Table of Contents

Summary of Contents for SBM SB-3000

- Page 1 We’ve been there when you need. SB-3000 Currency Discrimination Fitness Sorter SEVICE MANUAL Ver. 1.5 SBM Co., LTD Head Office/ R&D Center 6F, Hyunwoo Bldg 206, Anayang 7-Dong, Manan-Gu, Anyang-City, Gyeonggi-Do, Korea 430-817...

- Page 2 Note The information or material contained in this document is the property of SBM. Any recipient of the information or material contained in this document shall not disclose or divulge, directly or indirectly, this document or the information or material contained herein without the prior written consent of SBM.

- Page 3 Every person working at the Fitness Sorter; SB-3000 must have previously read and understand the user manual and, specially the safety information. The Fitness Sorter; SB-3000 may only be operated by authorized personnel and may be serviced by trained and authorized personnel.

- Page 4 Precaution When using the machine, these precautions should always be followed: 1. Never push objects of any kind into your machine through the case or cabinet openings. 2. Do not use your machine near water, in wet locations, or outdoors. 3.

- Page 5 Safety Notes Your machine and the supplies are designed and tested to meet strict safety requirements. Included are safety agency examination and approval and compliance to established environmental standards. Please read the following instructions carefully before operating your machine, and refer to them as needed to ensure the continued safe operation of your machine.

- Page 6 FCC Compliance Statement THIS DEVICE COMPLIES WITH PART 15 OF FCC RULES. OPERATION IS SUBJECT TO THE FOLLOWING CONDITIONS: THIS DEVICE MAY NOT CAUSE HARMFUL INTERFERENCE, AND THIS DEVICE MUST ACCEPT ANY INTERFERENCE RECEIVED, INCLUDING INTERFERENCE THAT MAY CAUSE UNDESIRED OPERATION. This manual user general symbols for safety information and symbols to identify special dangers.

- Page 7 Recommended Tools Picture Name and Spec. Picture Name and Spec. Hexagonal L Wrench Screwdriver Ø1.5 L Wrench Screwdriver(-) Ø2 2.5mm Spanner Screwdriver(+) Ø6 Long-Nose Multi-Meter Dust Blower Nipper Aerosol Anti-Static Gloves Dust Air Blower Rubber Coated Dust Blower: Dust may cause to make a short in PCB so periodically clear dust apt to be accumulated inside of machine.

-

Page 8: Table Of Contents

CONTENTS 1.0.0. INSTALLATION ------------------------------------------------------------------------------------------------------ 13 2.0.0. DESCRIPTION OF THE PARTS ------------------------------------------------------------------------------- 15 2.1.0. EXTERIOR VIEW ----------------------------------------------------------------------------------------------- 15 2.1.1. FRONT VIEW ------------------------------------------------------------------------------------------------- 15 2.1.2. REAR VIEW --------------------------------------------------------------------------------------------------- 15 2.1.3. INTERFACE VIEW ------------------------------------------------------------------------------------------- 16 2.2.0. INTERIOR VIEW ------------------------------------------------------------------------------------------------ 16 2.2.1. INSIDE VIEW (LEFT) ---------------------------------------------------------------------------------------- 16 2.2.2. - Page 9 5.1.6. PRINTING ------------------------------------------------------------------------------------------------------- 45 5.1.7. REJECT REASON (for SVC) ------------------------------------------------------------------------------ 48 5.2.0. WORKING MODE & FUNCTION ---------------------------------------------------------------------------- 49 5.2.1. SUMMARY ------------------------------------------------------------------------------------------------------ 49 5.2.2. BASIC WORKING MODE ---------------------------------------------------------------------------------- 49 ■ FITNESS Mode --------------------------------------------------------------------------------------------- 49 ■ COUNT Mode ------------------------------------------------------------------------------------------------ 51 ■ FACE Mode -------------------------------------------------------------------------------------------------- 52 ■...

- Page 10 7.0.0 ADMIN MENU (for ADMINISTRATOR) ------------------------------------------------------------------------- 66 ■ LOADING DEFAULT --------------------------------------------------------------------------------------- 67 ■ CHAGNE PASSWORDS ---------------------------------------------------------------------------------- 67 ■ MACHINE SETTING --------------------------------------------------------------------------------------- 67 1. STATION ID ----------------------------------------------------------------------------------------------- 67 2. ETHERNET ------------------------------------------------------------------------------------------------ 67 3. PRINTER -------------------------------------------------------------------------------------------------- 67 4. CUSTOMER DISPLAY --------------------------------------------------------------------------------- 68 ■...

- Page 11 8.5.1. SET DATE/ TIME ----------------------------------------------------------------------------------------------- 84 8.5.2. SET A/S CALL -------------------------------------------------------------------------------------------------- 84 8.5.3. ETHERNET ---------------------------------------------------------------------------------------------------- 84 8.6.0. VALUE SETTING ------------------------------------------------------------------------------------------------ 84 8.6.1. CF LEVEL ------------------------------------------------------------------------------------------------------ 84 8.6.2. HOPPER LEVEL ---------------------------------------------------------------------------------------------- 85 8.6.3. DOUBLE LEVEL ---------------------------------------------------------------------------------------------- 85 8.6.4. FITNESS -------------------------------------------------------------------------------------------------------- 85 8.7.0.

- Page 12 14.0.0. MAINTENANCE ---------------------------------------------------------------------------------------------------- 124 14.1.0. SENSORTS ------------------------------------------------------------------------------------------------------ 124 14.2.0. ROLLERS --------------------------------------------------------------------------------------------------------- 131 14.3.0. DUST TRAP ------------------------------------------------------------------------------------------------------ 131 15.0.0. BOARD & COMPONENT ---------------------------------------------------------------------------------------- 132 15.1.0. Connection Diagram ------------------------------------------------------------------------------------------- 132 15.2.0. Board Descriptions --------------------------------------------------------------------------------------------- 133 16.0.0. DRAWINGS --------------------------------------------------------------------------------------------------------- 147 17.0.0. SPECIFICATION --------------------------------------------------------------------------------------------------- 253...

- Page 13 Cleaning Brush 1 pc. Sensor Cleaning Cloth 1 pc. Serial Cable 1 pc. Optional (Connection between SB-3000 & PC) Printing Cable 1 pc. Optional (Used in connecting a printer) ※The manufacturer does not provide a Micro SD Memory Card. Work Area To help guarantee trouble-free operation of your machine, place it on a flat, stable surface near your workstation.

- Page 14 3. The set can be upgrade through LAN [Serial Pinter] SB-3000 has a serial interface port, which allows you to connect your printer to print out counting result. To connect your printer to the machine, follow the steps as below: Make sure that both the SB-3000 and the printer are turned off.

-

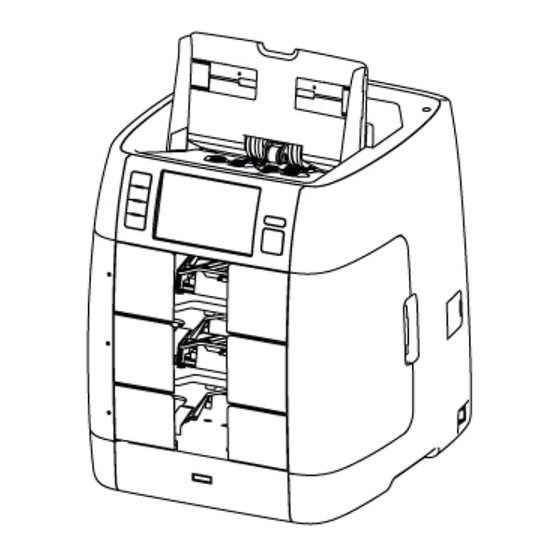

Page 15: Description Of The Parts

2.0.0. DESCRIPTION OF THE PARTS 2.1.0. EXTERIOR VIEW 2.1.1. FRONT VIEW (FIG 3-01) BILL GUIDE HOPPER CONTROL PANEL POCKET LED DUST CAP FRONT DOOR STACKER #1 OPEN HANDLE STACKER #2 POWER SWITCH REJECT POCKET 2.1.2. REAR VIEW (FIG 3-02) REAR DOOR A FRONT DOOR REAR DOOR B AC POWER... -

Page 16: Interface View

2.1.3. INTERFACE VIEW (CUSTOEMR DISPLAY) (FOR USB MEMORY STICK) RJ11 USB A TYPE POWER CORD PRINTER USB B TYPE (RS 232PORT) (FOR PC CONTROL) 2.2.0. INTERIOR VIEW 2.1.1. INSIDE VIEW (LEFT) Pick up Position Sensor Feeding Motor Encoder (Inside) Hi/Low Sensor 1 Connector Board Overflow Sensor 1 Image 2 Board... -

Page 17: Inside View (Right)

2.1.2. INSIDE VIEW (RIGHT) Feeding Motor Main Motor 2.1.3. INSIDE VIEW (REAR) MTU Board Tape Detect Receive... -

Page 18: Parts

2.3.0. PARTS 2.3.1. SENSORS T: TRN (Transmitter) ⑩ R: RCV (Receiver) P: Prism ① ② ⑪ ③ ⑧ ⑨-1 ⑫ ⑨-2 ⑦ ⑨-3 ⑨-4 ⑬ ④ ⑥ ⑤ ■ Positions of Sensors Description Description ① ⑨-1 RP1 sensors, JAM1 position CIS &... -

Page 19: Sensor

■ Specifications of Sensors Sensor Specification 1) 405nm Transmission 1ch (UV) X 2ea UV Sensors 2) 375nm Transmission 1ch (SUV) X 2ea 3) 375nm Reflection 2 ch (SUV) X 2ea 1) 60mm MR ARRAY 6 ch X 1(EA) MR Sensors 2) 6mm MG SIGNLE X 6 (EA) 1) 885 ~ 890nm, 100dpi Transmission Image IR &... - Page 20 ■ Sensors as View ① VIEW A RP2 Trans. sensors RP1 Trans. sensors RP1 Rcv. sensors RP2 Rcv. sensors ② VIEW B RP3 Rcv. sensors IR Trans. sensor Roller Detect Tape OPT CIS sensor RP4 Rcv. Sensors & UV sensors RP4 Trans.

- Page 21 ③ VIEW C Trans. and Rcv. Sensors (Hidden) Prism for RP6 sensors Prism for RP5 sensors ④ VIEW D Prisms of RP8 RP8 Trans. sensors RP8 Rcv. sensors Prisms of RP7 RP7 Trans. sensors RP7 Rcv. sensors...

- Page 22 ⑤ VIEW E Hopper sensor ⑥ VIEW F Stacker 1 Stacker1 Trans. sensor Stacker1 Rcv. sensor Prism of Stacker1 Stacker 2 Stacker2 Trans. sensor Stacker2 Rcv. sensor Prism of Stacker2 Reject Pocket Reject Trans. sensor Stacker2 Rcv. sensor Prism of Reject...

-

Page 23: Rollers

2.3.2. ROLLERS Part Name Part Name ROLLER_PICKUP ROLLER_FEED_MG ROLLER_PRESS CROWN_EXIT_ROLLER ROLLER_SEPARATE CROWN_TRANSFER_ROLLER_PINCH_S ROLLER_ADF CROWN_TRANSFER_ROLLER_PINCH ROLLER_PINCH_FEED CROWN_TRANSFER_ROLLER FEED_ROLLER_A CROWN_EXIT_ROLLER FEED_ROLLER_B CROWN_EXIT_ROLLER_PINCH_A FEED_ROLLER ROLLER_PIHCN_MR MOUDLE_ROLLER_T CROWN_EXIT_ROLLER_PINCH_1 ROLLER_DETECT_TAPE_S3000 ROLLER_FEED_OUTLET ROLLER_PINCH_MR ROLLER_PINCH_TRANS_POCKET... -

Page 24: Pulley

2.3.3. PULLEY : Forward part, : Backward part Part Name Part Name PULLEY_ADF_V_S3M-40 PULLEY_STEP_MOTOR_S3M_15 PULLEY_ADF_CLUTCH40 PULLEY_S3M_18 PULLEY_ADF_S3M-40 PULLEY_S3M_16 PULLEY_FEED PULLEY_FEED_4_V_S3M-32 PULLEY_FEED_1_V_S2M-24 GEAR_M08_T35-2 PULLEY_S3M-20 GEAR_M08_T35 PULLEY_FEED_1_V_S2M-24... -

Page 25: Timing Belts

2.3.4. TIMING BELTS Belt Code Part Name S3M 345 BELT ADF PICK MOTOR S3M 186 BELT ADF LINK S3M 237 BELT DETECT 1 S3M 171 BELT DETECT 2 S3M 213 BELT DETECT 3 S3M 180 BELT MOTOR-2 S3M 216 BELT GEAR LINK S3M 273 BELT OUTLET S3M 213... -

Page 26: Function Of Each Board

2.4.0. Function of each Board ■ Main Board The part controlling on Main Board is as follows Operation Panels : LCD displaying, Audio Codec, Hopper sensor, SD Card, USB Hopper Sensor SDRAM Audio Codec SD Card Slot LCD Conn. UART... - Page 27 ■ Image Board The part controlling on Image board as follows Control & Processing Counterfeit Detection: UV, MR Array, MRS L/R. IR Fitness: CIS, CAP (Tape) Positing sensors: RP 1 ~ 8 Output Port: Serial, Parallel, USB, RJ11 (Customer Display) SDRAM Image Processor Flash...

- Page 28 ■ MTU Board (‘CF AMP’ & ‘CAP AMP’) MTU: Magnetic, Tape, Ultraviolet The part controlling on MTU board is CF Amp.(for Magnetic sensor) and Cap Amp.(for tape detection) CF AMP Input: MR array (6 channels), MRS L/R Role & Output: Amplifying MR signal and transferring it to the Image Board. ...

- Page 29 ■ Motor Board The part controlling on Motor Board is as follows Operation Panels Main Motor Pickup Motor Main Motor Pickup Motor...

- Page 30 ■ Connector Board RP1, 2 Tran. RP 7 RP1, 2 Rcv. RP 8 Comparator RP 5, 6 RP 3 Rcv. & IR Trans Image Board...

- Page 31 ■ Pocket Board The part controlling on Pocket Board is as follows Control & Processing Operation Panel: Stacker 1, 2 and Reject Pocket Sensors: Stacker 1, Stacker 2, Reject Pocket, Stacker Overflow, Stacker Hi & Low Geared Motor 1 Comparator Solenoid 1 Stacker 2 Sensor...

-

Page 32: Overall Of Control

3.0.0. OVERALL OF CONTROL 3.1.0. OVERALL OF CONTROL PANEL (FIG 3-03) Indication Description - Manually START (when manual starting is set) - Emergency STOP & START while counting. - Save or set the mode - This key means ‘OK’ and ‘YES.’ - CLEAR the count result or go back to previous stage. -

Page 33: Overall Of Touch Screen

3.2.0. OVERALL OF TOUCH SCREEN [Before counting] (FIG 3-04) [After counting] (FIG 3-05) - Page 34 Tape Sensor To show Tape Sensor On/Off except for in Fitness Mode PC Control To show SB-3000 is controlled by PC or not Customer Display To show Customer display is on operation (Display A, B) To show the using Print Port...

-

Page 35: Preparation Of Operation

4.0.0. PREPARATION OF OPERATION 4.1.0. Banknotes Preparation [PROCEDURE] (FIG 4-01) Step Figure Description Prepare the banknotes under the 1 Step condition of below ⒜ Put one side of banknotes on the table 2 Step and align them. And make them square horizontally 3 Step and vertically. -

Page 36: How To Adjust The Bill Guide Hopper

4.2.0. HOW TO ADJUST THE BILL GUIDE HOPPER Before putting the banknotes into the Hopper, User needs to adjust the Bill Guide. Users should make sure that there is enough room on the sides for the banknotes to be pulled in the Hopper easily (banknote length + approximately 5mm) 4.3.0. -

Page 37: Counting

4.4.0. COUNTING In AUTO mode, SB-3000 starts to count the bill automatically as it detects the existence of the banknotes in the hopper. In MANUAL mode, the machine will start to count the banknotes only if the banknotes are placed into the hopper and START key is pressed. While counting, the machine will display the number of the banknotes on LCD display and it stops working when it meets the conditions described as below;... -

Page 38: Basic Operation

5.0.0. BASIC OPERATION 5.1.0. PROCEDURE OF OPERATION 5.1.1. FLOW CHART Operation Start Banknotes Preparation ▶ Page Bill Guide Adjusting ▶ Page 16 Setting of Currency, Working Mode, Pocket, etc ▶ Page 19 Put the notes on Hopper ▶ Page Start Counting In case of manual start, press [START/STOP] key Close Counting INPUT... -

Page 39: Working Mode Setting

5.1.2. Currency Selection In order to change the Currency, touch [CURRENCY] icon. If you need to purchase more software to handle different currencies, PLESASE CONSULT WITH YOUR DEALER. (FIG 5-01) (FIG 5-02) 5.1.3. Working Mode Setting Can set working mode as below. [1] Pressing [MODE] button in initial screen (FIG 5-01), the screen will change Mode screen like below (FIG 5-03). - Page 40 ① Basic Working Mode: Fitness, Count, Face, Orient, Issue, Dispense, OCR Mode ② User Define Mode: User can set up Max 8 modes for his/her usual or specific purpose. [3] Can select the ‘Working Mode’ by touching the icon. [4] The screen will change into initial screen of wokring mode selected ...

-

Page 41: Counting Result Confirmation

1. [F] First Detected Denom. Stacker 1: First detected Fit Denom. notes 2. [F] Second Detected Denom. Stacker 2: Second detected Fit Denom. notes 1. [F] $1 Stacker 1: Fit $1 2. [U] $1 Stacker 2: Unfit $1 1. [F] $2 Stacker 1: Fit $2 2. - Page 42 (FIG 5-10) (FIG 5-12) (FIG 5-11) (FIG 5-13) [2] If you touch the section of result in screen (fig 5-10), the screen will show specific results. ① If you touch the section (ⓐ) in Stacker 1, the screen will show the ‘COUNTING DETAILS’ (FIG 5-11). ②...

-

Page 43: Grand Total

Grand Total means the accumulation of counted notes that user accepted. Namely, if you touch [ACCEPT] icon after counting, the result will be added to GRAND TOTAL. SB-3000 can show 3 kinds of count result. One is present ‘Total,’ another is the ‘Day Total,’ and the other is ‘Grand Total.’... - Page 44 1. There are 2 ways how to calculate Grand Total (Referring to page 23). [1] Can touch [ACCEPT] icon in counting result screen (FIG 5-04), [2] Or if you touch ‘total’ area in counting result screen (FIG 5-04), can see GRAND TOTAL screen (FIG 5- 16).

-

Page 45: Printing

5.1.6 Print SB-3000 can print out below 3 results. Present count result /GRAND TOTAL per user/GRAND TOTAL of SB-3000 Present Count Result Printing Press [Print] Key after counting, and can print out as below. (FIG 5-20) * Caution) In order to print out, notes in Reject Pocket must be removed. - Page 46 Grand Total Print per user Up to 8 users can count banknotes with one SB-3000. And each user can print out his/her own GRAND TOTAL. 1. Can check your own counting result at MY TOTAL RECORD in USER MENU.

- Page 47 [2] Press [CHANGE] button or touch the each area of sum(ⓐ/ⓑ/ⓒ/ⓓ) in MY TOTAL RECORD screen (FIG 5-24) for selecting the print item, can press [PRINT] button or touch [PRINT] icon in order to print out. How to print Grand Total of SB-3000 Can check in ADMIN MENU (Referring to page 55).

- Page 48 5.1.7 Reject Reasons Display on Screen Meaning NO I.D The machine failed to identify the denomination. Out of height NO I.D.1 Out of width NO I.D.2 Out of Skew NO I.D.3 Can't find top edge NO I.D.4 Can't find side edge NO I.D.5...

-

Page 49: Working Mode & Function

● ADD Function: Counting result will be not cleared but added. After the ‘ADD Function’ is on, the counted result and the present result will be summed up. ● BATCH Function: SB-3000 provides the preset numbers of banknotes or the preset amount of value. 5.2.2. Basic Working Mode ■... - Page 50 Fitness conditions ① Soiling (Dirty): General Distribution of dirt across the entire banknote ② Tapes: Self -explanatory ③ Tear: Self -explanatory ④ Missing corner: Self -explanatory ⑤ Holes: Self -explanatory ⑥ Corner folded (Dog -ears): Self-explanatory ⑦ Oil stain: Localized concentration of dirty ⑧...

-

Page 51: Count Mode

In order to use single mode function, select single denomination in Pocket Arrange screen, and in order to use mixed mode, select all denominations in Pocket Arrange screen. In addition, the pockets of SB-3000 can be set up separately by user’s classification. -

Page 52: Face Mode

■ FACE Mode FACE Mode discriminates and count the FACE (HEAD) and BACK (TAIL) of notes. ● Pocket Arrange designation: Can classify and designate previously set [Stacker 1] and [Stacker 2] by pressing [CHANGE] button in FACE Mode (FIG 5-31) Below is description of the designated pocket. -

Page 53: Issue Mode

● Pocket Arrange Designation: Can classify and designate previously set [Stacker 1] and [Stacker 2] by pressing [CHANGE] Button in ORIENT mode. (FIG 5-32) Below is description of the designated pocket. Pocket Arrange Display Earmarked Banknote in Stacker 1, Stacker 2 1. -

Page 54: Dispense Mode

● Pocket Arrange Designation: Can classify and designate previously set [Stacker 1] and [Stacker 2] by pressing [CHANGE] button in ISSUE mode. (FIG 5-33) Below is description of the designated pocket Pocket Arrange Display Earmarked banknote in Stacker 1, Stacker 2 1. -

Page 55: Ocr Mode

(FIG 5-38) OCR Mode has four sub options as below. 1 SERIAL Mode (Serial Number Printing Mode): In SRLP mode, SB-3000 reads serial No of banknote and prints it as an image. 2 SOCR (SB series-Optical Character Reader Mode): In S-OCR mode, SB-3000 reads the serial no. of... - Page 56 OCR data so that user can store and manage it. 4 [OPTION] SNC Mode (Serial Number Comparison Mode): In SNC mode, SB-3000 can read the serial number and can identify the both serial numbers in the banknote. In case the serial numbers are not identical, the note will be sent to the reject pocket and indicated as “SNC ERROR”...

- Page 57 5.2.3. User Define Mode ‘User Define Mode’ means that user can set up Max 8 modes for his/her usual or specific purpose. User can set and save his/her own mode and can select easily just touching this icon. ● How to set User Define Mode 1 In order to set in initial screen [1] Touch [DEFINE] icon in initial screen (FIG 5-01), and can enter ‘MAKE DEFINED MODE SETTING (FIG...

- Page 58 2 In order to set in ‘User Define Mode’ [1] Pressing [MODE] button in initial screen (FIG 5-01), the screen will be will changed into’MODE selection.’(FIG 5-03). [2] Pressing [CHANGE] button in ‘MODE selection’(FIG 5-03), the screen will be changed into ‘User Define Mode’...

-

Page 59: Functions

● Can change the stacker pockets like below in User Define Mode. [1] In order to activate ‘MAKE DEFINED MODE SETTING(FIG 5-05),’ User can touch [DEFINE] icon in initial screen (FIG 5-01). (FIG 5-05) [2] Press [Stacker 1]/[Stacker 2], then user can see ‘SET STACKER-FITNESS(FIG5-09)’... - Page 60 ■ BATCH Function Batch is used when user want to count specific number of banknotes. For example, Batch is used when user want to count 50pcs of banknotes while Stacker pocket capacity is set to 100pcs. When BATCH Function is on, operation is stopped after counting the number user set in advance even if banknotes still remain on Hopper.

- Page 61 ③ Total Count: Set Batch number for Stacker 1 and Stacker 2 in total. (FIG 5-43) ④ Total Amount: Set Batch amount for Stacker 1 and Stacker 2 in total. (The same as Dispense Mode from other models) (FIG 5-44) [3] Change to the initial screen after Batch setting.

-

Page 62: User Menu (For User)

Set up date/time Selection way Set up selection method User Interface Sorting order Set up sorting order LCD brightness Set up LCD brightness. Beep Set up warning beep Power saving Set up power saving Information About SB3000 Set up SB-3000 inside. -

Page 63: Language

A/S call number Check service call number. In order to move on lower menu section, it’s available with “Touch Screen” or [CHANGE] key, [START/STOP] key, and [C] key. Language: Set up the language for Menu. My grand total: Instructing “The Day Total & Grand Total” of current user. [1] MY TOTAL RECORD (FIG 6-02) ⓐ... -

Page 64: Pocket Capacity

2 Pocket capacity: How to set up stacker capacity of each pocket. 1) Stacker Pocket #1: Can be selected one of 100/150/200 2) Stacker Pocket #2: Can be selected one of 100/150/200 3) Reject pocket: Can be selected one of 50/70/100 3 Accept result: How to set up the “Accept”... -

Page 65: Information

Information 1 About SB-3000 : Machine information 2 A/S call number: After Service call number The Factory default settings are like below. Function Default Value 1000NPM Speed (Fitness Mode: Approx. 700) [Count interface] Starting counting Auto Stacker Pocket #1... -

Page 66: Loading Default

7.0.0. ADMIN MENU (Administrator Menu) Can alter each function and parameter at this menu. Press [Mode] button and put [12345] in Password screen, and will be moved to [ADMIN MENU]. Touch the screen items, and can move to menus. (FIG 7-01) MENU SUB MENU Description... - Page 67 Administrator has to select a printer type before connecting the printer. Needs to be discussed with the dealer about available printer If, the printer type is Serial, the setting of printer in SB-3000 is like below. (FIG 7-02) 2) Cutting code Can set up the Cutting code with reference the manual and it can apply up to 6 byte.

- Page 68 Set up printer ports for each user. About COM port (USB in P-OCR Mode) means that generally COM port is used and USB ports are used at the same time in P-OCR mode. (FIG 7-03) 4 Customer display Set up the Customer Displays to be connected to Display A/ B Ports. 1) Display A: Set up a Customer Display for Display A.

- Page 69 [How to set] [1] Select Currency. (ⓐ) [2] Move each circle and set the levels (ⓑ) ⓐ ① Move the circle of the first bar and set UV level. ② Move the circl e of the second bar ⓑ and set IR level. ③...

- Page 70 The file is created in USB memory stick. (File folder name: SB3000_Fitness_Level) ⑤ Insert USB Memory Stick, which has ‘SB3000_Fitness_Level’ folder, to another SB-3000 that supervisor want to input previously fitness level to. ⑥ Select ‘Import fitness level’ in this menu.

- Page 71 ⑦ LCD of another SB -3000 will be displayed as follows -1. After checking the file which you want to apply to another SB-3000. And then touch [NEXT] Icon (FIG 7-10) -2. Select the currencies and fitness Sub- Mode which supervisors want to apply to another SB-3000.

-

Page 72: Cf Items

Tape function On, Tape indicator will be shown like right picture (FIG 6-18). (FIG 7-13) User setting 1 Concurrent User 2 users can user SB-3000 at the same time. This is how to set Concurrent User. Without selecting Concurrent User, ‘USER 1’ will be set. -

Page 73: Setting Place

(FIG 7-14) (FIG 7-15) [1] USER 1 and USER 2(ⓐⓑ) can operate SB-3000 at the same time in other modes. User can slect one of Concurrent User and can set Count modes and functions as one user does. [2] One of Concurrent User(ⓐⓑ) can use the allocated Print Port. -

Page 74: Each User

Can check, delete and print the summary of THE DAY TOTAL and GRAND TOTAL. [1] THE DAY TOTAL by currency: Pressing [CHANGE] button, the currency will be changed. (FIG 7-16) [2] GRAND TOTAL by currency: Pressing [CHANGE] button, the currency will be changed. - Page 75 [1] the screen of TOTAL RECORD-USER1 DISPLAY is like below (FIG 6-25) ⓐ ⓑ ⓒ ⓑ (FIG 7-20) [2] If [CHANGE] button is pushed consecutively or if the section of the above screen is touched, the above screen is changed to 4 DETAIL screens. ①...

-

Page 76: Log Data

Upgrade Number / Calibration Number / ETC ) and provide exporting function to EXCEL file. The procedure of Log Data Exporting is here below, ① Insert USB Memory Stick into the USB Port of SB-3000. ② Select ‘Export log data’ in this menu (ADIMN MENU _ Log Data/ Export log Data) ③... - Page 77 ⑥ In USB Memory Stick, Log DATA file will be created as right screen. (FIG 7-27)

-

Page 78: Sevice Menu

8.0.0. SEVICE MENU Service engineer can download, manage, set and adjust levels in this SERVICE MENU. You can enter SERVICE MENU as following.. [MENU] Key + [MODE] Key + CODE: ***** MENU MODE CODE: ***** If you want to move to upper level or want to be out of MENU, press [C] key. If you want to set the MENU or want to go to lower level, press [STAR/STOP] key. -

Page 79: Admin Pwd

8.3.0. Download target You can designate the pocket for downloading data and send the data to “Vol” program(special program which SBM provides). Refer to the right picture. (FIG 8-02) 1. From all pockets: When you need all data in the beginning stage of developing S/W. -

Page 80: Machine Management

8.4.0. Machine management 8.4.1. Program update In this mode, user can simply install new software for upgrade by USB Memory Stick. The steps for update are as follows. [1] With the machine on, insert USB Memory which has the file provided from service provider to the USB B port in the machine. -

Page 81: Machine Test

* If NG, update S/W once again and change the Boards (Image, Option) and test. ② Lamp: SB-3000 checks the IR transmission and White transmission. ③ Pocket plate: SB-3000 checks the Up and low Sensor of Stacker #1 & Stacker #2 Plate. ④ Motor: SB-3000 checks Main Motor, Feed motor and Pick-up Motor. - Page 82 ■ Sensor status report : This report shows the sensor status value by every 500ms. (FIG 8-06) ■ Motor test : You can test motor is working and the speed. (FIG 8-07) ■ Note-path test : If you put some notes on the hopper, you can see the notes are distributed as the choice.

-

Page 83: Log Data

/ Upgrade Number / Calibration Number / ETC ) and provide exporting function to EXCEL file. The procedure of Log Data Exporting is here below, [1] Insert USB Memory Stick into the USB Port of SB-3000. [2] Select ‘Export log data’ in this menu (ADIMN MENU _ Log Data/ Export log Data) [3] Select the Range of the Period. -

Page 84: Machine Setting

[6] In USB Memory Stick, Log DATA file will be created as right screen. (FIG 8-13) 8.5.0. Machine setting 8.5.1. Set date/time 8.5.2. Set A/S call: Setting A/S phone number 8.5.3. Ethernet: You can manage LAN here and can set IP address. 8.6.0. -

Page 85: Hopper Level

8.6.2. Hopper level If the machine does not detect it, even though there are notes on the Hopper, Lower the level (Default-200) * If the level is not within acceptance, you can change the value by controlling the adjustable resistance. (FIG 8-15) 8.6.3. - Page 86 -. [NO]: Apply only to current Fitness Sub-mode -. [CANCEL]: Do not apply ② [ALL]: Decide if the data below is also applied or not to another denomination. -. Fitness Levels & On/Off set -. Fitness Levels -. Fitness On/Off set ③...

- Page 87 (FIG 8-19) [1] Setting of the basic contents for adjusting the Fitness Level - CURRENY: Setting of the currency by touching the section (①) (FIG 8-20) DENOMINATION: Setting denomination by touching the section (②) (FIG 8-21) - SUB MODE: Setting of Sub mode in Fitness by touching the section (③) (FIG 8-22) - Fitness condition: Setting of Fitness...

- Page 88 You can apply the specified fitness level from one machine to another by Import fitness level & Export fitness level Menu. This is how to export the specified fitness level and how to import. Follow the below steps [1] Insert USB Memory Stick to USB port in SB-3000 [2] Select ‘Export fitness level’ in this menu...

- Page 89 [4] The file is created in USB memory stick. (File folder name: SB3000_Fitness_Level) [5] Insert USB Memory Stick, which has ‘SB3000_Fitness_Level’ folder, to another SB-3000 that supervisor want to input previously fitness level to. [6] Select ‘Import fitness level’ in this menu.

- Page 90 (FIG 8-32) ① CURRENCY: Currency which needs correction of the tolerance of SOIL LEVE In SB-3000, wee use US 1$ need for ADJUST SOIL VALUE in all currency. ② RESET: reset all adjusting offset. ③ SOIL LEVEL: key for changing value of LIGHT SOURCE ④...

- Page 91 3. How to adjust 1) Press “ MENU -> MODE -> ***** -> VALUE_FITNESS_SOIL ADJUSTMEN”,. Then, The Screen will be displayed as below (FIG 8-33) 2) Adjust Bill Guide and place one standard note (US 1$). - When adjusting the soil level in the machines, you have to put the standard note with same direction - The quality of the note shall be Fit note.

-

Page 92: Function On/Off

5) Soil level in No2 Machine is higher than in No2 machine. So, decrease value of Light source by using key (LIGHTER & DARKER) to make Soil level same in two machines. As you can see the picture () value of IRT, RGB, and WHT are decrease by 1. -

Page 93: Tape In Count Mode

IR off IR off, MR off UV on, MR on UV on 8-7-2 TAPE in count mode Can set Tape Sensor ON/Off here, except for Fitness Mode. In case of Fitness Mode, should set Tape sensor in Fitness setting. Tape function On, Tape indicator will be shown like right picture (FIG 6-18). -

Page 94: Calibration (Shading)

9.0.0. CALIBRATION WHAT IS THE CALIBRATION? Calibration is to make a full swing reference waveform to read the full level of a signal. If the machine rejects too many notes in CF Detection Mode, the system might not analyze the input of waveform. It is possible to make a standard waveform for the system. -

Page 95: Cis Calibration

9.1.0 CIS Calibration (IMAGE Calibration) This CIS Calibration is for CIS Sensors. 11.7 7.6 3.6 CIS Calibration Sheet (opaque) 27.2 220.8 (FIG 9-10) [Procedure] [1] Touch on CIS Calibration MENU [SEVICE MENU _ Machine management/ Calibration/ CIS calibration] (FIG 9-11) [2] Open the REAR DOOR B, and Open the REAR MIDDLE COVER [3] Put the sheet in this machine as right picture... - Page 96 [6] Check if CIS Calibration result is “OK” or “NG” ① The result of CIS Calibration (FIG 9-14) ② The result of Option CIS Calibration (FIG 9-15) ② The result of Option CIS IRR Calibration (FIG 9-16) [7] After doing calibration, Open the Rear Door B and the Rear Middle Cover, and then take out the sheet. [The detail information for CIS Calibration’s NG] The Cause expected Action to be taken...

- Page 97 Average NG: if the average voltage is more than 1V ± 10%. 1. Need to clean CIS sensors (CIS1 and Opt CIS) Uniformity NG: If the uniformity is less 2. Need to check CIS’s defect than 65% 3. Need to check Image board’s defect NG if each R.G.B On time is more than 150.

-

Page 98: Tape Calibration

9.2.0. TAPE Calibration This Tape Calibration is for Tape Sensors. You should use the Tape calibration sheet provided from SBM as below <CAP SHADING SHEET> (180x 105 mm) (FIG 9-06) [Procedure] [1] Touch on TAPE Calibration MENU [SEVICE MENU _ Machine management/... - Page 99 [5] Press [START/STOP] Key [6] Check if TAPE Calibration result is “OK” or “NG” (FIG 9-09) [7] After doing calibration, Open the Rear Door B and the Rear Middle Cover, and then take out the sheet. [The detail information for TAPE Calibration’s NG] The Cause expected Action to be taken standard...

-

Page 100: Uv Calibration

9.3.0. UV Calibration This UV Calibration is for UV Sensors. You should use the UV calibration sheet provided from SBM as below <UV SHADING SHEET: SHINWOO UV SHADING V1.0> 165 mm 75 mm (FIG 9-17) [Procedure] [1] Touch on UV Calibration MENU... - Page 101 [4] Close the REAR MIDDLE COVER and Close the REAR DOOR B [5] Press [START/STOP] Key (FIG 9-20) [6] Check if UV Calibration result is “OK” or “NG” (FIG 9-21) [7] After doing calibration, Open the Rear Door B and the Rear Middle Cover, and then take out the sheet. [The detail information for UV Calibration’s NG] If you meet UV NG, clean the UV sensors with soft cloth or check the cable connected with UV sensors.

-

Page 102: Mr Calibration

9.4.0. MR Calibration This MR Calibration is for MR Sensors. <MR CALIBRATION SHEET: Real Banknote ‘US$ 1’ > (FIG 5-02) [Procedure] [1] Touch on MR Calibration MENU [SEVICE MENU _ Machine management/ Calibration/ MR calibration] (FIG 5-03) [2] Place 1 ~ 5 bills of US$ 1 on the hopper with the same direction as shown on the right figure (The condition of US$1 should be good!!) (FIG 9-04) - Page 103 [The detail information for MR Calibration’s NG] The Cause expected Action to be taken MR TEST ERROR [Fail to detect the Edge] 1. Make sure to check the CIS lens, ▶ When CIS cannot recognize the 2. Make sure to check harness connection condition, calibration sheet (US$ 1) this error where harness is cut off or not happens...

-

Page 104: Adjustment

10.1.0. GAP between Separator Roller and ADF Roller (CAUTION) Turn off the machine before adjustment. In SB-3000, there are 2 Gap adjustments of ADF Roller as below picture GAP Troubles ■ Too Wide: Double, Overrun ■ Too Narrow: Miss Feeding, Jam 1... - Page 105 [How to adjust Gap between Separator Roller and ADF Roller] [1] Prepare 2 banknotes [2] First, one of Gap adjustment will be chosen [3] Fix one of the pick-up rollers with one hand as same as SB-2000 [4] Grasp the note with one hand as right picture, and try to insert and draw it between gap of ADF and Separator roller until the note is passed through the gap...

-

Page 106: Pick-Up Position Sensor

10.2.0. Pick-up Position SENSOR There is Pick-up Roller position sensor in SB-3000. After counting, this sensor makes sure that the machine is ready for next counting. ① ② ③ As you can see the above picture, When the Pick-up roller position is like (①), Pick-up Position sensor should be in the position (②). -

Page 107: Gap Of Selector

10.3.0. GAP of SELECTOR If the notes are damaged as Jam7 or Jam8 often happens or if there is noisy at selector, Selector may be not properly adjusted. Selector should be 1 mm gap between below position. If the gap is more than 1mm, there is Jam 7 or jam 9 happen. - Page 108 [How to adjust Gap of Selector] [1] Loosen SCREW slightly of SOLENOID [2] Open the Front Door. And put your hand the inside of the machine and lift up guide selector as below image [3] Be careful with the tip of Selector Guide so that notes are not jammed in the Selector while the notes Right Side...

-

Page 109: Timing Between Pick-Up And Adf Roller

10.4.0. Timing between ADF and Pick-up Roller 2~4 Teeth Pick-up Roller ADF Roller ■ set the Timing belt (S3M 345) [1] Take off timing belt (S3M 355) [2] Turn the Pick-up roller and ADF roller till the teeth position of two rollers is same as the above picture. -

Page 110: The Hopper Level

10.5.0. Adjust the hopper level. [1] Prepare the business card and black matt tape. [2] Run the Sensor Status and place the card face attached the tape covering over the Hopper sensor [3] adjust the hopper value to ‘200’ High... -

Page 111: S/W Upgrade

11.0.0 S/W Upgrade 11.1.0. S/W VERSIOIN AND CURRENCY CHECK In SEVICE MENU, you can check the SW version and currencies in [ABOUT SB 3000] menu 11.2.0. UPGRADE BY USB MEMORY STCK In [Program update] menu, user can simply install new software for upgrade by USB Memory Stick. The steps for update are as follows. - Page 112 11.3.0. UPGRADE BY VOL PROGRAM You can update program of SB-3000 with the connection of USB. Follow the procedure. 1. Check USB PORT 1) Verify which COM is allocated to USB port in your PC SB-3000 will be allocated 2 COMs of option and image.

- Page 113 ① Select Image B’d#2(Opt) in Upgrade2. ② Select the COM Port for Option B’d in the picture of Chapter 2. ③ Click the Browse button and select *.opt file and click Upgrade button. You don’t need to Restart SB-3000 after Upgrade Option B’d. ③...

- Page 114 ② Select the COM Port for Image B’d in the picture of Chapter 2. ③ Click the Browse button and select *.opt file and click Upgrade button as in 3-1). SB-3000 will restart automatically. ① ③ ③ ②...

-

Page 115: Getting Data

12.0.0. Getting DATA Starting Vol V3.0 Double click Vol V3.0 and you can see below window. Download Menu Selection Com. Port Display How to connect SB-3000 and a PC Connect SB-3000 and a PC using a USB cable as shown below. - Page 116 How to set COM port Connect SB-3000 and PC with USB cable. If you turn on SB-3000, you can see 2 ports are connected as below. ① SB Series USB2Serial device – Image B’d ② SB Series USB(Opt) device – Option B’d.

- Page 117 Prepare notes Sort the notes by each denomination and version and arrange with same direction. < Attention > Please do not mix Do not mix different denomination. Do not mix different version (old and new version) Do not mix different face and orientation. Do not mix true notes and counterfeit notes.

- Page 118 < Notice > Position of note When you put on the money, place a bundle of notes on the each 3 position (Left, middle, right position) inside of the bill guide. We can get various and substantial data in this way. How to set Download Target if you press Menu →...

- Page 119 Make sure all ‘CF’ item is activated 1) Set Download target (Refer to step 6. How to set the Download Target) 2) Put the money on the hopper. (Refer to step 5. set up the machine) 3) Counting 4) Click “multi image” and “Start Multi Down or Change Filename” 5) Then, scanned images will be saved in the designated folder automatically.

- Page 120 Trial Number Direction of Note Currency & Denomination Data Usage FU (Face Up) Direction: FD (Face Down) Direction: BU (Back side Up) Direction: BD (Back Down) Direction: * Warning! SB-3000 has different CIS direction, so the note directions are called differently.

- Page 121 After complete getting the data, please save and send them us < Note > How many images do we need? If you send us as many images as you can, it is really helpful to renew our software as well as machine One denomination should be scanned in four different directions, FU, FD, BU and BD.

-

Page 122: Troubleshooting

Initializing Running Error When SB-3000 Power On, if there is any trouble at the sensors, pocket plates, motors and stackers and so on, it shows below figure [MACHINE STATUS INFOMRATION]. Green means “OK”, Red Means trouble or suspect then required check sensors described following table. - Page 123 3. Cleaning required, in case of covering dust. Error on counting It shows following figure [SB-3000 STAUS], when any error occurs on counting (FIG 7-02) Error Messages Action to be taken Pocket Overflow!! Empty pocket 1 Remove remaining note accordance with the...

-

Page 124: Maintenance

14.1.0. Sensor cleaning SB-3000 is built in various sensors to detect the malfunction of the machine the status of the notes in the machine and to recognize the denominations of the notes. The sensors are very delicate and if they are... - Page 125 T: TRN (Transmitter) ⑩ R: RCV (Receiver) P: Prism ① ② ⑪ ③ ⑧ ⑨-1 ⑫ ⑨-2 ⑦ ⑨-3 ⑨-4 ⑬ ④ ⑥ ⑤ ■ Positions of Sensors Description Description ① ⑨-1 RP1 sensors, JAM1 position CIS & Optional CIS ②...

- Page 126 Front Door Rear Door A Rear Top Cover Rear Middle Cover Rear Bottom Cover Rear Door B ■ View points ■ Accessible sensors in each view point View-E View Accessible sensors View Accessible sensors View-A ① ⑤ RP1 Sensor RP5 Sensor ②...

- Page 127 ■ Part to maintain [VIEW A] It’s available to clean the Trans & Rcv sensors of RP1 & RP2 in View A RP2 Trans. sensors RP1 Trans. sensors RP1 Rcv. sensors RP2 Rcv. sensors [VIEW B] It’s available to clean the Trans & Rcv sensors of RP3 & RP4, CIS, Optional CIS, Tape, MR, and UV sensors in View B RP3 Rcv.

- Page 128 [VIEW C] It’s available to clean the Trans & Rcv sensors of RP5 & RP6 and Prism in View C. However, it is strongly required to clean the Trans & Rcv sensors and prism for RP6 using in cloth sice they are located in the deep inside.

- Page 129 [VIEW E] It’s available to clean the Hopper sensor in View E. Hopper sensor [VIEW F] It’s available to clean the Trans & Rcv sensors of Stacker1, 2, and Reject pocket, and also the Prism in View Stacker 1 Stacker1 Trans. sensor Stacker2 Rcv.

- Page 130 [Up/Down Sensors] [Overflow Sensors]...

-

Page 131: Rollers

Press Roller Pick up Rollers ADF Roller 14.3.0. Cleaning Dust trap SB-3000 is designed that prevents for Misrecognition and malfunction by 3 kinds of “Dust traps” at the locations on right figure. They collect dust when the machine is running. -

Page 132: Board & Component

15.0.0. Board & Component 15.1.0. Connection Diagram... -

Page 133: Board Descriptions

15.2.0. Board Descriptions 15.2.1. VD_MAIN_V4.0 (Front Side) PMIC SDRAM... - Page 134 15.2.2. VD_MAIN_V4.0 (Rear Side) Power-Distribution RS-232 Boost Converter AUDIO CODEC Crystal Switch Tact FLASH Switch RS-232 Hopper SDCard Slot...

- Page 135 15.2.3. VD_IMAGE_V4.0 (Front Side) Comparator RS232 AK8444 CPLD OP Amp 16x1 Analog MUX LDO Regulator SDRAM FLASH CPLD AK8444 SDRAM LCD Regulator...

- Page 136 15.2.4. VD_IMAGE_V4.0 (Rear Side) Flash OP Amp Comparator OP Amp LDO Regulator...

- Page 137 15.2.5. VD_MTU_V1.2 (Front Side) OP Amp OP Amp LDO Regulator OP Amp...

- Page 138 15.2.6. VD_Motor_V2.5 (Rear Side) IR2181S MOSFET BUFFER Main Motor OP Amp Pickup Motor...

- Page 139 15.2.7. Pocket_V4.0 (Front Side) PWM Motor Driver Comparator...

- Page 140 15.2.8. Conn._V4.0 (Front Side) MOSFET Comparator...

- Page 141 15.2.9. VD_MRA (Front Side, Rear Side) MR SENSOR(60mm) 15.2.10. VD_MRS_L (Front Side) MR SENSOR (6mm) 15.2.11. VD_MRS_R (Front Side)

- Page 142 15.2.12. VD_UVA (Front Side, Rear Side) R2 TRN. UV LED UV Reflect MOSFET Dual OP-Amp 15.2.13. VD_UVB (Front Side, Rear Side) R2 RCV. UV Reflect UV LED Dual OP-Amp Comparator Dual OP-Amp...

- Page 143 15.2.14. VD_RP_TRN (Front Side) RP1 TRN. 15.2.15. VD_RP_RCV (Front Side) RP1 RCV.

- Page 144 15.2.16. Thickness AMP V1.1 (Front Side) LDO Regulator OP-Amp...

- Page 145 15.2.17. MR_AMP (Front Side, Rear Side) MR_AMP V1.0 (Front Side) OP-Amp MR_AMP V1.0 (Rear Side)

- Page 146 15.2.18. Encoder 1 (Front Side) 15.2.19. Encoder 2 (Front Side) Encoder 1 V2.0 (Front Side) Photointerrupter Encoder 2 V1.0 (Front Side) Photointerrupter...

-

Page 147: Drawings

16.0.0 Drawings 1. SIDE COVER OPEN SIDE COVER OPEN CODE PART NAME Q`TY COVER-SIDE-L ASSY COVER-SIDE-R ASSY 8405E049XA SCREW_M/C_PWH_M3X6_Fe_Ni DOOR-REAR-MIDDLE ASSY 741015200A BRK-MIDDLE-DOOR-HINGE 8400E033XA SCREW_T/P_PH_T2_Ø3X6_Fe_Zy... - Page 148 2. OUTLET COVER OPEN AND HIDDEN OPEN OUTLET COVER OPEN AND HIDDEN OPEN CODE PART NAME Q`TY 1A10X1231A ASS'Y_DOOR_FRONT_R 1A10X1232A ASS'Y_DOOR_FRONT_L 8405E049XA SCREW_M/C_PWH_M3X6_Fe_Ni 721022400A CASE_HIDDEN_R 721022300A CASE_HIDDEN_L 8400E021XA SCREW_M/C_PH/SWW_M3X6_FE_ZY...

- Page 149 3. COVER TOP AND DOOR REAR TOP COVER TOP AND DOOR REAR TOP CODE PART NAME Q`TY 721018500A COVER_TOP(SB3000) 721019000A DOOR_REAR_TOP 8405E049XA SCREW_M/C_PWH_M3X6_Fe_Ni...

- Page 150 4. PBA PBA ASSY CODE PART NAME Q`TY 1A10X1154A SB-3000 MOTOR B'D V2.6 1A10X1153B SB-3000 CONN B'D V4.1 1A10X1152B SB-3000 IMAGE_1 B'D V5.0 1A10X1182A SB-3000 IMAGE_2 B'D V5.0 8400E021XA SCREW_M/C_PH/SWW_M3X6_Fe_Zy 8407B063XA HEX_SUPPORT_M3X10_Fe_Ni...

- Page 151 5. BELT BELT ASSY CODE PART NAME Q`TY BELT ADF PICK MOTOR 8210A041XA BELT ADF LINK 8210A042XA BELT DETECT 1 8210A043XA BELT DETECT 2 8210A044XA BELT DETECT 3 8210A045XA BELT MOTOR-2 8210A046XA BELT GEAR LINK 8210A047XA BELT OUTLET 8210A048XA BELT OUTLET SMALL 8210A049XA...

- Page 152 6. PULLEY-1 PULLEY-1 ASSY CODE PART NAME Q`TY 721025700A PULLEY_ADF_CLUTCH40 720508701A PULLEY_FEED 720712800A PULLEY_FEED_1_V_S2M-24 721025600A PULLEY_S3M-20 721025800A PULLEY_S3M_16...

- Page 153 7. PULLEY-2 PULLEY-2 ASSY CODE PART NAME Q`TY 720713300A PULLEY_ADF_V_S3M-40 7810A111XA PULLEY_ADF_S3M-40 720712800A PULLEY_FEED_1_V_S2M-24 721025600A PULLEY_S3M-20 720713000A PULLEY_FEED_4_V_S3M-32 721025900A GEAR_M08_T35 720508701A PULLEY_FEED...

- Page 154 8. DETECT_MODULE DETECT_MODULE ASSY CODE PART NAME Q`TY 1A10X1207A ASSY_DETECT_MODULE 8400E025XA SCREW_M/C_PH/SWW_M4X8_Fe_Ni...

- Page 155 9. OUTLET OUTLET ASSY CODE PART NAME Q`TY OUTLET ASSY 741014200A HINGE_BODY_TOP 741013600A HINGE_DOOR 8400E025XA SCREW_M/C_PH/SWW_M4X8_Fe_Ni...

- Page 156 10. TRANSFER A ASSY AND HOPPER GUIDE ASSY TRANSFER A ASSY AND HOPPER GUIDE ASSY CODE PART NAME Q`TY 721018400A HOPPER_GUIDE 8400E034XA SCREW_T/P_PH_T2_Ø3X8_Fe_Zy TRNASFER_A_ASSY 8400E025XA SCREW_M/C_PH/SWW_M4X8_Fe_Ni...

- Page 157 11. OP PANEL ASSY AND TRANSFER E ASSY OP PANEL ASSY AND TRANSFER E ASSY CODE PART NAME Q`TY 1A10X1205A ASS'Y_OP-PANEL 8405E049XA SCREW_M/C_PWH_M3X6_Fe_Ni 1A10X1201A ASS'Y_TRANSFER_E 8400E034XA SCREW_T/P_PH_T2_Ø3X8_Fe_Zy...

- Page 158 12. TRANSFER D BOTTOM ASSY TRANSFER D BOTTOM ASSY CODE PART NAME Q`TY 1A10X1197A ASS'Y_TRANSFER_B_BOTTOM 7810A114XA BUSH_TRANS_C 8400E021XA SCREW_M/C_PH/SWW_M3X6_Fe_Zy...

- Page 159 13. TRANSFER_GUIDE_B_TOP ASSY TRANSFER_GUIDE_B_TOP ASSY CODE PART NAME Q`TY 1A10X1194A ASS'Y_TRANSFER_GUIDE_B_TOP 8400E021XA SCREW_MC_PH_SWW_M3X6_FE_ZY 721022200A CAP_BEARING 8400A004XA E_RING_Ø6(6x12x0.8)_Fe_ZB 7810A097XA COUPLE_SHAFT 7810A096XA COUPLE_1 8200A005XA BEARING_LF_1680ZZ 8400E033XA SCREW_T/P_PH_T2_Ø3X6_Fe_Zy...

- Page 160 14. HOPPER PART ASSY HOPPER PART ASSY CODE PART NAME Q`TY 1A10X1204A ASS'Y_COVER_HOPPER 1A10X1186A ASS'Y_UNDER_COVER_OP_PANEL(SB3000) 8400E034XA SCREW_T/P_PH_T2_Ø3X8_Fe_Zy...

- Page 161 15. TRANSFER A BOTTOM ASSY TRANSFER A BOTTOM ASSY CODE PART NAME Q`TY 1A10X1187A ASS'Y_TRANSFER_A_BOTTOM 8400E021XA SCREW_M/C_PH/SWW_M3X6_Fe_Zy 741012400A BKT_GUIDE_TRANS_BOTTOM 8400E034XA SCREW_T/P_PH_T2_Ø3X8_Fe_Zy...

- Page 162 16. ADF MOTOR ASSY ADF MOTOR ASSY CODE PART NAME Q`TY MOTOR_PART_ASSY 8410E075XA SCREW_M/C_PH_M6X16 1A10X1230A ASS'Y_BKT_IDLE_PLATE 7610A040XA TORSION_SPRING_IDLE 8400A002XA E_RING_Ø4(4x11x0.6)_Fe_ZB...

- Page 163 17. ENDCODER ASSY ENDCODER ASSY CODE PART NAME Q`TY 8400E021XA SCREW_M/C_PH/SWW_M3X6_Fe_Zy 721022600A COVER_ENCORDER_WHEEL 8400E025XA SCREW_M/C_PH/SWW_M4X8_Fe_Ni 8400A004XA E_RING_Ø6(6x12x0.8)_Fe_ZB 720515500A ENCODER_WHEEL 1A10X1177A SB-3000 ENCODER-1 V2.0 1A10X1178A SB-3000 ENCODER-2 V1.0 7810A109XA ADF_STOPPER...

- Page 164 18. RAINFORCE PLATE ASSY RAINFORCE PLATE ASSY CODE PART NAME Q`TY COVER_FRONT_ASSY 8400E021XA SCREW_MC_PH_SWW_M3X6_FE_ZY 8400E025XA SCREW_M/C_PH/SWW_M4X8_Fe_Ni HINGE_BODY_BTM_ASSY 741012200A REINFORCE_PLATE_DETECT 741014100A REINFORCE_PLATE_BOTTOM...

- Page 165 19. SMPS ASSY AND INTERFACE BOARD ASSY SMPS ASSY AND INTERFACE BOARD ASSY CODE PART NAME Q`TY 1A10X1183A ASS'Y_BKT_SMPS(SB3000) 8400E021XA SCREW_MC_PH_SWW_M3X6_FE_ZY 8400E017XA SCREW_M/C_FH_M3X6_Fe_Ni 721019200A COVER_REAR(SB3000) 1A10X1185A ASS'Y_BKT_PCB_IF(SB3000) 7010A181XA KHP-39 2P (SMPS- AC lnLet)

- Page 166 20. RIGHT SIDE ASSY RIGHT SIDE ASSY CODE PART NAME Q`TY 8400E016XA SCREW_M/C_FH_M3X12_Fe_Ni 8400E019XA SCREW_M/C_PH_M2X8_Fe_Zy 8605A009XA COOLING_FAN_40X40(t=10mm) 1A10X1234A ASS`Y_MICRO_SWITCH(SB3000)

- Page 167 21. ROLLER ASSY ROLLER ASSY CODE PART NAME Q`TY 8400A004XA E_RING_Ø6(6x12x0.8)_Fe_ZB 8200A005XA BEARING_LF_1680ZZ 801003600A ROLLER_PICK_UP_ASSY (SB3000) 801003500A ROLLER_ADF_ASSY (SB3000) 801004000A FEEDER_ROLLER_A (SB3000) 801004100A FEEDER_ROLLER_B (SB3000)

- Page 168 22. SIDE PLATE ASSY SIDE PLATE ASSY CODE PART NAME Q`TY 741012000A PLATE_SIDE_LE 741012100A PLATE_SIDE_RI 8400E025XA SCREW_M/C_PH/SWW_M4X8_Fe_Ni...

- Page 169 전체분해도 1. COVER-SIDE-R COVER-SIDE-R ASS'Y CODE PART NAME Q`TY 721019400A COVER_SIDE_R 721022500A DUST-CAP...

- Page 170 2. DOOR-FRONT-R ASS'Y_DOOR_FRONT_R CODE PART NAME Q`TY 721019600A DOOR_FRONT_R 7805A060XA PIN_REJECT_BAR 7610A044XA TORSION_SPRING_DOOR_LATCH 7810A106XA FRONT_HANDLE_SHAFT 721021100A LATCH_MAIN 8410A077XA E_RING_Ø3(3x6x0.4)_Fe_ZB...

- Page 171 3. DOOR-FRONT-L ASS'Y_DOOR_FRONT_L CODE PART NAME Q`TY 721019700A DOOR_FRONT_L 8405E049XA SCREW_M/C_PWH_M3X6_Fe_Ni 8400E033XA SCREW_T/P_PH_T2_Ø3X6_Fe_Zy 721020400A REFLECTOR_LED 1A10X1175A SB-3000 POCKET_LED V3.0...

- Page 172 4. COVER-FRONT COVER-FRONT ASS'Y CODE PART NAME Q`TY 721019300A COVER_FRONT 8805B043XA ELECTRO_FORMING_BADGE...

- Page 173 5. DOOR-REAR-MIDDLE DOOR-REAR-MIDDLE ASS'Y CODE PART NAME Q`TY 721019100A DOOR_REAR_MIDDLE 8810E087XA RUBBER_MAGNET_DOOR 741015200A BRK-MIDDLE-DOOR-HINGE 8400E033XA SCREW_T/P_PH_T2_Ø3X6_Fe_Zy 8810E100XA TAPE_MAGNET...

- Page 174 6. HOPPER ASS'Y_COVER_HOPPER CODE PART NAME Q`TY 8400E034XA SCREW_T/P_PH_T2_Ø3X8_Fe_Zy 721018300A COVER_HOPPER 720004400B WINDOW_HOPPER 1A10X1179A SB-3000 HOPPER 720517200A PICK_UP_SUPPORT 8400E016XA SCREW_M/C_FH_M3X12_Fe_Ni 8400C007XA HEX_NUT_M3X0.5_Fe_Zy...

- Page 175 7. UNDER-COVER-OP-PANEL ASS'Y_UNDER_COVER_OP_PANEL(SB3000) CODE PART NAME Q`TY 721018900A UNDER_COVER_OP_PANEL 8400E034XA SCREW_T/P_PH_T2_Ø3X8_Fe_Zy 8400E033XA SCREW_T/P_PH_T2_Ø3X6_Fe_Zy 1A10X1180A SM-208M9 (SPEAKER) 8805E046XA SIDE_LOCKING_SADDLE_DS-110 1A10X1171A SB-3000 STACKER_SENSOR1 V 3.0 720713500A CAP_RP1_V...

- Page 176 8. BILL_GUIDE ASS'Y_BILL_GUIDE CODE PART NAME Q`TY 721018700A HOPPER_GUIDE_L(SB3000) 8810E078XA TAPE_HOPPER_GUIDE_L 741015000A HOOPER-GUIDE-PLATE-L 721018600A BILL_GUIDE 741015100A HOOPER-GUIDE-PLATE-R 8810E079XA TAPE_HOPPER_GUIDE_R 721018800A HOPPER_GUIDE_R(SB3000)

- Page 177 9. TRANSFER_A_VIEW TRANSFER_A_VIEW CODE PART NAME Q`TY 8400E025XA SCREW_M/C_PH/SWW_M4X8_Fe_Ni 8400A003XA E_RING_Ø5(5x11x0.6)_Fe_ZB 8200A004XA BEARING_LF_1360ZZ 1A10X1188A ASS'Y_TRANSFER_A_TOP SEPARATOR_PART_ASS`Y...

- Page 178 9-1. TRANSFER_A_TOP_VIEW TRANSFER_A_TOP_VIEW CODE PART NAME Q`TY 8400E033XA SCREW_T/P_PH_T2_Ø3X6_Fe_Zy 8400E034XA SCREW_T/P_PH_T2_Ø3X8_Fe_Zy 1A10X1189A ASS'Y_ROLLER_PINCH_FEED 741013700A BKT_TRANSFER_GUIDE_A 1A10X1183A SB-3000 RP1_TRN V3.0 1A10X1184A SB-3000 RP2_TRN V3.0 720713500A CAP_RP1_V 721024300A TRANSFER_GUIDE_A_TOP 8400A003XA E_RING_Ø5(5x11x0.6)_Fe_ZB 8400D010XA PLASTIC_WASHER_Ø6(6.2x10x_0.5T) 7810A094XA OPEN_SHAFT_TRANSFER_A 7610A030XA COIL_SPRING_PIVOT_TRANSFER 8805E035XA COVER_SADDLE_DS-2...

- Page 179 9-2. TRANSFER_A_BOTTOM_VIEW ASS'Y_TRANSFER_A_BOTTOM CODE PART NAME Q`TY 721024400A TRANSFER_GUIDE_A_BOTTOM 741012400A BKT_GUIDE_TRANS_BOTTOM 8400E021XA SCREW_M/C_PH/SWW_M3X6_Fe_Zy 8400E033XA SCREW_T/P_PH_T2_Ø3X6_Fe_Zy 8400E034XA SCREW_T/P_PH_T2_Ø3X8_Fe_Zy 1A10X1185A SB-3000 RP1_RCV V3.0 1A10X1186A SB-3000 RP2_RCV V3.0 720713500A CAP_RP1_V...

- Page 180 10. SEPARATOR_ASSY 01-SEPARATOR_ASSY CODE PART NAME Q`TY 8400E021XA SCREW_M/C_PH/SWW_M3X6_Fe_Zy 8400E025XA SCREW_M/C_PH/SWW_M4X8_Fe_Ni MODULE_SEPARATOR_ASS`Y...

- Page 181 10-1. SEPARATOR_ASSY 02-SEPARATOR_ASSY CODE PART NAME Q`TY 7810A076XA SCREW_SPACE_CONTROL 7610A031XA COIL_SPRING_SCREW_SPACE_CONTROL 8400E025XA SCREW_M/C_PH/SWW_M4X8_Fe_Ni 741011200A SUPPORT_SEPARATOR 7810A110XA BLOCK_PAPER_SPACE_CONTROL...

- Page 182 10-2. SEPARATOR_ASSY 03-SEPARATOR_ASSY CODE PART NAME Q`TY BKT_SEPARATOR_P_ASSY 7610A029XA COIL_SPRING_PIVOT_BLOCK 8400A003XA E_RING_Ø5(5x11x0.6)_Fe_ZB 8410E079XA WAVE_WASHER_Ø6 8200A004XA BEARING_LF_1360ZZ 7810A108XA BLOCK_PIVOT_SEPARATOR BKT_FIX_SEPARATOR_ASSY...

- Page 183 10-3. SEPARATOR_ASSY 04-SEPARATOR_ASSY CODE PART NAME Q`TY 1A10X1192A ASS'Y_BKT_TRANSFER 741011100A BKT_FIX_SEPARATOR 8400E021XA SCREW_M/C_PH/SWW_M3X6_Fe_Zy 8400A004XA E_RING_Ø6(6x12x0.8)_Fe_ZB 8210A036XA BEARING LF1280ZZ 7810A074XA SHAFT_PIVOT_SEPARATOR...

- Page 184 10-4. SEPARATOR_ASSY 05- ASS'Y_BKT_TRANSFER CODE PART NAME Q`TY 741011000A BKT_TRANSFER 7810A075XA SHAFT_PIVOT_TRANSFER 8400A003XA E_RING_Ø5(5x11x0.6)_Fe_ZB 7610A030XA COIL_SPRING_PIVOT_TRANSFER 721022800A GUIDE_PIVOT_TRANSFER 801003800A ROLLER_TRANSFER_ASSY (SB3000) 7810A077XA SHAFT_TRANSFER 8400A002XA E_RING_Ø4(4x11x0.6)_Fe_ZB...

- Page 185 10-5. SEPARATOR_ASSY 06- ASS'Y_ROLLER_PRESS CODE PART NAME Q`TY 801003700A ROLLER_SEPARATOR_ASSY (SB3000) 721022900A GUIDE_PRESS_ROLLER (SB3000) 7810A078XA PRESS_ROLLER 8410D072XA O_RING (AN_014)

- Page 186 11. TRANSFER_B_TOP_VIEW ASS'Y_TRANSFER_GUIDE_B_TOP CODE PART NAME Q`TY 8400E033XA SCREW_T/P_PH_T2_Ø3X6_Fe_Zy 1A10X1168A SB-3000 RP5_6 V3.0 720713800A CAP_RP2_V 8210A037XA SE_BELT_1 8405E049XA SCREW_M/C_PWH_M3X6_Fe_Ni 721022200A CAP_BEARING 8400D038XA PLASTIC_WASHER_Ø8(8.2x13x_0.25T) 8400A004XA E_RING_Ø6(6x12x0.8)_Fe_ZB 8200A005XA BEARING_LF_1680ZZ 7810A096XA COUPLE_1 7810A097XA COUPLE_SHAFT 1A10X1195A ASS'Y_CROWN_EXIT_ROLLER 8400E034XA SCREW_T/P_PH_T2_Ø3X8_Fe_Zy 1A10X1196A ASS'Y_CROWN_TRANSFER_ROLLER 721024500A TRANSFER_GUIDE_B_TOP...

- Page 187 11-1. ASS'Y_TRANSFER_GUIDE_B_TOP ASS'Y_TRANSFER_GUIDE_B_TOP-1 CODE PART NAME Q`TY 8405E049XA SCREW_M/C_PWH_M3X6_Fe_Ni 721022200A CAP_BEARING 8400D038XA PLASTIC_WASHER_Ø8(8.2x13x_0.25T) 8400A004XA E_RING_Ø6(6x12x0.8)_Fe_ZB 8200A005XA BEARING_LF_1680ZZ 7810A096XA COUPLE_1 7810A097XA COUPLE_SHAFT 8400E034XA SCREW_T/P_PH_T2_Ø3X8_Fe_Zy...

- Page 188 11-2. ASS'Y_TRANSFER_GUIDE_B_TOP ASS'Y_TRANSFER_GUIDE_B_TOP-2 CODE PART NAME Q`TY 8400E033XA SCREW_T/P_PH_T2_Ø3X6_Fe_Zy 1A10X1168A SB-3000 RP5_6 V3.0 720713800A CAP_RP2_V 8210A037XA SE_BELT_1...

- Page 189 11-3. ASS'Y_TRANSFER_GUIDE_B_TOP ASS'Y_TRANSFER_GUIDE_B_TOP-3 CODE PART NAME Q`TY 1A10X1196A ASS'Y_CROWN_TRANSFER_ROLLER 8400A004XA E_RING_Ø6(6x12x0.8)_Fe_ZB 8210A036XA BEARING LF1280ZZ 8400E034XA SCREW_T/P_PH_T2_Ø3X8_Fe_Zy 1A10X1195A ASS'Y_CROWN_EXIT_ROLLER 721024500A TRANSFER_GUIDE_B_TOP...

- Page 190 12. TRANSFER_B_ BOTTOM_VIEW...

- Page 191 ASS'Y_TRANSFER_B_BOTTOM CODE PART NAME Q`TY 8400E021XA SCREW_M/C_PH/SWW_M3X6_Fe_Zy 8400E034XA SCREW_T/P_PH_T2_Ø3X8_Fe_Zy 721020700A GUIDE_LENS_STACKER 721022700A LENS_TRANSFER_B 1A10X1199A ASS'Y_CROWN_TRANSFER_ROLLER_PINCH_S 1A10X1195A ASS'Y_CROWN_EXIT_ROLLER 8400E021XA SCREW_M/C_PH/SWW_M3X6_Fe_Zy 7810A114XA BUSH_TRANS_C 1A10X1198A ASS'Y_CROWN_TRANSFER_ROLLER_PINCH 721024500A TRANSFER_GUIDE_B_BOTTOM 8400A003XA E_RING_Ø5(5x11x0.6)_Fe_ZB 8400D010XA PLASTIC_WASHER_Ø6(6.2x10x_0.5T) 7810A101XA SHAFT_TRANSFER_B 8400E033XA SCREW_T/P_PH_T2_Ø3X6_Fe_Zy HANDLE_TRNS_B ASSY 721021600A DUST_COVER 721021900A DUST_COVER_OUTLET 741013800A BKT_TRANSFER_GUIDE_B 7610A036XA TORSION_SPRING_OPEN_L...

- Page 192 12-1. ASS'Y_TRANSFER_B_BOTTOM 00- ASS'Y_TRANSFER_B_BOTTOM CODE PART NAME Q`TY 8400E021XA SCREW_M/C_PH/SWW_M3X6_Fe_Zy 7810A114XA BUSH_TRANS_C...

- Page 193 12-2. ASS'Y_TRANSFER_B_BOTTOM 01- ASS'Y_TRANSFER_B_BOTTOM CODE PART NAME Q`TY 8400E034XA SCREW_T/P_PH_T2_Ø3X8_Fe_Zy 1A10X1200A ASS'Y_BKT_TRANSFER_GUIDE_B...

- Page 194 12-3. ASS'Y_TRANSFER_B_BOTTOM 02- ASS'Y_TRANSFER_B_BOTTOM CODE PART NAME Q`TY 741013800A BKT_TRANSFER_GUIDE_B 8410A077XA E_RING_Ø3(3x6x0.4)_Fe_ZB 7810A115XA SHAFT_HINGE_HANDLE_TRANS_LOWER 741013000A HANDLE_TRNS_B 7610A038XA TORSION_SPRING_HANDLE_LOWER 721021600A DUST_COVER 721021900A DUST_COVER_OUTLET 8400E021XA SCREW_M/C_PH/SWW_M3X6_Fe_Zy...

- Page 195 12-4. ASS'Y_TRANSFER_B_BOTTOM 03- ASS'Y_TRANSFER_B_BOTTOM CODE PART NAME Q`TY 8400A003XA E_RING_Ø5(5x11x0.6)_Fe_ZB 8400D010XA PLASTIC_WASHER_Ø6(6.2x10x_0.5T) 7610A037XA TORSION_SPRING_OPEN_R 7610A036XA TORSION_SPRING_OPEN_L 7810A101XA SHAFT_TRANSFER_B 8210A038XA SE_BELT_2...

- Page 196 12-5. ASS'Y_TRANSFER_B_BOTTOM 04- ASS'Y_TRANSFER_B_BOTTOM CODE PART NAME Q`TY 8400E033XA SCREW_T/P_PH_T2_Ø3X6_Fe_Zy 1A10X1198A ASS'Y_CROWN_TRANSFER_ROLLER_PINCH 1A10X1199A ASS'Y_CROWN_TRANSFER_ROLLER_PINCH_S 1A10X1195A ASS'Y_CROWN_EXIT_ROLLER 8400E034XA SCREW_T/P_PH_T2_Ø3X8_Fe_Zy...

- Page 197 12-6. ASS'Y_TRANSFER_B_BOTTOM 05- ASS'Y_TRANSFER_B_BOTTOM CODE PART NAME Q`TY 721020600A GUIDE_LENS_STACKER 721022500A LENS_TRANSFER_B 721024500A TRANSFER_GUIDE_B_BOTTOM...

- Page 198 13. ASSY_DETECT_MODULE ASSY_DETECT_MODULE CODE PART NAME Q`TY 8400A004XA E_RING_Ø6(6x12x0.8)_Fe_ZB 7810A091XA SHAFT_HINGE_TRANSFER_B 8405E049XA SCREW_M/C_PWH_M3X6_Fe_Ni 8400A002XA E_RING_Ø4(4x11x0.6)_Fe_ZB 741014900A LINK_REAR_OPEN-R 1A10X1210A ASS`Y_DETECT_CASE_TOP 7610A043XA COIL_SPRING_DAMPER 1A10X1208A ASS'Y_DETECT_CASE_BOTTOM 741014800A LINK_REAR_OPEN-L...

- Page 199 13-1. ASS`Y_DETECT_CASE_TOP ASS`Y_DETECT_CASE_TOP ( 1/5 ) CODE PART NAME Q`TY 721025100A DETECT_CASE_BOTTOM 6600G002XA SUV_FILTER 6600G005XA UV_FILTER(N) 7810G116XA GLASS_UV_REFLECTOR_SB3000 8810E082XA TAPE_UV_REFLECTOR...

- Page 200 13-2. ASS`Y_DETECT_CASE_TOP ASS`Y_DETECT_CASE_TOP ( 2/5 ) CODE PART NAME Q`TY 8400E033XA SCREW_T/P_PH_T2_Ø3X6_Fe_Zy 1A10X1157B SB-3000 UVB V1.5 720713800A CAP_RP2_V 6608H017XA CIS(SB9) 1A07X1098A PBA_IR_TRN_MODULE 721021200A LOCK_IR_LED 1A10X1167B SB-3000 RP3_RCV V3.1 720713500A CAP_RP1_V ASS`Y_DETECT_CASE_TOP ( 1/5 )

- Page 201 13-3. ASS`Y_DETECT_CASE_TOP ASS`Y_DETECT_CASE_TOP ( 3/5 ) CODE PART NAME Q`TY 801004300A FEEDER_ROLLER_MG_BRUSH (SB3000) 8410A076XA O_RING_Ø10(10X15X0.8) 8207A016XA BEARING_F63800ZZ 7810A118XA SHAFT_DUST_PAN_LOWER 801004400A ROLLER_TAPE_DETECT (SB3000) 801004200A FEEDER_ROLLER_DETECT (SB3000) ASS`Y_DETECT_CASE_TOP ( 2/5 )

- Page 202 13-4. ASS`Y_DETECT_CASE_TOP ASS`Y_DETECT_CASE_TOP ( 4/5 ) CODE PART NAME Q`TY 8400E034XA SCREW_T/P_PH_T2_Ø3X8_Fe_Zy 741013900A BKT_DETECT_CASE_BOTTOM 720713600A DUST_ROLLER 8807E065XA CUSHION_DUST_ROLLER 8400E021XA SCREW_M/C_PH/SWW_M3X6_Fe_Zy LOCKER_RING 8410A077XA E_RING_Ø3(3x6x0.4)_Fe_ZB ASS`Y_DETECT_CASE_TOP ( 3/5 )

- Page 203 13-5. ASS`Y_DETECT_CASE_TOP ASS`Y_DETECT_CASE_TOP ( 5/5 ) CODE PART NAME Q`TY 8400E034XA SCREW_T/P_PH_T2_Ø3X8_Fe_Zy 741012800A BKT_HINGE-L 8400A004XA E_RING_Ø6(6x12x0.8)_Fe_ZB 8200A005XA BEARING_LF_1680ZZ 741012900A BKT_HINGE-R ASS`Y_DETECT_CASE_TOP ( 4/5 )

- Page 204 13-6. ASS'Y_DETECT_CASE_BOTTOM ASS'Y_DETECT_CASE_BOTTOM ( 1/6 ) CODE PART NAME Q`TY 721025200A DETECT_CASE_TOP 6600G002XA SUV_FILTER 6600G005XA UV_FILTER(N) 7810G116XA GLASS_UV_REFLECTOR_SB3000 8810E082XA TAPE_UV_REFLECTOR...

- Page 205 13-7. ASS'Y_DETECT_CASE_BOTTOM ASS'Y_DETECT_CASE_BOTTOM ( 2/6) CODE PART NAME Q`TY 8400E033XA SCREW_T/P_PH_T2_Ø3X6_Fe_Zy 1A10X1156A SB-3000 UVA V1.3 720713800A CAP_RP2_V 8810E097XA BLOCK_DUSTPAN 7810A117XA SHAFT_DUST_PAN 1A10X1211A ASS`Y_ROLLER_PINCH_FEED-1 1A10X1166A SB-3000 RP3_TRN V3.0 720713500A CAP_RP1_V DETECT_MODULE_OUT_ASS`Y ( 1/6 )

- Page 206 13-8. ASS'Y_DETECT_CASE_BOTTOM ASS'Y_DETECT_CASE_BOTTOM ( 3/6 ) CODE PART NAME Q`TY 8400A003XA E_RING_Ø5(5x11x0.6)_Fe_ZB 800703200A ROLLER_PINCH_V 7810A103XA SHAFT_PINCH-MR 7610A039XA TORSIOIN_SPRING_PINCH_E 8400E033XA SCREW_T/P_PH_T2_Ø3X6_Fe_Zy 1A10X1160A SB-3000 MRS_R V2.0 1A10X1158A SB-3000 MRA V2.0 1A10X1159A SB-3000 MRS_L V2.0 6608H017XA CIS(SB9) 721021300A LOCK_CIS DETECT_MODULE_OUT_ASS`Y ( 2/6 )

- Page 207 13-9. ASS'Y_DETECT_CASE_BOTTOM ASS'Y_DETECT_CASE_BOTTOM ( 4/6 ) CODE PART NAME Q`TY 8405E049XA SCREW_M/C_PWH_M3X6_Fe_Ni 1A10X1163A SB-2000 VD_RECEIVE V2.2 8407A059XA SCREW_M/C_PH/SW_M3X16_Fe_Zy 7807A066XA BUSH_SCREW 7607A022XA COIL_SPRING_TAPE_DETECT 1A07X2167A ASS'Y_BLOCK_TAPE_DETECT DETECT_MODULE_OUT_ASS`Y ( 3/6 )

- Page 208 13-10. ASS'Y_DETECT_CASE_BOTTOM ASS'Y_DETECT_CASE_BOTTOM ( 5/6 ) CODE PART NAME Q`TY 8400E033XA SCREW_T/P_PH_T2_Ø3X6_Fe_Zy 1A10X1162B SB-3000 MTU V1.3 8400E029XA SCREW_SET_SIH_FP_M4X6_FE_ZB 741012700A LOCKER_SENSOR-R 7610A042XA TORSION_SPRING_HANDLE_R 7810A089XA SHAFT_SENSOR 741012500A HANDLE_SENSOR 8405E049XA SCREW_M/C_PWH_M3X6_Fe_Ni 7610A038XA TORSION_SPRING_HANDLE_L 741012600A LOCKER_SENSOR-L DETECT_MODULE_OUT_ASS`Y ( 4/6 )

- Page 209 13-11. ASS'Y_DETECT_CASE_BOTTOM ASS'Y_DETECT_CASE_BOTTOM ( 6/6 ) CODE PART NAME Q`TY 8400E034XA SCREW_T/P_PH_T2_Ø3X8_Fe_Zy 741012300A BKT_DETECT_CASE_TOP 8400E016XA SCREW_M/C_FH_M3X12_Fe_Ni 8605A009XA COOLING_FAN_40X40(t=10mm) DETECT_MODULE_OUT_ASS`Y ( 5/6 )

- Page 210 14. ASS'Y_OP-PANEL ASS'Y_OP-PANEL ( 1/3 ) CODE PART NAME Q`TY 6210A011XB RUBBER_BUTTON_2KEY 721018200A BUTTON_2KEY 8810E090XA CUSHION_LCD 6210A010XB RUBBER_BUTTON_4KEY 721018100A BUTTON_4KEY 721018000A OP_PANEL...

- Page 211 14-1. ASS'Y_OP-PANEL ASS'Y_OP-PANEL ( 2/3 ) CODE PART NAME Q`TY 8810E091XA CUSHION_BKT_LCD 741013100A BKT_LCD 6610H018XA LCD-PANEL-AT050TN43-V1 ASS'Y_OP-PANEL ( 1/3 )

- Page 212 14-2. ASS'Y_OP-PANEL ASS'Y_OP-PANEL ( 3/3 ) CODE PART NAME Q`TY 8400E033XA SCREW_T/P_PH_T2_Ø3X6_Fe_Zy 1A10X1155B SB-3000 MAIN B'D(통합) V5.0 8400E021XA SCREW_M/C_PH/SWW_M3X6_Fe_Zy ASS'Y_OP-PANEL ( 2/3 )

- Page 213 15. CROWN_EXIT_ROLLER_PINCH 01-CROWN_EXIT_ROLLER_PINCH CODE PART NAME Q`TY 8400A004XA E_RING_Ø6(6x12x0.8)_Fe_ZB 721023000A CROWN_EXIT_ROLLER_PINCH 7810A107XA PIN_ROLLER_STOPPER (SB3000) 7810A098XA SHAFT_CROWN_TRANSFER_ROLLER 16. CROWN_EXIT_ROLLER 02-CROWN_EXIT_ROLLER CODE PART NAME Q`TY 8410A074XA O_RING_Ø8(8X15X0.8) 721024600A CROWN_EXIT_ROLLER 7810A099XA SHAFT_CROWN_EXIT_ROLLER...

- Page 214 17. CROWN_EXIT_ROLLER 03-CROWN_EXIT_ROLLER_1 CODE PART NAME Q`TY 8400A003XA E_RING_Ø5(5x11x0.6)_Fe_ZB 7810A105XA ROLLER-STOPPER-BUSH 721025000A CROWN_EXIT_ROLLER_1 7810A104XA SHAFT_CROWN_EXIT_ROLLER-1 18. CROWN_TRANSFER_ROLLER_PINCH_S 04-CROWN_TRANSFER_ROLLER_PINCH_S CODE PART NAME Q`TY 8400A003XA E_RING_Ø5(5x11x0.6)_Fe_ZB 7810A105XA ROLLER-STOPPER-BUSH 721024800A CROWN_TRANSFER_ROLLER_PINCH_S 7810A102XA SHAFT_CROWN_TRANS_ROLLER_PINCH_...

- Page 215 19. CROWN_TRANSFER_ROLLER 05-CROWN_TRANSFER_ROLLER CODE PART NAME Q`TY 721023000A CROWN_EXIT_ROLLER_PINCH 8400A004XA E_RING_Ø6(6x12x0.8)_Fe_ZB 7810A107XA PIN_ROLLER_STOPPER (SB3000) 7810A098XA SHAFT_CROWN_TRANSFER_ROLLER 20. CROWN_TRANSFER_ROLLER_PINCH 06-CROWN_TRANSFER_ROLLER_PINCH CODE PART NAME Q`TY 7810A100XA SHAFT_CROWN_TRANS_ROLLER_PINCH 721024600A CROWN_EXIT_ROLLER 8410A074XA O_RING_Ø8(8X15X0.8)

- Page 216 21. ROLLER_PINCH_FEED 07-ROLLER_PINCH_FEED CODE PART NAME Q`TY 8400A005XA E_RING_Ø7(7x14x0.8)_Fe_ZB 8210A034XA BEARING L1910ZZ 7610A035XA COIL_SPRING_PINCH(SHAFT) 7810A093XA SHAFT_PINCH_FEED 22. ROLLER_PINCH_MR 08-ROLLER_PINCH_MR CODE PART NAME Q`TY 8400A003XA E_RING_Ø5(5x11x0.6)_Fe_ZB 7810A103XA SHAFT_PINCH-MR 800703200A ROLLER_PINCH_V 7610A039XA TORSIOIN_SPRING_PINCH_E...

- Page 217 23. ASS'Y_TRANSFER_E ASS'Y_TRANSFER_E CODE PART NAME Q`TY 8210A039XA SE_BELT_3 721024900A OUTLET_GUIDE_BOTTOM 8400E033XA SCREW_T/P_PH_T2_Ø3X6_Fe_Zy 1A10X1202A ASS'Y_SHAFT_PINCH_MR 720713500A CAP_RP1_V 1A10X1170A SB-3000 RP8 V2.0 1A10X1169A SB-3000 RP7 V2.0 1A10X1195A ASS'Y_CROWN_EXIT_ROLLER 1A10X1203A ASS'Y_CROWN_EXIT_ROLLER-1 8400E034XA SCREW_T/P_PH_T2_Ø3X8_Fe_Zy...

- Page 218 24. ASS'Y_BKT_SMPS(SB3000) ASS'Y_BKT_SMPS(SB3000) CODE PART NAME Q`TY 8400E021XA SCREW_M/C_PH/SWW_M3X6_Fe_Zy 1A10X1181A SB-3000 SMPS 8810A080XA FLIM_BKT_SMPS 741013500A BKT_SMPS 8805E035XA COVER_SADDLE_DS-2 8810E077XA COVER_SADDLE_DS-1...

- Page 219 24-1. ASS'Y_REINFORCE_PLATE_BOTTOM(SB3000) ASS'Y_REINFORCE_PLATE_BOTTOM(SB3000) CODE PART NAME Q`TY 8400E025XA SCREW_M/C_PH/SWW_M4X8_Fe_Ni 721025400A SLIDE_OUTLET 741014100A REINFORCE_PLATE_BOTTOM...

- Page 220 25. ASS'Y_BKT_PCB_IF(SB3000) ASS'Y_BKT_PCB_IF(SB3000) CODE PART NAME Q`TY 8805E046XA SIDE_LOCKING_SADDLE_DS-110 1A10X1176B SB-3000 IF V2.4 8400E021XA SCREW_M/C_PH/SWW_M3X6_Fe_Zy 8405E049XA SCREW_M/C_PWH_M3X6_Fe_Ni 741014400A BKT_PCB_IF 8810A081XA PLATE_SHEET 7010A181XA KHP-39 2P (SMPS- AC lnLet)

- Page 221 26. MOTOR_PART ASS'Y MOTOR_PART ASS'Y CODE PART NAME Q`TY 741013200A BKT_MOTOR_SHIELD 8610A014XA BLDC MOTOR (SB3000)(8 PIN) 8610A016XA MAIN BLDC MOTOR (SB3000)(10 PIN) 8410E075XA SCREW_M/C_PH_M6X16 7810A112XA PULLEY_STEP_MOTOR_S3M_15 8405E048XA SCREW_SET_SIH_FP_M3x4_Fe_ZB 7810A113XA PULLEY_S3M_18...

- Page 222 27. ASS'Y_BKT_IDLE_PLATE ASS'Y_BKT_IDLE_PLATE CODE PART NAME Q`TY 741013300A BKT_IDLE_PLATE 7610A040XA TORSION_SPRING_IDLE 8405E049XA SCREW_M/C_PWH_M3X6_Fe_Ni 721026000A GEAR_M08_T35-2 8210A035XA BEARING L1060ZZ 7810A120XA FLANGE_GEAR 8400A003XA E_RING_Ø5(5x11x0.6)_Fe_ZB...

- Page 223 28. MECH_OUTLET ASS'Y MECH_OUTLET ASS'Y CODE PART NAME Q`TY 8405E049XA SCREW_M/C_PWH_M3X6_Fe_Ni 741015500A STOPPER_OPEN_LOCK 741013600A HINGE_DOOR 8400E025XA SCREW_M/C_PH/SWW_M4X8_Fe_Ni 741014300A HINGE_BODY_BTM 8400A002XA E_RING_Ø4(4x11x0.6)_Fe_ZB 7610A046XA TORSION_SPRING_HINGE_DOOR 7810A121XA STOPPPER_HINGE_SPRING 8400A005XA E_RING_Ø7(7x14x0.8)_Fe_ZB...

- Page 224 29. BOTTOM_ASS`Y BOTTOM_ASS`Y CODE PART NAME Q`TY 741013400A PLATE_BOTTOM 720507300A FOOT_MOLD 8400E021XA SCREW_M/C_PH/SWW_M3X6_Fe_Zy 8805D034XA RUBBER_FOOT_P...

- Page 225 OUTLET ASSY 1 OUTLET ASSY 1 CODE PART NAME Q`TY 741011400A PLATE_OUTLET_SIDE_RI 1A10X1212A ASS'Y_BKT_OUTLET_REINFORCE 741011300A PLATE_OUTLET_SIDE_LE 8400E021XA SCREW_M/C_PH/SWW_M3X6_Fe_Zy...

- Page 226 ASS'Y_BKT_OUTLET_REINFORCE ASS'Y_BKT_OUTLET_REINFORCE CODE PART NAME Q`TY 741015600A BKT_OUTLET_REINFORCE 721025400A SLIDE_OUTLET...

- Page 227 OUTLET ASSY 2 OUTLET ASSY 2 CODE PART NAME Q`TY 801003900A ROLLER_FEED_OUTLET_ASSY(SB3000) 8200A005XA BEARING_LF_1680ZZ 8400A004XA E_RING_Ø6(6x12x0.8)_Fe_ZB...

- Page 228 OUTLET ASSY 3 OUTLET ASSY 3 CODE PART NAME Q`TY 1A10X1213A ASS'Y_GUIDE_TRANS_POCKET 721023900A GUIDE_TRS_REJECT_POCKET 8400E034XA SCREW_T/P_PH_T2_Ø3X8_Fe_Zy...

- Page 229 ASS'Y_GUIDE_TRANS_POCKET ASS'Y_GUIDE_TRANS_POCKET CODE PART NAME Q`TY 721024000A GUIDE_TRANS_POCKET 1A10X1217A ASS'Y_GUIDE_PINCH_TRANS_POCKET 8400E033XA SCREW_T/P_PH_T2_Ø3X6_Fe_Zy...

- Page 230 ASS'Y_GUIDE_PINCH_TRANS_POCKET ASS'Y_GUIDE_PINCH_TRANS_POCKET CODE PART NAME Q`TY 721024100A GUIDE_PINCH_TRANS_POCKET 7610A033XA COIL_SPRING_TRANS_POCKET 1A10X1218A ASS'Y_SHAFT_PINCH_TRANS_POCKET 8400A003XA E_RING_Ø5(5x11x0.6)_Fe_ZB 8210A032XA BEARING R1960ZZ 7810A087XA SHAFT_PINCH_TRANS_POCKET...

- Page 231 OUTLET ASSY 4 OUTLET ASSY 4 CODE PART NAME Q`TY 1A10X1215A ASS'Y_STACKING_GUIDE_BAR 1A10X1222A ASS'Y_TOP_POCKET 1A10X1233A ASS'Y_MID_POCKET 1A10X1214A ASS'Y_REJECT_POCKET 8400E034XA SCREW_T/P_PH_T2_Ø3X8_Fe_Zy...

- Page 232 ASS'Y_STACKING_GUIDE_BAR ‘ ASS'Y_STACKING_GUIDE_BAR CODE PART NAME Q`TY 721020800A STACKING_GUIDE_BAR 721023700A STACKING_GUIDE 8810E088XA PORON_STACKING_BAR 1A10X1216A ASS'Y_STACKER-GUIDE 741011800A STACKER_GUIDE_SUB 721022000A STACKER_GUIDE 8810E083XA TAPE_STACKER_GUIDE 741015300A BRK-STACKER-GUIDE...

- Page 233 ASS'Y _POCKET-1 ASS'Y _POCKET-1 CODE PART NAME Q`TY 721023100A STACKER_POCKET 8405E049XA SCREW_M/C_PWH_M3X6_Fe_Ni 741011600A STACKER_SUPPORT_HINGE...

- Page 234 ASS'Y _POCKET-2 ASS'Y _POCKET-2 CODE PART NAME Q`TY 8405E049XA SCREW_M/C_PWH_M3X6_Fe_Ni 721023400A STACKING_RACK_R 7810A082XA SHAFT_1 7810A083XA SHAFT_HINGE 721023300A STACKING_RACK_L 721021700A GEARED_STACKER 8410A077XA E_RING_Ø3(3x6x0.4)_Fe_ZB 8210A030XA BEARING LF 940ZZ 1A10X1219A ASS'Y_STACKING_PLATE...

- Page 235 ASS'Y_STACKING_PLATE ASS'Y_STACKING_PLATE CODE PART NAME Q`TY 741014700A STACKER_SHEET 8810E084XA TAPE_STACKER_PLATE 8210A031XA BEARING R1350ZZ 721023200A STACKING_PLATE 721020600A LENS_STACKER 721020700A GUIDE_LENS_STACKER...

- Page 236 ASS'Y _POCKET-3 ASS'Y _POCKET-3 CODE PART NAME Q`TY 8400E033XA SCREW_T/P_PH_T2_Ø3X6_Fe_Zy 741011500A BKT_STACKER_PLATE...

- Page 237 ASS'Y _POCKET-4 ASS'Y _POCKET-4 CODE PART NAME Q`TY 1A10X1172B SB-3000 STACKER_SENSOR-2 V 1.1(1 POCKET) 1A10X1187A SB-3000 REJECT_SENSOR V 1.1(2 POCKET) 720713500A CAP_RP1_V 721022100A SENSOR_STACKER_FRAME 8400E033XA SCREW_T/P_PH_T2_Ø3X6_Fe_Zy...

- Page 238 ASS'Y _POCKET-5 ASS'Y _POCKET-5 CODE PART NAME Q`TY 721019800A REJECT_COVER_TOP_L 7810A088XA PIN_STACKER_COVER 7610A045XA TORSION_SPRING_STACK_GUIDE 721019900A REJECT_COVER_TOP_R...

- Page 239 ASS'Y _POCKET-6 ASS'Y _POCKET-6 CODE PART NAME Q`TY 721021400A STACKER_DUMMY_L 8810E085XA TAPE_STACKER_DUMMY_L 721020000A REJECT_COVER_MID_L 721020100A REJECT_COVER_MID_R 7610A045XA TORSION_SPRING_STACK_GUIDE 7810A088XA PIN_STACKER_COVER 8810E086XA TAPE_STACKER_DUMMY_R 721021500A STACKER_DUMMY_R...

- Page 240 ASS'Y_REJECT_POCKET ASS'Y_REJECT_POCKET CODE PART NAME Q`TY 7810A088XA PIN_STACKER_COVER 7610A045XA TORSION_SPRING_STACK_GUIDE 721020200A REJECT_COVER_BTM_L 721020300A REJECT_COVER_BTM_R 721020600A LENS_STACKER 721020700A GUIDE_LENS_STACKER...

- Page 241 OUTLET ASSY 5 OUTLET ASSY 5 CODE PART NAME Q`TY 8200A005XA BEARING_LF_1680ZZ 8400E034XA SCREW_T/P_PH_T2_Ø3X8_Fe_Zy OUTLET_GUIDE_TOP_ASSY 8400A004XA E_RING_Ø6(6x12x0.8)_Fe_ZB...

- Page 242 ASS'Y_OUTLET_GUIDE_TOP-1 ASS'Y_OUTLET_GUIDE_TOP-1 CODE PART NAME Q`TY 8400E033XA SCREW_T/P_PH_T2_Ø3X6_Fe_Zy 1A10X1188A SB-3000 POCKET_MOVE_DOWN V2.2 1A10X1189A SB-3000 POCKET_MOVE_UP V2.2...

- Page 243 ASS'Y_OUTLET_GUIDE_TOP-2 ASS'Y_OUTLET_GUIDE_TOP-2 CODE PART NAME Q`TY 8210A040XA SE_BELT_4 8400E033XA SCREW_T/P_PH_T2_Ø3X6_Fe_Zy 1A10X1195A ASS'Y_CROWN_EXIT_ROLLER 1A10X1224A ASS'Y_CROWN_EXIT_ROLLER_PINCH...

- Page 244 ASS'Y_OUTLET_GUIDE_TOP-3 ASS'Y_OUTLET_GUIDE_TOP-3 CODE PART NAME Q`TY 721020700A GUIDE_LENS_STACKER 721021000A LENS_TRANSFER...

- Page 245 ASS'Y_CROWN_EXIT_ROLLER_PINCH ASS'Y_CROWN_EXIT_ROLLER_PINCH CODE PART NAME Q`TY 721023000A CROWN_EXIT_ROLLER_PINCH 8400A004XA E_RING_Ø6(6x12x0.8)_Fe_ZB 7800A034XA PIN_ROLLER_STOPPER 7810A081XA SHAFT_CROWN_EXIT_ROLLER_PINCH ASS'Y_CROWN_EXIT_ROLLER ASS'Y_CROWN_EXIT_ROLLER CODE PART NAME Q`TY 721024600A CROWN_EXIT_ROLLER 8410A074XA O_RING_Ø8(8X15X0.8) 7810A099XA SHAFT_CROWN_EXIT_ROLLER...

- Page 246 OUTLET ASSY 6...

- Page 247 OUTLET ASSY 6 CODE PART NAME Q`TY 8400A003XA E_RING_Ø5(5x11x0.6)_Fe_ZB 8200A004XA BEARING_LF_1360ZZ 721020900A GUIDE_SELECTOR (SB3000) 8405E047XA SCREW_M/C_PH_M3X8_Fe_Zy 7810A085XA SHAFT_SELECTOR_CONNECTOR 741011900A BKT_SELECTOR(SB3000) 8400E025XA SCREW_M/C_PH/SWW_M4X8_Fe_Ni 8600B002XA SOLENOID 8400E021XA SCREW_M/C_PH/SWW_M3X6_Fe_Zy 1A10X1174B SB-3000 MOVE_OVERFLOW V5.0 1A10X1221A ASS'Y_STACKING_POSITION_BAR 8410E078XA SCREW_T/P_PH_T2_Ø2.X10_Fe_Zy 1A10X1221A ASS'Y_STACKING_POSITION_BAR 721023600A STACKING_POSITION_BAR 741015400A OVERFLOW_PLATE 8400E032XA SCREW_T/P_PH_T2_Ø2.6X6_Fe_Zy...

- Page 248 OUTLET ASSY 7 OUTLET ASSY 7 CODE PART NAME Q`TY 1A10X1226A ASS'Y_OUTLET_MOTOR 8400E021XA SCREW_M/C_PH/SWW_M3X6_Fe_Zy...

- Page 249 ASS'Y_OUTLET_MOTOR ASS'Y_OUTLET_MOTOR CODE PART NAME Q`TY 8610A015XA GEARD MOTOR (SB3000) 741011700A PLATE_GEARED_MOTOR 8400E042XA SCREW_M/C_PH_M2.5X4 721021600A GEARED_MOTOR_GEAR 721023500A STACKING_MOTOR_PIVOT 8210A029XA BEARING L740ZZ 7610A032XA TORSION_SPRING_POCKET 7810A084XA DISK_HINGE 8410A077XA E_RING_Ø3(3x6x0.4)_Fe_ZB...

- Page 250 OUTLET ASSY 8 OUTLET ASSY 8 CODE PART NAME Q`TY 1A10X1161B SB-3000 POCKET V5.0 8400E021XA SCREW_M/C_PH/SWW_M3X6_Fe_Zy...

- Page 251 OUTLET ASSY 9 OUTLET ASSY 9 CODE PART NAME Q`TY 1A10X1228A ASS'Y_BKT_LATCH_DOOR 8400E021XA SCREW_M/C_PH/SWW_M3X6_Fe_Zy 741014500A BKT_LATCH_DOOR 7610A034XA SPRING_LATCH_DOOR 721025500A LATCH_DOOR_A 8400A002XA E_RING_Ø4(4x11x0.6)_Fe_ZB...

- Page 252 OULET ASSY 10 OUTLET ASSY 10 CODE PART NAME Q`TY 720508701A PULLEY_FEED 8400A004XA E_RING_Ø6(6x12x0.8)_Fe_ZB 8210A049XA BELT OUTLET SMALL 721025900A GEAR_M08_T35 8210A048XA BELT OUTLET 721025600A PULLEY_S3M-20 8400D010XA PLASTIC_WASHER_Ø6(6.2x10x_0.5T) 8200A004XA BEARING_LF_1360ZZ 8400A003XA E_RING_Ø5(5x11x0.6)_Fe_ZB...

-

Page 253: Specification

17.0.0. Specifications Item Unit Specification Size (W x D x H) 307[W] x 334[D] x 380[H] Weight Approx. 20 Hopper capacity Notes MAX. 700 Stacker1 capacity Notes 100 [Max.200] Stacker2 capacity Notes 100 [Max.200] Reject pocket capacity Notes 50 [Max. 100] Display Type 800 x 480 Color LCD 3 RS232C Port(9 Pin D-SUB &...

Need help?

Do you have a question about the SB-3000 and is the answer not in the manual?

Questions and answers