9473

106804c

Consolidated Metco, Inc.

www.conmet.com

•

lubricant as will be used in the hub and install it into

the inner bearing cup (see figure 34).

32

Figure 3

Bearing Cone Assembly for Drive Hub

When using an oil bath system, do not pack the bearing

with grease. Grease will prevent the proper circulation of

axle lubricant and can cause premature wheel seal and

bearing failure.

4. Ensure the hub seal bore is free of rust, dirt, scratches and

14

Consolidated Metco, Inc.

Consolidated Metco, Inc.

sharp edges.

Do not apply any gasket sealant to the seal outer or inner

diameter.

5. Position the seal into the hub bore with the "AIR SIDE" visible.

Use the appropriate ConMet installation plate (see chart below)

and a generic seal tool handle or a flat plate and small mallet

to hammer seal into place. Do not hammer directly on the seal.

Make sure the seal is uniformly bottomed out in the bore. (see

Figure 4). Check to be certain the seal is not cocked and that

the seal inner diameter and the inner bearing turn freely.

5. R

EASSEMBLY

ConMet Seal Installation Plates

33

Axle Type

Part Number

FF Steer

10084010

FL Steer

10084011

R Drive

10084012

TN Trailer

10084013

TP Trailer

10084013

OUTRUNNER OR

SKF SCOTSEAL PLUS XL

STEMCO ENDEAVOR

SEAL

8. Check to be certain the seal is not cocked and that

the seal inner diameter and the inner bearing turn

freely.

Failure to lubricate the inner diameter of the seal, and the seal

journal, may result in premature seal failure.

9. Lubricate the inner diameter of the seal with a light

Figure 4

film of the same lubricant as will be used in the hub.

105744a

10. Turn the hub over, and place it seal end down. For

all drive and trailer hubs, install a bearing spacer. If

6. Turn the hub over, and place it seal-end down. Place the

the spacer has a tapered end, it should face

bearing spacer in the hub cavity ensuring that the small end, if

towards the outboard end of the hub (see figure

36).

present, faces the outboard end of the hub (see Figure 5).

34

Figure 5

Installing the Spacer

7.

106810a

FIGURE 34

– P

S

W

RE

ET

HEE

11. Lubr

lubri

the h

35

106811b

FIGURE 35

105745a

105748a

FIGURE 36

Advertisement

Table of Contents

Summary of Contents for Conmet PreSet

-

Page 1: Installation Instructions

PreSet / PreSet Plus ® ® b. If equipped with a PreSet or PreSet Plus spindle nut, remove the red locking ring from the spindle nut assembly. Use Figure 3 Seal & Spacer caution not to damage the locking ring. - Page 2 Spacer the opposite side of the axle 8 inches to allow the lubricant to 4. For hubs equipped with the integrated PreSet Plus spindle 106874b Figure 9 URE 36 run down the axle housing and into the hub assembly.

- Page 3 HM518410-04 or PS / HM518445-04 or PS NP593561 / NP174964 SET604 NP454561 / NP454964 ConMet, PreSet, and PreSet Plus are registered trademarks of Consolidated Metco Inc. All other trademarks are the property of their respective owners. ©2017 Consolidated Metco Inc. All Rights Reserved.

Need help?

Do you have a question about the PreSet and is the answer not in the manual?

Questions and answers

If pre set hubs have more preload ,what is the desirable air gap/ installation for bendix ws-24 wheel speed sensor?

The desirable air gap for installing a Bendix WS-24 wheel speed sensor with ConMet PreSet hubs that have more preload is 0.020 inches (0.5 mm).

This answer is automatically generated