Summary of Contents for Geeetech GT2560

- Page 1 GEEETECH Users Manual of GT2560 Rev A+ Compiler: kris.mao Date: Jan04, 2016 Reviewer: Alina, Le mon Date: Jan04, 2016 Approver: Linda.Fan Date: Jan13, 2016 www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 -858 - 1 -...

- Page 2 The copyright of this specification belongs to the Shenzhen GETECH CO., LTD. (hereinafter referred to as the "Geeetech"), and all rights reserved. No part of this specification should be reproduced or extracted in any forms or means without the prior written consent of Geeetech by any company and individuals.

- Page 3 16MHz operating frequency, high-performance USB serial converter FT232RQ, all these make the GT2560 an ideal option for a 3D printer control board. What’s more, GT2560 can run over 12V to 24V which gives higher torque and higher rotation rate.

- Page 4 GEEETECH 6. 3 55Amp MOSFET (with LED indicator, the actual output is restricted by the PCB board and the connector), all 3 MOSFET are equipped with heat sink to ensure sufficient heat dissipation and stable operation. 7. Support 5 A4988 stepper drivers (3 for X/Y/Z axis, and 2 for extruders); the subdivision of stepper motor can be setup by dial switch, eliminating jumper caps, easier to operate.

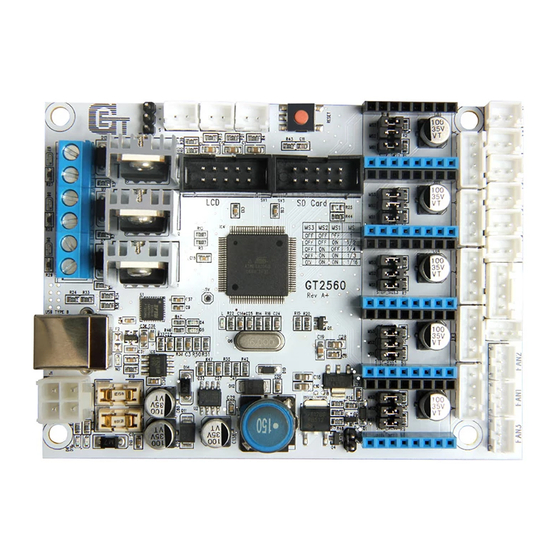

- Page 5 GEEETECH 1.1 Overview and Hardware Resources www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 -858 - 5 -...

- Page 6 GEEETECH 1-1(front and back images) Hardware resources 12V/24V 15A and 12V/24V 10A power supply 1 power port for heatbed and 2 for extruder 5 stepper motor input, (3 for X/Y/Z axis, and 2 for extruders) Extended LCD & SD card interface 6 endstop input(X-MIN ,Y-MIN ,Z-MIN 和...

- Page 7 Fan: PH (2.00mm-3pin) Endstop and thermistor: XH (2.54mm-2pin) 1.2 Software Resources Compiling environment: Arduino IDE Firmware: Marlin Host software:Easy print Repeater-Host Source Arduino IDE:http://www.geeetech.com/wiki/index.php/Download Marlin:http://www.geeetech.com/wiki/images/3/39/Marlin-Marlin_v1.zip Repetier-Host: http://www.geeetech.com/wiki/images/3/36/SetupRepetierHost_1_00.zip www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 -858 - 7 -...

- Page 8 GEEETECH 2 Interfaces 2.1 Interface Layout 2.2 Interface specifications 1.DC IN: 12V-24V 15A and 12V-24V 10A 2. HOT_BED: heat bed 3. HEATER1: power supply for extruder 1 4. HEATER2: power supply for extruder 2 www.geeetech.com Tel: +86 755 2658 4110...

- Page 9 GEEETECH 5.LCD ENCODER: LCD panel 6. SD Card 7. X_MIN/X_MAX/Y_MIN /Y_MAX /Z_MIN /Z_MAX: 6 end stop input, XH2.54-2Pin 8. TEMP1: temperature sensor for extruder 1, XH2.54-2Pin 9. TEMP2: temperature sensor for extruder 2, XH2.54-2Pin 10. TEMP3: temperature sensor for heatbed, XH2.54-2Pin 11.

- Page 10 GEEETECH Turn ON/OFF Subdivision full step 1/2 step 1/4 step 1/ 8 step 1/16 step 2. Subdivision on the base of Drv8825 stepper driving module: Turn ON/OFF Subdivision full step 1/2 step 1/4 step 1/ 8 step 1/16 step 1/32 step...

- Page 11 GEEETECH Note: this function is only available for versions after REV A. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 -858 - 11 -...

- Page 12 GEEETECH 3 Development Environment setting 3.1 Interface Connecting and Setting Note: Pay attention to the Plus-n-Minus of the power connector, reverse connection can cause irrevocably damages. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 -858 - 12 -...

- Page 13 GEEETECH A4988 should also be connected to the right port, mismatches and revered directions can cause damage to the main board. You can the correct connections are as follow: If you are using DRV8825 instead of A4988, The correct connections are as follow: 3.You are suggested to connect all the Periphery modules before testing.

- Page 14 GEEETECH Then, windows will open the dialog box “found new hardware wizard”, check “no, not this time”, then click “next” to continue. Then, windows will open the dialog box “found new hardware wizard”, Check “install from a list or specific location (advanced)”, then click “next”.

- Page 15 GEEETECH Specify installation directory where FT232RQ is to install driver. Click “browse” to find the directory and click “next” to continue. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 -858 - 15 -...

- Page 16 GEEETECH 图 3-7 If everything goes well, windows will install the Serial Driver for GT2560. The graph below shows installation completed. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 -858 - 16 -...

- Page 17 GEEETECH Now, you can find the corresponding Serial port in device manager of windows. 3.3 File Burning Windows users need install driver before uploading. The board: Tools > Board > Arduino Mega 2560 or Mega ADK, as shown below. www.geeetech.com...

- Page 18 GEEETECH 3-10 Configuring serial interface: Tools > Serial Port > the corresponding COM Port of GT2560 usually the last one. As shown below www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 -858 - 18 -...

- Page 19 GEEETECH 3-11 Load in the file you need to burn, Click the “check ( )” button to check if it is right and then click the “ ” button to upload firmware, as shown below. 图 3-12 www.geeetech.com Tel: +86 755 2658 4110...

- Page 20 GEEETECH 3-13 Upon uploading, the LED indicator corresponding to the TX, RX and L on the GT2560 will blink, if they stop blinking, it means the file has been uploaded successfully. 3-14 www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 -858...

- Page 21 The common mistakes are the wrong select of type of board or serial port etc. 4 Get Started GT2560 is the CPU of a 3D printer, manipulating the whole process of printing. GT2560 can’t be put in use directly without uploading firmware. 1. Firmware uploading- marlin.

- Page 22 GEEETECH #define TEMP_SENSOR_0 1 #define TEMP_SENSOR_BED 1 The two parameters are set for the type of temperature sensor respectively. They are the critical parameter to check if the sensor read temperature correctly. The printer can’t operate normally, even has potential risk (damage the device and even worse). You must modify depending on the temperature sensor you use.

- Page 23 GEEETECH Mistakes are often made in the above two parameters. The parameters are different for different machinery. In principle, the origin should be at lower-left corner of the print platform (origin: [0, 0]), or at up-right corner (origin: [max, max]). Only in this way will the printing be correct, otherwise, the printing is the mirror image of one axis which is not what expected.

- Page 24 REPRAP_DISCOUNT_SMART_CONTROLLER” to ensure the normal working. 5 FAQ 1. How many extruders can GT2560 support? At most 2 extruders, GT2560 supports 5 A4988 stepper motor drivers, they are X/Y/Z axis and 2 extruders. 2. What is the power required? You need to use the 12V-24V power supply, and if you are using the single extruder one, the total power is no less than 200W, if you are using the dual extruder one, the total power is no less than 2 40W.

- Page 25 GEEETECH 3. The stepper motor on for the extruder doesn’t turn? By default in the firmware, only when the temperature of the extruder reaches 170° C can the moto r turn. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 -858...

Need help?

Do you have a question about the GT2560 and is the answer not in the manual?

Questions and answers