Advertisement

For heavy duty work use a No. 62-413,

~

H. P.

1725 R. P. M. capacitor motor, 60 cycle, single phase,

115 volts, alternating current only.

PM-1697

U. S. Poteat No. 1,790,288; 1,967,791; 1,975,562;

~

•. 156,923

37-8: Jointer Instruction Manual

Revised: 8-15-58

4" JOINTER

Instructions

MOTOR, PULLEYS AND BELT

We recommend our No. 60-013

~

H. P., 11'5 volt, 60

cycle, 1725 R. P. M. bronze bearing motor with Y2" shaft

for medium duty work.

HOMECRAFf

and Maintenance

Power Tools

No. 37-110

Operating

_

....

Each jointer is inspected and tested before shipment.

These machines will give excellent results if properly

used and maintained. The adjustments for various

operations are described below; read and follow the

instructions carefully.

The Homecraft 4" Jointer is an accurate machine,

ideal for the home workshop. Its maximum depth of

cut is

~-inch.

CONSTRUCTION FEATURES

Consult your Delta dealer for the correct motor if the

electric current available is different from that indicated

above.

The cutter head of this jointer runs in sealed ball

bearings which need no lubrication throughout their

life. It carries three high speed steel knives which are

easily adjusted and securely locked in their dove-tail

grooves.

The fence is finish ground to increase accuracy, and

is heavily ribbed for rigidity and to prevent warping.

The fence can be easily locked in any position across

the table, and can be tilted 45° right or left.

It

is also

.provided with an adjustable stop so the fence can be

returned at right angles to the table.

FroRt and ,rear tables are finish ground after" as-

sembly on the base. This additional operation assures

the true alignment necessary for accurate work and is a

feature usually found only in the larger and more

expensive .machines.

Speed of the cutter head should be about 4000 rpm

for best results. The correct speed is obtained with the

No. 60-013 or 62-413 motor by using the 6Y2-inch motor

pulley No. 5650 in conjunction with the

2~-inch

cutter

head pulley

J

-17-S which is furnished on the jointer.

For any other motor, order a pulley of the correct

bore to fit the shaft, give the speed of the motor, and

sper;[ that you want the right diameter for running a

2~.

ch drive pulley at, 4000 rpm.

The cutter head must rotate forward on top. If

your motor runs in the wrong direction, reverse it

according to the manufacturer's instructions, or in the

case of a double-shaft motor, turn it end for end.

The No. 49-172 V-Belt, offered for use with this jointer,

has an outside circumference of 59% inches.

It

will

accommodate the usual installa

s. Consult your Delta

dealer if you need a belt of other length to fit special

conditions.

MOUNTING AND ASSEMBLING

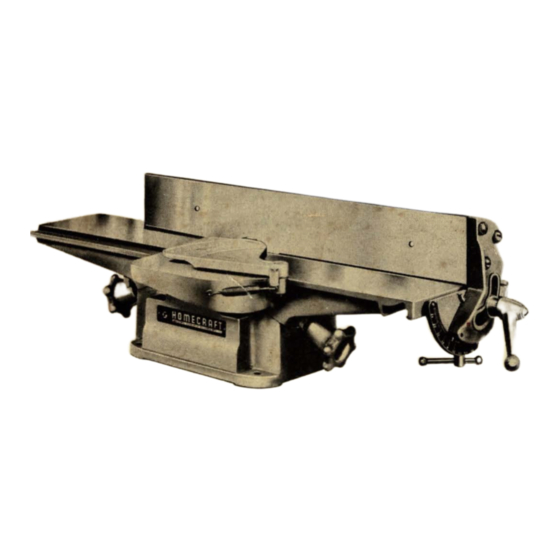

The jointer, shown in Fig. 1, is shipped complete in a

single package marked No. 37-110. It consists of two

units, the body and the fence. The knife guard and a

wrench for the lock screws of the cutter head are included.

The motor and other items of your order are supplied in

separate packages.

In choosing a location for the machine, be sure to

allow clearance in front of and behind the tables for

jointing long pieces.

A portable unit can be made by mounting the jointer

and motor on a 2 x 12-inch dressed pJank 30 inches long.

It may be placed on any convenient work table for opera-

tion and stored on a shelf when not in use. 2-inch blocks

must be inserted under the jointer base for such mount-

ing, to raise the machine so that the motor can be placed

directly back of the rear table and to allow removal of

chips. Use long bolts through the base, blocks and plank.

Advertisement

Table of Contents

Need help?

Do you have a question about the 37-110 and is the answer not in the manual?

Questions and answers