Advertisement

Quick Links

DBI SALA 8518579 Advanced Digital 200 Series Winch

DBI SALA 8518581 Advanced Digital 200 Series Winch

DBI-SALA ADVANCED DIGITAL WINCH

This manual is intended to meet industry standards, including OSHA

1910.146 and ANSI Z117.1, and should be used as part of an employee

WARNING: This product is to be used as part of a complete system.

These instructions must be provided to the user of this equipment. The

user must read and understand these instructions before using this

equipment. The user must follow the manufacturer's instructions for

each component of the complete system. Manufacturer's instructions

must be followed for proper use and maintenance of this product.

Alterations or misuse of this product, or failure to follow instructions

may result in serious injury or death.

IMPORTANT: If you have questions on the use, care, application, or

suitability for use of this safety equipment, contact DBI-SALA.

IMPORTANT: Before using this equipment record the product

identifi cation information from the ID label on the winch in the

inspection and maintenance log in section 9.0 of this manual.

Form: 8511324 Rev: D

netzerotools.com

netzerotools.com

Instructions for the following series products:

See the back pages for specifi c model numbers

USER INSTRUCTION MANUAL

training program as required by OSHA.

netzerotools.com

Digital Winch

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for 3M DBI SALA 8518581

- Page 1 Digital Winch See the back pages for specifi c model numbers DBI SALA 8518579 Advanced Digital 200 Series Winch DBI SALA 8518581 Advanced Digital 200 Series Winch USER INSTRUCTION MANUAL DBI-SALA ADVANCED DIGITAL WINCH This manual is intended to meet industry standards, including OSHA 1910.146 and ANSI Z117.1, and should be used as part of an employee...

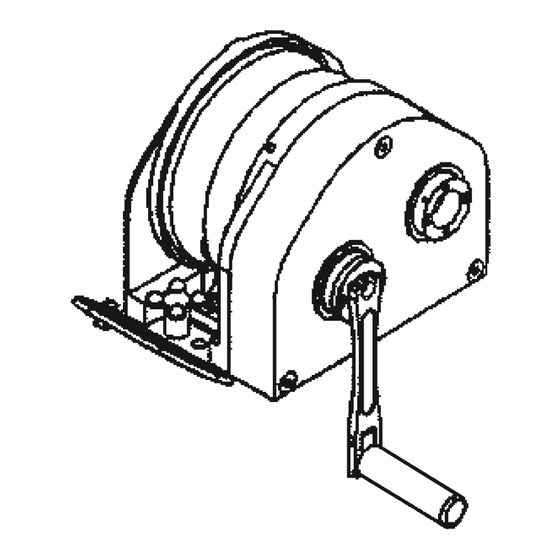

- Page 2 netzerotools.com Figure 1 - Parts Identifi cation Secondary Drive Hub 9:1 retrieval ratio Primary Drive Hub 4:1 retrieval ratio Winch Cable Retainer Spring Carrying Handle Permanent Crank Arm Manual Drive Hubs (Optional) Power Drive Hub (Optional) Universal Mounting Plate Removable Crank Arm Power Drive Clutch (Optional) (Optional)

- Page 3 netzerotools.com DESCRIPTIONS Digital Winches: 100 Series Winch: 100 feet (30 m) of 3/16 inch (5 mm) wire rope. 200 Series Winch: 200 feet (61 m) of 3/16 inch (5 mm) wire rope. 300 Series Winch: 300 feet (91 m) of 3/16 inch (5 mm) wire rope. APPLICATIONS PURPOSE: DBI-SALA Digital Series Winches are to be used for work positioning, personnel riding, material handling, climbing...

- Page 4 netzerotools.com • The worker climbing the ladder is wearing a full body harness and the winch line is connected to the dorsal (back) D-ring of the harness. • The winch operator is trained and competent in the operation of the winch. •...

-

Page 5: System Requirements

netzerotools.com SYSTEM REQUIREMENTS COMPATIBILITY OF COMPONENTS: DBI-SALA equipment is designed for use with DBI-SALA approved components and subsystems only. Substitutions or replacements made with non- approved components or subsystems may jeopardize compatibility of equipment and may effect the safety and reliability of the complete system. - Page 6 netzerotools.com DBI-SALA connectors (snap hooks and carabiners) are designed to be used only as specifi ed in each product’s user instructions. See Figure 3 for inappropriate connections. DBI-SALA snap hooks and carabiners should not be connected: A. To a D-ring to which another connector is attached. B.

-

Page 7: Operation And Use

netzerotools.com OPERATION AND USE WARNING: Do not alter or intentionally misuse this equipment. Consult DBI-SALA when using this equipment in combination with components or subsystems other than those described in this manual. Some subsystem and component combinations may interfere with the operation of this equipment. - Page 8 netzerotools.com REQUIREMENTS FOR PERSONAL FALL ARREST SYSTEMS (PFAS): PFAS used with the Digital Winch and support structure must meet applicable OSHA requirements. • The PFAS should be rigged to minimize any potential free fall and never allow a free fall greater than 6 ft. (1.8 m). The PFAS used with this equipment are required to include a full body harness as the body support component.

- Page 9 netzerotools.com Figure 4 - Required Load Strength 2,500 lbs. 2,500 lbs. in direction of pull in direction of pull 625 ft-lbs 1,900 ft-lbs moment load moment load Left Hand Retrieve Right Hand Retrieve (cable feeds off top) (cable feeds off bottom) 36 in.

- Page 10 netzerotools.com Figure 5 - Mounting Bracket DBI-SALA Quick Mount Bracket Clamp Knob Universal Mounting Plate Structural Handle DBI-SALA Advanced Series Mounting Bracket Universal Mounting Plate Connecting device must capture handle Structural Handle OPERATION OF WINCH: A. CONNECTING THE WINCH LINE TO A LOAD: See Figure 6. For applications that do not require a secondary PFAS, the winch line should be connected to the worker’s harness back D-ring.

- Page 11 netzerotools.com should be attached to the worker’s harness shoulder D-rings. The secondary lifeline should be connected to the worker’s harness back D-ring. For material handling applications, connect the winch line to the load using a tie-off adapter or other anchoring device. B.

- Page 12 netzerotools.com D. WINCH REMOVAL: Disconnect the lifeline from the worker’s harness or from the material load. Maintain at least a 10 lb. (4.5 kg) load on the lifeline winding the lifeline onto the drum. Retract the lifeline through the support structure. See the support structure user instructions.

- Page 13 netzerotools.com While a worker is suspended Figure 8 - Swing Angle maintain the swing angle at less than 5°. The worker can be Anchor seriously injured in a swing fall at more than 5° (see Figure 8). 5° Max. 5° Max. If the worker is not suspended and there is no chance of a Lifeline...

- Page 14 netzerotools.com If the inertia brake engages, the operator can still extend or retract the lifeline from its stopped position by turning the crank arm. However, if the crank arm is released, the winch would free- wheel until the inertial brake engages again. Use the crank arm to retrieve the entrant or load without releasing the handle.

- Page 15 netzerotools.com external components. Failure to provide proper service may shorten product life and could endanger performance. • After An Impact: Inspect entire winch according to section 5.2. WARNING: If the winch has been subjected to impact forces, it must be immediately removed from service and inspected. If the winch fails to pass the inspection, do not use.

- Page 16 netzerotools.com • Check the digital counter, Figure 10 - Brake Wear Indicator (see Figure 11) if it exceeds 30,000 cycles Green Section from the last factory service recorded in the inspection log in Section 9, Indicator Pin return the winch to DBI-SALA or an authorized repair center for service.

- Page 17 netzerotools.com B. The wire rope assembly must be replaced by an authorized service center if there are six (6) or more randomly distributed broken wires in one lay, or three (3) or more broken wires in one strand in one lay. Note: A “lay” of wire rope is the length of wire rope that it takes for a strand (the larger groups of wires) to complete one revolution or twist along the rope.

-

Page 18: Specifications

netzerotools.com LUBRICATION OF Figure 13 - Brake Pad Lube Hole DIGITAL WINCH BRAKE PADS: A light lubricant such as WD-40 Lube hole in center should be sprayed into of primary the brake pad lubrication drive hub holes every fi ve to eight uses of the winch. - Page 19 netzerotools.com WEIGHT 100 Series Advanced Digital Winch: 26.5 lbs (12 kg) plus lifeline. 200 Series Advanced Digital Winch: 27 lbs (12.2 kg) plus lifeline. 300 Series Advanced Digital Winch: 27.5 lbs (12.4 kg) plus lifeline. LOADS: Maximum Working Load: 450 lbs (204 kg) Winch Mechanism Proof Load 5000 lbs (22.2 kN) DIMENSIONS: A.

- Page 20 netzerotools.com D. UNIVERSAL MOUNTING PLATE: (19 mm) 2.06 2.06 (52.3 mm) (52.3 mm) .406 (10.3 mm) netzerotools.com...

- Page 21 netzerotools.com LABELING The following labels must be present and fully legible. For ordering purposes, the part number is listed near the lower right hand corner of each label. 9504598 REV. C 5 TO 8 USES. ® WD-40 0086 STOP Advanced Systems Digital Winch 9504600 REV.

-

Page 22: Inspection And Maintenance Log

netzerotools.com INSPECTION AND MAINTENANCE LOG SERIAL NUMBER: __________________________________________ MODEL NUMBER: ___________________________________________ DATE PURCHASED: ______________DATE FIRST USED: __________ INSPECTION INSPECTION CORRECTIVE MAINTENANCE DATE ITEMS NOTED ACTION PERFORMED Approved By: Approved By: Approved By: Approved By: Approved By: Approved By: Approved By: Approved By: Approved By: Approved By:... - Page 23 netzerotools.com This instruction applies to the following models: 8514602 8518561 8518579 8518592 8518613 8518706 8518016 8518562 8518580 8518601 8518614 8524868 8518017 8518563 8518581 8518602 8518615 8526404 8518018 8518564 8518582 8518603 8518616 8526534 8518021 8518565 8518583 8518604 8518617 8530010 8518551 8518566 8518584 8518605 8518623...

- Page 24 netzerotools.com LIMITED LIFETIME WARRANTY Warranty to End User: D B Industries, Inc., dba CAPITAL SAFETY USA (“CAPITAL SAFETY”) warrants to the original end user (“End User”) that its products are free from defects in materials and workmanship under normal use and service. This warranty extends for the lifetime of the product from the date the product is purchased by the End User, in new and unused condition, from a CAPITAL SAFETY authorized distributor.

Need help?

Do you have a question about the DBI SALA 8518581 and is the answer not in the manual?

Questions and answers