Advertisement

Models covered

• STBA48026

WARNING: Equipment

must be installed to

comply with applicable

federal, state, and local plumbing/

electrical codes having jurisdiction.

WARNING: Follow this

setup procedure before

attempting to use this

brewer. Failure to follow these

instructions can result in injury

and/or void of warranty.

CAUTION: DO NOT

connect the brewer

to hot water. The inlet

valve is not rated for hot water.

IMPORTANT: After

setup, run a FULL

brew cycle. Place a

tea container to catch both hot

water from the brew basket and

dilution water from spout on the

front cover.

ISO 9001:2008 REGISTERED

WILBUR CURTIS CO., INC.

6913 Acco Street

Montebello, CA 90640

For the latest information go to

www.wilburcurtis.com

Phone: 800-421-6150

Service Manual – McDonald's Sweet Tea Brewer

Important Safeguards/Symbols

This appliance is designed for commercial use. Any servicing other than cleaning and routine

maintenance should be performed by an authorized Wilbur Curtis Co., Inc. service technician.

• DO NOT immerse the brewer in water or any other liquid.

• To reduce the risk of fire or electric shock, DO NOT open service panels. There are no user

serviceable parts inside.

• Keep hands and other items away from hot areas of the brewer during operation.

• Never clean with scouring powders or harsh chemicals.

Symbols:

WARNING/CAUTION – To advise about conditions that my result in property damage,

personal injury or death

IMPORTANT – Notes about proper operation

Sanitation requirements

Following are the factory settings for the STBA48026 Iced Tea Brewing System:

• Brew Temperature = 200°F

• Brew Volume = Set to dispensing vessel requirements

Usually, there will never be a reason to change the programming on the system's G3 series

controller. However, should you need to make slight adjustments to meet your brewing needs,

programming instructions are provided later in this manual.

System Requirements:

• Water source: 50 – 90 psi (minimum flow rate of 3.0 gpm)

2

• CO

/compressed air source: 50 psig max.

• Electrical: See schematic in this manual

SETUP STEPS

NOTE: Some type of water filtration device must be used to maintain trouble-free operation.

In areas with extremely hard water, we suggest that a sedimentary, taste and odor filter be

installed. This will prolong the life of your brewing system and enhance tea quality.

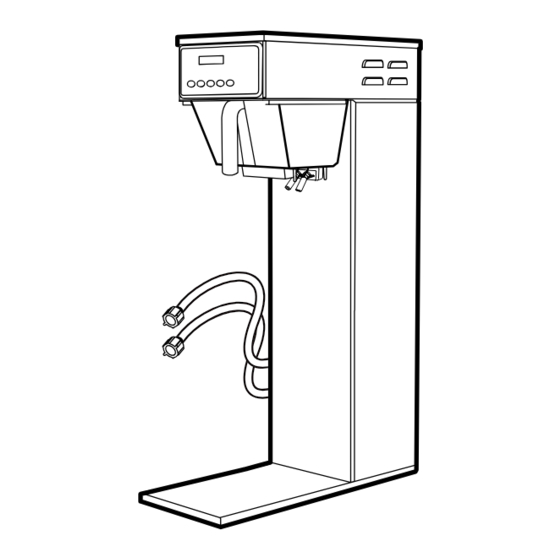

1. Locate the brewer on a secure surface. Level it left to right and

front to back by rotating the feet on the 4 corners.

2. Connect a water line from the water filter to the brewer.

Plumb water lines. A 1/2" hose barb has been supplied for water

line connections. See page 3 for location.

NSF International requires the following water connection:

1. A quick disconnect or additional coiled tubing (at least 2x the depth of the brewer) is required so

that the brewer can be moved for cleaning underneath.

2. This equipment is to be installed with adequate back-flow protection to comply with applicable

federal, state and local codes.

3. Water pipe connections and fixtures directly connected to a potable water supply shall be sized,

installed and maintained in accordance with federal, state and local codes.

Use tubing sized sufficient to provide a minimum of 3.0 gpm for the ambient INLET WATER

(2 places) and CHILLED WATER connections.

2

3. Connect the CO

or compressed air line.

4. Connect the brewer to an electrical outlet with the appropriate

amperage rating (see serial tag on brewer).

W

C

C

ilbur

urtis

o

., i

.

nC

(2.2 liters)

WARNING: Use the

leveling legs to level the

brewer only. Do not use

them to adjust brewer height. Do not

extend them higher than necessary.

WARNING: The CO

compressed air input

pressure must not

exceed 50 psig.

continued...

/

2

Page 1

Advertisement

Table of Contents

Summary of Contents for Wilbur Curtis Company STBA48026

- Page 1 IMPORTANT – Notes about proper operation Sanitation requirements Models covered • STBA48026 Following are the factory settings for the STBA48026 Iced Tea Brewing System: • Brew Temperature = 200°F • Brew Volume = Set to dispensing vessel requirements (2.2 liters) Usually, there will never be a reason to change the programming on the system’s G3 series...

-

Page 2: Setup Steps

Wilbur Curtis Co., Inc. SETUP STEPS (CONT.) 5. Connect two Bag-in-Box (BIB) sweeteners to the brewer sweetener supply hoses as instructed IMPORTANT: The sweetener must be on page 5. Connecting two bags allows the brewer to continue operating if one bag runs out. between 50°F and 120°F 6. -

Page 3: Rear Panel Connections

Service Manual - STBA48026 Tea Brewer 11. Center an empty tea dispenser under the brew basket. Press the SWEET TEA BREW button to run one full brew cycle with the brew basket empty (Ready to Brew must be on the display). This process will purge the hoses and valves of any remaining air. -

Page 4: Brewing Instructions

Wilbur Curtis Co., Inc. S T BA 4 8 0 2 6 - S W EE T T E A Your Curtis Sweet Tea Brewer is Factory Pre‑Set for Optimum Performance. After connection to water and power; the rear toggle switch must be on. You will hear a beep sound, indicating power is available to the controller. The control displays MCDONALD’S . - Page 5 Service Manual - STBA48026 Tea Brewer SWEETENER REPLACEMENT/CONNECTION PROCEDURE - BAG-IN-BOX (BIB) The PRIME button is used to fill the sweetener hoses when the unit is first installed or after servicing. The system automatically refills the hoses when the BIB is changed.

- Page 6 Wilbur Curtis Co., Inc. SWEETENER SCHEMATIC BAG IN BOX (BIB) SWEETENERS (2 PER BREWER) TEA BREWER (SIDE VIEW) SWEETENER HOSES PROGRAMMING ENTER PROGRAMMING MODE: Turn off power at the ON/OFF (yellow) button. Press and hold button 4 (see below), while you press and release the ON/OFF button.

-

Page 7: Program Menus

Service Manual - STBA48026 Tea Brewer PROGRAM MENUS (CONT.) Tea Dilution Volume - Press to select. The display will read “Select Brew Button!”. The display will read “Press BREW to Start”. Press the BREW button for which the dilution volume needs to be changed. Press BREW again and Tea Dilut. - Page 8 Wilbur Curtis Co., Inc. PROGRAM MENUS (CONT.) Master Reset Press to display Are You Sure? Then press ◄ for yes, or ► for no. When master reset is Master Reset used, all of the menu selections in the control module are reset to the factory defaults. Service Call (phone number factory set to [800] 000-0000) Press ...

-

Page 9: Electrical Schematic

Service Manual - STBA48026 Tea Brewer ELECTRICAL SCHEMATIC CONTROL MODULE UCM PIN ASSIGNMENTS (16-PIN) PIN ASSIGNMENTS (5-PIN) t s r PIN 03: CHILLED DILUTION VALVE PIN 03: Not Used PIN 04: INLET VALVE / TANK PIN 04: Vdd +5Vdc PIN 06: TRIAC GATE... - Page 10 Wilbur Curtis Co., Inc. TEA BREWER Daily Cleaning CLEANING 1. Wipe any spills, dust or debris from the exterior surfaces with a damp cloth. The outside surfaces of the brewer should be cleaned with stainless steel polish only, to prevent scratches.

- Page 11 Service Manual - STBA48026 Tea Brewer TEA BREWER MALE HOSE SWEETENER FITTING PUMP BREW BASKET FIGURE 1 MIX CLEANER IN 1 GAL HOT WATER CONTAINER TO CATCH USED CLEANER SWEETENER SEE FIGURE 1 PUMPS WEEKLY CLEANING AND SANITIZING - DIAGRAM 1...

- Page 12 Wilbur Curtis Co., Inc. EXPLODED VIEW - MAIN CHASSIS 18 19 20 Page 12...

- Page 13 WC-3518 LEG, GLIDE 3/8”-16 STUD SCREW WC-5310 TUBE, 5/16 ID X 1/8W SILICONE GEN USE WC-53145 TUBING, .25” ID X .438” OD BRAIDED PVC STBA48026 WC-53114 TUBING, .375” ID X .625” OD BRAIDED SILICONE 60 DUROMETER a, b WC-5231 COMPOUND SILICONE, 5 OZ...

- Page 14 Wilbur Curtis Co., Inc. EXPLODED VIEW - CONTROL PANEL 5A 5B PARTS LIST - CONTROL PANEL ITEM PART # DESCRIPTION WC-67101 BRACKET, UCM MOUNT ALPHA-GT D500GT/GTH/D1000GT, GEMINI GT WC-29044 SLEEVE, OVERFLOW ASSY GEN USE WC-786-108 CONTROL MODULE, UCM 120V MCD SWEET TEA BREWER WC-13486 HARNESS, ASSY COMPLETE MCD SWEET TEA WC-390274...

- Page 15 DESCRIPTION WC-1067K-L KIT, PUMP ASSY LEFT STBA48026 WC-1067K-R KIT, PUMP ASSY RIGHT STBA48026 (NOT SHOWN) WC-29107 FITTING, Y-BARB 3/8” x 3/8” x 3/8” KYNAR (NOT SHOWN) WC-29100 FITTING, ELBOW 1/4” BARB X 1/8 “ NPT W/ 1/6” BLEED HOLE BRSS WC-29106 FITTING, TEE 1/4”...

- Page 16 Wilbur Curtis Co., Inc. EXPLODED VIEW - TANK ASSEMBLY Page 16...

- Page 17 Service Manual - STBA48026 Tea Brewer PARTS LIST - TANK ASSEMBLY ITEM PART # DESCRIPTION WC-62108-35 TANK ASSY, COMPLETE 2500 WATT-220VAC 1.63 GAL WC-5527K KIT, PROBE WATER LEVEL O-RING & NUT WC-37266 KIT, FITTING TANK OVERFLOW (INCLUDES BUSHING) WC-37317 KIT, STRAIGHT FITTING & BUSHNG 8mm GEN USE...

- Page 18 Wilbur Curtis Co., Inc. This page intentionally left blank Page 18...

- Page 19 Service Manual - STBA48026 Tea Brewer This page intentionally left blank Page 19...

- Page 20 ECN 17458 RevE 07/13/16 @ 11.6 Wilbur Curtis Co., Inc. 6913 Acco Street, Montebello, CA 90640-5403 U.S.A. Phone: 800-421-6150 │ Fax: 323-837-2410 │ Technical Support Phone: 800-995-0417 (M-F 5:30 . - 4:00 . PST) │ Email: techsupport@wilburcurtis.com │ www.wilburcurtis.com FOR THE LATEST SPECIFICATION INFORMATION GO TO WWW.WILBURCURTIS.COM Printed in U.S.A.

Need help?

Do you have a question about the STBA48026 and is the answer not in the manual?

Questions and answers