Table of Contents

Advertisement

DA435HA: 99901219 20100927

Model DA435HA

Air Compressor

(PART NO. 20013)

(Single Cooler - 10GPM)

(Replaces Model DA435HAR-10)

IOWA MOLD TOOLING CO., INC.

BOX 189, 500 HWY 18 WEST, GARNER, IA 50438

TEL: 641-923-3711

MANUAL PART NUMBER 99901219

Iowa Mold Tooling Co., Inc. is an Oshkosh Truck Corporation company.

Advertisement

Table of Contents

Summary of Contents for Diamond DA435HA

-

Page 1: Air Compressor

DA435HA: 99901219 20100927 Model DA435HA Air Compressor (PART NO. 20013) (Single Cooler - 10GPM) (Replaces Model DA435HAR-10) IOWA MOLD TOOLING CO., INC. BOX 189, 500 HWY 18 WEST, GARNER, IA 50438 TEL: 641-923-3711 MANUAL PART NUMBER 99901219 Iowa Mold Tooling Co., Inc. is an Oshkosh Truck Corporation company. - Page 2 DA435HA: 99901219: -------- REVISIONS LIST DATE LOCATION DESCRIPTION OF CHANGE 20000731 4-10 I2 70395091 WAS 73095091 ID DECAL 20010925 EN-1365 - CHANGED BLOCK TO 301996, SOLENOID TO 301997, VALVE TO 301998 UPDATED ITEMS M6, M11, M24, M25 M46 WAS 90° F ELBOW, IS NOW ELBOW 3/4JIC X 3/4NPT...

- Page 3 DA435HA: 99901219: 19980930 PRECAUTIONS Read before operating your compressor! DANGER EXPLODING TANK WILL CAUSE DEATH, SERIOUS INJURY OR PROPERTY DAMAGE Drain air tank after each use to prevent moisture build-up and corrosion which leads to tank failure. Assure that tank and compressor relief valves work properly, and are at correct pressure settings.

-

Page 4: Table Of Contents

DA435HA: 99901219: 19980930 TABLE OF CONTENTS PARA TITLE PAGE SECTION 1. INTRODUCTION AND SPECIFICATIONS 1-1. INTRODUCTION ........................ 1-1 ORDERING REPAIR PARTS ..................... 1-1 1-3. GENERAL INFORMATION ....................1-1 1-4. SPECIFICATIONS ......................1-1 SECTION 2. INSTALLATION 2-1. GENERAL .......................... 2-1 2-2. -

Page 5: Section 1. Introduction And Specifications

19980930 SECTION 1. INTRODUCTION AND SPECIFICATIONS 1-3. GENERAL INFORMATION 1-1. INTRODUCTION The IMT DA435HA air compressor is a single This manual provides information on the installation, operation and repair of the IMT Model stage, air cooled, 4-cylinder, pressure lubricated, DA435HA Hydraulic Air Compressor. - Page 6 DA435HA: 99901219: 19980930 NOTES...

-

Page 7: Section 2. Installation

DA435HA: 99901219: 19980930 SECTION 2. INSTALLATION 2-1. GENERAL 2-2. PTO AND PUMP INSTALLATION 2-2-1. PTO INSTALLATION CAUTION AVOID CONTACT PERMATEX WITH TRANSMISSION FLUID. Registered Trademark of Permatex Co., Inc., Kansas City, Kansas CAUTION IT IS IMPORTANT THAT ADEQUATE SPACE BE ALLOWED FOR FULL ENGAGEMENT OF THE PTO. -

Page 8: Compressor Installation

DA435HA: 99901219: 19980930 WARNING 2-2-2. DRIVELINE AND PUMP THE INSTALLER OF THE DRIVELINE MUST INSPECT INSTALLATION THE FINAL POSITION OF THE DRIVELINE TO DETERMINE WHETHER ITS LOCATION PROVIDES SUFFICIENT PROTECTION TO AN OPERATOR, OR OTHER PERSONNEL, FROM HAZARDS ASSOCIATED WITH A ROTATING DRIVELINE. IF PROTECTION IS... -

Page 9: Driveline Installation Techniques

DA435HA: 99901219: 19980930 2-4. DRIVELINE INSTALLATION 2-4-2. SINGLE PLANE AND COMPOUND TECHNIQUES U-JOINT OPERATING ANGLES 2-4-1. U-JOINT OPERATING ANGLES SINGLE PLANE 1. U-joint operating angles at each end of a shaft should always be at least 1°. 2. U-joint operating angles on each end of a driveshaft should always be equal within 1°... -

Page 10: Eliminating Compound Angle Induced Vibration

DA435HA: 99901219: 19980930 Make sure that the transmission and pump are mounted so that their centerlines are parallel when viewed from 2-4-3. ELIMINATING COMPOUND both the side and the top. ANGLE INDUCED VIBRATIONS Make sure the offset between them is mall in both views. -

Page 11: Angle Size

DA435HA: 99901219: 19980930 2-4-4. ANGLE SIZE DRIVESHAFT MAXIMUM OPERATING ANGLE 5000 3.2° 4500 3.7° 4000 4.2° 3500 5.0° 3000 5.8° 2500 7.0° 2000 8.7° 1500 11.5° ANGLE CHART FOR DRIVESHAFTS HAVING AN ANGLE IN THE TOP VIEW... - Page 12 DA435HA: 99901219: 19980930...

-

Page 13: Section 3. Operation

DA435HA: 99901219: 19980930 SECTION 3. OPERATION 3-1. GENERAL 3-2. OPERATION Each compressor is bench tested under load at the To use the compressor, start the vehicle engine and factory to ensure proper break-in and operation. engage the compressor by operating the compressor While it is not necessary to follow any break-in switch. - Page 14 DA435HA: 99901219: 19980930 NOTES...

-

Page 15: Section 4. Maintenance & Parts

DA435HA: 99901219: 19980930 Section 4. MAINTENANCE & PARTS 4-1. GENERAL The following table provides list of routine maintenance items, including service intervals. The remainder of Section 4 includes a part lists and assembly drawings of the compressor. SERVICE INTERVALS MAINTENANCE OPERATION... -

Page 16: Oil Cooling System

DA435HA: 00200057.01: 20010925 OIL COOLING SYSTEM (200057) ITEM PART NO. DESCRIPTION 200057 OIL COOLING SYSTEM 80021 KIT HYD BLK N.O. SLND 301996 BLOCK-HYDRAULIC VALVE 301997 SOLENOID-HYDRAULIC 12VDC N.O. 301998 VALVE-RELIEF PILOTED SPOOL 970508-106 CONNECTOR 1/2JIC 3/4SAE 975508-019 HOSE ASM 1/2X19 SXE 976512-1212 TEE 3/4NPT 3/4JIC MALE RUN 975412-021 HOSE ASM 3/4X21”... - Page 17 CONTINUED ON FOLLOWING PAGE 00200056.01: 20100927 DA435HA: COMPRESSOR MTG SYSTEM (200056-1) ITEM PART NO. DESCRIPTION M22 301665 MOTOR-HYDRAULIC ITEM PART NO. DESCRIPTION M23 970408-088 ELBOW SAE#10 1/2JIC 70000-001 COMPRESSOR M24 301928-125 CLAMP CONDUIT 1 1/4 929806-150 BOLT 3/8-16X1-1/2 HHGR8 M25 934504-075 SCREW TAP 1/4X3/4...

- Page 18 DA435HA: 00200056.02: 20061127 COMPRESSOR ASM (200056-2) ITEM PART NO. DESCRIPTION 70014583 OIL PUMP SPRING ITEM PART NO. DESCRIPTION 70024122 WASHER .33X.5X.03 COPPER 200056 COMPRESSOR & MTG SYS 70029293 CYL BLOCK SPACER 70000-001 COMPRESSOR 51714023 INSERT ASM (INCL:6-10) 1. 51014947 RING SET-3 (INCL:2-3)

- Page 19 DA435HA: 00200056.03: 20010925 COMPRESSOR ASM (200056-3) CONTINUED ON FOLLOWING PAGE...

- Page 20 DA435HA: 00200056.04: 19990209 COMPRESSOR ASM (200056-4)

-

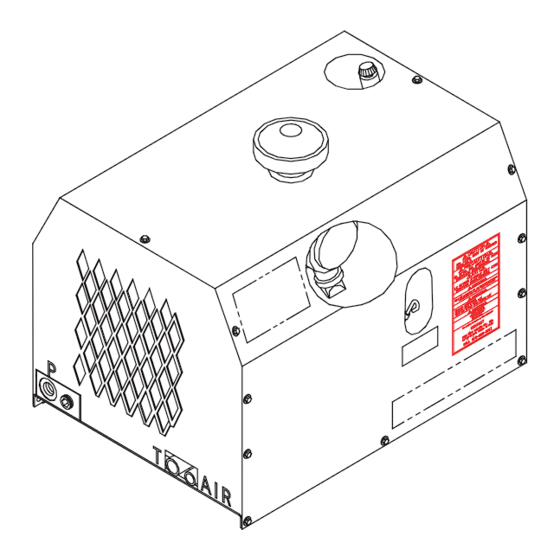

Page 21: Canopy System

DA435HA: CANOPY.01: 20010925 CANOPY SYSTEM 301437 CANOPY 977004-062 WASHER 1/4X.062X5/8 983904-075 BOLT, STAR DRIVE 1/4-20 x 3/4 961504-090 NUT 1/4-20 TINNERMAN 301436 PANEL-END RECIP 301435 PANEL-END COOLER 301381 HARNESS-35 RECIP 301581 HARNESS-TOWER 3-WAY 301607 HARNESS-SHROUD 3-WAY H10 98404-071 WASHER, FLAT WIDE 1/4” SS... -

Page 22: Compressor Wiring Diagram

DA435HA: WIRING.01: 19990209 COMPRESSOR WIRING DIAGRAM COOLING FAN ASM POWER RELAY HIGH TEMPERATURE SHUTDOWN SWITCH RELAY HYDRAULIC VALVE BLOCK ASM W/ N.O. SOLENOID AND RELIEF VALVES M10033 FURNAS HIGH TEMPERATURE SWITCH SHUTDOWN SWITCH SHUTDOWN RELAY SOCKET FURNAS PRESSURE SWITCH FAN RELAY... - Page 23 DA435HA: MOUNTING.01: 20050630 DA435HA MOUNTING LOCATIONS (99903712) DA435HA INSTALLATION ON SERIES 1 AND SERIES 2 DOMINATOR 4.40 13.38 0.44 TYP. (4) 12.75 12.00 DA435HA INSTALLATION ON SERIES 2 DOMINATOR WITH HEADACHE RACK AND STANDARD HEIGHT SIDEPACK ON COMPRESSOR SIDE 4.40 13.38...

-

Page 24: Installation Kit

DA435HA: 51712642.01: 20010925 4-10 INSTALLATION KIT (51712642) (THROUGH 3-15-05) (INSTALLATION DWG 99901281 SHOWN) ITEM PART NO. DESCRIPTION 1. 76391527 BUMPER-RUBBER 2. 938206107 WASHER 3/8 FLAT GR8 (938206107) 3. 929106200 BOLT 3/8-16X2 HHGR5 4. 99901281 DRAWING... - Page 25 DA435HA: 51712642.01: REV. B 20050630 4-11 INSTALLATION KIT (51712642) (EFFECTIVE 3-15-05) (INSTALLATION DWG 99901281 SHOWN) ITEM PART NO. DESCRIPTION 1. 76391527 BUMPER-RUBBER 2. 929106200 BOLT 3/8-16X2 HHGR5 3. 938206107 WASHER 3/8 FLAT GR8...

- Page 26 4-12 COMPRESSOR HARNESS CHART Effective March 15, 2005, the connectors in the harnesses used on the DA435HA were upgraded. The old and new connectors are not interchangeable, so for replacement parts, the correct harness and/or jumper must be ordered. Use the following chart to determine the correct harness and/or jumper.

- Page 27 DA435HA: 20050630 4-13 COMPRESSOR HARNESS CHART, CONTINUED If your DA435HA connector looks like Connector B: and your body connector looks like this: Use jumper # 77441158. and your body connector looks like this: No jumper is needed. If you are not using an IMT body and your connector looks like Connector B, use jumper 77441157.

- Page 28 304710: 20050629 DA435HA: 4-14 HARNESS (304710) EFFECTIVE 3/15/05...

-

Page 29: Decal Placement

DECAL PLACEMENT DECAL PLACEMENT (80015) ITEM LOCATION ITEM PART NO. DESCRIPTION HOSE REEL COMPARTMENT 71393715 DECAL-DIAMOND AIR HOSE REEL COMPARTMENT 70395091 DECAL-DA435HA COMPRESSOR INSIDE CANOPY 300913 DECAL-OIL DRAIN INSIDE CANOPY *300040 DECAL-DANGER BREATHING AIR *300042 DECAL-WARNING CONNECT AIR *300041 DECAL-WARNING FAN GUARD... -

Page 30: Hydraulic Installation Kit

DA435HA: INSTALL: 20010925 4-16 HYDRAULIC INSTALLATION KIT (91707052) 72532712 BEAD NIPPLE #16MSTR 1” 45° 1 72531427 ELBOW 3/4NPT #12MJIC 72053676 ADAPTER 3/4MPT #12MJIC 51706981 HOSE ASM 1/2X35 89392349 HOSE 3/4 300# 17” 51707317 HOSE ASM 3/4X100 51703585 HOSE ASM 1/2X220 FF... -

Page 31: Driveline Mounting Option

DA435HA: 31701761.01: 19980930 4-17 WARNING DRIVELINE MOUNTING OPTION THE INSTALLER OF THE DRIVELINE MUST INSPECT (31701761) THE FINAL POSITION OF THE DRIVELINE TO ITEM PART NO. DESCRIPTION DETERMINE WHETHER ITS LOCATION PROVIDES POWER TAKE-OFF SUFFICIENT PROTECTION TO AN OPERATOR, OR 2. - Page 32 DA435HA: 99901219: 20000221 4-18 RECOMMENDED SPARE PARTS LIST Model DA435HA Air Compressor SHELF ASSEMBLY LIFE ORDER DESIGNATION ITEM NO. PART NO. DESCRIPTION CODE (MO) 0020057.01.19990209 OIL COOLING SYSTEM 80009 CONTROLS-HYDRAULIC 301577 FAN PUSHER 300444 TAPE 1/16X3/4 CLOSED CELLO 300211 RELAY-POWER...

-

Page 33: Section 5. Repair

DA435HA: 99901219: 19980930 SECTION 5. REPAIR 5-1. GENERAL 5-2. PISTON RING REPLACEMENT NOTE A RUBBER FACED MALLET WILL HELP WHEN REMOVING THE HEAD. TAP THE SIDES OF THE HEAD CAREFULLY UNTIL THE HEAD IS LOOSE. LIFT OFF THE HEADS. CAUTION DO NOT LUBRICATE THE RINGS. -

Page 34: Oil Pump Replacement

DA435HA: 99901219: 19980930 5-4. CRANKSHAFT AND BEARING REPLACEMENT NOTE INSTALL THE VALVE PLATE WITH THE MARKED SURFACE FACING UP. NOTE DEPENDING ON THE CONDITION OF THE CRANKSHAFT, BEARING MAY BE REPLACED WITHOUT REPLACING THE CRANKSHAFT. REPLACE THE BEARING RACES WHENEVER THE BEARINGS ARE REPLACED. - Page 35 DA435HA: 99901219: 19980930 NOTE NOTE THE CRANKSHAFT SHOULD HAVE NEW BEARINGS GASKET KITS ARE SUPPLIED WITH TWO (2) EACH OF INSTALLED. IF NOT, PRESS THE NEW BEARINGS .006, .010, .015, AND .020 GASKETS. USE THESE INTO POSITION ON THE CRANKSHAFT.

-

Page 36: Troubleshooting

DA435HA: 99901219: 19980930 5-5. TROUBLESHOOTING LOW OIL PRESSURE LOW OIL LEVEL LOOSE PIPE PLUG ON OIL PUMP COVER WORN OR DEFECTIVE OIL PUMP CRACK OR SCRATCH ON OIL PUMP COVER NO OIL PRESSURE DEFECTIVE OIL PUMP BLOCKED OIL PASSAGE DAMAGED OIL PUMP DRIVE PIN... - Page 37 DA435HA: 99901219: 19980930...

- Page 38 DA435HA: 99901219: 20020328 6-10 This parts manual is provided to the user to assist in servicing the equipment. It is the propertyof Iowa Mold Tooling Co., Inc and, as such, may not be reproduced either whole or in part,whether by chemical, electrostatic, mechanical or photographic means without the expressedwritten permission of an officer of Iowa Mold Tooling Co., Inc.