Table of Contents

Advertisement

Advertisement

Chapters

Table of Contents

Summary of Contents for ASV ST50 Scout

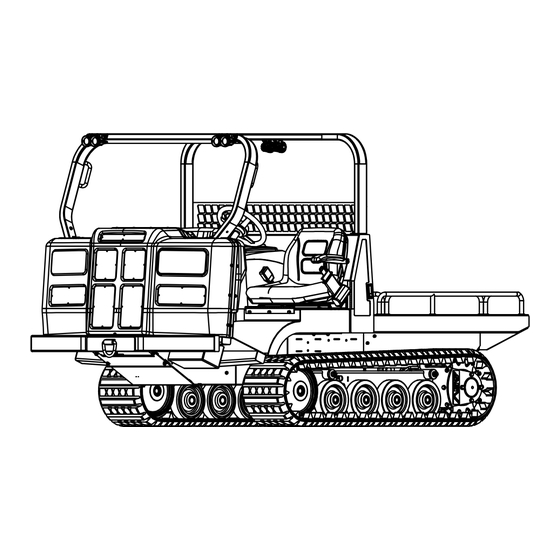

- Page 1 8/17/2016 Language: English Geographic Region: Serial Number Range: SN All ST50 Scout Operation and Maintenance Manual This manual is complements of TrackLoaderParts.com The world's best source for ASV parts. Track Loader Parts 6543 Chupp Road Atlanta, Georgia 30058 (800)616-8156...

- Page 2 I I N N T T R R O O D D U U C C T T I I O O N N Thank you for purchasing an ASV ST-50. With this machine, you will be able to perform tasks not possible with other “light duty”...

-

Page 3: Safety

S S A A F F E E T T Y Y O O V V E E R R V V I I E E W W SAFETY SYMBOL This symbol means: Attention! Be alert! Your safety is involved! A safety message will follow this symbol describing the hazard and the precautions that need to be taken to ensure your safety. - Page 4 M M A A C C H H I I N N E E I I D D E E N N T T I I F F I I C C A A T T I I O O N N Serial Numbers Manual Storage (C) Product ID Number (A)

-

Page 5: Table Of Contents

TABLE OF CONTENTS Introduction ........1 Safety Overview........ 2 Machine Identification....3 Safety ............... 6 Controls .............. 14 Operation............20 Maintenance ............. 26 Troubleshooting..........48 Machine Specifications......... 51 California Proposition 65......52 Recommended Fluids ........53 Standard Torque Guidelines ....... 54 Service Log ............ - Page 7 S S A A F F E E T T Y Y - CONTENTS Features .............. 7 Cargo Bed Capacity/GVW ......8 Fire Prevention..........9 Warning Decal Locations ......10 Warning Decals..........11 Dump Box Brace (if equipped)....13...

-

Page 8: Safety

SAFETY Features The ST-50 is equipped with C. Operator and Passenger many safety features to reduce Presence Switches the possibility of injury to the The presence switches are acti- operator or passenger during vated whenever their respective operation. seats are occupied. These features include: D. -

Page 9: Cargo Bed Capacity/Gvw

SAFETY Features/Cargo Bed Capacity/G.V.W. E. Auxiliary Hydraulic Safety Cargo Bed Capacity Switch (if equipped) The bed capacity is the amount This safety device has been of weight that can be safely included to ensure that attach- applied to the bed and carried ments do not engage when the by the ST-50. -

Page 10: Fire Prevention

SAFETY Fire Prevention Fire Prevention Precautionary Tasks: The ST-50 has components that • With the engine off and cool, operate at high temperatures. remove any debris present in Steps must be taken to make the engine compartment. sure that flammable items are Remove the belly pans and kept clear of these components pressure wash this area as... -

Page 11: Warning Decal Locations

SAFETY Warning Decal Locations... -

Page 12: Warning Decals

SAFETY Warning Decals W A R N I N G 2051-678 Prior to Operating Pre-Start Checklist Vehicle Capacity Always Read and fully under- 1. Operator and passen- 1 operator, 1 passenger. • Keep hands and feet stand the operation and ger (if present) seated No Riders Permitted inside the cab. - Page 13 SAFETY Warning Decals WARNING Operating with a Load The Scout's operating characteristics can change dramatically when carrying a load. Terrain and maneuvers that are considered safe when operating an unloaded machine may not be safe when carrying a load. Avoid inclines or side-hills when operating with a load.

-

Page 14: Dump Box Brace (If Equipped)

SAFETY Dump Box Brace (if equipped) Dump Box Brace 4. Have an assistant pivot the brace into position under the The ST-50 is available with a box. dump box attachment. The dump box brace (A) is a device 5. Lower the dump box slowly used to mechanically support until it comes to rest on the the weight of the box when in... - Page 15 C C O O N N T T R R O O L L S S - CONTENTS Switch Panels/Instrument Display.... 15 Motion Controls..........16 Throttle/Two Speed ........17 Auxiliary Hydraulics........18...

-

Page 16: Controls

CONTROLS Switch Panels/Instrument Display There are many instruments and switches involved in the normal operation of the ST-50. Make sure to learn the location and function of each of these items prior to operating your machine. Switch Panels A. Headlight Activation Switch B. -

Page 17: Motion Controls

CONTROLS Motion Controls Reverse Forward Motion Controls (and related) Bi-directional Speed Control Q. Bi-Directional Speed Control The scout is equipped with a R. Steering Control (wheel) foot pedal (Q) that controls both S. Throttle Control machine speed and movement T. Attachment Control in forward/reverse directions. -

Page 18: Throttle/Two Speed

CONTROLS Throttle/Two Speed Throttle Control The throttle (A) controls engine speed (RPM). When performing work that requires delicate, pre- cise movements, use a lower RPM. When more speed, power, or flow is required, use a higher RPM. The ST-50 is equipped with a hand operated throttle mecha- •... -

Page 19: Auxiliary Hydraulics

CONTROLS Auxiliary Hydraulics Top-View Rear-View Intermittent Flow Hydraulics (optional) The ST-50 (if equipped) has the capability to accept intermittent style attachments like a dump box or blade. These are con- trolled with the joystick style attachment control (C). Note: The operator must be seated in the cab with seat belt fastened in order for the attach- ment control (C) to function. - Page 20 CONTROLS Auxiliary Hydraulics Auxiliary Hydraulics The auxiliary hydraulics are gov- erned by controls in the machine circuitry that limit operation to certain conditions. Intermittent Flow: • The operator must be seated in the cab with his/her seat belt fastened in order for the intermittent flow hydraulics to operate.

- Page 21 O O P P E E R R A A T T I I O O N N - CONTENTS Pre-Operation........... 21 Starting Procedure ......... 22 Operation Techniques ........23 Cargo Bed Safety..........25...

-

Page 22: Operation

OPERATION Pre-Operation Pre-Operation Safety Check Note: The parking brake is auto- Before operating the machine, matically on/activated when: perform a safety check to identi- • the machine is turned off. fy any items that may affect safe • the machine is started until operation. -

Page 23: Starting Procedure

OPERATION Starting Procedure Starting Procedure 6. Once running, reduce throttle Upon completion of the pre- to a low idle by slowly pulling operation safety check, if all back on the hand lever. Allow items are in compliance, the the engine to idle for approxi- machine is ready to be started. -

Page 24: Operation Techniques

OPERATION Operation Techniques Overview Operating the ST-50 Operating the ST-50 is intended Once all of the pre-operation to be as safe and simple as pos- checks have been performed. sible. The controls section of this Start the engine according to the manual covers the various con- procedure on page 22. - Page 25 Operation Techniques Stopping the ST-50 Operating On Turf At any time, you may stop the ASV rubber track vehicles are machine by slowly lifting your designed to tread lightly and foot off of the directional control produce minimal ground distur- foot pedal.

-

Page 26: Cargo Bed Safety

OPERATION Cargo Bed safety Cargo Bed Safety WARNING The cargo bed is designed to carry loads and accommodate The ST-50's operating character- istics can change dramatically various attachments. when carrying a load. Terrain It is important to know some and maneuvers that are consid- basic safety guidelines for apply- ered safe when operating an unloaded machine may not be... - Page 27 M M A A I I N N T T E E N N A A N N C C E E - CONTENTS Precautions/Safety Warnings ..27 Jacking Procedure......28 Maintenance Schedule ......... 29 Radiator/Oil cooler/Engine Cleaning..30 Air Cleaner ............31 Fuel Filter............

-

Page 28: Maintenance

When service is • Never smoke or allow open required, ASV recommends that flame near flammable liquids all work be done by an author- or the battery. Fire or explo- ized ASV dealer. -

Page 29: Jacking Procedure

3. Once in place, jack the machine upwards making sure it remains stable until it has reached sufficient height to install an ASV jack stand beneath the machine. 4. Slide the jack stand into place making sure it is centered... -

Page 30: Maintenance Schedule

MAINTENANCE Schedule Maintenance Service Service Interval Notes Item required Capacity Grease fittings Lubricate Daily (Torsion Axle Pivots) Adjust levels as Fluid levels Check Daily necessary. Adjust tension as Fan belt tension Check Daily necessary. Fan belt Replace if worn or Inspect Daily condition... -

Page 31: Radiator/Oil Cooler/Engine Cleaning

MAINTENANCE Radiator/Oil Cooler & Engine Cleaning Radiator/Oil Cooler Engine The radiator and oil cooler must Periodic cleaning of the engine be kept clean to ensure proper compartment is also recom- operation. Engine and hydraulic mended to maintain safe and system overheating, damage reliable operation. -

Page 32: Air Cleaner

MAINTENANCE Air Cleaner Air Cleaner The ST-50 is equipped with two air filter elements that remove contaminants from the air drawn lift here into the engine. Regular inspec- tion and replacement is neces- sary to ensure proper perform- ance and to prolong engine life. slide To remove and inspect the air cleaner elements:... -

Page 33: Fuel Filter

2. Do not clean the air filter ele- ments while the engine warran- ty is in effect. During the war- ranty period, ASV recommends replacing the elements instead of cleaning them. Heavy- duty air filter manufacturers will not warrant the air filter once it has been cleaned. -

Page 34: Engine

ASV recommends an interval of 250 hours or six months for machines that are operated under these conditions. Harsh conditions may include:... - Page 35 9. Re-install the drain plug and tighten to secure it in place. 10.Remove the oil filler cap and fill the engine crankcase with ASV 10W-30 Heavy Duty Engine Oil. (capacity: 11.2 U.S. quarts including filter). (fig. 5) 11.Install the oil filler cap.

- Page 36 Engine Oil Specifications 7. If the level is low, add the Use ASV 10W-30 Heavy Duty proper grade and viscosity Engine Oil for most conditions. engine oil and re-check as In the event of an alternate...

-

Page 37: Electrical

MAINTENANCE Engine/Electrical Water Separator Fuse Panel The water separator removes The electrical system in the ST- water from the fuel supply as the 50 is equipped with fuses that engine runs. Drain the water protect the electrical compo- separator daily to maintain prop- nents from damage. -

Page 38: Hydraulic System

Introducing dirt 11. Open the passenger side or debris could be detrimental to access door to the rear con- the hydraulic system. ASV rec- sole enclosure (behind the ommends service intervals of seats) and remove the 500 hours for hydraulic fluid and hydraulic oil filler cap. -

Page 39: Undercarriages

The undercarriage assemblies typically operate in harsh work- ing conditions. They may work in mud, gravel, debris and various other abrasive materials during operation. ASV recommends a daily inspection of the undercar- riage assemblies and cleaning if necessary. Materials that are particularly... - Page 40 MAINTENANCE Undercarriages Grease Fittings Adjustment The undercarriages are To tighten tracks: equipped with grease fittings at 1. Locate the input grease zerk the main torsion axle pivot (H) on the tensioner unit (J) points. Lubricate fittings daily or mounted within the frame rail. after every 10 hours of operation (fig.

- Page 41 To remove tracks: 1. Raise the machine off of the ground and mechanically sup- port it on ASV jack stands at a height that allows just enough clearance for track removal. The recommended distance is 3-4” from the bottom of the track to the ground.

- Page 42 MAINTENANCE Undercarriages 4. Remove the two front 10” diameter wheels (second wheel back in the undercar- riage from the front) by first removing the outer snap rings and grease covers (fig. 8, 9). Then remove the nuts secur- ing the wheel assemblies to the axle (fig.

- Page 43 MAINTENANCE Undercarriages Note: The outer bearing on the 14” wheel will most likely fall out of the wheel as you remove it from the undercarriage. Make sure to remove it or catch it if possible to keep it clean (fig. 16). 7.

- Page 44 MAINTENANCE Undercarriages To install tracks: 1. Wrap the track around the sprocket at the rear of the undercarriage (fig. 1). 2. Lubricate the inner front 14” wheel and the inside of the track at the front to aid in slid- ing the track back onto the undercarriage (fig.

- Page 45 MAINTENANCE Undercarriages 4. Clean and reinstall (repack with grease if necessary) the outer bearing into the 14” wheel (fig. 8). 5. Reinstall the washer and lock nut and tighten to secure the 14” wheel in place. Do not install the grease cover or snap ring yet (fig.

- Page 46 MAINTENANCE Undercarriages 7. Install the inner and outer 10” wheels and secure them in position with their nuts, grease covers and snap rings (fig. 12, 13). 8. Attach a grease gun to the input zerk and pump grease into the tensioner unit until there is no visible sag in the track when viewed from the side (fig.

-

Page 47: Drive Sprocket Rollers

50 hours of replacement is now complete. operation and replaced if cracked or worn to less than Note: ASV recommends replac- 35% of original thickness. (.088”) ing external rollers as a set to simplify inspection and maintain Roller Replacement proper sprocket function. - Page 49 T T R R O O U U B B L L E E S S H H O O O O T T I I N N G G - CONTENTS Overview/No-Start ......... 49 Hydraulics/Electrical/Overheat ....50...

-

Page 50: Troubleshooting

TROUBLESHOOTING Overview/No-Start Overview Problem The most effective way to pre- Machine cranks, but will not vent a malfunction from occur- start. ring is to closely follow the rec- Possible causes: ommended maintenance sched- 1. Fuel tank empty, fuel filter ule and instructions throughout plugged or fuel line restricted. - Page 51 TROUBLESHOOTING Hydraulics/Electrical/Overheat Problem 8. Faulty resistor. (on back of Machine starts, but hydraulics fuse panel) will not operate. Problem Possible causes: Hydraulic oil light illuminated; 1. Operator not in seat. hydraulic system overheating. 2. Push to operate switch not Possible causes: activated.

-

Page 52: Engine Coolant

11.2 qt / 10.6 L Specifications are subject to change without notice. * Fluid levels full, 165 lb. operator seated in cab. ** When replacing or replenishing fluids, it is recommended that you specify genuine ASV products from your ASV dealer. -

Page 53: California Proposition 65

Terex/ASV complies with this requirement by providing the following information. CALIFORNIA... -

Page 54: Recommended Fluids

ASV factory. ASV products were developed for, tested and approved by ASV to assure opti- mum life and performance in all ASV Rubber Track Equipment, when used as recommended. The ASV product line includes: •... -

Page 55: Standard Torque Guidelines

STANDARD TORQUE GUIDELINES Inch Fasteners Machine Specific Fasteners Drive Sprocket Roller Thread size Standard Torque Bolts/Nuts 1/4" 9 +/- 2 lb ft Torque to: 88 +/- 10 Ft./Lbs. 5/16" 18 +/- 4 lb ft Drive Sprocket Retaining Bolts 3/8" 35 +/- 7lb ft Torque to: 160 +/- 10 Ft./Lbs 7/16"... -

Page 56: Service Log

SERVICE LOG Hours Service Performed Notes... - Page 57 SERVICE LOG Hours Service Performed Notes...

- Page 58 SERVICE LOG Hours Service Performed Notes...

- Page 59 SERVICE LOG Hours Service Performed Notes...

- Page 60 Terex Construction Americas 8800 Rostin Road Southaven, MS 38671 (888)-201-6008 (662)-393-1800 www.terex.com ASVST50 OM (1/09) Copyright 2009 Terex...

Need help?

Do you have a question about the ST50 Scout and is the answer not in the manual?

Questions and answers