Advertisement

Quick Links

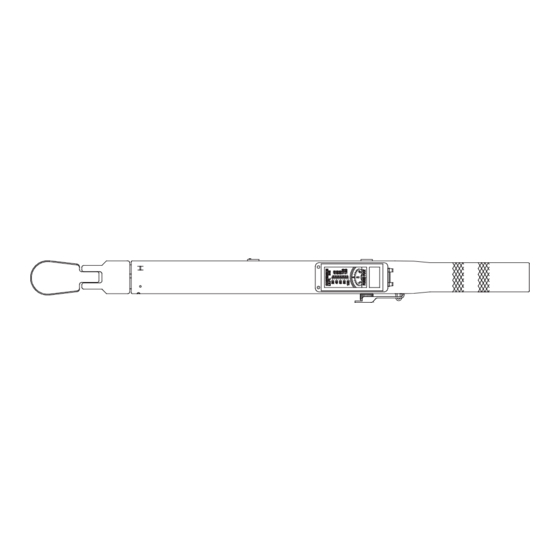

Split Beam Type Torque Wrench

User Manual

Accurate within 4% of the setting from 20% of full scale to full scale

Specifications

Drive

Stock No.

Range Torque

Increments

Length

Flex ratchet models

3/8"

C2FR600H*

100-600 lb. in. 10 lb. in.

17-5/8" 1 lb

3/8"

C2FR100F*

20-l00 lb. ft.

2 lb. ft.

17-5/8" 1 Ib

1/2"

C3FR250F*

40-250 lb. ft.

5 lb. ft.

22-1/8" 3 lbs

Metric reading

3/8"

C2FR14M*

2.2-14 kg•m

0.2 kg•m

17-5/8" 1 lb

1/2"

C3FR34M*

5-34 kg•m

1 kg•m

22-1/8" 3 lbs

Newton meter reading

3/8"

C2FR68N*

14-68 N•m

2 N•m

17-5/8" 1 lb

3/8"

C2FR130N*

25-135 N•m

5 N•m

17-5/8" 1 lb

1/2"

C3FR350N*

60-350 N•m

5 N•m

22-1/8" 3 lbs

Fixed ratchet models

3/8"

C2R100F*

20-100 lb. ft.

2 lb. ft.

17-5/8" 1 lb

3/8"

C2R100FB* **

16-100 lb. ft.

2 lb. ft.

17-1/8" 1 lb

1/2"

C3R250F*

40-250 lb. ft.

5 lb. ft.

22-1/8" 3 lbs

1/2"

C3R250FB* **

40-250 lb. ft.

5 lb. ft.

22-1/8" 3 lbs

Fixed head models

1/2"

C3F250F

50-250 lb. ft.

5 lb. ft.

18-1/2" 2 lbs 11 oz

Metric reading

1/2"

C3F34M

7-34 kg•m

1 kg•m

18-1/2" 2 lbs 11 oz

* Non-Reversible Ratchet

** Black Oxide Finish

Safety warnings and cautions

CAUTION: Torque Wrenches

Overtorquing can cause breakage. Do not exceed rated

torque.

Wear safety goggles. (Users and bystanders)

Wrench can break while breaking fasteners loose. Do not use a

torque wrench to break fasteners loose. Using force against flex

stops on flex head torque wrenches can cause head breakage.

Do not force head of flex head torque wrenches against stops.

A torque wrench that is out of calibration can cause part or tool

breakage.

Calibrate periodically to maintain accuracy. Broken tools and parts

can cause injury

CAUTION: Torque Wrenches

A wrench that is slipping can cause accidents.

On detachable wrenches, make sure the spring-loaded locking pins

that secure sections of the wrench are fully engaged in their locking

pin holes.

Make sure that the socket is properly seated on the nut or bolt.

Always pull (do not push) on the wrench handle and adjust your

stance accordingly.

* Slipping wrench can cause injury

WARNING: Ratchets

Ratchet mechanism may slip or break if dirty. Mismatched or

partially worn parts can cause ratchet to slip or break.

Do not immerse sealed ratchet in fluids.

Do not replace worn parts individually, use entire contents of the

service kit.

Ratchets that slip or break can cause injury.

Introduction

CAUTION: Do not use a torque wrench to break tight fasteners

loose. This can damage the tool and result in inaccurate set-

tings.

Precision Instruments Split-beam series torque wrenches are

precision measurement tools, designed to torque in the clock-

wise direction and guaranteed accurate within 4% of the set-

ting from 20% of full scale to full scale.

An innovative "split beam" torque measuring mechanism pro-

vides consistent accuracy throughout the torque setting range.

Weight

Because no coil spring is used, there is no need to "work-in" a

Split-beam series torque wrench before using it the first time

8 oz

during a work period. Nor is it necessary to adjust to the lowest

torque setting after use.

8 oz

In use, the wrench clicks and provides a few degrees of free

6 oz

movement when the desired torque is reached. When pres-

sure on the wrench is completely released, the wrench auto-

8 oz

matically resets for the next application.

6 oz

• Setting torque on adjustable wrenches is fast and easy be-

cause there is no spring tension on the set knob.

8 oz

• Torque setting is lockable on adjustable wrenches for repeti-

8 oz

tive applications.

6 oz

• Hand-hold position on pre-set wrenches is less critical than

with other click-type torque wrenches.

• The wrench length is designed to provide the leverage re-

8 oz

quired for maximum torque applications. The length also

8 oz

provides the needed reach for those-hard-to-get-at places.

6 oz

• Adjustable models have a convenient conversion scale lo-

6 oz

cated just above the scale window.

• The torque wrenches are chrome plated for appearance and

easy cleanup, and knurled handles help to provide a slip

resistant grip.

IN1201-PI

Instructions

Setting the torque wrench

For adjustable models with set knob:

Pull back on the lock lever to unlock the set knob. With the

set knob turned to the lowest value, turn the knob clockwise

to the desired value indicated at the set mark, located at the

top center of the scale window. If the value is exceeded,

back off and approach the proper setting from the low side.

Close the lock lever to lock the set knob at the torque set-

ting.

Torquing fasteners

Apply torque to fasteners by pulling the wrench smoothly.

When the torque setting is reached, a click will be heard as

the wrench releases. When you completely release the

pressure, the wrench automatically resets for the next

torque application.

Calibration

Periodic calibration is necessary with normal use. This

helps assure accurate readings and properly applied torque.

For additional information, check with your Precision Instru-

ments representative.

Ratchet maintenance

Ratchet service kits are available for maintaining the

wrenches at optimum operating efficiency. Check with your

Precision Instruments representative for the proper service

kit.

Split-Beam Series torque wrenches are designed to measure torque in the clockwise direction only.

Non-reversing Ratchet

(3/8" sq.dr. )

Fixed Head (F)

Flex Ratchet (FR)

or

Fixed Ratchet (R)

Non-reversing Ratchet

(1/2" sq.dr. )

Printed in U.S.A.

Torque wrench head styles

Split-beam series torque wrenches are manufactured in

three different head styles: flex ratchet (FR-models), fixed

ratchet (R-models) and fixed head (F-models). Preset mod-

els (CP) are available in a fixed ratchet and fixed head style.

Flex ratchet models provide a smooth ratcheting action for

efficiency and reduced operator fatigue. They flex 15° up

and down for additional knuckle clearance and the ability to

work around obstructions.

Fixed ratchet models have the same ratcheting action as

the flex ratchet head torque wrenches. They differ in the pin

that secures the ratchet head to the torque body. The pin on

fixed ratchet models eliminates up and down movement and

secures the head rigidly in line with the torque body.

Fixed head torque wrenches do not have flex or ratcheting

features. The square drive is fixed. This model is ideal for

many assembly line operations.

If Your Torque Wrench Needs Repair

1. Send it to an authorized Precision Instruments Service

Center, or give it to your Precision Sales representative. Do

not attempt to repair it yourself.

2. If the warranty is no longer in effect, your Precision

Instruments Customer Service Representative will contact

you with repair charges for your approval before being

repaired.

3. A series of testers are available from Precision Sales

for checking the accuracy of your Torque Wrench. See

your Precision Sales representative for more information.

NOTE:

These specifications were in effect at the time of publication. Specifications may

change. Consult your Precision Instruments Representative for current specifications

Scale Window

Knurled Handle

Conversion Scale

Lock Lever

Set Mark

Locked Position

Set Knob

.

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Precision instruments C2FR600H

- Page 1 If Your Torque Wrench Needs Repair For additional information, check with your Precision Instru- stance accordingly. 1. Send it to an authorized Precision Instruments Service ments representative. * Slipping wrench can cause injury Center, or give it to your Precision Sales representative. Do not attempt to repair it yourself.

- Page 2 0.945 1260 1480 PRODUCTS ARE FREE FROM DEFECTS IN WORKMANSHIP AND 400 lb.ft. 31660 27700 24227 19176 17663 MATERIALS. Precision Instruments will repair or replace these tools which fail to 30mm 1.181 1820 2520 2940 500 lb.ft. 39576 34592 30284...

- Page 3 Setting the Setting the Setting the Setting the Precision Instruments Precision Instruments Precision Instruments Precision Instruments C-Line Click-Type C-Line Click-Type C-Line Click-Type C-Line Click-Type Torque Wrench Torque Wrench Torque Wrench Torque Wrench Hold the Hold the Hold the Hold the...

Need help?

Do you have a question about the C2FR600H and is the answer not in the manual?

Questions and answers