Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Oce ProCut 1600 M

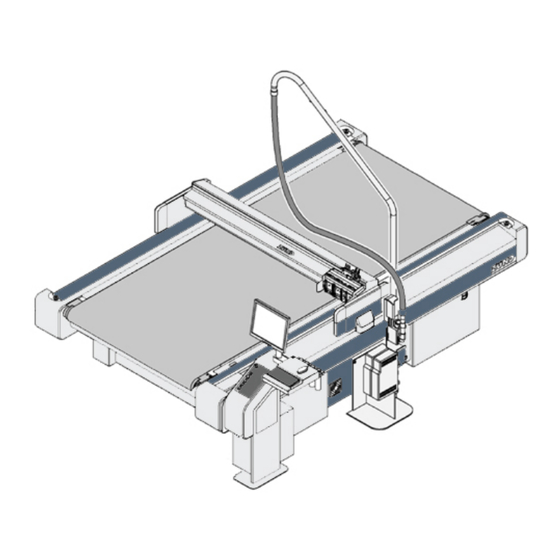

- Page 1 Océ ProCut 1600, 2500, and 3200 Series Cutters Revision E – July 23, 2010...

- Page 2 Océ ProCut Site Prep Océ Display Graphics Systems © 2010 All Rights Reserved Part Number: 3010108370 Océ ProCut Site Preparation Guide - Revision: E...

-

Page 3: Table Of Contents

Océ ProCut Site Prep Table of Contents Table of Figures........................iv Preface............................v Copyright ............................ v Document Summary........................v Product Support, Documentation, and Service ................v Introduction..........................1 Considerations:...........................1 System Requirements ......................2 Receiving the Océ ProCut ......................2 Crate Dimensions and Weight....................3 Facility Requirements ...................... - Page 4 Océ ProCut Site Prep List of Tables Table 1: Crate Dimensions and Weight ....................4 Table 2: Cutter Extension Crate Dimensions and Weights...............4 Table 3: Location Dimensions........................5 Table 4: Power Consumption and Variance ....................6 Table 5: Electrical Connections with 1-9kW Vacuum Turbine/Generator ..........6 Table 6: Power Consumption and Variance ....................7 Table 7: Electrical Connections with 1-9kW Vacuum Turbine/Generator ..........7 Table 8: Electrical Connections with 2.2/2.55kW Vacuum Pumps ............8...

-

Page 5: Preface

Océ Display Graphics Systems products visit our web site: Web: http://www.dgs.oce.com Comments on this manual? email to: DGSTechnical.Writer@oce.com Océ maintains a comprehensive support structure for its customers. Upon installation of your cutter, you will be provided with the name of the sales and service office responsible... -

Page 6: Introduction

Océ ProCut Site Prep Introduction This document contains information that will be helpful to you in determining the final location for the cutter, transporting the cutter to its final location, and all specifications for power, space, and environmental conditions required for the Océ ProCut manufactured by Zünd. Considerations: Determine where the cutter system will be located. -

Page 7: System Requirements

Océ ProCut Site Prep System Requirements Receiving the Océ ProCut Packed in its crate, the Océ ProCut can withstand normal vibrations from road or air travel. Severe shock, however, may damage the components within the machine. Document all visible damage to the packaging immediately upon delivery. -

Page 8: Crate Dimensions And Weight

Océ ProCut Site Prep Crate Dimensions and Weight 1600 M Crate Dimensions [mm] In Crate [kg] Crate 1: Basic unit 2260 x 1550 x 940 650 kg Crate 2: Basic unit 3080 x 1550 x 600 900 kg 2512 x 300 x 300 Largest part (unpackaged) 1600 XL Crate Dimensions [mm]... -

Page 9: Table 1: Crate Dimensions And Weight

Océ ProCut Site Prep All Models Crate Dimensions [mm] In Crate [kg] Pallet 1: Vacuum Generator 1200 x 800 x 970 Pallet 2: Workstation 2684 x 850 x 550 Table 1: Crate Dimensions and Weight Note: Models ordered with a vacuum cleaner will ship with the workstation inside a crate. Cutter Extension Option Crate Dimensions and Weight Cutter Extension Crate Dimensions [mm]... -

Page 10: Facility Requirements

Océ ProCut Site Prep Facility Requirements Facility Requirements Determine where the cutter system will be located in advance of the installation. Mark this with Determine where the cutter system will be located in advance of the installation. Mark this with adhesive tape so that you can confirm the dimensions. -

Page 11: Electrical Requirements

Océ ProCut Site Prep Electrical Requirements This apparatus is intended to be connected to a power network supplied from a high or medium voltage transformer dedicated to the supply of an installation feeding manufacturing or similar plant. This apparatus is not intended to be connected to public low-voltage networks. There are two electrical voltage configurations: 200V or 400V, and two power frequency configurations: 50 Hz or 60 HZ. -

Page 12: 200V Electrical Connection

Océ ProCut Site Prep Electrical connection – 208 V system with 1-9kW Vacuum Generator The cutter is connected with one power cord to the power main. The vacuum generator is connected with one power cord to the power main. The Cutter and Vacuum Generator need separate circuit breakers. -

Page 13: Table 8: Electrical Connections With 2.2/2.55Kw Vacuum Pumps

Océ ProCut Site Prep Electrical connections - 400 V system with 2.2/2.55 kW vacuum pump (1600 M Only) Comply with national instructions and laws at connection the cutter to the power supply system. The cutter is connected with one power cord to the power supply system. The vacuum pump is connected to the power box of the cutter. -

Page 14: Ground Fault Requirements

Océ ProCut Site Prep Ground Fault Requirements Electrical rules and regulations and vary from country to country and sometimes even within a country. A local electrician should be consulted to determine local ground fault requirements. Some countries require residual current devices (RCD) or residual current circuit breakers (RCCB). This is an electrical wiring device that disconnects a circuit whenever it detects that electrical current is not balanced between the phase (“hot”... -

Page 15: Table 11: Compressed Air

Océ ProCut Site Prep Compressed Air: Compressed air is not supplied internally with the Océ ProCut cutter. The customer must supply either house compressed air or an external air compressor that meets the following requirements: Connector hose interior Ø 6 - 7 mm 0.24 –... -

Page 16: Installation / Training

Océ ProCut Site Prep Installation / Training The operator must have some technical skill and knowledge of PC operation. Only specially trained personnel must operate the Cutter. Trainees must have prior knowledge of computers and basic mechanical abilities. Trainees must be available during the entire time allocated for training. Océ... -

Page 17: Specifications

Océ ProCut Site Prep Specifications Machine Dimensions and Weight: Table 12: 1600 Series Machine Dimensions and Weight 1600 M Dimensions [mm] Weight [kg] 2512 x 2055 Basic unit (L x B) Operator console (B1) Work Station (B2) Router Option (B3) 1600 XL Dimensions [mm] Weight [kg]... -

Page 18: Table 13: 2500 Series Machine Dimensions And Weight

Océ ProCut Site Prep 1600 XXXL Dimensions [mm] Weight [kg] Basic unit (L x B) 2512 x 3935 1120 Operator console (B1) Work Station (B2) Router Option (B3) 2500 M Dimensions [mm] Weight [kg] Basic unit (L x B) 3412 x 2055 Operator console (B1) Work Station (B2) 2500 L... -

Page 19: Table 14: 3200 Series Machine Dimensions And Weight

Océ ProCut Site Prep 3200 L Dimensions [mm] Weight [kg] Basic unit (L x B) 4112 x 2525 1110 Operator console (B1) Work Station (B2) 3200 XL Dimensions [mm] Weight [kg] Basic unit (L x B) 1280 4112 2995 Operator console (B1) Work Station (B2) 3200 XXL Dimensions [mm]... -

Page 20: Floor Conditions

Océ ProCut Site Prep Cutter Extension Dimensions and Weights: Cutter Extension CE2500 T1 [mm] T2 [mm] Weight [kg] 2445 1989 2500 L 2445 1519 2500 M Cutter Extension CE3200 T1 [mm] T2 [mm] Weight [kg] 3145 1989 3200 L 3145 2459 3200 XL 3145... -

Page 21: Environment

Safety Information Ear and eye protection required. Minimum PC Requirements Please check the www.dgs.oce.com web site for the latest PC specifications. Océ ProCut Macintosh Prepress Client • Intel MAC / G4 or faster • 2 GB RAM or more •... -

Page 22: Océ Procut Windows Server & Onyx Rip

Océ ProCut Site Prep Océ ProCut Windows Server & ONYX RIP It is recommended that the Océ ProCut Windows Server and ONYX RIP run on the same computer. Running the two applications on the same computer will provide the fastest file handling since all data files are local. -

Page 23: Check List

Océ ProCut Site Prep Check list In order to avoid complications and misunderstandings, please use this list for your preparation activities: The delivery truck can reach the unloading location without obstruction. A suitable forklift is available for installation. Additional labor is available (if necessary) to get the machine to the installation location. All the measures necessary to get the machine to the installation location are in place.

Need help?

Do you have a question about the ProCut 1600 M and is the answer not in the manual?

Questions and answers