Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for KMS MD35

- Page 1 MD35 Manual V4.16...

-

Page 2: Table Of Contents

Contents page. KMS (Kronenburg Management Systems) ..............4 Software installation ..................6 KMS software ....................8 The main screen ..................8 3.1.1 The injection characteristic diagram .............. 9 3.1.2 The ignition characteristic diagram ............... 9 The function bar ..................10 3.2.1... - Page 3 3D graph changing ..................67 Hardware installation ..................68 Fitting the ECU ..................68 Connecting the communication cable ............68 Fault tracing ....................69 Specifications ....................70 Wiring diagram MD35 ..................71 Appendix 1: Trigger wheel drawings ................72 KMS MD35 manual Version 4.16...

-

Page 4: Kms (Kronenburg Management Systems)

(without influence from outside) to work in. An engine or chassis dynamometer gives a more precise calibration for your (racing) applications. The KMS MD35 ECU offers a complete self learning air fuel ratio control (lambda control) for most common... - Page 5 WARNING: Disconnect the battery cables when you’re doing electrical work. Disconnect the KMS ECU from the wiring harness connector when welding on the vehicle. Make sure there are no fluid leaks and all connections are secured and/or tightened. Wiring and fuel system components must be mounted away from heat sources or shielded if necessary.

-

Page 6: Software Installation

The zip file consists of 3 files and a „readme‟ text file, see figure below. Unpack the zip file on your computer in the KMS Firmware downloader folder. This is the location where you installed the Firmware downloader, see example below. - Page 7 With the firmware downloader this update file can be sent to the ECU (only 1 of the 3 files is visible with the firmware downloader, (see figure below). The MD35 update file starts with the number 4 and also has extension *.FM1. Once installed, the program is set to work via communication port COM1. If this port is already being used or not available, another communication port can be used.

-

Page 8: Kms Software

The rows and columns are shown in graphs (in the form of bar charts), when the left mouse button is clicked on an engine speed or a load value. For further information, see section Programming. KMS MD35 manual Version 4.16... -

Page 9: The Injection Characteristic Diagram

In the ignition spreadsheet, figures can be entered that indicate the ignition advance (in crankshaft degrees before TDC). This means that for any engine speed and any engine load, the desired ignition moment can be entered. KMS MD35 manual Version 4.16... -

Page 10: The Function Bar

This function key enables a previously saved file to be opened from the hard disk, CD-ROM, USB memory key, etc. The files can be recognised by a floppy icon MD35 files have the extension *.M04 3.2.3 Function key F3 This function key is used to save modified files. -

Page 11: Options

3.2.4.1 Options If 'Options' is selected, a menu appears which lists several possible settings. These settings are described below. KMS MD35 manual Version 4.16... -

Page 12: Rpm Pickup

Hall sensor: a current runs through a thin Hall-plate. When this plate is undergoing a magnetic field a voltage arises between the two sides of the plate. When a tooth passes the plate the magnetic field changes. KMS MD35 manual Version 4.16... - Page 13 When using the „User defined trigger wheel‟, the number of coils (ignition outputs used on the MD35) and odd fire TDC‟s (see chapter 3.2.4.1.1.3) must be defined. Note: When using a 60-2 trigger pattern the maximum engine speed is limited to 12.500 rpm.

- Page 14 Select the kind of pickup signal, high or low. There is a easy way to find out whether the signal is high or low. Just apply power to the KMS system (engine not running) with the cam sensor connected. Right below in the main screen in the communication bar of the KMS software you can find „Cam valid‟.

- Page 15 Separate coils per cylinder is requiered for this sequential ignition. Make sure that the connections of the KMS ECU to the single coils are in the right igniting order. For example a 4 cylinder inline engine with firing order 1-3-4-2. The coil outputs get activated in the order 1-2-3-4. For direct-firing coil output 1 fires cylinder 1, coil output 2 fires cylinder 3, coil output 3 fires cylinder 4 and coil output 4 cylinder 2.

- Page 16 In the KMS software the degrees must be ascending. Set the degrees in the software and connect the right coil signal to each cylinder. You can find an example of the determination of odd-firing degrees on the following page. Example: 6 cylinder 90 degree 4-stroke V-engine with firing order 1-4-3-6-2-5 and reference point on cylinder 1.

- Page 17 Keep this number as low as possible to prevent backfiring when the engine is started. For engines with a high compression ratio it is recommended not to set this to a number higher than 1. KMS MD35 manual Version 4.16...

-

Page 18: Rpm Limiters And Power Shift

There is also the possibility to set an extra launch limiter which makes it possible to make the launch limiter variable between these two rpm‟s by connecting a potentiometer signal to the analog aux2 input or analog aux3 input for the MD35, which can be configured for this function, see 3.2.4.1.7 Hardware... - Page 19 (In the graph on the right, the recovery ignition advance is set to 10 deg) KMS MD35 manual Version 4.16...

- Page 20 „ok‟ to calibrate the output voltage for that gear. Before using the automatic calibration, the gears (reverse to 8 gear) must be selected in the top row using the drop down menu‟s. KMS MD35 manual Version 4.16...

-

Page 21: Engine Load Sensor

This is normally used for N/A engines with throttle bodies. Main Load is : MAP All the load tables included lambda target are linked to MAP value. This is normally used for turbo/supercharged engines . KMS MD35 manual Version 4.16... - Page 22 The ignition load table and lambda target are linked to MAP value (the ignition table for a turbocharged and supercharged engine should always be linked to MAP). The injection table however is linked to TPS and works in combination with the boost correction factor to determine the main fuel injection time. KMS MD35 manual Version 4.16...

- Page 23 7.5 ms at 75 kPa. If the engine runs on 50 kPa (0.5 bar vacuum) the injection value will be 50% of 10 ms = 5 ms. This is used for N/A engines. KMS MD35 manual Version 4.16...

- Page 24 Tip: first set the minimum value 15 and the maximum value 250. If you use a KMS 400 kPa Map sensor there are recommended settings for the calibration on the datasheet of the sensor.

- Page 25 Air mass sensor over a smaller number of steps and at higher loads it is divided over a larger number of steps. e-log The action is opposite to that of the Single Throttle body logarithmic parabola. setup KMS MD35 manual Version 4.16...

-

Page 26: Injection Settings

Then quickly make a „rough/global‟ mapping using the lambda control. If the engine runs ok, activate the banked injection and copy fuel map 1 to fuel map 2. After this activate the second lambda controller and map each bank separately. KMS MD35 manual Version 4.16... -

Page 27: Start-Up

(%) in the table can be set during the input of the rpm range. An enrichment map and a startup-pulse can be filled in for four coolant temperature ranges. Above the highest temperature the normal startup pulse will be used. KMS MD35 manual Version 4.16... -

Page 28: Throttle Pump Effect

No enrichment 0,95 Initial burst The figure on the right gives an Initial burst + Additional enrichment indication of how these two types of enrichments affect the mixture, when 0,85 suddenly the throttle valve is opened. KMS MD35 manual Version 4.16... -

Page 29: Hardware Configuration

For this input the 5V, gearpostion and map selector are the same as the first input but there are three different options. At this input you can‟t connect a second Oxygen sensor but you can connect a KMS EGT sensor, a potentiometer (1 kΩ - 47 kΩ) for variable A.L.S. or variable Launch RPM. See also section 3.2.4.1.10 A.L.S. - Page 30 Oil pressure sensor: You can use a VDO or a KMS oil pressure sensor. The VDO sensor must have a range from 0 – 10 bar (0 - 1000 kPa). You can calibrate the oil pressure sensor. This can be done to adjust to the right value to compensate the tolerance in the sensor.

-

Page 31: Lambda-Control

2 correction on injection group 1 and 2 with correction on Boost_correction map Lambda scaling: In this menu the values of the different types of sensors/controllers is visible. The KMS UEGO (display) controllers are pre-calibrated. KMS MD35 manual Version 4.16... - Page 32 All values will be converted. It is always possible to switch back to A/F ratio. When you switch between A/F and Lambda, these settings have to be saved in the ECU. The KMS software will do this automatically. When „yes‟ is selected in the pop-up screen, the software will start downloading to the ECU.

- Page 33 The coolant temperature above which the A/F ratio feedback control activates. If a KMS UEGO lambda controller is used, the lambda control can already be activated at cold water temperatures. If your using a standard BOSCH lambda sensor (narrow band) is used, it is recommended to activate the lambda control only above a water temperature of 60°...

- Page 34 During this warm-up period, the A/F ratio feedback control cannot function. The warm-up period in seconds can be set here. KMS UEGO recommended time: 10 - 15 sec. Standard BOSCH recommended time: 20 - 30 sec. Max % inc. in Fuel: Specifies the maximum positive (increase) injection compensation.

- Page 35 In the figure on the left side on the next page is a recommended target map shown for a N/A engine. Next to that (on the right) is a recommended target map shown for a turbocharged engne. KMS MD35 manual Version 4.16...

- Page 36 0.2 of the target (with level 1 ≤ 0.1). With level 2, a 95% accurate correction map is therefore created while a more precise one is created with level 1. Recommended: Map the engine first on level 2. This way you can create the correction map faster. KMS MD35 manual Version 4.16...

- Page 37 (higher A/F) than the values set in this table. This can be used when KMS UEGO control is set active at cold engine/water temperatures to prevent the engine from stalling, by limiting the A/F ratio, when lambda control will try to reach a too lean target.

-

Page 38: Boost Control

Boost at MAP output 1.25 V: For inputting the boost pressure (kpa) at a MAP sensor (manifold pressure sensor) output voltage of 1.25 V. These calibration values are included with the KMS MAP sensors. Solenoid off is: If there is no current to the solenoid valve, the boost pressure will adopt either minimum or maximum pressure depending on the connection of the solenoid valve. - Page 39 Once the setup target pressure has been reached and the pressure consequently decreases, it is advisable not to switch off the control at once, but to allow for a certain pressure reduction prior to switching off. KMS MD35 manual Version 4.16...

- Page 40 PWM map by selecting the cells and choose „copy boost to overboost map‟. So the values in the overboost PWM map can easily be increased/decreased by a percentage over the boost PWM map values. KMS MD35 manual Version 4.16...

- Page 41 Specifies the time span during which overboost functions are active after being triggered. Overboost pause time: To prevent the overboost from being activated too rapidly (after a preceding overboost), you can set a pause interval here before overboost can be triggered again. KMS MD35 manual Version 4.16...

- Page 42 3.2.4.1.9.4.4 Boost reduction to speed Boost pressure can also be reduced for up to ten speeds (only possible if the KMS speed sensor to CAN converter is used). The first row contains ten boxes where speeds can be entered, the first box is fixed at 0.

-

Page 43: A.l.s

23. When staged or banked injection is used, A.L.S. is not available. Warning: When using the A.L.S. be aware of extreme wear and shortage of lifespan of the turbo, exhaust-valves, exhaust manifold etc. KMS MD35 manual Version 4.16... -

Page 44: Aux 1

The aux output (aux pin in the graph) will be activated when the criteria (aux result) that have been set for mode 0 or mode 1, are met/fullfilled. The aux output will stay active untill the timer expires, regardless of the aux result. See the following graph for more information. KMS MD35 manual Version 4.16... - Page 45 0 or mode 1, are met/fullfilled and the timer has expired/finished. As soon as the aux result drops below the criteria, the timer isn‟t reset untill the aux output also expires. KMS MD35 manual Version 4.16...

-

Page 46: Aux 2

(aux result) that have been set for mode 0 or mode 1, are met/fullfilled or expire. 3.2.4.1.12 AUX 2 See section 3.2.4.1.11 AUX 1 3.2.4.1.13 AUX 3 See section 3.2.4.1.11 AUX 1 KMS MD35 manual Version 4.16... -

Page 47: External Dashboard

Configure the channels, design your display and „transmit‟ the configuration to the AIM logger. Connect TX (pin 2 of the KMS MD35 connector) to the RX input from AIM. Not all channels are working from KMS, this depends on which sensors are connected to KMS. You can see this „on line‟... -

Page 48: Speed Settings

First the vehicle configuration must be defined as a front wheel drive car of rear wheel drive car. This way, the KMS ECU knows which of the speed inputs is the real vehicle speed (non-driven wheels) and how much slip the vehicle is having on the driven wheels. -

Page 49: Traction Control Settings

To enable the traction control you have to enable the box in front of the „Activate traction control‟. Traction control is only possible if the KMS speed sensor -> CAN converter 4-channel is used! Users can put a switch in the 12V supply of the speed sensors or KMS speed sensor ->... - Page 50 Ignition reduction to gear position Ignition can be reduced for each separate gear (only possible after the gear positions are calibrated) shown in the first row. The second row contains the corresponding reduction in ignition for each gear. KMS MD35 manual Version 4.16...

-

Page 51: Communication Port

Windows Vista and Windows 7 use a different kind of communication compared to for example Windows XP. The KMS software must be modified to match the compatibility of Windows XP. To match the KMS software compatibility to a Vista or 7 computer, look for the „KMS motormanagement.exe‟ file. (if you installed the KMS software the standard way, you can find this file at C:/program files/KMS/KMS Motormanagement). -

Page 52: Output Test

Electronic interference can occur when the leads are not properly shielded or positioned close to the coil and spark leads. KMS MD35 manual Version 4.16... -

Page 53: Motor + System Diagnostics

With “save logfile” you can save the diagnostics on your computer. If the adress isn‟t changed the data will be stored in the KMS Management folder. The name of the log- file can be changed to whatever you want. Keep the extension .log. -

Page 54: Crank Sensor

The changes you made have to be saved to the ECU. The management software will automatically ask if you want to save the changes you made when you close the system diagnostics screen. The maximum water temperature that was reached is shown. KMS MD35 manual Version 4.16... -

Page 55: Air Temperature Sensor

The overboost limit in kPa is shown. 3.2.4.4.9 Battery voltage The time the battery voltage reaches a voltage lower than 11V or a voltage higher than 15V will be recorded. The lowest and highest battery voltage reached are shown here. KMS MD35 manual Version 4.16... -

Page 56: Air Pressure Sensor

3.2.4.4.13 5V sensor supply The time the 5V sensor supply is less than 4.8V is recorded here. Also the lowest sensor supply voltage is shown here. 3.2.4.4.14 ECU System status indicator (for manufacturer only). KMS MD35 manual Version 4.16... -

Page 57: Change User Access Level

For example when you have connected four UEGO CAN controllers on each cylinder of a 4-cylinder engine, users can set the UEGO CAN controller on cylinder 1 as lambda 1, etc. When a KMS CAN display has been connected, you can display the lambda of all 4 cylinders in accordance to the cylinder number. -

Page 58: Function Key F5

In the ignition correction table you can enter percentages for more/less pre-ignition. For example, this helps protect turbo engines from knocking when intake temperatures become too high. KMS MD35 manual Version 4.16... - Page 59 12.6V. The table is suitable for injectors with a resistance of 12Ω - 15Ω. Atmospheric pressure correction: If you use an internal or separate atmospheric pressure sensor, you can set correction percentages for ambient pressure levels in this table. KMS MD35 manual Version 4.16...

-

Page 60: Function Key F6

Tick the box when the airco switch is normally closed. The airco activating signal from the pump needs to be connected on the powershift input pin. For the MD35 this is pin 22. The maximum current on the powershift input pin must not exceed 60mA. With a 12V sensor a resistor of ±1.0kΩ... -

Page 61: Function Key F7

When the interpolation function is off, there will be no interpolation to adjacent boxes, but the value shown in the box matching the situation in which the system is functioning at that moment will be adhered to. KMS MD35 manual Version 4.16... -

Page 62: Function Key F10

This function key is used to toggle between the injection diagram (blue) and the ignition diagram (red). 3.2.12 Remaining shortcuts Alt + H To activate this menu press Alt+H. In this menu the remaining shortcuts are shown. KMS MD35 manual Version 4.16... -

Page 63: The Communication Bar

There are nine check lights in the communication bar, which indicate the status of the relevant outputs. The following readings will show: These readings can be used to check whether the right sensors are being used and all settings are correct. KMS MD35 manual Version 4.16... - Page 64 There is an option to get an enlarged picture of the lambda sensor reading by clicking on the display bar. An extra reading window will appear at the top of the screen. KMS MD35 manual Version 4.16...

-

Page 65: Programming

When the upward or downward arrow key is used, the value will go up or down 0.10 with each touch of the key. If the Alt key is pressed simultaneously, the value will KMS MD35 manual Version 4.16... - Page 66 To go to another engine speed or engine load, use the Page Up / Page Down keys. The correction tables can also be shown in the form of a bar chart if a correction figure is clicked. And here can also the arrow keys be used to change the values. KMS MD35 manual Version 4.16...

-

Page 67: Graph Changing

1.00 with each touch of the key. If the Shift key is pressed simultaneously, the value will change 0.10 per touch and if instead of the Shift key the Alt key is pressed, the value will change 0.01 per touch. KMS MD35 manual Version 4.16... -

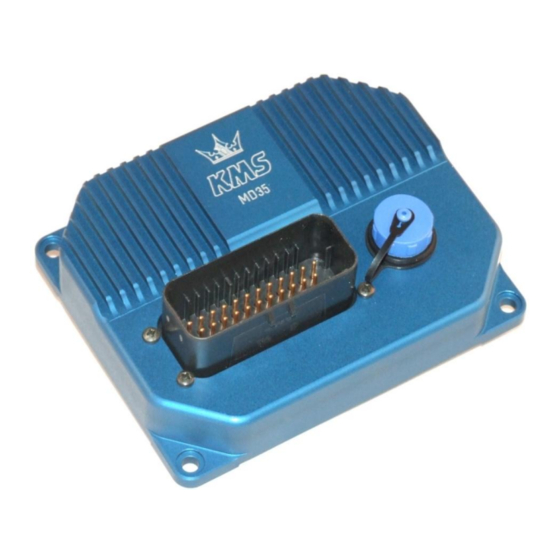

Page 68: Hardware Installation

There is a cover at the front of the ECU. Removing this cover gives access to the communication connector. A standard USB cable (A-male : B-male) can be connected to this connector. This cable is included in the standard package. KMS MD35 manual Version 4.16... -

Page 69: Fault Tracing

- Interruption in potentiometer signal wiring or potentiometer does not turn when the throttle valve is opened Only coils 1-4 give ignition - Dis coil box not ticked - See paragraph 3.2.4.1.1 RPM pickup KMS MD35 manual Version 4.16... -

Page 70: Specifications

Injector output can deliver at most 7A at 12V (for instance 6 injectors with a resistance of 16Ω) Shift-lamp, AUX, cooling fan and fuel pump outputs: max. 1A at 12V per output Dimensions: MD35 LxWxH: 126 x 98 x 36 mm Weight: 440 gram KMS MD35 manual Version 4.16... -

Page 71: Wiring Diagram Md35

8 Wiring diagram MD35 Standard colours KMS management MD35 wiring loom Pin nr. KMS Colour Length Diameter: 0,5mm² Diameter: 0,75mm² Function CAN High green CAN Low orange/black Boost Control yellow/red Idle Control white/black Fuel pump relay yellow/green Diagnostic out / Ignition output 6... -

Page 72: Appendix 1: Trigger Wheel Drawings

Appendix 1: Trigger wheel drawings KMS MD35 manual Version 4.16... - Page 73 KMS MD35 manual Version 4.16...

- Page 74 KMS MD35 manual Version 4.16...

Need help?

Do you have a question about the MD35 and is the answer not in the manual?

Questions and answers

Idle valve programing

To program the idle valve for the KMS MD35, follow these steps:

1. Access Idle-Control Settings: Use function key F6 to open the idle-control settings.

2. Set Solenoid Frequency: Enter the operating frequency of the idle-control valve, which should be between 16 and 40 Hz.

3. Define Activation Conditions: Specify the engine speed and load conditions under which the idle-control will be active.

4. Adjust Fuelling and Ignition: Set the fuelling in milliseconds (ms), ignition timing in degrees advance, and idle-valve opening in percentage (%) for engine speeds between 500 and 1250 rpm.

5. Use Idle Maps: When idle-control is active, the system will use idle maps instead of the main fuel and ignition maps.

This allows fine-tuning of the idle valve's operation for optimal engine performance.

This answer is automatically generated