Summary of Contents for Wombot Drafter

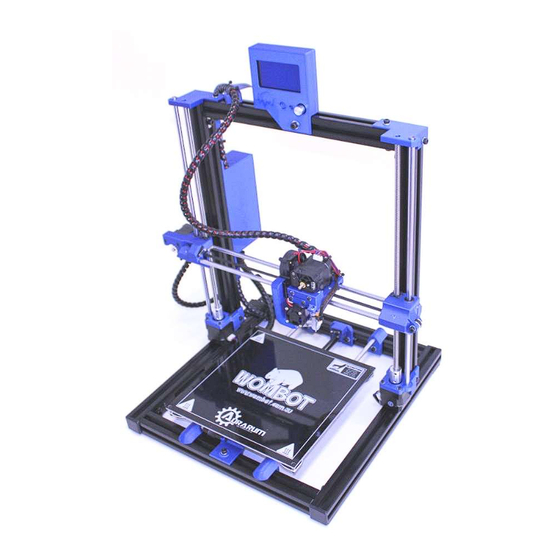

- Page 1 Personal 3D Printer Kit Assembly Manual P a g e Controlled Document – Wombot Drafter Kit Manual V1.3...

- Page 2 LCD Control Module Part 8 Wiring Part 9 Finishing Touches Part 10 Powering Up & Initial Tests Part 11 Component Listing / B.o.M Part 12 Recommended Spare Parts List P a g e Controlled Document – Wombot Drafter Kit Manual V1.3...

-

Page 3: Introduction

Instant and serious burns can result from contact with the skin. Please also ensure that your Drafter is situated in a safe place away from the reach of children and household pets during operation. Once you have completed the assembly of your Wombot Drafter, please also... -

Page 4: Tools Required

Tools Required to complete your Wombot Drafter All components required to complete assembly are included with your Wombot Drafter Kit. You will also require some basic hand tools and equipment as follows: P a g e Controlled Document – Wombot Drafter Kit Manual V1.3... -

Page 5: How To Use This Manual

This manual contains a great deal of detailed information about how to assemble your Wombot Drafter and about 3D Printers and 3D Printing in general. It is laid out in a logical, methodical order with written descriptions in non-technical terms and is fully illustrated with high quality colour images so that you can see exactly what you are aiming for with each step. - Page 6 Tighten the Screws and Grub screws making sure that the vertical rail is perpendicular to the base rail: Repeat this process so that you have two identical side frame assemblies. Set these two frames aside for the moment. P a g e Controlled Document – Wombot Drafter Kit Manual V1.3...

- Page 7 Lay out your remaining 3 extrusion pieces and load the Sliding Nuts as per the following images: P a g e Controlled Document – Wombot Drafter Kit Manual V1.3...

- Page 8 Arrange your frame rails as per the attached images ready to be slotted together and fasteners tightened: VIEW FROM FRONT OF FRAME VIEW FROM REAR OF FRAME P a g e Controlled Document – Wombot Drafter Kit Manual V1.3...

- Page 9 Now slide the remaining 4 M5 Sliding nuts into the sides of the vertical rails as indicated by the green arrows in the following images: P a g e Controlled Document – Wombot Drafter Kit Manual V1.3...

- Page 10 10 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

-

Page 11: Part 1 Printer Frame

This completes the Printer Frame Assembly section of the manual. Please set the frame aside for the moment and proceed to the next section. 11 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e... -

Page 12: Part 2 Y Axis Assembly & Heated Bed

Gently feed each of the smooth rods through the bearing blocks and fit a Y Rod Bracket to each end of both rods, as per the following image: 12 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e... - Page 13 Y Axis assembly to the frame, that you use the outer-most sliding nuts. Leave the sliding nuts between the brackets in place for later use by the Y Motor and Y Idler: 13 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 14 – the bolt should still be able to spin freely when you are finished – all we need to do here is to engage the nylon locking ring within the Nyloc Nut. 14 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 15 Place the Nema 17 stepper motor flat on your work space and fit the Y Motor Bracket into place. Fasten it with the 3 M3 Bolts and Flat washers paying particular attention to the orientation of the bracket to the motor connector: 15 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 16 Using the remaining two M5 Screws and Flat Washers, fit the completed Y Motor assembly to the front rail of the Printer Frame Loosely using the remaining two sliding nuts in the frame as per the below image: 16 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 17 Y Idler. Pass the Belt around the Y Idler pulley and back towards the Y Belt block. Make a loop and press fit the belt into the matching cavity in the Y Block as per the following images: 17 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 18 (you can temporarily rest the frame on two of your stepper motors to achieve full travel on the Bed Trolley to assist in correct alignment): 18 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 19 Y Rod Bracket outward an additional 0.25mm until accurate, slop free travel is achieved along the full travel of the bed. 19 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 20 Now it is time to fit the Heated Bed to the Bed Trolley. Fit the M3 x 20mm Countersunk Screws to the Heated Bed, locking them in place using M3 Nyloc Nuts as per the below images: 20 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 21 Wrap the bed cables with spiral wrap and cable tie to the Bed Trolley: This completes the Y Axis assembly module. Set your frame aside for the moment and proceed to the next section. 21 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

-

Page 22: Part 3 Extruder Module

In your kit of parts, locate the following items: ITEM DESCRIPTION STEPPER MOTOR NEMA 17 MK10 EXTRUDER MODULE Disassemble the Extruder Module into it’s individual components: 22 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e... - Page 23 (towards the extruder backing plate) and when tightening this grub screw, the hex key must lay flat on the face of the extruder plate: 23 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 24 Insert the heater Cartridge into the block noting the orientation of the holes in the block and alignment of the cables on the cartridge. Tighten the screw on the edge of the block to clamp the heater cartridge in place. 24 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 25 Now cable tie the thermistor wires to the heater cartridge wires so that there is some extra wire on the thermistor to allow for movement without placing strain on the thermistor cables. 25 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 26 Do not over-tighten, a snug fit is all that is required. Over- tightening of the heatsink will lead to damage of the thin section of the thermal break: 26 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 27 For more information on this topic please see the maintenance section of the Drafter User Manual. 27 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 28 BLTouch Module Pin (this can also be fine-tuned later if required). 28 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 29 Then, using the two M3 x 20mm Cap Head Screws, secure the 50mm Radial Part Cooling Fan into position noting the direction of the fan exhaust port: 29 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 30 Extruder Stepper Motor: Connect the BLTouch Extension Leads to the Terminals on the BLTouch unit EXACTLY as per the following image. 30 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 31 Add cable ties to secure the loom and spiral wrap as indicated in the following image: 31 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 32 If you are planning to run flexible materials such as TPE, TPU and Flex-PLA type materials, we suggest that you read and follow the instructions in the Drafter User Manual for tips on how to modify your MK10 Extruder to perform properly at reasonably high speeds.

-

Page 33: Part 4 Z Axis Assembly

– they must be correctly orientated or the cables will be too short when it comes time to wire them up and plug them in: 33 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e... - Page 34 34 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

-

Page 35: Part 5 Motherboard Enclosure & Saddles

(do not permanently tighten, they are only meant to be temporarily fitted and will need to be adjusted in later steps): Leave your Drafter frame on your work bench and proceed to the next section. Part 5 - Motherboard Enclosure & Saddles... -

Page 36: Part 6 X Axis Assembly

M3 x 25mm HEX HEAD CAP SCREW M3 NUT NYLOC BEARING LM8LUU M4 GRUB SCREW M6 GRUB SCREW STEPPER MOTOR NEMA 17 PULLEY GT2 20 TOOTH 5mm ID 36 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e... - Page 37 M6 Grub Screws as per the following images (do not tighten the grub screws at this point, only turn them in a couple of threads – they will be tightened in the next steps): 37 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 38 X Motor Bracket: 38 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 39 Gently slide the Extruder Module onto the smooth rods paying particular attention to the orientation of the extruder module in relation to the X motor mount: 39 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 40 Now take the remaining two 430mm long smooth rods and trapezoidal lead screws you prepared earlier and fit them to the X Motor and X Idler assemblies as per the following image: 40 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 41 When mounted correctly, the Trapezoidal Lead Screw should be perfectly aligned with the slot in the Vertical Rail. 41 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 42 Only fasten enough so that the thread locking portion of the nut is engaged. Do not overtighten as this may lead to damage of the X Idler: 42 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 43 Now fit the corresponding belt clamp to the underside of the extruder module using the M3 x 12mm Screw with an M3 Washer under the head so that once tightened, the clamp compresses against the belt holding it in place: 43 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 44 Extruder carriage and using the remaining Belt Clamp, M3 x 12mm Screw and M3 Flat Washer, secure the belt in place to the underside of the extruder carriage: 44 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 45 Motor) and fit the GT2 Belt Spring to the belt on the right hand side (closest to the X Idler Bracket) exactly as per the following image: 45 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 46 Lay the LCD Front Fascia down. Drop the Silver Reset Buton into place then remove the protective film and buzzer label from the LCD Module. Place the LCD in the Front Fascia, Face down as per the following images: 46 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

-

Page 47: Part 7 Lcd Control Module

Using the remaining M5 x 12mm Bolt and M5 Washer, fit the LCD Control Module to the top of the printer frame as per the following images: 47 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e... -

Page 48: Part 8 Wiring

Turn your printer frame so that the underside (base) can be accessed. Remove the backing from the four self-adhesive rubber feet and fit one to each corner of the base frame: 48 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e... - Page 49 49 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 50 Using the two M5 Sliding Nuts, M5 x 12mm Screws and M5 Flat Washers, fit the Anderson Connector Assembly to the rear right corner of the frame as per the following images: 50 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 51 This is done to make the cables easier to conceal inside the channel in the Extrusion and to reduce bulk inside the Motherboard Enclosure to make it easier to tidy the wiring once done. 51 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 52 Cable tie the spiral wrap to the cables to secure the spiral wrap in place: Now set the motherboard enclosure and the lower cable saddle into their final positions and gently tighten in place: 52 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 53 Feed the cables from the base wiring bundle through the hole in the bottom of the motherboard enclosure: 53 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 54 54 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 55 Fit the Extruder Module Loom to the second saddle at the top of the Motherboard Enclosure, cable tie it in place and run the cables into the Motherboard Enclosure as per the following image: 55 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 56 M5 x 16mm HEX HEAD SCREW SCREW SELF TAPPER SILVER Your Drafter Motherboard already has the firmware (3D Printer Operating System) loaded, the Stepper Motor Drivers fitted/pre-tuned and the functionality of the motherboard tested prior to shipping, so there is nothing to do to prepare the Motherboard, simply terminate the wiring from each part of the system and screw the board into place.

- Page 57 Please see the below table and image for the correct termination point for each set of power related cables on your Wombot Drafter. Familiarise yourself with where each component needs to be wired to then follow the steps below in sequence. We have...

- Page 58 Please note the polarity of the Main Power Cables. They are colour-coded for your convenience, RED for Positive and BLACK for Negative. With these two sets of cables 58 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 59 With the wiring to the screw terminals complete, you can proceed to fit the motherboard to the rear of the enclosure using four of the self tapping screws as highlighted in the following image. 59 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 60 Motherboard. Thermistors In your wiring looms, locate the Heated Bed and Extruder Thermistor cables. Connect them to the motherboard as per the following image: 60 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 61 Aim to achieve something like this once all wiring is completed: Locate the Stepper Motor Looms for each stepper motor on your Exilis. Plug them in to the 61 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

- Page 62 62 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

-

Page 63: Part 9 Finishing Touches

Fit the Part Cooling Fan Duct to the Turbo fan on the side of the Extruder Module using the M3 x 10mm Hex Head Screw. Do not overtighten: Gently tap the System 30 end caps into place: 63 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e... - Page 64 Assemble your spool holder as per the following images: 64 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

-

Page 65: Part 10 Powering Up & Initial Tests

Part 10 - Powering Up & Initial Tests Now that you have completed the assembly of your Wombot Drafter it is time to power up the machine and make sure everything is operating correctly. Place your Drafter on a flat, level surface making sure that there is enough room behind and in front of the machine for the bed assembly to reach full travel. - Page 66 This concludes the assembly and initial diagnostics of the 3D Printer. Please proceed to fully read and follow the Wombot Drafter User Manual for troubleshooting, calibration, tuning and operation of the Wombot Drafter.

- Page 67 THERMISTOR 100K NTC CONSUMABLE PTFE TUBE 2mmID 4mmOD 46mm Length EXTRUSION CHASSIS RAIL/GANTRY RAIL 3030 BLACK x 340mm EXTRUSION LEFT/RIGHT CHASSIS RAIL 3030 BLACK x 410mm 67 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e...

-

Page 68: Internal R/A Bracket

Z MOTOR BRACKET LEFT PRINTED PART Z MOTOR BRACKET RIGHT PRINTED PART Z TOP BRACKET LEFT PRINTED PART Z TOP BRACKET RIGHT SAMPLE FILAMENT SAMPLE PACK 68 | Controlled Document – Wombot Drafter Kit Manual V1.3 P a g e... - Page 69 Heater Cartridge 40W, 24V 6mm OD Build Surface Label END OF DOCUMENT Wombot values your feedback. If you feel that we can improve this manual or that further clarification is required on any item in this manual, please let us know by email to support@wombot.com.au 69 | Controlled Document –...

Need help?

Do you have a question about the Drafter and is the answer not in the manual?

Questions and answers