Subscribe to Our Youtube Channel

Summary of Contents for Molecular Devices AquaMax 2000

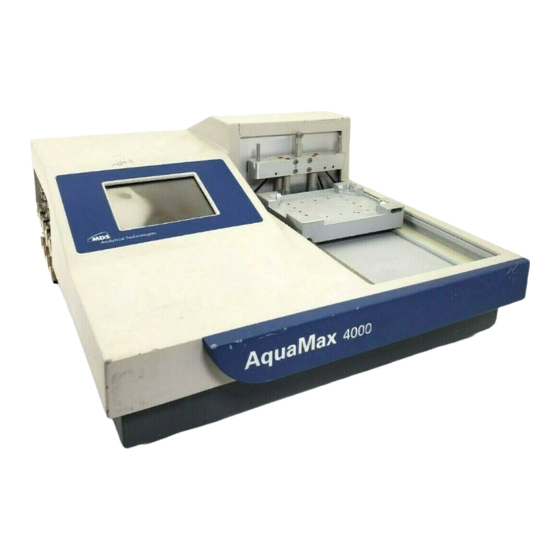

- Page 1 AquaMax 2000/4000 ® Microplate Washer User Guide 0112-0151 K June 2014 www.moleculardevices.com...

- Page 2 For research use only. Not for use in diagnostic procedures. The trademarks mentioned herein are the property of Molecular Devices, LLC or their respective owners. These trademarks may not be used in any type of promotion or advertising without the prior written permission of Molecular Devices, LLC.

-

Page 3: Table Of Contents

Contents Contents..........3 Foreword . - Page 4 AquaMax 2000/4000 Microplate Washer User Guide ® Program Options ........41 Program Messages .

- Page 5 Contents Moving an AquaMax Microplate Washer ....92 ® Preparing for Storage ........93 Chapter 6: Troubleshooting.

- Page 6 AquaMax 2000/4000 Microplate Washer User Guide ® Appendix E: Robot Command Interface ....121 Instrument Configurations ....... . 121 Hardware Interfaces .

-

Page 7: Foreword

Foreword Who This User Guide Is For This guide is intended for users of the AquaMax 2000 and AquaMax ® 4000 Microplate Washers. The user guide contains setup, operation, and general maintenance information. Conventions Within the scope of this user guide, the following typographical conventions are used: WARNING! A warning indicates an operation that can cause personal injury if precautions are not followed. - Page 8 AquaMax 2000/4000 Microplate Washer User Guide ® 0112-0151 K...

-

Page 9: Chapter 1: Introduction

The modular design provides affordable upgrade options when your lab requirements change. Instrument Features AquaMax 2000 and AquaMax 4000 Microplate Washers can be configured to process 96-well and 384-well microplates used in both biochemical and cell-based assays. •... -

Page 10: Robot And Stacker Compatibility

AquaMax 2000/4000 Microplate Washer User Guide ® Robot and Stacker Compatibility AquaMax Microplate Washers are compatible with Molecular Devices StakMax Microplate Handling System. Third party robots can be set up ® to control the AquaMax Microplate Washers through a USB command interface. -

Page 11: Touch Screen

Introduction Touch Screen Figure 1-1: AquaMax touch screen ® Instrument operation is controlled through a touch-screen user interface. The touch screen displays instrument status, provides access to instrument settings and programs, and controls the optional StakMax Plate Stacker. Wash Heads AquaMax wash heads have either 96 or 384 paired probes. - Page 12 AquaMax 2000/4000 Microplate Washer User Guide ® Table 1-2: 96-plate wash head lock Item Description Close Open Note: A mismatched wash head and microplate will cause a motor pinch error when the wash head tries to descend toward the wells. A mismatch should not damage the wash head.

- Page 13 Introduction Each wash head has a clear plastic guard to protect the probes from damage, and to prevent spills, sprays, and injury to users. Table 1-3: 384-plate wash head and guard Item Description Plastic guard Aspiration and dispensing probes on underside of wash head 0112-0151 K...

-

Page 14: Microplate Carriage

AquaMax 2000/4000 Microplate Washer User Guide ® Microplate Carriage The microplate carriage is located on the right side of the washer. The plate carriage slides in and out of the washing chamber for loading and unloading. Table 1-4: Plate carriage Item Description Plate carriage, in eject position 384-well microplate... - Page 15 Introduction Supported Microplates AquaMax Microplate Washers accommodate rigid SBS-standard polystyrene and polypropylene microplates with dimensions 128.2 mm (L) × 86.0 mm (W), and heights ranging from 13.5 mm to 15.5 mm, including: • 96-well and 384-well standard formats (U-bottom, V-bottom, or Flat) •...

-

Page 16: Reagent And Waste Bottle Ports

Reagent and Waste Bottle Ports The source channels and waste connections are located on the left side of the instrument. The AquaMax 2000 Microplate Washer has two source channels, while the AquaMax 4000 Microplate Washer has four. Each source channel can be connected to a reagent bottle, and is composed of a fluid input, a pressure output, and an optional level sensor connector. -

Page 17: Back Panel

Introduction *The AquaMax 2000 Microplate Washer has only green and red inlets. Back Panel The power switch, power cord receptacle, communication ports, and instrument information, are located on the back panel of the instrument. Table 1-6: Back panel, right side... - Page 18 AquaMax 2000/4000 Microplate Washer User Guide ® Table 1-7: AquaMax Microplate Washer USB and StakMax connectors ® ® Item Description USB port StakMax connector ® The USB Type B port is designated for external robotic control. The StakMax communication port is dedicated to control StakMax stacker operations.

-

Page 19: Chapter 2: Installation

CAUTION! Do not operate the instrument in an environment with a temperature below 15°C. CAUTION! Do not touch or loosen any screws or parts unless specifically instructed by Molecular Devices. Doing so can cause misalignment and voids the instrument warranty. 0112-0151 K... -

Page 20: Unpacking

• The base unit box contains the washer unit and accessories (manual, power cord, waste tube, and tubing label kit): AquaMax 2000 Microplate Washer (Part Number: 0310- 5363) AquaMax 4000 Microplate Washer (Part Number: 0310- 5227) ... -

Page 21: Setting Up The Instrument

To install the wash head on page 26 To turn on the instrument Molecular Devices recommends that you use a surge protector between the power cord and the grounded power outlet. 1. Connect the power cord to the back panel. - Page 22 5 years of service. Eventually, they will show signs of aging such as yellowing, plastic degradation, or thread wear. Therefore, it is imperative to replace bottles at the earliest signs of aging. Use only bottles supplied for use with the AquaMax 2000 and 4000 Microplate Washers. 0112-0151 K...

- Page 23 Installation 1. Fill the bottle with a reagent, and tighten the cap firmly. Tip: For quick and accurate assembly of reagent bottles, use slip- on rings to color-code all tubing and sensor connections. 2. Connect one end of the fluid tubing to the large fitting on the bottle cap.

- Page 24 AquaMax 2000/4000 Microplate Washer User Guide ® To connect a waste bottle Table 2-2: Waste bottle and connection fittings Item Description Waste sensor connector Waste output fitting Waste bottle Waste full sensor Waste tubing 0112-0151 K...

- Page 25 Installation 1. Connect the quick connect fitting of the waste tubing to the Waste Output fitting on the left side of the instrument. 2. Connect the free end of the tubing to any vented waste container. For non-toxic waste the free end of the tubing can be placed directly into a sink.

- Page 26 AquaMax 2000/4000 Microplate Washer User Guide ® To install the wash head CAUTION! The probes on the underside of the wash head are delicate. Take care when handling the wash heads. 1. Install the wash head (96 or 384) of choice. Wash heads are shipped pre-qualified and will work with any base unit.

-

Page 27: Connecting To A Stakmax Plate Stacker

Installation Connecting to a StakMax Plate Stacker ® 88 1 Table 2-3: AquaMax Microplate Washer with StakMax Plate Stacker ® ® installed Item Description StakMax Plate Stacker ® To connect the AquaMax Microplate Washer to the StakMax Plate ® Stacker you will need the StakMax integration kit (Part Number: 0310- 5454). - Page 28 AquaMax 2000/4000 Microplate Washer User Guide ® Table 2-4: StakMax Plate Stacker to AquaMax Microplate ® ® Washer adapter plate Item Description AquaMax Microplate Washer ® StakMax Plate Stacker ® Adapter plate 3. Connect the StakMax communication cable to the serial port on the back of the StakMax Plate Stacker.

- Page 29 Installation Figure 2-2: StakMax Stacker indicator The washer controls the stacker through its on board programs. For information about using the stacker in a program, see Program Stacker Settings on page 0112-0151 K...

- Page 30 AquaMax 2000/4000 Microplate Washer User Guide ® 0112-0151 K...

-

Page 31: Chapter 3: Getting Started

Getting Started This chapter provides the information required to get started with the AquaMax 2000 and AquaMax 4000 Microplate Washers. ® • Starting the Instrument on page 31 • Main Tab on page 32 • Running Programs on page 34 •... -

Page 32: Main Tab

AquaMax 2000/4000 Microplate Washer User Guide ® Main Tab The Main tab is used to execute stored programs. It features quick access buttons for the one-touch maintenance programs and a list of user-defined programs. Table 3-1: Main tab Item Description Function Tabs–The Main tab is selected. - Page 33 Getting Started Table 3-1: Main tab (cont’d) Item Description Rinse–Runs the one-touch rinse program. The one-touch rinse program runs the standard rinse cycle three times to flush the internal fluidics with rinse solution from the default green inlet. At the end of the rinse program, the system drains the rinse solution from the fluid paths.

-

Page 34: Running Programs

AquaMax 2000/4000 Microplate Washer User Guide ® Running Programs To run a stored program Note: Gray programs are not compatible with the installed wash head. You cannot run a gray program. Note: Red programs indicate a change in the plate type. When you run a red program, the message “Plate parameters changed”... -

Page 35: Stopping Programs

Getting Started To run a one-touch maintenance program 1. Make sure that all appropriate reagent bottles are connected to Liquid Input and Pressure fittings on the left side of the instrument. 2. Make sure that the waste tubing is connected to the Waste Output fitting and the Waste bottle. -

Page 36: Shutting Down The Instrument

AquaMax 2000/4000 Microplate Washer User Guide ® 3. If fluid remains in the trough, then in the Options tab, touch Purge. Note: The wash head must be re-primed to continue. Shutting Down the Instrument The AquaMax Microplate Washer supports the following shutdown options: •... -

Page 37: Chapter 4: Operation: The Touch Screen Interface

Operation: The Touch Screen Interface Operation of the AquaMax Microplate Washer is controlled by the on- ® board touch screen. This chapter provides information about the functions that are available on each tab of the interface. • Administrative Mode on page 37 •... -

Page 38: Program Tab

AquaMax 2000/4000 Microplate Washer User Guide ® The passcode is not required to run existing programs, view program details and plate details, or access Depressurize, Purge, and Shutdown on the Options tab. Program Tab The Program tab contains the functions to manage the program library. Table 4-1: Program tab, general access to all functions Item Description Function Tabs–The Program tab is selected. -

Page 39: Program Tab: Administrative Mode

Operation: The Touch Screen Interface Table 4-1: Program tab, general access to all functions (cont’d) Item Description 9,10 Move Up and Move down–Moves the selected program up or down in the program list. The one-touch programs cannot be moved. They are always listed at the top of the program list. -

Page 40: Program Settings Dialog

AquaMax 2000/4000 Microplate Washer User Guide ® For information about restricting access to editing functions, see Restricting Functions on page Program Settings Dialog The Program Settings dialog controls step-independent program information. It appears automatically when you create a new program and is the first item in the program after the program has been saved. -

Page 41: Program Options

Operation: The Touch Screen Interface To access the Program Settings dialog for a program 1. Touch the Program tab. 2. Select a program from the list. 3. Touch Edit. 4. Touch Program Settings at the top of the list of program steps. 5. -

Page 42: Program Messages

AquaMax 2000/4000 Microplate Washer User Guide ® Program Messages You can set up the program to display a message before and after running the steps of the program. Messages are optional. Table 4-5: Messages dialog Item Description Program Start Message–Opens the keypad where you can enter a message to display on the touch panel when the current program is run. -

Page 43: Program Stacker Settings

Operation: The Touch Screen Interface Program Stacker Settings In the stacker settings dialog you can enable stacker options for the current program. Stacker settings are optional. See To access the stacker options for the current program on page With the stacker enabled, plates are supplied from the stacker input. Each plate is washed using the same program and then placed in the stacker output. -

Page 44: Adjust Dispense

AquaMax 2000/4000 Microplate Washer User Guide ® To access the stacker options for the current program 1. Select Program Settings from the list of steps. 2. Touch Edit. 3. Touch Program Options. 4. Touch Stacker. Adjust Dispense The Adjust Dispense dialog lets you optimize the accuracy of the dispense volumes based on the specific requirements of the individual program. -

Page 45: Program Tab: Program Editing

Operation: The Touch Screen Interface Program Tab: Program Editing The Program Tab contains the functions to manage the steps in the current program. See To access program details on page Table 4-7: Program details Item Description New–Opens the New Step dialog where you can select the type of new step to add to the current program. -

Page 46: New Step Selection

AquaMax 2000/4000 Microplate Washer User Guide ® To access program details 1. Touch the Program tab. 2. Touch a program. 3. Touch Edit. New Step Selection The New Step dialog lists the steps that can be included in the current washer program. -

Page 47: Dispense Settings

Operation: The Touch Screen Interface • Repeat Settings on page 56 • Purge Settings on page 57 • Rinse Settings on page 58 • Standby Settings on page 59 • Prime Settings on page 60 Dispense Settings The Dispense step dispenses fluid into a microplate using predefined parameters. - Page 48 AquaMax 2000/4000 Microplate Washer User Guide ® Table 4-8: Dispense settings Item Description Volume–Volume to be dispensed. Use 5 to 150 μL for 384-well plates and 20 to 400 μL for 96-well plates. The volume must be within the specified range for the plate or the program cannot be saved or run.

-

Page 49: Aspirate Settings

Operation: The Touch Screen Interface Dispense accuracy is set to specification during manufacturing. The following factors can affect dispense accuracy: • Types of reagent. • Locations and size of reagent bottles. The AquaMax Microplate Washer supports 4 L or 10 L bottles only. -

Page 50: Wash Settings

AquaMax 2000/4000 Microplate Washer User Guide ® Table 4-10: Aspirate settings Item Description Probe height–final probe height above the bottom of the well. The range is 0 to the top of well. The maximum probe height is the well depth specified in the plate library. To avoid damage to probes and plate bottom, the AquaMax ®... - Page 51 Operation: The Touch Screen Interface Table 4-12: Wash settings Item Description Inlet–Liquid to be used for this step. The available options correspond to the color-coded reagents connected to the washer. Prompt–Indicates that the system will pause before dispensing and wait for the user to specify an inlet. Rate–Wash rate (see Table 4-13: Wash Rates).

- Page 52 AquaMax 2000/4000 Microplate Washer User Guide ® Table 4-13: Wash Rates Model # Options 96 (μL/well/sec) 384 (μL/well/sec) AQ 2000 (no option) Tip: Wash volume should not exceed 10x the well volume. Tip: The wash step leaves the wells partially empty (bottom wash) or full (top wash).

-

Page 53: Fastwash Settings

Operation: The Touch Screen Interface FastWash Settings The FastWash step is designed for rapid microplate washing using multiple aspirate-dispense cycles with predefined parameters. FastWash performs a final aspiration after the last cycle. All aspirations use a rate of 5 and a fast descent speed. See Table 4-11: Aspiration Rates. -

Page 54: Shake Settings

AquaMax 2000/4000 Microplate Washer User Guide ® Shake Settings The Shake step shakes a microplate in the carriage using predefined parameters. Table 4-15: Shake settings Item Description Shake speed–Speed of shaking (Slow, Medium, or Fast). A fast shake is vigorous and generally mixes the wells in 10 to 30 seconds. -

Page 55: Soak Settings

Operation: The Touch Screen Interface Soak Settings The Soak step pauses the program for a specified duration. During a Soak step, probes are removed from the microplate wells. No other operations are performed for the duration. Table 4-16: Soak settings Item Description Time–Duration of soak, in minutes and seconds. -

Page 56: Repeat Settings

AquaMax 2000/4000 Microplate Washer User Guide ® Repeat Settings 1. The Repeat step repeats a set of previous program steps. Table 4-17: Repeat settings Item Description Repeat from step–The numbered step at which to start the repetition. The list contains the previous steps in the current program. Repetitions–The number of extra cycles to be performed. -

Page 57: Purge Settings

Operation: The Touch Screen Interface Purge Settings The Purge step evacuates liquids from the installed wash head. It has no programmable parameters. Figure 4-3: Purge screen (no settings) Tip: Run a Purge step when the washer will not be used again immediately. -

Page 58: Rinse Settings

AquaMax 2000/4000 Microplate Washer User Guide ® Rinse Settings The Rinse step flushes the selected reagent through the internal fluidics and the installed wash head. Table 4-18: Rinse settings Item Description Inlet–Liquid to be used for this step. The available options correspond to the color-coded reagents connected to the washer. -

Page 59: Standby Settings

Operation: The Touch Screen Interface Standby Settings Use Standby mode to keep wash fluid in the head without the need to prime the head if there is a delay between uses. The Standby step fills the prime/soak trough with a wash fluid and leaves the dispense/aspirate probes in the wash fluid. -

Page 60: Prime Settings

AquaMax 2000/4000 Microplate Washer User Guide ® Prime Settings The Prime step primes the internal fluidics and installed wash head with the selected reagent. During the Prime step, the needles are immersed in the priming liquid to wash the outsides of the needles. This is a maintenance step and does not require a microplate to run. -

Page 61: Managing The Program Library

Operation: The Touch Screen Interface Managing the Program Library All programs can be modified. Factory-provided one-touch programs can be edited, but not renamed or deleted. Note: Program options and menus are optimized for the installed wash head. Before creating or editing a program, make sure that the appropriate wash head is installed. - Page 62 AquaMax 2000/4000 Microplate Washer User Guide ® 3. In the Program Settings dialog, touch a plate type from the Plate list. Figure 4-5: Program settings Note: Plates that are not compatible with the installed wash head appear gray. 4. If applicable, click Program Options to add Program Start and Program Done messages to the program (see Program Messages on page...

- Page 63 Operation: The Touch Screen Interface Note: Test dispense accuracy separately and use the results to adjust the settings in your program. For more information, see adjust dispense accuracy for a program on page 5. Touch OK to save your changes and close the Program Settings dialog.

- Page 64 AquaMax 2000/4000 Microplate Washer User Guide ® To copy a program 1. On the Program tab, touch the program to be copied, and touch Copy. 2. In the Copy Program dialog type the name of the new program. The default name of the copy is the name of the existing program followed by an asterisk (*).

- Page 65 Operation: The Touch Screen Interface To rename a program 1. Select the program to be renamed, and touch Rename. 2. Type a new name for the program. 3. Touch OK to save the change. Note: One-touch programs cannot be renamed. To delete a program Note: A deleted program cannot be recovered.

- Page 66 AquaMax 2000/4000 Microplate Washer User Guide ® Figure 4-7: Program tab, program editing 2. To add a step, touch New and touch the type of step you want to add. The parameters dialog for the selected step type appears. 3. Complete the parameters dialog and touch OK when finished. The newly-created program step appears in the program list.

- Page 67 Operation: The Touch Screen Interface To edit a step in a program 1. Select the program to be edited and touch Edit. The Program tab displays the details for the selected program. 2. Select the step you want to work with and choose one of the following options: ...

- Page 68 AquaMax 2000/4000 Microplate Washer User Guide ® To adjust dispense accuracy for a program Dispense accuracy in the AquaMax Microplate Washer is set to specification during manufacturing. However, various installation configurations can also affect accuracy, such as location and size of reagent bottles, types of reagent, and so on.

- Page 69 Operation: The Touch Screen Interface 8. Weigh the plate after the dispense to measure the amount of liquid dispensed. 9. Divide the fluid mass by the fluid density and number of wells to get the measured volume per well: Fluid mass §...

-

Page 70: Plates Tab

AquaMax 2000/4000 Microplate Washer User Guide ® Plates Tab The Plates tab contains the functions for managing the plate library. Table 4-21: Plates tab Item Description New–Creates a new plate type. Edit–Opens the details of the selected plate type for editing. Delete–Deletes the selected plate type. -

Page 71: Plates Tab: Administrative Mode

Operation: The Touch Screen Interface Plates Tab: Administrative Mode In administrative mode, general users have access to only the View button and the Admin button. The Admin button and the administrator passcode access the plate editing options. Table 4-22: Plates tab with administrative mode Item Description View–Opens the selected plate so that you can view the plate details. -

Page 72: Plate Definition Dialog

AquaMax 2000/4000 Microplate Washer User Guide ® Plate Definition Dialog A plate definition details the parameters used by the instrument during operations. The plate definition controls the position of the plate and the probes. Inaccurate settings can cause some operations to run incorrectly. Table 4-23: Plate definition Item Description Name–Name of the plate type. -

Page 73: Managing The Plate Library

Operation: The Touch Screen Interface Table 4-23: Plate definition (cont’d) Item Description Well Depth (mm): Distance in millimeters from the bottom of the well to the top of the well. Well depth is critical to reliable instrument operation. An incorrect well depth can result in inefficient plate aspiration, plate and wash head damage, or “Vertical Error 225”... -

Page 74: Options Tab

AquaMax 2000/4000 Microplate Washer User Guide ® To edit a plate type 1. Select the plate to be edited in the Plate tab, and touch Edit. 2. Select new plate parameters in the dialog. 3. Touch OK to save and exit, or Cancel to exit without saving. All programs that refer to the edited plate type are listed in red in the program list to indicate changes in the plate definition. - Page 75 Operation: The Touch Screen Interface Table 4-24: Instrument options Item Definition Depressurize–Releases the system and bottle pressure. During operation, the source bottles can be under mild pressure—up to 500 mmHg (10 psi or 70 kPa). Before changing the fluid in the source bottles, depressurize to avoid releasing pressure when opening the cap.

-

Page 76: Advanced Options Dialog

AquaMax 2000/4000 Microplate Washer User Guide ® Advanced Options Dialog Table 4-25: Advanced options Item Description Shutdown Options–Opens the Shutdown Options dialog where you can modify the instrument’s automatic shutdown options. See Shutdown Options Dialog on page Auto Drain–Drains the trough every time the plate is ejected. Done–Closes the Advanced Options dialog. - Page 77 Operation: The Touch Screen Interface Table 4-26: Options tab with administrative mode Item Description Depressurize–Releases the system and bottle pressure. During operation, the source bottles can be under mild pressure—up to 500 mmHg (10 psi or 70 kPa). Before changing the fluid in the source bottles, depressurize to avoid releasing pressure when opening the cap.

-

Page 78: Shutdown Options Dialog

AquaMax 2000/4000 Microplate Washer User Guide ® Shutdown Options Dialog Table 4-27: Shutdown options Item Description Timeout–Wait time in hours and minutes before the system enters Shutdown mode. Rinse–Indicates whether the system should be rinsed before shutting down (On or Off). Inlet–Liquid Input to be used for rinse fluid (Green, Red, Blue, or Yellow). -

Page 79: Managing The Software

Operation: The Touch Screen Interface Managing the Software Automatic Shutdown The shutdown runs automatically when the instrument has been inactive for a user-specified amount of time. While the system is in shutdown mode, its power consumption is minimal. Note: You can trigger the shutdown manually by touching Shutdown on the Options tab. -

Page 80: Restricting Functions

AquaMax 2000/4000 Microplate Washer User Guide ® Restricting Functions By default, no passcode is set, and all functions are available to all users. The AquaMax Microplate Washer can be set up to use an Administrative passcode to prevent unintentional modifications to stored programs, plate types, and instrument settings. -

Page 81: Screen Calibration

Operation: The Touch Screen Interface Screen Calibration The AquaMax Microplate Washer has a screen calibration feature that enables the user to calibrate the position of the touch screen overlay on the LCD screen. To calibrate the screen 1. On the Options Tab, touch Calibrate Screen. Figure 4-9: Screen calibration screen 2. - Page 82 AquaMax 2000/4000 Microplate Washer User Guide ® 0112-0151 K...

-

Page 83: Chapter 5: Maintenance

Review the manual prior to beginning the maintenance procedures. Maintenance not covered in this manual should be performed only by a Molecular Devices representative. Technical Support Molecular Devices is a leading worldwide manufacturer and distributor of analytical instrumentation. -

Page 84: Routine Maintenance

Refer servicing to Molecular Devices service representatives. WARNING! Never perform any operation on the instrument in an environment where potentially damaging liquids or gases are present. -

Page 85: Purging The Instrument

Maintenance Purging the Instrument CAUTION! All maintenance programs must be run with a wash head installed. CAUTION! If using decontaminant solutions other than AquaMax Sterilant, consult the chemical compatibility table (Table B-1 on page 113) to verify that the decontaminant solution will not cause damage to the instrument. -

Page 86: Decontaminating The Instrument

AquaMax 2000/4000 Microplate Washer User Guide ® Decontaminating the Instrument WARNING! Biohazardous Material. Wear protective equipment and dispose of waste materials in accordance with laboratory site regulations and procedures. Solutions used in the instrument and waste materials might be biohazardous. WARNING! Chemical Waste Disposal Hazard. -

Page 87: Cleaning The Exterior

Waste material might contain toxic, corrosive, and biohazardous material. WARNING! Risk of electrical shock. There are no user-serviceable parts inside the instrument. Refer servicing to Molecular Devices service representatives. CAUTION! Risk of equipment damage. Do not open the panels and covers to clean inside the instrument. -

Page 88: Removing And Storing Wash Heads

AquaMax 2000/4000 Microplate Washer User Guide ® Fluids that spill in the instrument during operation drain through the prime/soak trough. CAUTION! If the trough fluid overfills or spills elsewhere, it leaks through the bottom of the instrument to the counter beneath and must be wiped up immediately to prevent damage. - Page 89 Maintenance To remove the wash head 1. To prepare the wash head for removal, run the one-touch Rinse program using sterile water as the rinse fluid. (See Program Tab on page 38.). Note: Repeat several times if a particularly harsh reagent was used previously.

- Page 90 AquaMax 2000/4000 Microplate Washer User Guide ® To recover the microplate and wash head manually The Reset button on the bottom right corner of the Options tab performs a software reset without power cycling the instrument. If the washer fails during an operation, perform a reset to manually retrieve any microplate still stuck in the system.

-

Page 91: Cleaning Wash Heads

Maintenance Cleaning Wash Heads Occasionally one or more of the aspiration/dispense probes might be clogged if the wash heads are not purged properly after use. When one or more probes are clogged, you might see uneven dispense/aspirate rates, or liquid dripping out of the probes. To clean wash heads using the on-board programs 1. -

Page 92: Moving An Aquamax Microplate Washer

AquaMax 2000/4000 Microplate Washer User Guide ® Moving an AquaMax Microplate Washer ® Make sure that the new location meets the specifications as described in Setting Up the Instrument on page To move an AquaMax Microplate Washer to another location ®... -

Page 93: Preparing For Storage

Maintenance Preparing for Storage To turn off the instrument Use this procedure for prolonged inactivity. For regular use, the automatic shutdown feature manages power, screen, motors, and valves. (See Automatic Shutdown on page 79.) 1. Make sure that the wash head remains installed throughout the procedure. - Page 94 AquaMax 2000/4000 Microplate Washer User Guide ® To prepare the wash head for storage Note: If you have followed the instructions in To turn off the instrument on page 93, then skip Step 1 Step 2 of this procedure and start at Step 1.

-

Page 95: Chapter 6: Troubleshooting

Support department at the number listed in Technical Support on page Note: It is your responsibility to decontaminate the instrument, as well as any accessories, before requesting service by Molecular Devices representatives and before returning the instrument or any components to Molecular Devices. General Instrument Issues... -

Page 96: System Fluidics Issues

AquaMax 2000/4000 Microplate Washer User Guide ® System Fluidics Issues Table 6-2: System Fluidics Issues Problem Possible Causes & Remedies Air in the bottle lines. Prime lines using the one-touch Prime program. Leaks from the liquid inlet When the bottle tubing is disconnected from quick connects on the left side the quick-connect, it is normal for a small of the washer. -

Page 97: System Pressure Issues

Troubleshooting System Pressure Issues Table 6-3: System Pressure Issues Problem Possible Causes & Remedies Pressure timeout error If the system cannot achieve target bottle 154. pressure: • Check that all pressure fittings are properly connected. • Tighten caps on all reservoir bottles. •... -

Page 98: External Communication Issues

AquaMax 2000/4000 Microplate Washer User Guide ® External Communication Issues Table 6-4: External Communication Issues Problem Possible Causes & Remedies The StakMax stacker is not Verify that the StakMax cable is connected to ® communicating. both the StakMax stacker and the AquaMax ®... -

Page 99: Dispense Issues

Troubleshooting Dispense Issues Table 6-5: Dispense Issues Problem Possible Causes & Remedies No liquid in the plate after Verify that the dispense parameters (inlet, dispense. volume) are set correctly. Verify that all appropriate bottles and tubing are connected to the instrument, and that the bottles are not empty. -

Page 100: Aspiration Issues

AquaMax 2000/4000 Microplate Washer User Guide ® Aspiration Issues Table 6-6: Aspiration Issues Problem Possible Causes & Remedies The microplate is stuck on the Microplates with conical or tapered bottoms wash head after aspiration or (such as certain V-bottom or small- wash. - Page 101 Troubleshooting Table 6-6: Aspiration Issues (cont’d) Problem Possible Causes & Remedies Significant residual liquids in a One or more aspiration probes might be few wells. clogged: • Follow the procedures in Cleaning Wash Heads on page 91 to unclog the probes. Aspiration probe tips might be touching the well bottoms: •...

-

Page 102: Wash Issues

AquaMax 2000/4000 Microplate Washer User Guide ® Wash Issues Table 6-7: Wash Issues Problem Possible Causes & Remedies Some wells overflow during Aspiration probe tips might be touching the wash. well bottoms during bottom wash: • Verify that all plate parameters in the plate library match the plate in use. -

Page 103: Cell Wash Issues

Troubleshooting Cell Wash Issues Table 6-8: Cell Wash Issues Problem Possible Causes & Remedies Coating or cells in wells are Decrease the aspiration rate (96-cell wash damaged after wash or head only). aspirate. Decrease the aspiration dwell time Increase the aspiration probe height. Coating or cells in wells are Decrease the dispense rate. - Page 104 AquaMax 2000/4000 Microplate Washer User Guide ® Table 6-9: Instrument Error Messages Problem Possible Causes & Remedies “Z-Motor Pinched” or Obstruction to the motion of the wash head: “Z-Motor Stalled” • Turn off the power to the washer and then remove Error.

- Page 105 Troubleshooting Table 6-9: Instrument Error Messages (cont’d) Problem Possible Causes & Remedies “Z: Failed find home” Obstruction to the motion of the wash head: Error 220 • Turn off the power to the washer and then remove any obstructions from the path of the wash head. The wash head home sensor might be malfunctioning: •...

- Page 106 AquaMax 2000/4000 Microplate Washer User Guide ® Figure 6-1: Plate stage home sensor Figure 6-2: Plate sensor 0112-0151 K...

-

Page 107: Chapter 7: Specifications

Specifications Technical specifications are subject to change without notice. AquaMax Microplate Washer ® Table 7-1: AquaMax Microplate Washer Specifications ® Microplate Compatibility Microplates 96-well and 384-well with SBS footprint (128.2 mm × 86.0 mm) and height (13.5 to 15.5 mm) Note: Compatibility with 96-well strip plates varies across brands due to plate designs. - Page 108 AquaMax 2000/4000 Microplate Washer User Guide ® Table 7-1: AquaMax Microplate Washer Specifications (cont’d) ® Microplate Compatibility 384-well three cycles 28 seconds FastWash Times (optimized for speed) 96-well wash head, 300 μL per well, three cycles 14 seconds 384-well wash head, 100 μL per well, three cycles 16 seconds...

- Page 109 Specifications Table 7-1: AquaMax Microplate Washer Specifications (cont’d) ® Microplate Compatibility Liquid-contact materials Nylon, Polypropylene, Teflon, Polyethylene, Stainless Steel, Silicone Electrical Power Universal voltages: 100 V to 240 V~, 50 Hz to 60 Hz, 1.75 A 0112-0151 K...

- Page 110 AquaMax 2000/4000 Microplate Washer User Guide ® 0112-0151 K...

-

Page 111: Appendix A: Microplate Library

Microplate Library Table A-1: Dimensions for Default Microplates in Plate Library Height Depth Name # Wells Bottom Manufacturers’ # (mm) (mm) Costar Flat 3650, 3916, 3915, 3361, 3590, 14.20 10.67 9018, 3591, 9017, 3641, 3628, 3370, 2507, 2509, 2503, 3665, 3600, 3362, 3917, 3912 Falcon Flat... - Page 112 AquaMax 2000/4000 Microplate Washer User Guide ® 0112-0151 K...

-

Page 113: Appendix B: Cleaning Solutions

Cleaning Solutions Table B-1: AquaMax Microplate Washer Compatible and Incompatible ® Cleaning Solutions Compatible solutions Incompatible solutions • AquaMax Sterilant * (see AquaMax • Strong Acids ® Sterilant on page 115) • Xylene, Toluene • 5% to 20% household bleach, •... - Page 114 AquaMax 2000/4000 Microplate Washer User Guide ® 0112-0151 K...

-

Page 115: Appendix C: Aquamax Sterilant

AquaMax Sterilant AquaMax Sterilant (Part Number: R8156) can be used to clean and ® sterilize the fluid paths in the AquaMax Microplate Washer. Principle of Use Accumulated residues and contaminating microorganisms can impair the operation of liquid handling equipment. Proteins in cell culture media, salts and minerals in buffers, and other reagent components can build up on fluid path surfaces. -

Page 116: Contents

AquaMax 2000/4000 Microplate Washer User Guide ® Contents • Sterilant Solution A Concentrate (4X): detergent in buffered aqueous solution (two 1 L bottles). • Sterilant Solution B: sodium hypochlorite in aqueous solution (two 14 mL bottles) Materials Required but Not Provided •... -

Page 117: Preparing The Reagent

The automated cleaning cycle on the AquaMax Microplate Washer liquid handling system uses approximately 420 mL of Complete Sterilant. Molecular Devices recommend that you prepare 500 mL of Complete Sterilant to make sure that you have enough. Preparing the Complete Sterilant To prepare 500 mL of Complete Sterilant: 1. -

Page 118: Warnings, Precautions, And Limitations

Community Right-To-Know Regulations: Sterilant Solution A Concentrate (4X) Chemical Composition The chemical composition of this solution is a trade secret and proprietary property of Molecular Devices. Sterilant Solution B Chemical Composition: Sodium Hypochlorite, Solution CAS #: 7681-52-9 0112-0151 K... -

Page 119: Appendix D: Tips And Applications

Tips and Applications Using the Washer for ELISA Based Applications Objective: wash effectively to get a dry plate to achieve low background and improved signal. All ELISA assays differ in their binding properties. Biochemical antigen- antibody interactions can be strong or weak. In general, use: •... - Page 120 AquaMax 2000/4000 Microplate Washer User Guide ® For best results with the 96 Cell Wash Head, use: • Low dispense rate • Medium to high aspiration rate • Fast aspiration descent rate • Short aspiration dwell time • Probe height of 3 mm or more above the bottom of the well •...

-

Page 121: Appendix E: Robot Command Interface

Robot Command Interface Instrument Configurations AquaMax Microplate Washers can be externally controlled by a host ® computer. Using commands described here, the host computer can completely bypass the operation of the on-board touch screen. A StakMax Plate Stacker can be directly connected to an AquaMax ®... -

Page 122: Command Format

AquaMax 2000/4000 Microplate Washer User Guide ® Command Format Document Conventions Table E-1: Command Formatting CAPS ITALICIZED Command names Indicates the possible choices for that argument A comma separates the arguments. In the instrument, arguments are space delimited; therefore the comma is shown here only for clarity italicized Command arguments... -

Page 123: No Error (Ok) Responses

Robot Command Interface No Error (OK) Responses Valid commands with no response data and empty lines will be acknowledged by the “no data OK” response: > TABCRLF Where OK identifies the no error response terminated by the character (>) and added for better readability in terminal CRLF applications. -

Page 124: General Commands

AquaMax 2000/4000 Microplate Washer User Guide ® General Commands Initialization Reset Command: / RESET [no arg] Action: Resets the washer. Stops pumps, closes all valves, homes all axes, and moves the plate carrier to the loaded position. It requires polling of the instrument status for completion with “/status”... -

Page 125: Device Information

StakMax firmware versions. Name Command: / [no arg] NAME Action: Returns the name and model of the instrument. Response: Name and model ASCII string, “AquaMax 2000” or “AquaMax 4000”. Example: AquaMax 4000 > CRLF Serial Number Command: / [no arg]... - Page 126 AquaMax 2000/4000 Microplate Washer User Guide ® Status Command: / [no arg | y | z] STATUS Action: Provides information describing either the status of the other instrument (no arguments) or the requested axis status: Response IDLE the instrument or AXTS is idle, no errors, ready to run.

- Page 127 Robot Command Interface State Report Command: / [no arg] REPORT Action: Returns a text message describing the current action in progress or status. Response: “text message” n m Where n is an action flag: (-127) = display post-program user message (in Pause state). (-2) = display pre-program user message (in Pause state).

-

Page 128: Motion Control

AquaMax 2000/4000 Microplate Washer User Guide ® Motion Control Eject a Plate Command: / EJECT [no arg | (0 | 1)] Action: Ejects or loads the plate, reports current “eject” position. Returns current “eject” position (= 0 if plate is arg]: loaded, = 1 if plate is ejected). -

Page 129: Program Control

Robot Command Interface Program Control Pause / Resume Command: / PAUSE [no arg | 0 | 1] Action: Temporarily pauses (or resumes) execution of a running program. Reports current state. arg]: [0]: Resumes execution of a paused program. [1]: Requests a pause. The program is paused and the status reports PAUSE only after the current step is done. - Page 130 AquaMax 2000/4000 Microplate Washer User Guide ® Shutdown Command: / SHUTDOWN [no arg | Proc {Inlet}] Action: The command runs the instrument shutdown procedure. Note: The command returns an error if the instrument status is busy running a program or motion command.

-

Page 131: User Adjustment

Robot Command Interface User Adjustment Liquid Factor Command: / LIQF [no arg | P0 {P1 P2 P3}] Action: For currently open protocols, specifies a liquid factor value to adjust effective dispense time for a specified inlet for any dispense (wash) step in 50-200[%] of the calculated nominal. -

Page 132: Program Management Commands

AquaMax 2000/4000 Microplate Washer User Guide ® Program Management Commands You create programs to wash plates and perform maintenance. These programs or protocols are composed of basic primitives for wash functions (dispense, aspirate, wash, shake), program control (soak/pause, repeat), or maintenance functions (prime, purge, rinse). Firmware maintains these protocols in non-volatile storage, with a total of 103 slots available. -

Page 133: Protocol (Program) Control

Robot Command Interface Protocol (Program) Control Command: / PROTOCOL <Index> | Run <index>| Open | Close <save>| New <name>| Delete <index>| Copy <index> <name>| Rename <index> <name>| Get <m>| Set <m> <Args> Action: Edits and views the stored protocol list. Used in conjunction with the /step command to edit protocol steps. - Page 134 AquaMax 2000/4000 Microplate Washer User Guide ® Close “No data OK” response if the command succeeds. Response: New Action: Creates a new blank protocol with the name set to <name>. <Name> is limited to 19 characters. Default program settings are: no start or end messages, “no-plate” attached, manual stacker mode, no restacking.

- Page 135 Robot Command Interface Rename Renames Index protocol to <name>. One-touch protocols Action: 0-2 cannot be renamed. Rename “No data OK” response if the command succeeds. Response: Get Action: Reads a field, <m>, from the open protocol settings, where <m> is 0 = start message, 1 = end message, 2 = protocol parameters.

-

Page 136: Edit/View Opened Protocol Steps

AquaMax 2000/4000 Microplate Washer User Guide ® Set Action: Sets a field, <m>, of the open protocol settings, where <m> is 0 = start message, 1 = end message, 2 = protocol parameters. A protocol must be opened (/protocol open) before /protocol set can succeed. - Page 137 Robot Command Interface New Action: Creates a new blank step at the specified <index>. Former steps <index> and greater are incremented. “No data OK” response if the command succeeds. Response: Delete Deletes <index> step. Existing subsequent steps are Action: decremented. Delete “No data OK”...

-

Page 138: Function-Specific Step Arguments And Return Data

AquaMax 2000/4000 Microplate Washer User Guide ® Function-specific Step Arguments and Return Data The < > and < > parameters of the / command and response code tokens STEP are mnemonics for protocol steps primitives and required parameters. <Code> is one of the following step types (all are four characters except nop): disp dispense... - Page 139 Robot Command Interface mode speed address (index) of another step number Dispense (DISP) Dispense step delivers a specified amount of fluid into the plate. The dispense needles are moved to just above the top of the plate and the requested horizontal position.The appropriate dispense valve is opened for a calculated time to deliver the specified volume at the specified flow rate.

- Page 140 AquaMax 2000/4000 Microplate Washer User Guide ® Aspirate (ASPI) Aspiration removes fluid from the plate. Vacuum begins prior to the needles coming into contact with the liquid surface. Vacuum continues as the needles descend at the specified rate to the specified position. The needles are left at the specified height for the specified time.

- Page 141 Robot Command Interface Wash (WASH) Washing is simultaneous aspiration and dispensing. Aspiration begins as with whole plate aspiration. However when the aspiration needles reach the specified height, dispensing begins. No crosswise aspiration is allowed in this mode. The aspiration rate should be greater than the dispense rate.

- Page 142 AquaMax 2000/4000 Microplate Washer User Guide ® Fast Wash (WHSQ) Washing is sequential aspiration and dispensing. Aspiration at the highest rate begins as with whole plate aspiration. After the aspiration needles reach the specified height and the dwell period expires, the head starts moving up and dispensing begins.

- Page 143 Robot Command Interface Shake (SHAK) The plate is shaken for the specified time at the given intensity level. Shaking is linear only (along horizontal axis). Parameter tokens are: Speed: 0 =slow, 1=medium, 2=fast Time: 1-600 [sec] Example: /step set 2 SHAK T120 returns OK >...

- Page 144 AquaMax 2000/4000 Microplate Washer User Guide ® Repeat (REPE) The protocol repeats steps from the specified first step to the repeat command in order, the specified number of times. Firmware supports up to 8 repeat loops per protocol. Parameter tokens are: Address (index) to repeat from [0-49] Number of repetitions [1-99] Example:...

- Page 145 Robot Command Interface Purge (PURG) Purge removes all fluid from the internal fluidics path. The vacuum valves are opened in the wash manifold and waste trough to remove all liquid. Parameter tokens are: none Example: /STEP set 1 PURG returns OK >...

- Page 146 AquaMax 2000/4000 Microplate Washer User Guide ® Rinse-flush (RFLU) Rinse-flush step rinses all common fluidics (prime/soak trough, head, valves) with fluid from the requested inlet. Upon completion the head is left empty. Parameter tokens are: Inlet: [0-3], 0= green, 1= red, 2=blue, 3=yellow, -1= prompt Example: /step set 2 RFLU i0 returns OK...

-

Page 147: Plate Library Access

Robot Command Interface Plate Library Access The plate library stores up to 32 plate descriptions (indexed 0-31). Plate descriptions include a unique configuration ID, the plate name, number of wells, well geometry (flat, V-bottom, U-bottom, small volume), plate height, and well depth. The first 8 plates, though editable, are set to factory default values listed Table E-2. - Page 148 AquaMax 2000/4000 Microplate Washer User Guide ® <plate> Reads the specified plate’s configuration ID and its name. Action: <plate> Returns the configuration ID and name of the plate at index Response: <plate>. If the index does not contain a plate, the “no data OK”...

- Page 149 Robot Command Interface Ren Action: Renames <index> plate to <name>, given in double quotes and limited to 19 characters. “No data OK” response if the command succeeds. Response: Del Action: Deletes <index> plate. “No data OK” response if the command succeeds. Response: Get Action: Reads the <index>...

- Page 150 AquaMax 2000/4000 Microplate Washer User Guide ® Set Response: “No data OK” response if the command succeeds. Set Example: /plate set 8 W0 B1 D5000 H10000 returns OK > TAB CRLF Used Action: Determines the total number of programs (protocols) currently using the <index>...

-

Page 151: Stakmax ® Robot Control

Robot Command Interface StakMax Robot Control ® The StakMax robot is automatically detected by the washer during power-on initialization. The AquaMax Microplate Washer controls the StakMax Plate Stacker via the StakMax communication port connection. Stacker Control Command: / STACKER Init Restack Load 0 Plates... - Page 152 AquaMax 2000/4000 Microplate Washer User Guide ® Load “1” = Load a plate from stack A, “0” = unload a plate from the Action: AquaMax Microplate Washer to stack B. Load “No data OK” response if the command succeeds. Response: Plates Returns the number of plates successfully loaded from the Action:...

-

Page 153: Errors

Robot Command Interface Errors Errors that arise during runtime are stored in an error buffer. The error buffer is maintained in non-volatile memory, so all error messages will survive an instrument power cycle or reset. The error buffer is a circular first-in, first-out list with 128 elements. When full, additional errors overwrite the earliest error and an “error buffer is full”... -

Page 154: Error Recovery

AquaMax 2000/4000 Microplate Washer User Guide ® Error Recovery Errors ³ 600 are caused by improper input. No recovery is required. The error prevented instrument operation. Instrument operation continues with the next valid command. Errors between 100 and 199 permit continued operations. Continued operation is possible following acknowledgement and/or correction of the error. -

Page 155: Index

Index components 10 back panel 17 microplate carriage 14 administrative mode reagent ports 16 passcode 80 touch screen 11 advanced options 76 wash heads 11 AquaMax® Sterilant 115 aspiration 49 rate table 50 automatic shutdown 79 decontaminating 86 Dexter Magnetic Technologies 15 dispensing 47 rates table 48 back panel 17... - Page 156 AquaMax 2000/4000 Microplate Washer User Guide ® plates BD/Falcon 15 bead-separator 15 LifeSep 15 calibrating well depth 73 locking lever 11 Corning/Costar 15 creating 73 default library 111 definition 72 deleting 74 magnetic bead washing 15 Dexter Magnetic 15 editing 74 Main tab 32 Greiner 15 maintenance 83...

- Page 157 Index setting up programs 38 connecting to StakMax® 27 adding a step 65 power 21 changing a plate type 65 reagent bottles 21 copying 64 wash head 24 creating 61 waste 24 deleting 65 editing 64 shaking 54 editing a step 67 shutdown 36 messages 42 automatic 79...

- Page 158 AquaMax 2000/4000 Microplate Washer User Guide ® wash heads 11 installing 26 locking lever 11 preparing for storage 94 removing 88 removing manually 90 wash rates table 51 washing 50 fastwash 53 waste ports 16 0112-0151 K...

Need help?

Do you have a question about the AquaMax 2000 and is the answer not in the manual?

Questions and answers